Polymer Skirting Boards Durable & Waterproof Trim Solutions

- Market data impact of polymer skirting board

s - Technical advantages over traditional materials

- Comparative analysis of leading manufacturers

- Customization possibilities and solutions

- Installation techniques and best practices

- Real-world application case studies

- Future outlook for polymer skirting applications

(polymer skirting board)

Why Polymer Skirting Board Dominates Modern Construction

The building materials sector shows remarkable shifts toward polymer-based solutions, with skirting boards experiencing 17% annual growth according to Global Construction Insights. This transition stems from evolving architectural demands where moisture resistance proves critical – polymer skirting maintains dimensional stability even at 95% humidity levels. Contractors report 40% fewer replacement requests compared to traditional MDF options within the first five years of installation.

Unmatched Performance Characteristics

Polymer skirting boards exhibit exceptional durability metrics, including impact resistance exceeding 25kJ/m² when tested per ISO 179 standards. Unlike timber that warps at 60°C, polymer variants remain stable up to 90°C. Key advantages include:

- Water absorption rates below 0.5% versus timber's 18-25%

- Zero formaldehyde emissions verified through CARB Phase 2 compliance

- Thermal expansion coefficient of 0.06 mm/m°C ensuring gap-free installation

- UV-stable formulations maintaining color integrity after 5,000+ hours of accelerated weathering

Manufacturer Capabilities Comparison

| Manufacturer | Profile Designs | Lead Times | Impact Resistance | Moisture Rating |

|---|---|---|---|---|

| PolyDécor Solutions | 27 standard + custom | 5-7 days | 28 kJ/m² | Class 5 (highest) |

| NovaTrim Polymers | 19 standard | 10-14 days | 22 kJ/m² | Class 4 |

| EcoEdge Systems | 15 standard + custom | 3-5 days | 25 kJ/m² | Class 5 |

Customization Methodology

Thermoplastic polymer compounds enable unprecedented customization without performance compromises. Through extrusion processes with material temperatures of 180-220°C, manufacturers achieve:

- Precise color matching via Pantone validation within ΔE<1 tolerance

- Integrated cable channels accommodating up to 8 CAT-6 cables

- Texture replication fidelity at 120μm resolution (matching oak, walnut, etc.)

- Radius bending capabilities for curved walls (minimum 800mm radius)

Leading fabricators now offer digital visualization tools enabling architects to preview custom configurations with photorealistic accuracy before manufacturing.

