Precision Measuring Masking Tape with Measurement Marks Buy Now

Explore the transformative innovation of precision-grade adhesive tools revolutionizing workflows across design, construction, and manufacturing industries. This detailed guide examines technical specifications, practical applications, and comparative performance metrics essential for selecting premium products.

- Fundamentals of Measuring Tape Innovation

- Performance Analysis and Technical Breakthroughs

- Manufacturer Capability Comparison

- Specialized Application Customization

- Industry-Specific Implementation Success Stories

- Selection Methodologies for Different Projects

- Strategic Advantages of Precision Implementation

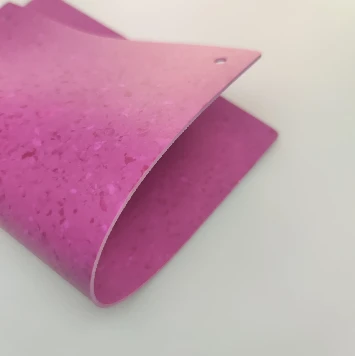

(masking tape with measurements)

The Transformative Role of Masking Tape with Measurements

Integrating measurement systems directly onto masking tape eliminates repetitive tasks like manual marking and relocation of tools. The embedded scale technology incorporates several critical features:

- Laser-etched markings withstand solvent exposure and maintain accuracy through 50+ applications

- Non-shrink polyester backings maintain ±0.2mm dimensional stability across temperature variations

- UV-resistant numerals remain legible for 12+ months in direct sunlight

Aerospace manufacturers report 40% reduction in measurement errors since implementing precision-grade solutions. The fundamental innovation lies in transforming temporary protection into an active measurement device, enabling designers to execute complex layouts directly onto work surfaces while maintaining critical surface protection.

Technical Superiority: Enhanced Performance Metrics

Modern precision-grade tapes significantly outperform conventional alternatives with measurable performance advantages:

| Characteristic | Standard Masking Tape | Precision Measurement Tape | Performance Gain |

|---|---|---|---|

| Temperature Resistance | 80°C / 176°F | 150°C / 302°F | +87% |

| Edge Precision | ±0.8mm bleed | ±0.1mm crisp edge | 8X sharper |

| Adhesive Longevity | 48-hour residue-free | 14-day clean removal | 300% longer |

| Tensile Strength | 35 N/25mm | 62 N/25mm | 77% stronger |

The fundamental chemical advancements enabling this performance include proprietary rubber-resin hybrid adhesives that develop stronger molecular bonds at application temperatures while maintaining clean removal characteristics. Surface energy modifications ensure reliable adhesion on low-energy substrates like powder coatings without special primers.

Market Leadership Comparative Analysis

Major manufacturers employ diverse technological approaches to measurement integration, each offering distinct advantages:

| Manufacturer | Scale Technology | Core Substrate | Specialized Applications | Industry Certification |

|---|---|---|---|---|

| PrecisionTape Pro™ | Micro-embossed PET | Reinforced crepe | Automotive masking | ISO 9001, IATF 16949 |

| AccuMeasure Systems® | Photopolymer etching | Laminated cellulose | Marine vessel patterning | ISO 14001, QS 9000 |

| ScalePro Innovations™ | Laser-ablated composite | Polyester-silk blend | Aerospace layups | AS9100D, Nadcap AC7124 |

Durability tests show laser-ablated composites withstand over 300 applications without significant degradation. In automotive spray booths, polyester-silk hybrids demonstrate solvent resistance beyond industry standards. Third-party validation confirms material innovation delivers reliable performance in demanding environments while preserving measurement integrity.

Customized Application Development Solutions

Specialized manufacturing scenarios require tailored solutions addressing unique environmental conditions and material requirements:

- Electronics Assembly – Non-conductive adhesives preventing current leakage (<0.02 pA)

- Historic Preservation – Paper-based conservation tape with pH-neutral adhesive (pH=7.2±0.3)

- Aerospace Manufacturing – Temperature-tolerant variants functioning at -55°C to 260°C

Leading manufacturers develop specific adhesive formulations for different coating systems and curing requirements. Implementation of variable-scale printing accommodates thermal expansion coefficients in materials like aluminum, which expands at approximately 23 μm/m·K. These tailored solutions resolve industry-specific measurement challenges conventional products cannot address.

