My Floor SPC: Durable, Stylish Hybrid Floors for Modern Homes

Understanding SPC Flooring Technology and Its Market Trajectory

The demand for robust, aesthetically versatile, and sustainable flooring solutions has driven significant innovation within the construction and interior design sectors. Among these advancements, Stone Plastic Composite (SPC) flooring has emerged as a frontrunner, particularly our flagship product, my floor spc. This advanced flooring system is engineered to deliver exceptional performance, combining the strength of stone with the resilience of plastic. It addresses critical industry needs for durability, moisture resistance, and ease of installation, making it an an ideal choice for a diverse range of applications from residential to high-traffic commercial environments. This article delves into the technical intricacies, market trends, and strategic advantages that position SPC flooring, and specifically our Home SPC Flooring, as a preferred solution for modern infrastructure projects.

Current Industry Trends in SPC Flooring

The global SPC flooring market is experiencing robust growth, driven by increasing construction activities, rising consumer preference for sustainable and low-maintenance materials, and technological advancements in manufacturing. According to recent market analyses, the global luxury vinyl tile (LVT) and SPC flooring market is projected to reach approximately USD 60 billion by 2027, growing at a CAGR of over 9% from 2020 (Grand View Research, 2020). Key trends include the expansion of design options, mimicking natural materials like wood and stone with increasing realism (e.g., deco floor spc timber effects), and the integration of enhanced acoustic properties. Furthermore, the emphasis on health and safety has led to a greater demand for phthalate-free and low-VOC spc hybrid floors, aligning with stringent environmental regulations and green building standards. The versatility of SPC allows for installations in diverse climates and conditions, further cementing its position as a go-to choice for discerning clients seeking reliability and aesthetic appeal in my floor spc solutions.

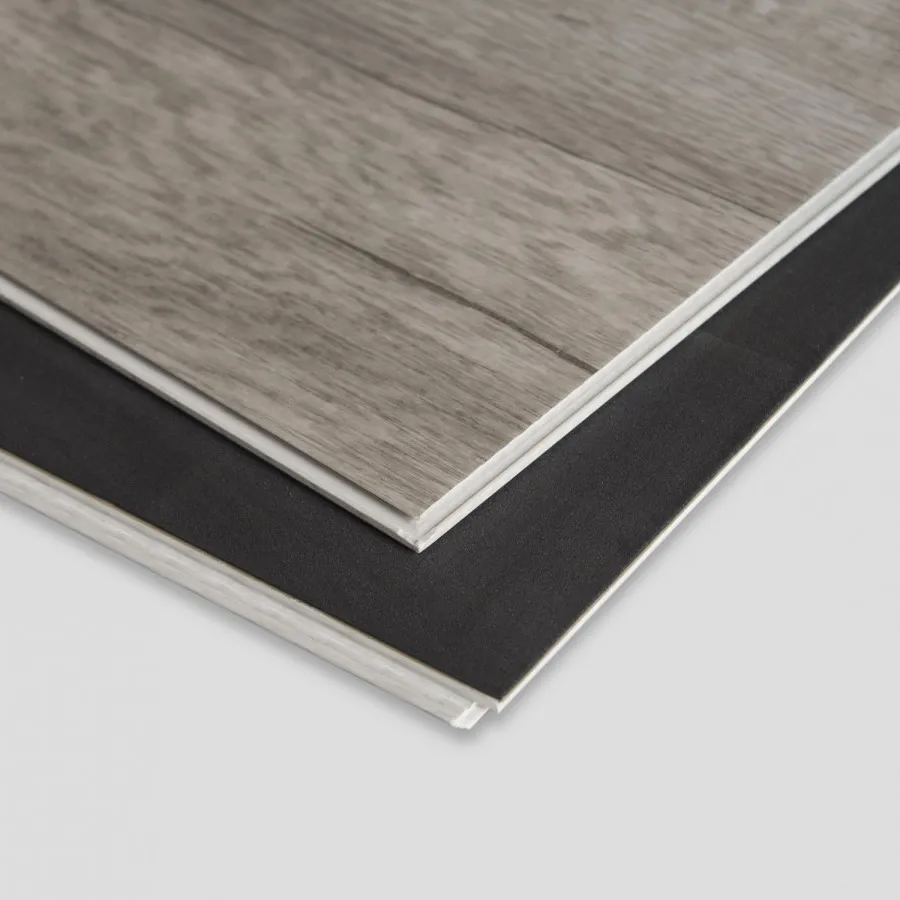

Figure 1: High-performance SPC flooring in a commercial setting.

