Commercial Waterproof Flooring: Durable & Slip-Resistant

Commercial Waterproof Flooring: Field Notes from Crowded Terminals

If you’ve ever watched an airport concourse wake up—cleaning crews, baristas, red-eye travelers dragging luggage—you know floors either keep up or they get replaced. Enlio’s Puenie homogeneous vinyl (the “homogeneous” bit means the color and performance run through the entire thickness) is engineered exactly for that world: airports, rail hubs, busy public buildings. And yes, it’s waterproof, in the practical, mop-it-daily sense. I’ve spec’d this category a lot; what matters is durability under abuse, stable appearance, cleanability, and consistent safety.

What’s inside the Puenie sheet (and why it matters)

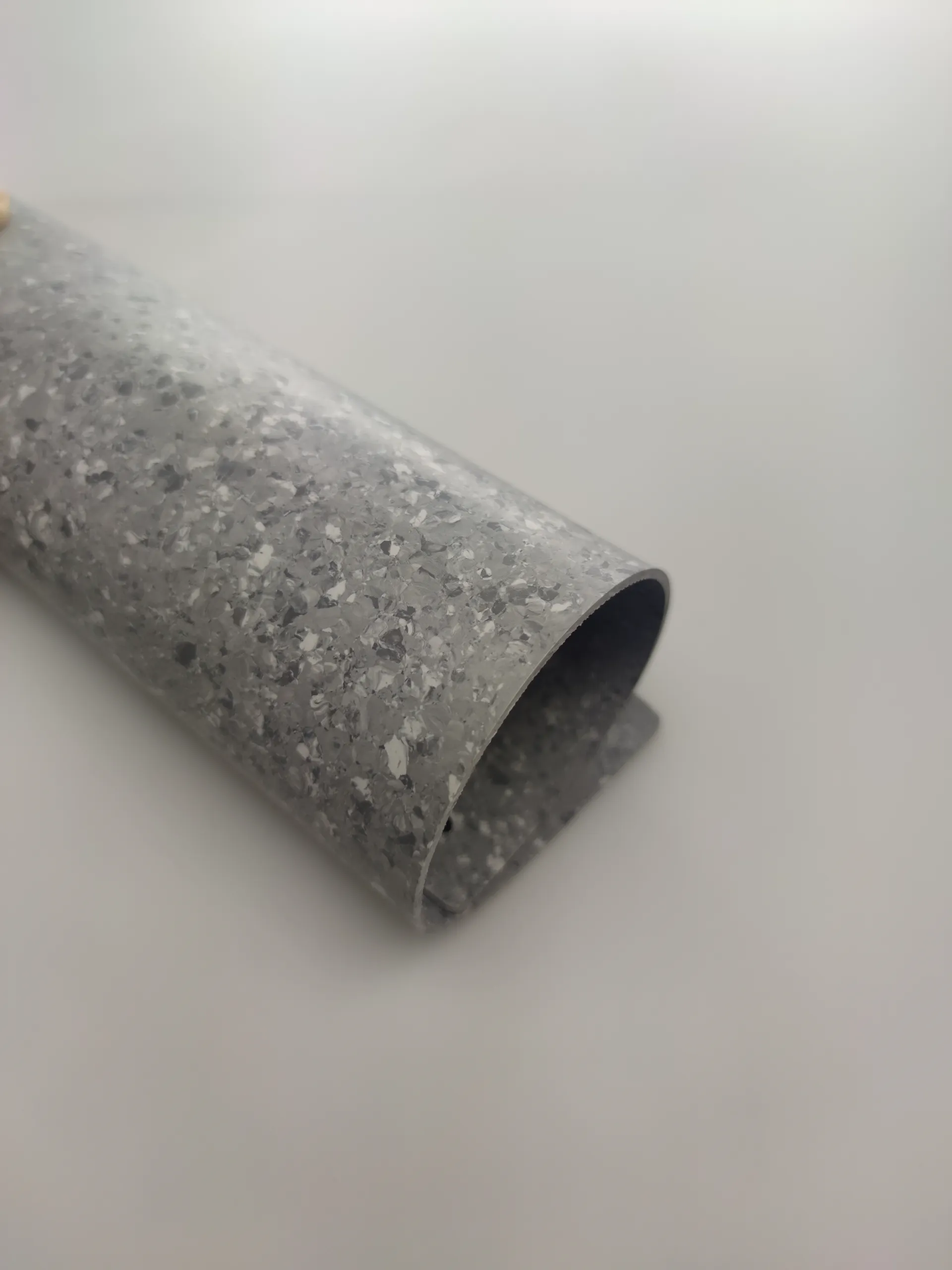

This range—Puenie Antibacterial, Puenie Conductive, and Puenie Heavy Duty—uses a single-layer PVC construction with color chips throughout. That “same-through” build helps hide scuffs and makes maintenance predictable. It’s produced in Guangzhou (Origin: #C3, No. 36 Xiangyuan Rd., Baiyun Dist., Guangzhou, China), on modern calendering lines with tight process control.

