Premium VCT Flooring: Durable, Cost-Effective & Versatile

Understanding Vinyl Composition Tile (VCT) and its Evolution

Vinyl Composition Tile, commonly referred to as pisos vct, represents a foundational segment within resilient flooring solutions, valued for its durability, cost-effectiveness, and versatility. Originating from advanced polymer engineering, modern VCT flooring has evolved significantly, incorporating enhancements that address contemporary demands for performance, aesthetics, and sustainability in high-traffic commercial and industrial environments. This comprehensive guide delves into the intricate aspects of VCT, from its manufacturing to its diverse applications and technological advancements.

The industry continues to witness innovations, with leading manufacturers like Tarkett VCT, Mohawk VCT, and Johnsonite VCT pushing boundaries in material composition and surface treatments. Specialized offerings such as Enlio Johnsonite VCT and Enlio Tarkett VCT II exemplify the market's trajectory towards optimized wear resistance, simplified maintenance, and improved indoor air quality. These advancements are critical for facilities requiring robust, long-lasting flooring that can withstand rigorous operational demands while maintaining a professional appearance.

The Manufacturing Process of Advanced VCT Flooring

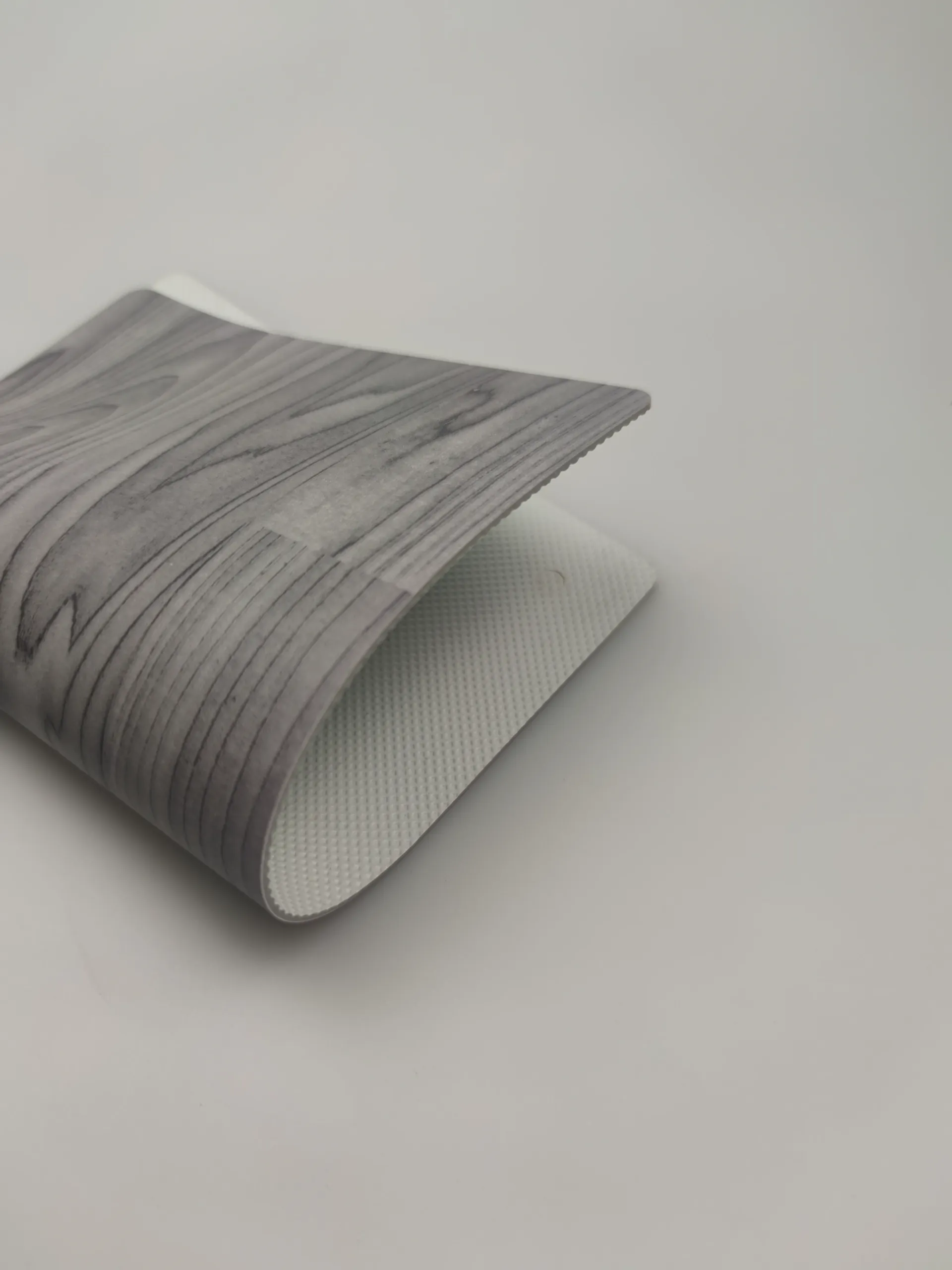

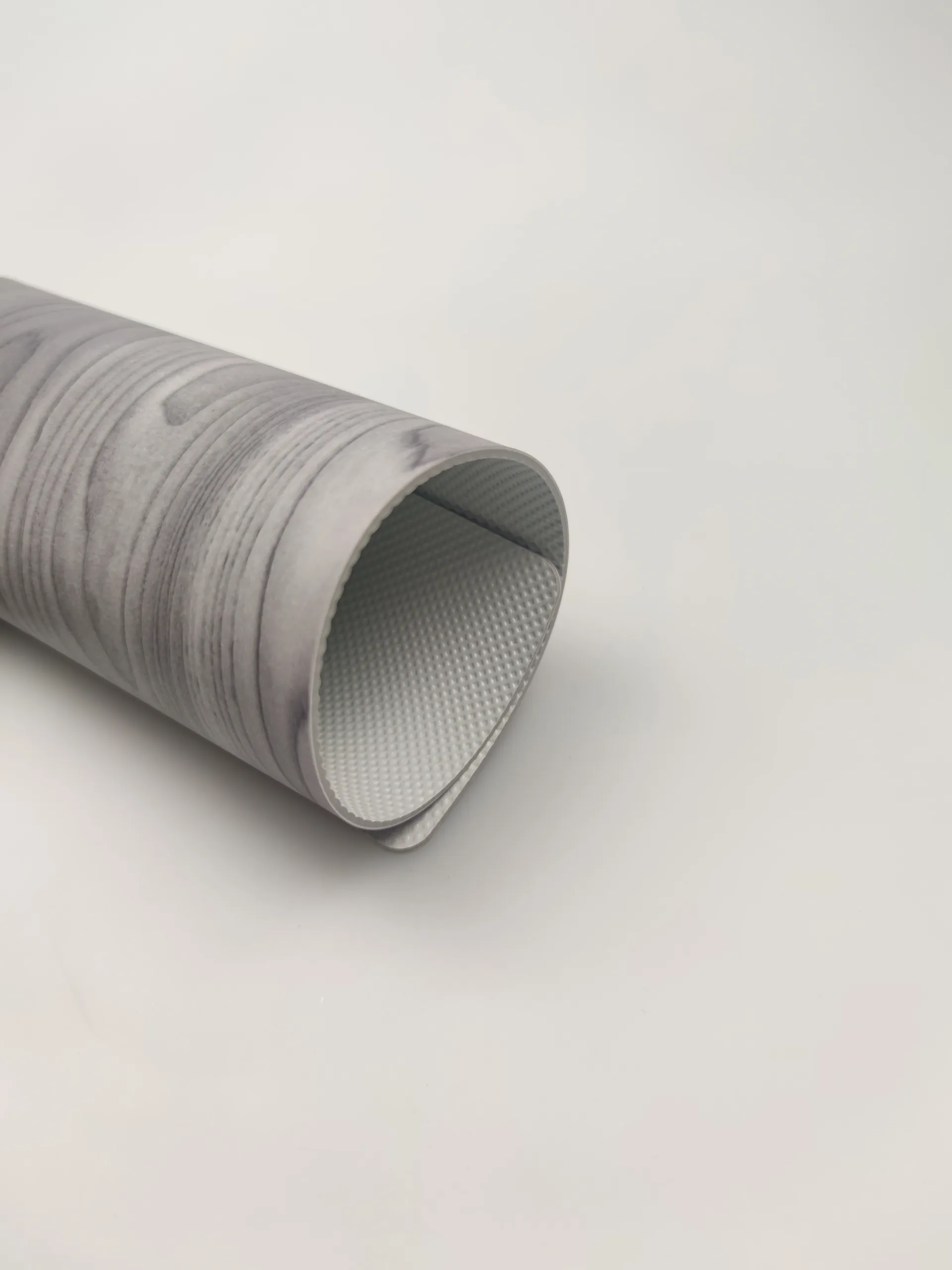

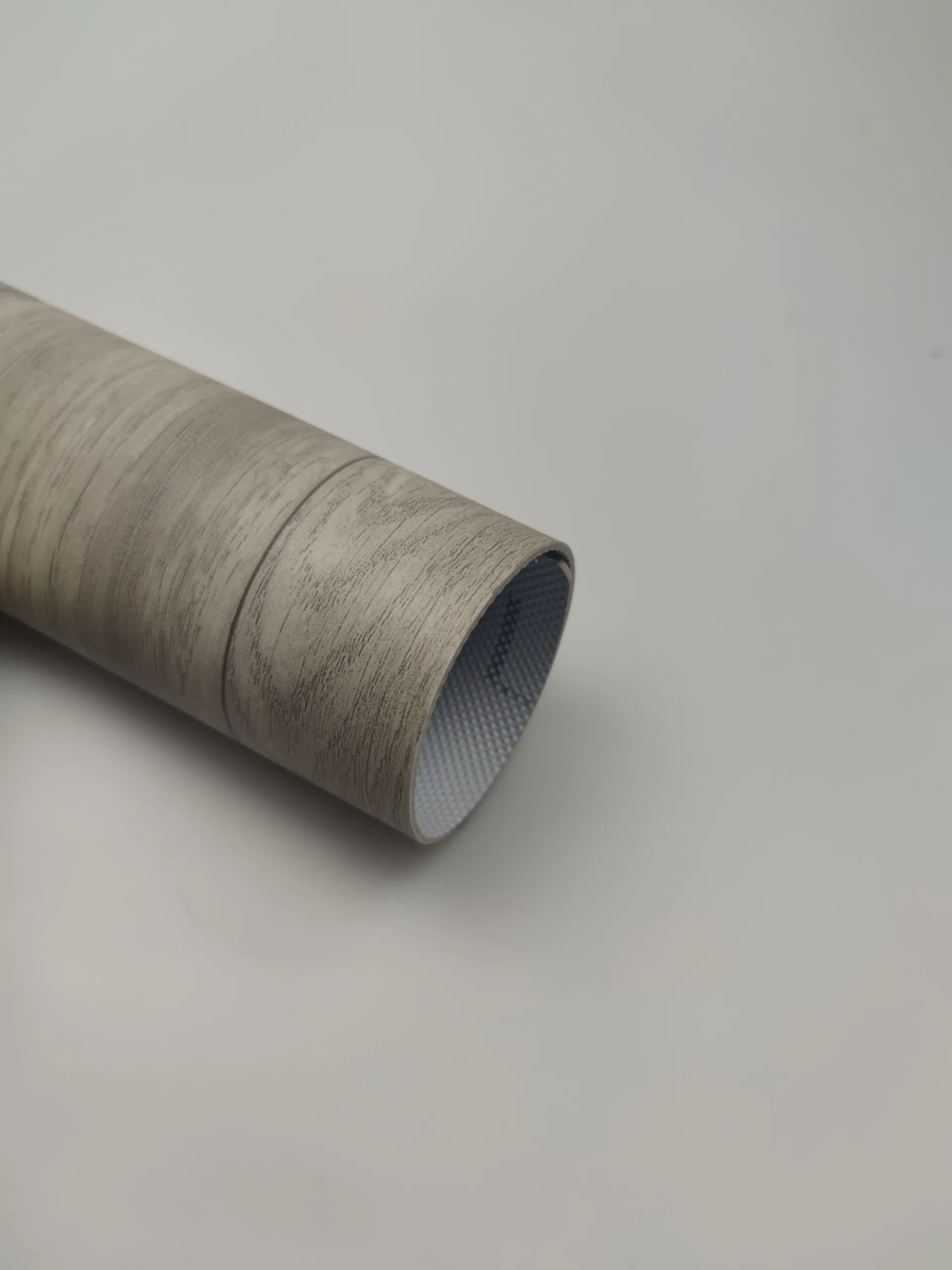

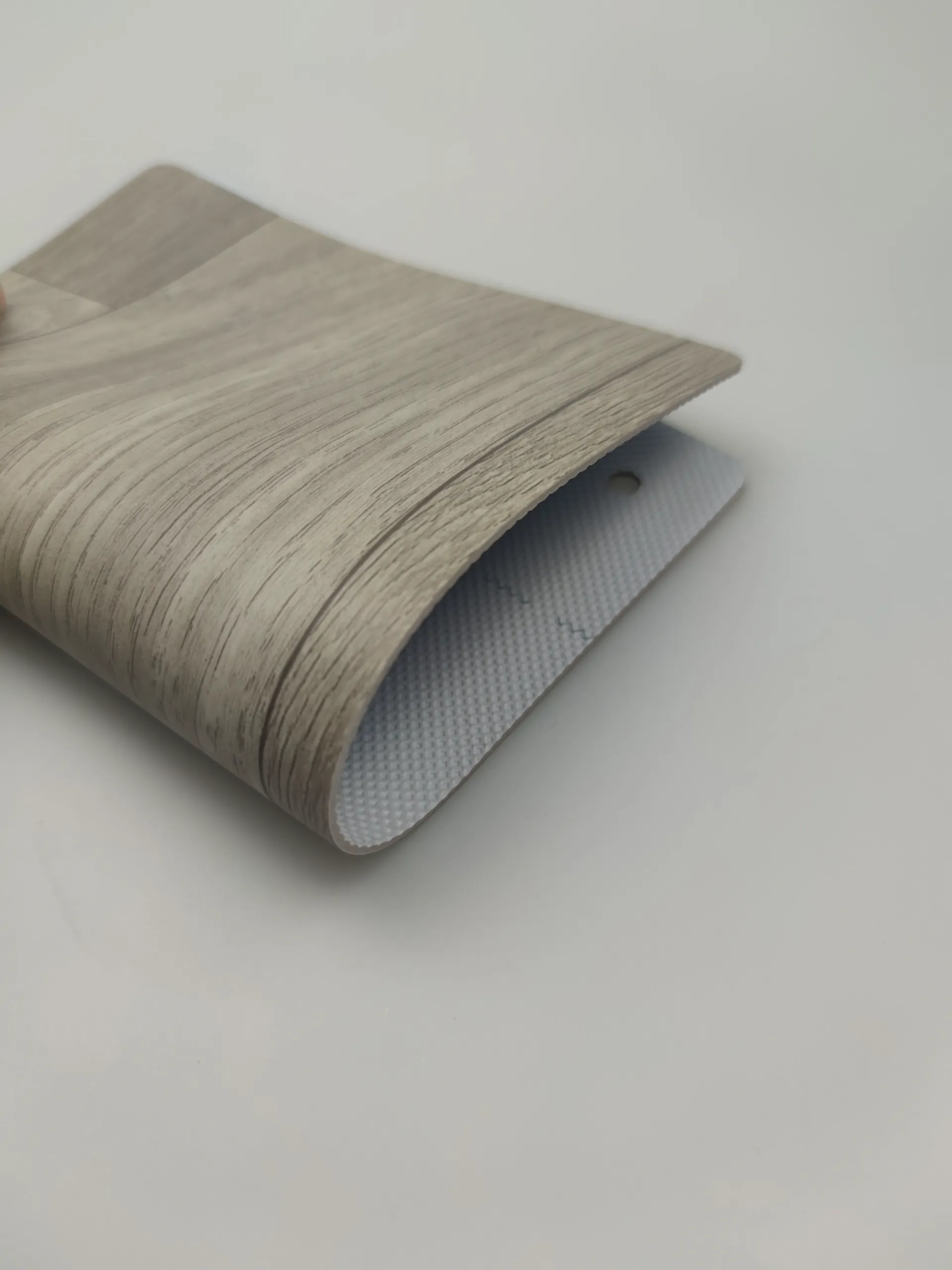

The production of high-performance pisos vct involves a meticulously controlled multi-stage process, ensuring the final product meets stringent industry standards for durability and consistency. Unlike traditional homogeneous