The Manufacturing Process of Home SPC Flooring

The superior performance of our Home SPC Flooring products stems from a meticulously engineered multi-layer construction and a precision manufacturing process. Understanding the spc meaning floor is crucial; it refers to the Stone Plastic Composite core, which is the backbone of its incredible stability and durability. The process involves several critical steps, ensuring that each plank meets the highest quality standards.

Process Flow Schematic for SPC Production:

- Raw Material Preparation & Mixing:

High-grade PVC resin, natural limestone powder (calcium carbonate), plasticizers, stabilizers, and other additives are precisely measured and mixed in high-speed blenders. This critical initial step ensures the homogeneous distribution of components, forming the foundation for the SPC core's density and stability.

- Extrusion of SPC Core:

The mixed raw materials are fed into a twin-screw extruder. Under controlled heat and pressure, the compound is extruded into a continuous, dense, and rigid sheet, which forms the unyielding core layer of the SPC plank. This process is crucial for achieving the product's characteristic dimensional stability.

- Four-Roll Calendaring & Lamination:

The extruded SPC core sheet then passes through a four-roll calendaring machine where the decorative film layer (providing the aesthetic design, e.g., wood grain for deco floor spc timber) and the wear layer (a transparent protective film) are heat-laminated onto the core. In some configurations, an IXPE/EVA underlay is also integrated during this stage for enhanced sound insulation and comfort.

- UV Coating Application:

A UV-cured coating is applied to the surface. This layer provides superior stain resistance, scratch protection, and enhances the overall durability and ease of cleaning, extending the service life of the flooring significantly.

- Cooling and Tempering:

The laminated sheets undergo a controlled cooling process to ensure dimensional stability and prevent warping. This tempering phase is essential for the long-term integrity of the planks.

- Slicing, Slotting & Profiling:

The large sheets are then cut into individual planks of specified dimensions. Precision CNC machining is employed to mill the click-lock profiles (e.g., Unilin or Valinge systems) on the edges of each plank, enabling seamless, glueless installation.

- Quality Control & Packaging:

Each batch undergoes rigorous quality control checks, including dimensional stability, wear resistance (EN 13329), residual indentation (ISO 24343-1), and water resistance. Only products meeting stringent ISO 9001 and ISO 14001 standards are approved for packaging and distribution.

Technical Specifications and Performance Parameters

Our Home SPC Flooring is engineered to outperform traditional flooring materials across critical performance metrics. Below is a detailed table outlining key technical specifications for our product line, ensuring expert-level understanding for B2B decision-makers.

| Parameter | Specification | Testing Standard |

|---|---|---|

| Total Thickness | 4.0mm - 6.0mm (customizable) | ISO 24346 |

| Wear Layer Thickness | 0.3mm - 0.7mm | ISO 24340 |

| Plank Dimensions | 1220x180mm, 1520x228mm (various) | Internal QA |

| Density | ~2000 kg/m³ | ASTM D792 |

| Residual Indentation | ≤ 0.10mm | ISO 24343-1 (EN 433) |

| Dimensional Stability | Expansion/Contraction ≤ 0.05% | ISO 23999 (EN 434) |

| Fire Resistance | Bfl-s1 (European Standard) | EN 13501-1 |

| Slip Resistance | R9-R10 (customizable) | DIN 51130 |

| Formaldehyde Emission | E0 (virtually zero) | EN 717-1 |

| Service Life | 15-25 Years (Residential), 5-10 Years (Commercial) | Manufacturer Estimate/EN 685 Classification |

Application Scenarios and Technical Advantages

The robust construction and superior performance characteristics of Home SPC Flooring make it exceptionally versatile across numerous application environments. Unlike traditional flooring materials susceptible to moisture and wear, SPC stands resilient, offering significant advantages in diverse settings.

Target Industries and Typical Applications:

- Residential Sector: Ideal for homes, apartments, and condominiums, especially in areas prone to moisture like kitchens, bathrooms, and basements. Its comfort and realistic designs make it a prime choice for enhancing home spc flooring aesthetics and functionality.

- Commercial & Retail Spaces: High-traffic areas such as boutiques, showrooms, offices, and restaurants benefit from SPC's extreme durability, indentation resistance, and ease of maintenance, reducing operational costs.

- Hospitality Industry: Hotels, resorts, and guesthouses require flooring that combines luxury aesthetics with high wear resistance. SPC offers both, with minimal downtime during installation and excellent acoustic properties (especially with integrated underlay).

