pvc plastic welding

Peb . 12, 2025 23:19

Back to list

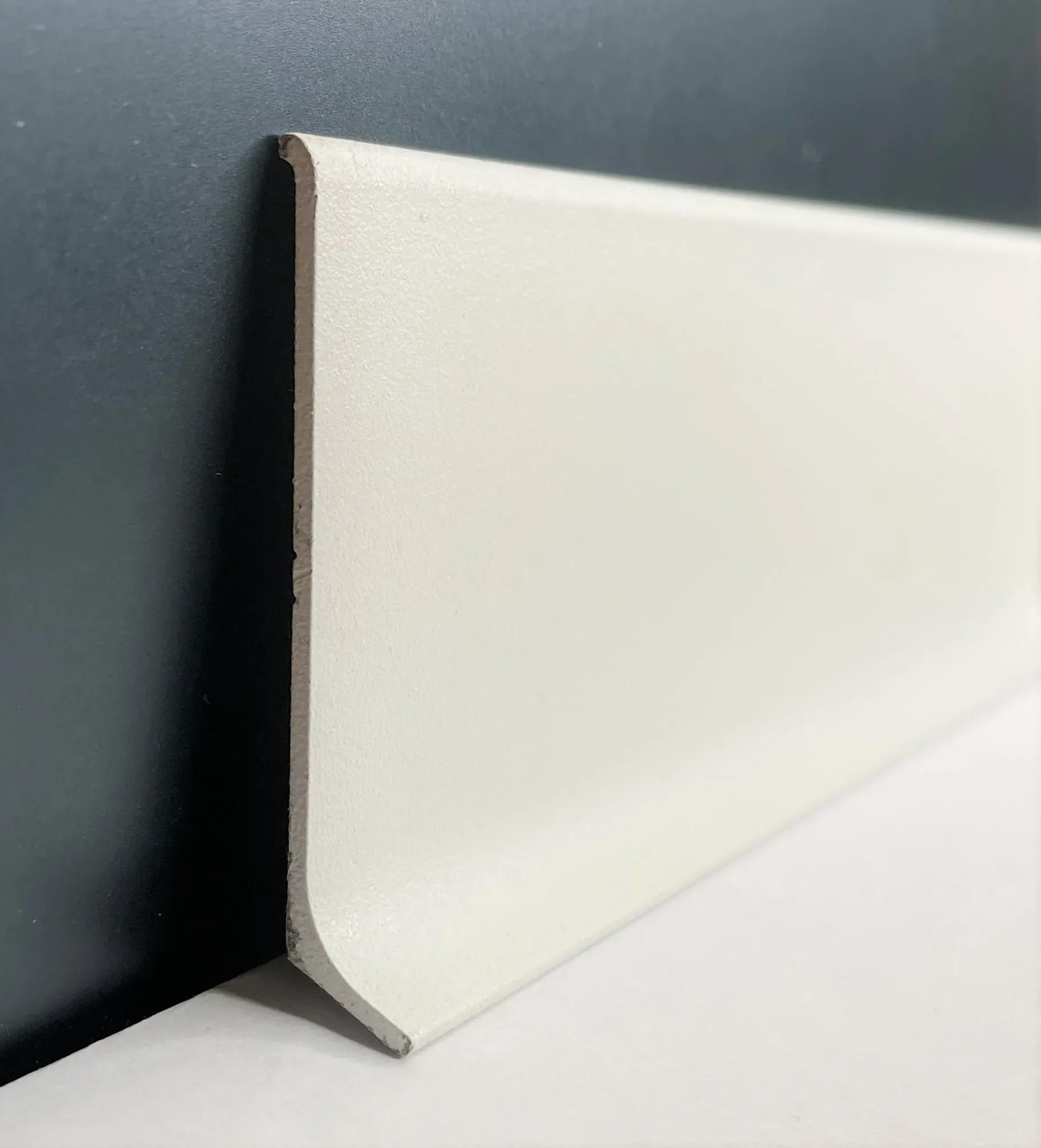

pvc plastic welding

PVC plastic welding is more than just a technique—it's an art form that merges technology with craftsmanship, crucial in industries ranging from automotive to healthcare. With decades of combined expertise, our insights delve deep into the nuances of creating seamless, durable welds in PVC materials, harnessing top-tier equipment and innovative methodologies.

The authoritative nature of PVC plastic welding is bolstered by adhering to international standards and protocols—ensuring the process meets safety and quality requirements. Organizations such as the American Welding Society (AWS) and the International Organization for Standardization (ISO) provide guidelines that outline the best practices in plastic welding. Following these guidelines not only ensures a high-quality product but also reinforces trust with clients and stakeholders, who rely on these standards as a hallmark of excellence. Trustworthiness in the realm of PVC plastic welding is established through consistent quality and reliability. Professionals in this industry often engage in rigorous testing procedures—such as tensile testing and leak testing—to validate the integrity of the welds. Routine inspections and maintenance of equipment also play a crucial part in maintaining operational excellence, reducing the risk of errors, and mitigating potential hazards. Furthermore, building a reputation in PVC plastic welding involves transparency with clients, educating them about the process, setting realistic expectations, and providing post-weld support. Demonstrating a commitment to quality and customer satisfaction not only builds trust but also fosters long-term relationships. In conclusion, PVC plastic welding is a multifaceted discipline where experience, expertise, authoritativeness, and trustworthiness converge. It is not merely about joining pieces of plastic; it's about transforming raw materials into reliable, functional products that meet the rigorous demands of various industries. With an unwavering commitment to quality and continuous improvement, practitioners in this field help push the boundaries of what's possible with PVC welding, setting new standards and contributing to advancements across sectors.

The authoritative nature of PVC plastic welding is bolstered by adhering to international standards and protocols—ensuring the process meets safety and quality requirements. Organizations such as the American Welding Society (AWS) and the International Organization for Standardization (ISO) provide guidelines that outline the best practices in plastic welding. Following these guidelines not only ensures a high-quality product but also reinforces trust with clients and stakeholders, who rely on these standards as a hallmark of excellence. Trustworthiness in the realm of PVC plastic welding is established through consistent quality and reliability. Professionals in this industry often engage in rigorous testing procedures—such as tensile testing and leak testing—to validate the integrity of the welds. Routine inspections and maintenance of equipment also play a crucial part in maintaining operational excellence, reducing the risk of errors, and mitigating potential hazards. Furthermore, building a reputation in PVC plastic welding involves transparency with clients, educating them about the process, setting realistic expectations, and providing post-weld support. Demonstrating a commitment to quality and customer satisfaction not only builds trust but also fosters long-term relationships. In conclusion, PVC plastic welding is a multifaceted discipline where experience, expertise, authoritativeness, and trustworthiness converge. It is not merely about joining pieces of plastic; it's about transforming raw materials into reliable, functional products that meet the rigorous demands of various industries. With an unwavering commitment to quality and continuous improvement, practitioners in this field help push the boundaries of what's possible with PVC welding, setting new standards and contributing to advancements across sectors.

Next:

Latest news

-

SPC FlooringJun.24,2025

-

Bathroom Wall CoveringsJun.24,2025

-

Why Dry Back LVT Flooring Is the Smart Choice for Modern InteriorsJun.05,2025

-

Transform Your Interiors with Elegant Luxury Vinyl Flooring OptionsJun.05,2025

-

The Rise of SPC Vinyl Flooring: A Modern Solution for Durable and Stylish SpacesJun.05,2025

-

Click LVT Flooring: The Perfect Blend of Style, Strength, and SimplicityJun.05,2025