VCT, the manufacturing of a product like 'heterogeneous floor with nora surface' integrates multiple distinct layers, each engineered for specific performance attributes.

Detailed Process Flow:

- Raw Material Preparation: This initial phase involves the precise weighing and blending of primary components. Key materials include polyvinyl chloride (PVC) resins, high-grade plasticizers to enhance flexibility, limestone (calcium carbonate) as a primary filler for dimensional stability and density, pigments for color, and various stabilizers and processing aids to ensure material integrity during manufacturing. The quality of these raw materials directly impacts the final product's performance.

- Compounding and Intensive Mixing: The pre-weighed raw materials are fed into high-intensity mixers. Through controlled heating and mechanical agitation, these components are thoroughly compounded to create a homogeneous, molten mass. This critical step ensures that all additives are evenly dispersed throughout the polymer matrix, preventing inconsistencies in the final tile. The result is a viscous compound ready for extrusion or calendering.

- Calendering and Layer Formation: The compounded material is then processed through a series of heated calendering rollers under precise pressure. For heterogeneous floors, this stage involves the controlled lamination of different layers. A base layer (often a dense vinyl composition) is formed, followed by the application of a design layer (featuring printed patterns) and then a robust transparent wear layer. In the case of a 'heterogeneous floor with nora surface', this could involve applying a specialized rubberized wear layer or a highly durable polyurethane (PUR) finish that mimics the performance characteristics of Nora rubber, directly onto a VCT-like base or a multi-layered vinyl structure. This precise layer consolidation ensures superior performance and aesthetic integrity.

- Cooling, Stabilization, and Curing: After calendering, the continuous sheet is gradually cooled through a series of temperature-controlled zones. This process is crucial for dimensional stability, preventing shrinkage or warping. For certain surface treatments, a curing phase may follow to enhance the wear layer's hardness and chemical resistance.

- Precision Cutting and Finishing: Once the material is fully stabilized, it proceeds to automated cutting stations where it is precisely cut into individual tiles of specified dimensions (e.g., 12"x12" or 24"x24"). Edge beveling or squaring may occur at this stage to ensure seamless installation.