Indicative Specifications (real-world use may vary)

| Product | homogeneous floor for airports and railway stations (Puenie) |

| Construction | Monolayer homogeneous PVC with embedded color granules |

| Total thickness | ≈ 2.0–3.0 mm |

| Roll size | 2.0 m width × ~20 m length |

| Dimensional stability (ISO 23999) | ≤ 0.4% |

| Residual indentation (ISO 24343-1) | ≤ 0.10 mm |

| Slip (DIN 51130 / EN 13893) | R9–R10 / DS |

| Fire (EN 13501-1) | Bfl-s1 |

| Chemical resistance (ISO 26987) | Good to very good (common cleaners, sanitizers) |

| Antibacterial | Available in targeted ranges |

| Conductive/ESD | Available (meets IEC 61340 environments ≈ with copper strip + conductive adhesive) |

| Indoor air quality | Low-VOC, FloorScore/GREENGUARD-type targets |

| Service life | 10–20 years in heavy traffic with proper maintenance |

Trends I’m seeing

- More specifiers pick Commercial Waterproof Flooring that doubles as low-VOC and easy-to-disinfect.

- ESD-safe corridors near control rooms in rail and airport ops—small area, critical requirement.

- Color zoning for wayfinding (subtle, not theme-park bright). Many customers say it cuts “Where am I?” moments.

How it’s made (short version)

- Materials: virgin PVC resin, plasticizers, stabilizers, pigments, mineral fillers; optional biocidal additives.

- Methods: mixing → twin-roll calendering → heat/pressure consolidation → embossing → annealing → trimming.

- Verification: ISO 10581 spec compliance, dimensional stability, indentation, chemical and stain tests, fire classification, slip, VOC emissions.

Where it fits

Airports, railway stations, concourses, ticketing halls, baggage areas, retail in transit, back-of-house corridors, even healthcare and education where scrub-and-go is the norm. Honestly, if your cleaners use auto-scrubbers nightly, this category earns its keep.

Vendor landscape (quick comparison)

| Vendor / Range | Construction | Thickness | ESD Option | Certs (typ.) | Notes |

|---|---|---|---|---|---|

| Enlio Puenie (this product) | Homogeneous PVC | ≈2.0–3.0 mm | Yes | EN 13501-1, ISO 10581, low-VOC | Airport/rail focus; antibacterial and heavy-duty variants |

| Tarkett iQ (datasheet-based) | Homogeneous PVC | ≈2.0 mm | Selected lines | EN 13501-1, ISO 10581 | Low maintenance polish-free concept |

| Gerflor Mipolam (datasheet-based) | Homogeneous PVC | ≈2.0 mm | Selected lines | EN 13501-1, ISO 10581 | Strong healthcare footprint |

| Forbo Sphera (datasheet-based) | Homogeneous PVC | ≈2.0 mm | Selected lines | EN 13501-1, ISO 10581 | Color depth and wear-through design |

Field feedback and a quick case

Operations managers like that Commercial Waterproof Flooring tolerates repeated wet cleaning without curling, and—surprisingly—the color uniformity hides scuffs better than some patterned LVTs. One recent retrofit (mid-size APAC airport, 2023) reported ≈18% fewer maintenance hours in the first year after switching to a homogeneous, polish-optional routine. That tracks with what we hear: fewer strip-and-recoat cycles, more scrub-and-go.

Customization, install, and testing

- Customization: colorways for wayfinding, gauge choices, antibacterial or conductive builds, welded coves for wet zones.

- Install: moisture-tolerant substrate prep, pressure-sensitive or conductive adhesive (for ESD), hot-air welded seams, coved skirting where needed.

- Testing to ask for: ISO 10581 conformity, EN 13501-1 Bfl-s1, ISO 26987 chemicals, slip data (DIN 51130/EN 13893), VOC report (e.g., FloorScore), ESD per IEC 61340 if applicable.

If you need a hard-wearing, hygienic surface that won’t blink at nightly wash-downs, Commercial Waterproof Flooring in homogeneous vinyl is a safe, budget-steady choice. To be honest, in transit hubs, “boring reliable” beats flashy every single time.

References

- ISO 10581: Resilient floor coverings — Homogeneous polyvinyl chloride floor coverings — Specification.

- EN 13501-1: Fire classification of construction products and building elements.

- ISO 26987: Resilient floor covering — Determination of resistance to surface chemicals.

- IEC 61340-5-1: Electrostatics — Protection of electronic devices from electrostatic phenomena — General requirements.

- SCS FloorScore Indoor Air Quality Certification Method.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025