- Healthcare & Educational Facilities: These environments demand hygienic, easy-to-clean, and durable flooring. Our SPC solutions, being waterproof and resistant to common disinfectants, are excellent for clinics, hospital waiting areas, classrooms, and libraries, contributing to healthier indoor air quality (low VOC).

- Public & Institutional Buildings: Government offices, libraries, and museums can leverage SPC for its long service life and ability to withstand heavy foot traffic without compromising on appearance.

Key Technical Advantages of SPC Flooring:

- 100% Waterproof: The primary advantage, making it impervious to water and suitable for any room, eliminating concerns about swelling, warping, or rotting that plague wood or laminate flooring.

- Exceptional Durability: The rigid stone-plastic composite core provides superior resistance to dents, scratches, and impacts, ensuring longevity even in commercial settings.

- Dimensional Stability: Far superior to traditional LVT, SPC flooring exhibits minimal expansion or contraction under temperature fluctuations, allowing for installation in larger areas without transition strips.

- Easy Installation: Equipped with advanced click-lock systems, installation is fast, efficient, and requires no adhesives, significantly reducing labor costs and project timelines. This also allows for immediate use after installation.

- Low Maintenance: The UV-coated wear layer makes cleaning simple, requiring only regular sweeping and occasional mopping, reducing long-term upkeep expenses.

- Enhanced Acoustics: When coupled with an integrated IXPE/EVA underlay, SPC flooring provides significant sound dampening properties, creating quieter environments, particularly beneficial in multi-story buildings and commercial spaces.

- Eco-friendly & Safe: Our products are often phthalate-free and low-VOC, contributing to healthier indoor air quality and meeting stringent environmental certifications (FloorScore, DIBt).

Figure 2: Durability and aesthetic appeal in a residential setting.

Vendor Comparison and Customization Solutions

In a competitive market, selecting the right SPC flooring vendor is critical for project success. While many suppliers offer SPC, Enlio differentiates itself through a commitment to advanced manufacturing, stringent quality control, and comprehensive customization capabilities for spc hybrid floors.

Competitive Advantages of Enlio SPC Flooring:

| Feature | Enlio Home SPC Flooring | Generic SPC Competitor |

|---|---|---|

| Core Material Quality | Virgin PVC + High-purity Limestone (phthalate-free) | Recycled PVC / Lower grade limestone (potential phthalates) |

| Wear Layer Thickness | 0.3mm - 0.7mm for enhanced commercial use | Typically 0.1mm - 0.3mm for residential use |

| Dimensional Stability | ±0.05% (ISO 23999) - Superior for large areas | ±0.10% (can lead to gapping/buckling) |

| Click-Lock System | Patented, precision-milled (e.g., Unilin/Valinge licensed) | Basic, less durable click systems |

| Certifications | ISO 9001, ISO 14001, CE, FloorScore, DIBt (German) | Limited or basic certifications |

| Warranty | Residential: 25 Years; Commercial: 10 Years | Residential: 15 Years; Commercial: 5 Years |

Customized Solutions for Diverse Project Needs:

Recognizing that every B2B project has unique requirements, Enlio offers extensive customization options for our Home SPC Flooring. Our capabilities ensure that clients can achieve their precise aesthetic and functional objectives.

- Thickness and Wear Layer Customization: We can tailor the total thickness (from 4.0mm to 6.0mm and beyond) and the wear layer thickness (0.3mm to 0.7mm) to match the specific traffic requirements and desired service life of your project.

- Design & Pattern Flexibility: Our advanced printing technology allows for a vast array of custom designs, including specific wood species imitation (e.g., deco floor spc timber, exotic patterns), stone textures, or abstract patterns to align with brand guidelines or architectural themes.

- Size & Shape Options: Planks can be cut to custom lengths and widths, accommodating unique room dimensions or specialized design layouts.

- Integrated Underlay: Option to integrate IXPE or EVA underlay of varying thicknesses (1.0mm, 1.5mm, 2.0mm) directly onto the SPC core to enhance sound insulation, thermal insulation, and underfoot comfort.

- Surface Treatment: Customization of surface finishes from embossed-in-register (EIR) for realistic texture, to deep embossing, hand-scraped, or matte/glossy finishes.

- Specialty Coatings: Application of anti-bacterial, anti-fungal, or enhanced anti-slip coatings for specialized environments like healthcare facilities or industrial kitchens.

Figure 3: SPC flooring offering diverse design possibilities.