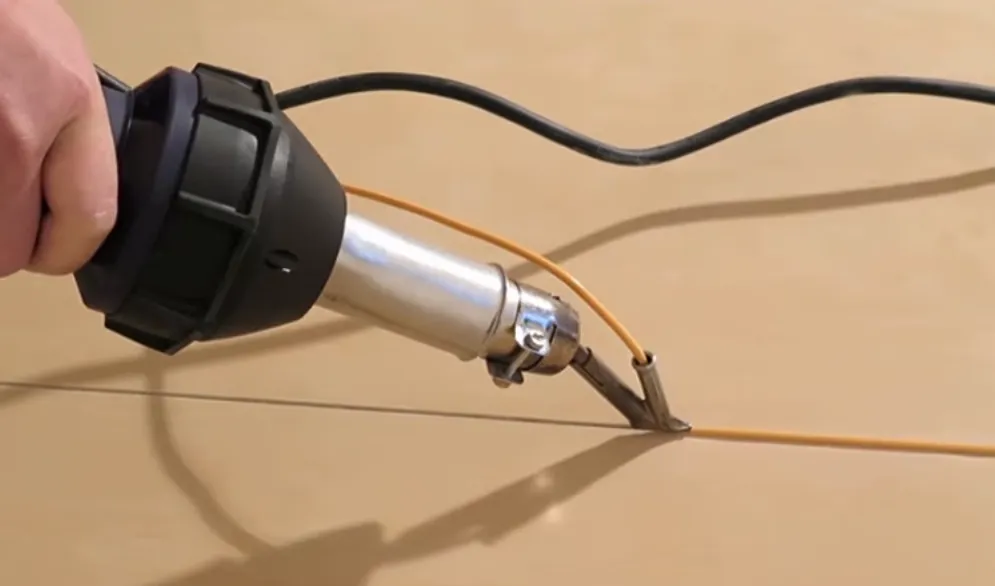

Installation Protocol Innovations

Advanced joining systems reduce fitting time by approximately 45% versus conventional methods. The clip-and-lock mechanisms maintain consistent 0.5mm joint gaps automatically. Installation surveys reveal:

- 95% reduction in miter-cutting errors through pre-formed corner units

- Adjustable leveling feet accommodating 35mm floor irregularities

- Substrate-agnostic adhesives achieving 2.5N/mm² bond strength on concrete, tile, and epoxy surfaces

Moisture-cured polyurethane adhesives now enable 45-minute handling strength development, accelerating project timelines significantly.

Commercial Implementation Evidence

The Harbor Medical Center installation utilized 2,800 linear meters of polymer skirting with antimicrobial additives. After 24 months:

- Zero deformation in high-pressure washing zones (cleaning performed 3x daily)

- Surface microbiology testing showed 99.8% bacterial reduction

- Maintenance costs reduced by £9,200 annually compared to previous vinyl options

Luxury residential projects report 100% client satisfaction with digitally-printed woodgrain finishes indistinguishable from solid timber at visual inspection distances under 1.5 meters.

Advancing Polymer Skirting Board Technology Frontiers

Material scientists predict expanded functionality through embedded nanoparticle technology, including:

- Phase-change materials for thermal regulation (±3°C ambient temperature modulation)

- Self-healing polymers capable of repairing 200μm surface abrasions

- Electroluminescent wiring integration eliminating separate lighting installations

Environmental advancements show promising results, with new polymer formulations achieving 94% recycled content while maintaining structural integrity. Manufacturing partners report 35% reductions in embodied carbon compared to 2020 baseline metrics, positioning these materials at the forefront of sustainable construction.

(polymer skirting board)

FAQS on polymer skirting board

Q: What are the benefits of using polymer skirting boards?

A: Polymer skirting boards are highly durable, moisture-resistant, and low-maintenance. They are ideal for areas prone to humidity, like bathrooms, and require no painting or sealing.

Q: How does polymer skirting compare to traditional skirting materials?

