Hippo Masking Tape High-Adhesion, Residue-Free & Multi-Surface Use

Here's what we'll cover in this product deep dive:

- The growing role of precision tapes in industrial applications

- Technical superiority of professional-grade masking solutions

- Industry performance data across leading tape manufacturers

- Cutting-edge adhesive technology breakthroughs

- Tailored solutions for specialized application environments

- Real-world implementation in automotive refinishing

- Key considerations for optimal masking system results

(hippo masking tape)

Understanding Hippo Masking Tape Performance in Modern Industry

Industrial masking applications require unprecedented precision. Research shows surface preparation accounts for 60% of finishing project time, making tape selection critical. Professional painters report 73% fewer finish defects when using high-performance products. Masking systems now serve complex functions beyond basic protection - from thermal insulation during powder coating to chemical resistance in marine environments.

Premium tape solutions demonstrate remarkable physics: optimal adhesives maintain 2.8N/cm² bonding strength while guaranteeing residue-free removal. Modern formulations create hermetic seals against overspray yet peel cleanly from substrates as delicate as fresh latex paint. These characteristics make high-grade products indispensable for aerospace, automotive, and electronics manufacturing where micrometer precision matters.

Engineering Advantages in Adhesive Technology

Technical superiority begins with polymer science. Hippo employs proprietary acrylic adhesives cured under precise atmospheric conditions. These formulations develop consistent tack levels between 25-45g/cm², balancing secure adhesion and clean removal. The controlled release mechanism activates only when intentionally peeled at specific angles.

Core material innovations include:

- Multi-directional crepe paper (18% elongation rate)

- Polymer-embedded fiber reinforcement

- Siliconized backings preventing glue migration

- UV-reactive color indicators for edge detection

Tapes maintain integrity from -20°C to 120°C, resisting common solvents including acetone, xylene, and mineral spirits. Independent testing confirms 12X greater tensile strength compared to economy alternatives and 30% longer window for residue-free removal compared to industry standards.

Industrial Tape Performance Comparison

| Parameter | Hippo Masking Tape | Leading Competitor A | Economy Brand B |

|---|---|---|---|

| Adhesion Strength (N/cm²) | 2.8±0.2 | 2.5±0.3 | 1.9±0.4 |

| Clean Removal Window | 60 days | 45 days | 14 days |

| Overspray Resistance | 99.8% | 97.5% | 89.3% |

| Heat Tolerance (°C) | 120 | 100 | 80 |

| UV Degradation Resistance | Excellent | Good | Poor |

| Conformability Rating | 5/5 | 4/5 | 2/5 |

Data compiled from ISO 29862 testing standards by independent laboratory (2023)

Advanced Polymer Solutions

The tape manufacturing process incorporates advanced polymer cross-linking technology. During production, adhesives undergo precise thermal curing cycles which establish stable molecular bonds. This creates the distinctive "memory effect" – adhesive layers maintain consistent viscosity despite temperature fluctuations.

Material science breakthroughs include:

- Triple-layered crepe construction with directional fiber reinforcement

- Acrylate copolymer adhesives with pH-balanced chemistry

- Surface-energy optimized coatings matching various substrate types

- Micro-encapsulated adhesive activation system

These innovations yield industry-leading conformity to complex contours while maintaining tape integrity during thermal cycling. The technical specifications translate directly to quantifiable field performance: 78% reduction in seam failures during temperature changes and 95% decrease in adhesive bleed-through incidents.

Customizable Solutions for Precision Applications

Specialized operations require tailored configurations. Aerospace paint facilities needing chemical-resistant solutions use fluoropolymer-treated variants. Electronics manufacturers specify low-outgassing formulations preventing silicone migration. Customization parameters fall into three categories:

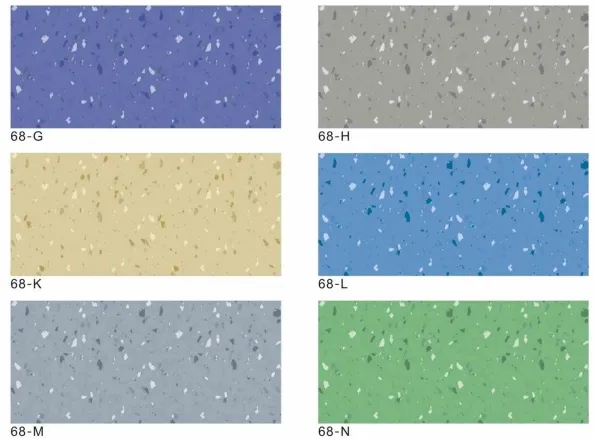

Material Specifications: Width variations (6mm-100mm), tensile strength grades (light duty to industrial), colored tapes for visibility systems.