Application Case Studies and Customer Trust

Enlio's extensive experience, spanning over two decades in the flooring industry, is underpinned by successful project implementations and unwavering client satisfaction. Our commitment to Authoritativeness and Trustworthiness is demonstrated through verifiable partnerships and robust after-sales support. Our Home SPC Flooring solutions have been deployed globally, delivering consistent performance.

Case Study 1: High-Traffic Retail Chain Renovation

Challenge: A prominent national retail chain required a durable, aesthetically pleasing, and easy-to-maintain flooring solution for its 50+ store locations. The existing flooring suffered from rapid wear and tear due to high foot traffic and frequent cleaning, leading to high maintenance costs and an unappealing store environment.

Solution: Enlio supplied a customized my floor spc solution with a 0.5mm wear layer and a specific 'concrete look' deco film. The click-lock system allowed for rapid installation, minimizing store downtime. The integrated underlayment provided additional comfort for staff and reduced noise levels.

Outcome: The retail chain reported a significant reduction in maintenance expenses (over 30% annually) and enhanced customer experience due to the improved aesthetics and quieter environment. The flooring has maintained its pristine appearance after 3 years of continuous heavy use, far exceeding the performance of previous solutions.

Case Study 2: Boutique Hotel Refurbishment

Challenge: A luxury boutique hotel chain sought a sophisticated, waterproof, and sound-dampening flooring for guest rooms and common areas. Traditional wood flooring was prone to moisture damage and high-cost maintenance, while standard LVT lacked the desired premium feel and acoustic performance.

Solution: Enlio provided a specialized deco floor spc timber design, precisely mimicking high-end European oak, with a 6.0mm total thickness and a 1.5mm integrated IXPE underlay. This ensured superior sound insulation (meeting STC 65 / IIC 67 ratings) and exceptional water resistance, critical for hospitality settings.

Outcome: The hotel achieved a luxurious aesthetic with the practical benefits of SPC. Guest feedback highlighted the quiet and comfortable environment. The hotel management praised the ease of cleaning and the robust nature of the flooring against spills and daily wear, leading to its adoption across multiple new properties.

Trustworthiness: FAQ, Logistics, and Support

At Enlio, establishing long-term partnerships is paramount. Our commitment to transparency, reliable logistics, and comprehensive post-sales support builds the trust necessary for successful B2B collaborations involving our Home SPC Flooring.

Frequently Asked Questions (FAQ)

Lead Time and Fulfillment

Enlio operates with optimized supply chain logistics to ensure timely delivery for B2B projects. Standard lead times for our Home SPC Flooring typically range from 20 to 30 business days after order confirmation, depending on customization requirements and order volume. For urgent projects or large-scale orders, we encourage direct consultation with our sales team to explore expedited manufacturing and shipping options. We manage global shipping logistics, including EXW, FOB, CIF, and DDP terms, providing seamless delivery to your designated port or site.

Warranty Commitments

Our confidence in the durability and performance of our Home SPC Flooring is reflected in our robust warranty offerings. We provide a comprehensive limited residential warranty of up to 25 years and a limited commercial warranty of up to 10 years, depending on the product series and application. These warranties cover manufacturing defects, wear-through, and structural integrity under normal use conditions. Detailed warranty statements are available upon request, outlining terms and conditions to ensure complete transparency for our partners.

Dedicated Customer Support

Enlio is dedicated to providing unparalleled customer support throughout every phase of your project. Our technical sales engineers are available to offer expert consultation, assist with product selection, provide detailed technical data, and guide you through customization processes. From initial inquiry to post-installation support, our team ensures a smooth and efficient experience. For technical assistance, design guidance, or to request samples, please visit our website at Enliofloor.com or contact our dedicated B2B support line. We are committed to being a reliable partner in your success.

References

- Grand View Research. (2020). Luxury Vinyl Tile (LVT) and SPC Flooring Market Size, Share & Trends Analysis Report. Retrieved from https://www.grandviewresearch.com/industry-analysis/luxury-vinyl-tile-lvt-flooring-market

- International Organization for Standardization (ISO). (Various). ISO 24346: Resilient floor coverings — Determination of thickness. Retrieved from https://www.iso.org

- European Committee for Standardization (CEN). (Various). EN 13501-1: Fire classification of construction products and building elements. Retrieved from https://www.cen.eu

- ASTM International. (Various). ASTM F1700: Standard Specification for Solid Vinyl Floor Tile. Retrieved from https://www.astm.org

- FloorScore. (2023). SCS Global Services: Indoor Air Quality Certification Program. Retrieved from https://www.scsglobalservices.com/certified-products/floorscore

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025