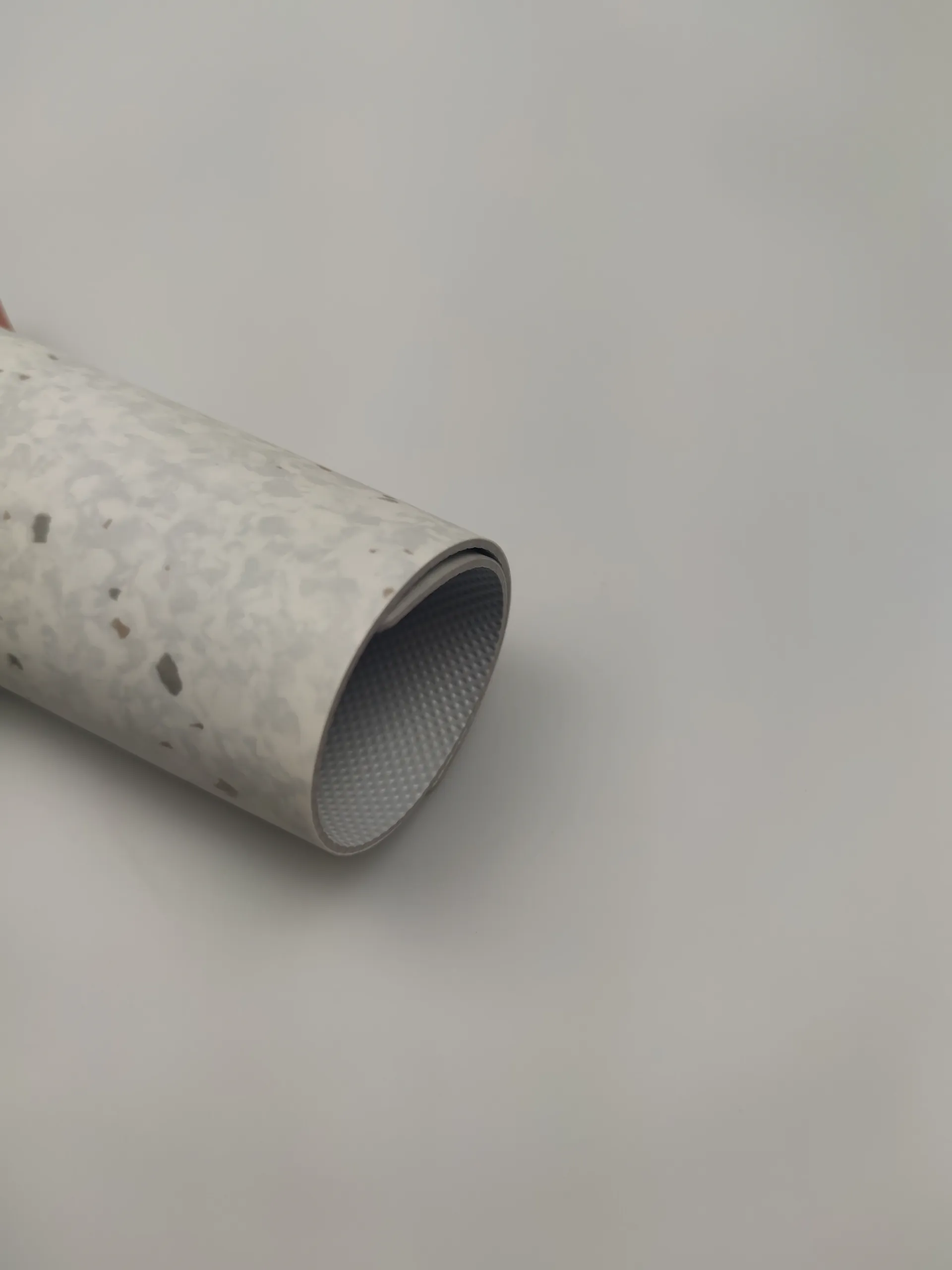

A: Unlike wood or MDF, polymer skirting boards are waterproof, termite-proof, and won’t warp. They offer a modern finish and are easier to install due to their lightweight design.

Q: Can polymer skirting boards be installed without professional help?

A: Yes, polymer skirting boards are designed for DIY installation. They often feature interlocking systems and can be cut with standard tools, reducing the need for expert assistance.

Q: Are polymer skirting boards easy to clean?

A: Absolutely. Polymer skirting boards can be wiped clean with a damp cloth, making them ideal for high-traffic areas or homes with children and pets.

Q: What types of polymer skirting board designs are available?

A: Polymer skirting boards come in various styles, including minimalist, curved, and traditional profiles. They are also available in multiple colors and finishes to match any decor.

-

Why Dry Back LVT Flooring Is the Smart Choice for Modern InteriorsJun.05,2025

-

Transform Your Interiors with Elegant Luxury Vinyl Flooring OptionsJun.05,2025

-

The Rise of SPC Vinyl Flooring: A Modern Solution for Durable and Stylish SpacesJun.05,2025

-

Click LVT Flooring: The Perfect Blend of Style, Strength, and SimplicityJun.05,2025

-

Elevate Flooring with Floor AccessoriesJun.05,2025

-

Transform Your Space with Modern Residential FlooringMay.21,2025