pvc plastic welding rod

Peb . 13, 2025 01:43

Back to list

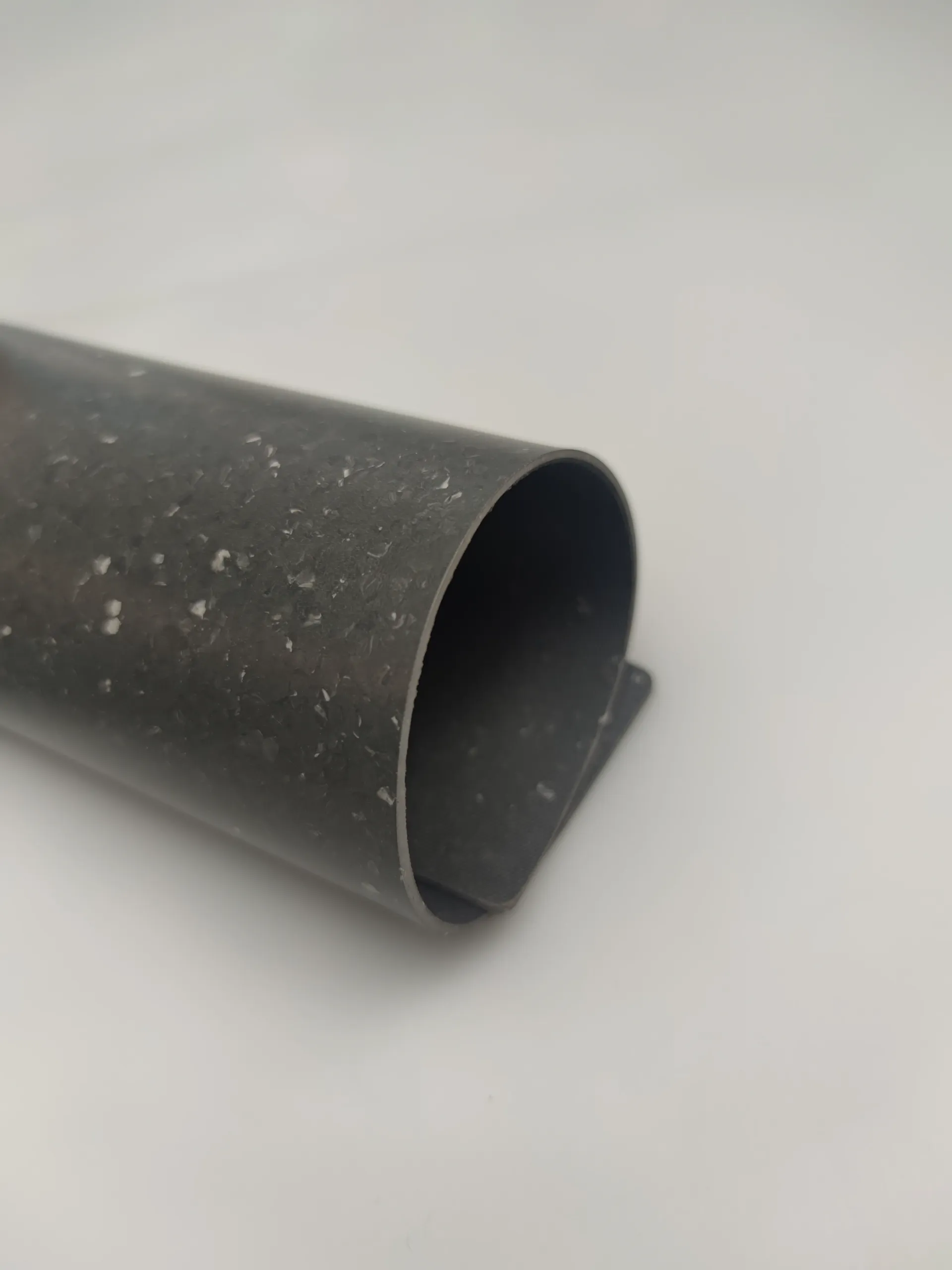

pvc plastic welding rod

Welding rods made of PVC (polyvinyl chloride) offer a versatile solution for joining pieces of PVC material, essential in various industries ranging from construction to plumbing. However, understanding the intricacies of PVC welding rods can enhance the quality and durability of your joint projects, while boosting your market competitiveness.

The authority of a PVC welding rod largely depends on the manufacturer's reputation and the rod's compliance with industry standards. Look for rods meeting ISO, ASTM, or other relevant certifications, guaranteeing that the product has been tested and proven to perform reliably. Quality brands not only assure performance but also often provide detailed guides and customer support, enhancing usability and satisfaction. Trustworthiness in PVC welding rods translates to peace of mind knowing that your joints will withstand stress and environmental factors over time. When evaluating a product, examine user reviews and case studies that speak to the rod's durability and performance. Seasoned professionals can often provide recommendations based on first-hand experience, guiding your selection process. In conclusion, the effectiveness of a PVC welding project hinges on selecting the appropriate rod, employing the correct welding technique, understanding material specifications, and ensuring adherence to safety standards. Meticulously chosen, these rods provide a durable, reliable method for joining PVC materials, empowering professionals to achieve robust and lasting results. By aligning your purchasing decisions with these insights, you can optimize your project's longevity and efficiency, thus securing a reputable standing within your field.

The authority of a PVC welding rod largely depends on the manufacturer's reputation and the rod's compliance with industry standards. Look for rods meeting ISO, ASTM, or other relevant certifications, guaranteeing that the product has been tested and proven to perform reliably. Quality brands not only assure performance but also often provide detailed guides and customer support, enhancing usability and satisfaction. Trustworthiness in PVC welding rods translates to peace of mind knowing that your joints will withstand stress and environmental factors over time. When evaluating a product, examine user reviews and case studies that speak to the rod's durability and performance. Seasoned professionals can often provide recommendations based on first-hand experience, guiding your selection process. In conclusion, the effectiveness of a PVC welding project hinges on selecting the appropriate rod, employing the correct welding technique, understanding material specifications, and ensuring adherence to safety standards. Meticulously chosen, these rods provide a durable, reliable method for joining PVC materials, empowering professionals to achieve robust and lasting results. By aligning your purchasing decisions with these insights, you can optimize your project's longevity and efficiency, thus securing a reputable standing within your field.

Next:

Latest news

-

modern-interior-solutions-with-durable-pvc-material-skirtingAug.22,2025

-

elevating-outdoor-spaces-with-premium-wood-material-skirtingAug.22,2025

-

Waterproof Advantages of SPC Flooring Vinyl in KitchensAug.06,2025

-

SPC Hybrid Waterproof Flooring Thickness GuideAug.06,2025

-

Leveling Subfloor Before My Floor SPC InstallAug.06,2025

-

How Mesh Deck Skirting Improves Outdoor Pest ControlAug.06,2025