Durable Heterogeneous Vinyl Sheet | Hawk Flooring Solutions

In the rapidly evolving landscape of commercial and institutional flooring, the demand for high-performance, durable, and aesthetically versatile solutions is paramount. Among the leading innovations, heterogeneous viny stands out as a material engineered to meet the stringent requirements of modern facilities. This comprehensive article delves into the technical intricacies, application benefits, and strategic considerations for deploying advanced heterogeneous viny systems, offering insights critical for B2B decision-makers and technical procurement specialists.

Industry Trends and Market Dynamics in High-Performance Flooring

The global flooring market, particularly within the B2B sector, is experiencing significant growth driven by urbanization, infrastructure development, and an increasing emphasis on health, safety, and sustainability. Key trends influencing the adoption of heterogeneous viny include:

- ✓ Enhanced Hygiene and Antimicrobial Properties: Post-pandemic, there's an intensified focus on surfaces that are easy to clean, disinfect, and resist microbial growth, making seamless, non-porous heterogeneous sheet vinyl highly desirable in healthcare and educational settings.

- ✓ Sustainability and Eco-conscious Manufacturing: Demand for products with lower VOC emissions, recycled content, and longer lifespans is rising. Manufacturers are investing in greener production processes and transparent lifecycle assessments.

- ✓ Durability and Longevity: Commercial environments require flooring capable of withstanding heavy foot traffic, rolling loads, and abrasion. Engineered solutions like heterogeneous vinyl sheet offer extended service life, reducing replacement cycles and total cost of ownership.

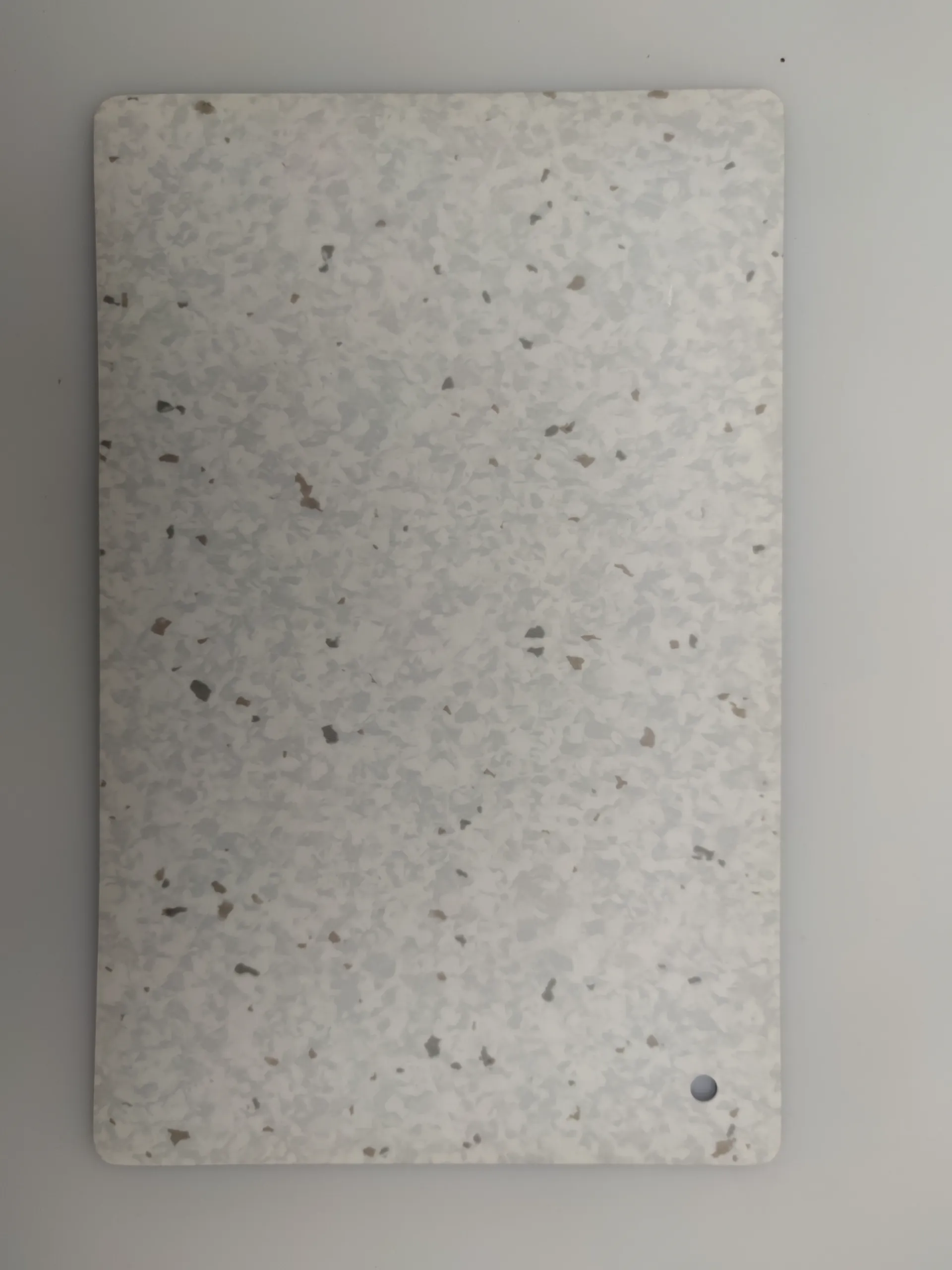

- ✓ Aesthetic Versatility: The ability to mimic natural materials (wood, stone) or create unique, brand-specific designs allows architects and designers greater creative freedom without compromising performance.