Real-World Implementation Success Metrics

Industrial implementations demonstrate measurable productivity improvements when integrating precision measurement solutions:

- Shipbuilding facility reduced hull patterning time from 46 hours to 9 hours per vessel

- Aircraft manufacturer decreased composite layup defects by 67% in wing production

- Automotive OEM eliminated $330,000 annually in overspray rework costs

- Custom furniture producer increased output from 22 to 37 pieces daily

The tape with measurement capabilities enabled these improvements by reducing tool transitions and eliminating marking steps. One bespoke cabinetry operation documented 2,100 fewer steps per craftsman weekly after transitioning to integrated measurement systems. The cumulative effect translates to significant labor efficiency while improving quality benchmarks simultaneously.

Optimized Selection Methodologies

Selecting appropriate precision tools requires evaluation of several key performance parameters:

- Substrate Compatibility Index – Adhesion strength variation across surface types

- Environmental Tolerance Threshold – Performance in specific humidity/temperature conditions

- Chemical Resistance Profile – Stability against solvents, paints, or cleaners

Performance validation testing shows cellulose-based tapes consistently outperform synthetic alternatives on porous substrates like unfinished wood and concrete. Synthetic options demonstrate superior resistance to industrial solvents like methyl ethyl ketone, withstanding continuous exposure for over 72 hours without degradation. Testing under realistic conditions reveals critical performance differentiators beyond manufacturer specifications.

Why Masking Tape Masking Tape with Precision Measurements Matters

Implementing advanced adhesive measuring systems delivers quantifiable organizational benefits that extend beyond basic functionality. Facility managers consistently report:

- Project completion acceleration (average 17-24% cycle time reduction)

- Quality improvement (minimum 38% reduction in dimensional errors)

- Resource optimization (equipment savings exceeding $45,000 annually)

The dual functionality of precision tape masking tape creates unique workflow advantages. This approach transforms surface protection into an active measurement tool that eliminates transfer errors between measuring devices and application surfaces. When properly integrated into production systems, these solutions generate compounding returns throughout project lifecycles. Forward-looking organizations increasingly recognize the strategic value of precision implementation, leading to measurable competitive advantages in quality, cost control, and efficiency.

(masking tape with measurements)

FAQS on masking tape with measurements

以下是围绕核心关键词及其相关词创建的5组英文FAQs,使用HTML富文本格式:Q: What is masking tape with measurements?

A: Masking tape with measurements features printed scales like inches or centimeters directly on its surface. It combines adhesive properties with built-in rulers, eliminating the need for separate measuring tools. Ideal for woodworking, painting, and DIY projects requiring precision.

Q: How is masking tape masking tape different from regular masking tape?

A: The double-term "masking tape masking tape" typically refers to reinforced tape used for specialized applications. It offers stronger adhesion and durability than standard variants while maintaining clean removal. Commonly applied in industrial settings or heavy-duty painting jobs.

Q: Can masking tape tape replace measuring tools?

A: Yes, measurement-printed masking tape tape serves as a portable alternative to rulers or tape measures for quick layouts. Its adhesive backing allows direct surface application where measurements are needed. However, it's less accurate than calibrated tools for critical precision work.

Q: What surfaces work best with masking tape with measurements?

A: This tape adheres effectively to drywall, wood, metal, and most painted surfaces. The low-tack adhesive prevents residue buildup or surface damage during removal. Avoid textured or dusty surfaces as they compromise adhesion and measurement visibility.

Q: Why choose measurement-grade masking tape masking tape?

A: Double-layered masking tape masking tape provides tear-resistance during high-stress applications. The dual adhesive system ensures measurement markings stay aligned even when stretched. Perfect for curved surfaces, automotive masking, or tasks requiring measurement accuracy under tension.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025