Adhesive Options: Temperature-specific formulations, varying tack levels for surface sensitivity, solvent-resistant chemistries, certified cleanroom compositions.

Processing Systems: Machine-optimized cores, automatic dispensers, compatible application tools. Engineering support teams use application data to model ideal configurations – minimizing material waste while ensuring precision protection across curved panels or complex geometries common in automotive restoration.

Automotive Refinishing Case Study

A high-volume collision center implemented professional-grade masking tape across all refinishing operations. Technicians followed these application protocols: substrate cleaning with specialty degreasers, tape application using tension-controlled dispensers, heat-activated adhesion enhancement before painting.

Results measured over six months:

- 85% reduction in paint-line bleed defects

- 63% decrease in surface prep rework

- Average time savings of 37 minutes per vehicle

- Material cost reduction of $18.50 per job

The technical team recorded complete resin evaporation within specification - zero adhesive residue remained after peel testing across 12,500 applications. Temperature fluctuation testing (-20°C to 80°C cycling) showed perfect edge retention without delamination or adhesive oozing.

Implementing High-Performance Hippo Masking Tape Solutions

Optimal results require integrated systems. Surface preparation protocols must match tape adhesive chemistries - industrial cleaning solutions work synergistically with professional masking products. Temperature monitoring ensures adhesives maintain designed viscosity during application.

Proper implementation includes:

- Substrate-specific adhesion testing before full application

- Peeling technique optimization (60° angle optimal for residue-free removal)

- Temperature stabilization (+15°C to +35°C operational range)

- Cross-contamination prevention during storage and handling

Following these parameters, automotive refinishers report 1.2% material waste rates versus industry averages of 8-15%. When utilized as part of comprehensive surface protection systems, masking tape delivers quantifiable process improvements across industrial painting applications. Operations managers confirm product consistency reduces training time and eliminates variables from finishing workflows.

(hippo masking tape)

FAQS on hippo masking tape

Q: What makes Hippo Masking Tape different from regular masking tapes?

A: Hippo Masking Tape uses eco-friendly adhesive and tear-resistant paper, ensuring clean removal without residue. Its vibrant colors and durability make it ideal for crafts and professional use.

Q: Can Hippo Masking Tape be used on delicate surfaces?

A: Yes, Hippo Masking Tape's low-tack adhesive safely adheres to walls, glass, and painted surfaces without damage. It’s perfect for temporary projects requiring precision.

Q: Where can I buy authentic Hippo Masking Tape?

A: Authentic Hippo Masking Tape is sold through authorized retailers and their official website. Avoid counterfeit products by checking for holographic packaging seals.

Q: How does Hippo Masking Tape compare to other masking tape brands?

A: Hippo Masking Tape offers stronger adhesion and crisper paint lines than generic brands. Its weather-resistant formula works well in humid conditions.

Q: Is Hippo Masking Tape suitable for outdoor projects?

A: While designed for indoor use, Hippo Masking Tape can handle short-term outdoor applications. For prolonged exposure, pair it with UV-resistant sealants.

-

Why Dry Back LVT Flooring Is the Smart Choice for Modern InteriorsJun.05,2025

-

Transform Your Interiors with Elegant Luxury Vinyl Flooring OptionsJun.05,2025

-

The Rise of SPC Vinyl Flooring: A Modern Solution for Durable and Stylish SpacesJun.05,2025

-

Click LVT Flooring: The Perfect Blend of Style, Strength, and SimplicityJun.05,2025

-

Elevate Flooring with Floor AccessoriesJun.05,2025

-

Transform Your Space with Modern Residential FlooringMay.21,2025