These trends collectively underscore the strategic importance of selecting flooring solutions that not only meet immediate functional needs but also align with long-term operational and sustainability goals. Brands like Hawk Flooring and other premium manufacturers are continuously innovating to address these evolving market demands.

Understanding Heterogeneous Vinyl: Process Flow and Composition

Heterogeneous viny refers to multi-layered vinyl flooring, distinguishing it from homogeneous vinyl, which consists of a single layer. This layered construction provides superior performance characteristics tailored to specific application demands. The manufacturing process is a sophisticated blend of material science and precision engineering.

Manufacturing Process of Heterogeneous Vinyl

1. Raw Material Preparation

Materials: PVC resin (suspension or emulsion grade), plasticizers (e.g., DINP, DOTP for flexibility), stabilizers (heat, UV), fillers (calcium carbonate for bulk/cost), pigments, and other additives. These are precisely weighed and mixed.

2. Backing Layer Production

The base layer, typically a calendared or coated PVC foam layer, is formed. This layer provides dimensional stability, sound absorption, and comfort underfoot. Processes often involve calendering (rolling between heated rollers) or spreading liquid PVC paste onto a substrate.

3. Print Layer Application

A high-definition decorative film (print layer), often made of PVC, is printed with various designs—wood, stone, abstract patterns. This layer is then laminated onto the backing layer using heat and pressure or an adhesive coating.

4. Wear Layer and Surface Treatment

A transparent PVC wear layer is applied over the print layer. This is the critical component for durability. It can be a clear film laminated on or a liquid PVC applied and cured. Subsequently, a PU (polyurethane) surface treatment (e.g., Enlio's Stariver surface) is applied for enhanced scratch, stain, and scuff resistance, and easier cleaning.

5. Curing, Cooling, and Finishing

The multi-layered structure undergoes curing in ovens to ensure material integrity, followed by cooling. The material is then trimmed, rolled into sheets, or cut into tiles, and subjected to rigorous quality control checks.

Testing Standards: Throughout the process, materials and finished products adhere to international standards such as ISO 10582 for general specifications of PVC flooring, EN 660-2 for wear resistance, ISO 24346 for thickness, and EN 13893 for slip resistance. These standards ensure the product's performance, safety, and consistency.

Service Life: Due to their robust layered construction, particularly the wear layer and surface treatment, high-quality heterogeneous viny floors typically offer a service life of 10-20 years in commercial environments, significantly outperforming many alternative materials.

Target Industries and Advantages: These floors are ideal for sectors demanding high performance and hygiene. In healthcare, energy saving is less about the floor itself but the overall building envelope. For flooring, advantages include superior corrosion resistance to common disinfectants and chemicals, exceptional durability in high-traffic areas, and ease of maintenance contributing to operational efficiency. In metallurgy or petrochemical, specific chemical resistance properties can be engineered into the top layers for targeted protection.

Technical Specifications of High-Performance Heterogeneous Vinyl

The performance of heterogeneous viny is defined by a series of critical technical parameters. Below, we detail the specifications typical for a premium product like the heterogeneous floor with Stariver surface, emphasizing the significance of each metric for B2B applications.

Product Specification Table: Heterogeneous Floor with Stariver Surface

| Parameter | Value (Typical) | Standard / Significance |

|---|---|---|

| Total Thickness | 2.0 mm - 4.0 mm | ISO 24346. Dictates comfort, sound absorption, and structural integrity. Thicker options offer more resilience. |

| Wear Layer Thickness | 0.35 mm - 0.70 mm | EN ISO 10582. Critical for durability, abrasion resistance, and service life. Higher values indicate suitability for heavy traffic. |

| Total Weight | 2.8 kg/m² - 5.0 kg/m² | ISO 23997. Influences handling, installation logistics, and structural load considerations for buildings. |

| Residual Indentation | ≤ 0.10 mm | EN ISO 24343-1. Measures resistance to permanent marks from static loads (e.g., furniture). Lower values are better. |

| Slip Resistance | R9 - R10 (DIN 51130) / ≥ 0.5 (ASTM D2047) | Crucial for safety in commercial and public spaces, especially where spills may occur. Higher values reduce slip hazards. |

| Fire Classification | Bfl-s1 (EN 13501-1) | Indicates reaction to fire, with Bfl-s1 representing very limited contribution to fire and very low smoke production, essential for public buildings. |

| Sound Absorption (ΔLw) | 15 dB - 19 dB | EN ISO 717-2. Measures impact sound reduction, vital for quiet environments like hospitals, libraries, and offices. |

| Chemical Resistance | Excellent (e.g., against dilute acids, alkalis, alcohols, common disinfectants) | ISO 26987. Essential for healthcare, laboratories, and industrial environments where spills are common. |

| VOC Emissions | Very Low (e.g., A+ for French VOC, FloorScore certified) | Ensures good indoor air quality, critical for health-sensitive environments and LEED certification. |

-

Modern Interior Solutions with Durable PVC Material SkirtingAug.22,2025

-

Elevating Outdoor Spaces with Premium Wood Material SkirtingAug.22,2025

-

Waterproof Advantages of SPC Flooring Vinyl in KitchensAug.06,2025

-

SPC Hybrid Waterproof Flooring Thickness GuideAug.06,2025

-

Leveling Subfloor Before My Floor SPC InstallAug.06,2025

-

How Mesh Deck Skirting Improves Outdoor Pest ControlAug.06,2025