- Quality Control and Testing: Throughout the process, rigorous quality control checks are performed. Finished tiles undergo extensive testing to verify compliance with international standards such as ISO 10581 (Homogeneous and heterogeneous poly(vinyl chloride) floor coverings), ASTM F1066 (Standard Specification for Vinyl Composition Floor Tile), and ASTM F1700 (Standard Specification for Solid Vinyl Tile), ensuring parameters like dimensional stability, indentation resistance, static load limit, color consistency, and chemical resistance are met. This includes testing for fire safety (e.g., ASTM E648 Critical Radiant Flux).

- Packaging: Approved tiles are packaged securely for distribution.

The service life of these engineered pisos vct solutions, especially those with advanced wear layers, typically exceeds 20 years under proper maintenance and usage conditions. Their robust construction and specialized surfaces offer significant advantages in terms of longevity and reduced total cost of ownership compared to lesser quality alternatives.

Technical Specifications and Performance Parameters

Modern pisos vct are engineered to meet demanding performance criteria, making them suitable for a wide range of commercial and light industrial applications. The 'heterogeneous floor with nora surface' exemplifies a product designed for superior technical performance, combining the benefits of VCT with advanced surface characteristics.

Typical Product Specifications (Example: Heterogeneous Floor with Nora Surface Characteristics):

| Parameter | Standard/Method | Typical Value | Benefit |

|---|---|---|---|

| Total Thickness | EN ISO 24346 | 2.0 - 3.0 mm | Enhanced underfoot comfort & durability. |

| Wear Layer Thickness | EN ISO 24346 | 0.5 - 0.8 mm | Superior resistance to abrasion and scuffs. |

| Residual Indentation | EN ISO 24343-1 | < 0.1 mm | Minimizes permanent marks from static loads. |

| Dimensional Stability | EN ISO 23999 | < 0.15 % | Prevents gapping and curling over time. |

| Chemical Resistance | EN ISO 26987 | Excellent (Class I/II) | Resists common chemicals, acids, and alkalis. |

| Slip Resistance (Dry) | EN 13893 (DS) / DIN 51130 (R-Value) | ≥ 0.30 (DS) / R9-R10 | Enhances safety in high-traffic areas. |

| Fire Reaction Classification | EN 13501-1 | Bfl-s1 | High fire safety performance, low smoke emission. |

These robust specifications highlight the technical superiority of advanced pisos vct solutions. The incorporation of a Nora-like surface, for instance, can significantly improve characteristics such as slip resistance, sound absorption, and ease of cleaning, making it highly desirable for environments where hygiene and safety are paramount.

Application Scenarios and Technical Advantages

The inherent properties of pisos vct make them exceptionally well-suited for a wide array of demanding commercial and industrial applications. Their technical advantages translate directly into operational benefits, impacting cost efficiency, safety, and long-term durability.

Target Industries:

- Healthcare Facilities: Hospitals, clinics, laboratories, and elderly care homes benefit from VCT's chemical resistance to disinfectants, ease of maintenance for infection control, and durability in high-traffic corridors. The specified 'heterogeneous floor with nora surface' offers enhanced underfoot comfort and acoustic properties critical for patient and staff well-being.

- Educational Institutions: Schools, universities, and daycare centers require flooring that can withstand constant foot traffic, resist stains, and is easy to clean. VCT provides an economical and robust solution for classrooms, hallways, and administrative offices.

- Retail and Commercial Spaces: Supermarkets, department stores, and corporate offices leverage VCT for its aesthetic versatility, design flexibility, and ability to endure heavy foot traffic without showing significant wear.

- Light Industrial and Manufacturing: In areas like cleanrooms, assembly lines, or control rooms within petrochemical, metallurgy, or water supply & drainage facilities, where heavy machinery is not directly on the floor but chemical spills or frequent cleaning are concerns, VCT offers excellent chemical resistance and easy decontamination. It serves as a resilient and reliable flooring for administrative and low-impact operational zones within these larger industrial complexes.

- Government and Public Buildings: Libraries, municipal offices, and transportation hubs rely on VCT for its longevity and low maintenance requirements, even under extreme public usage.

Demonstrated Technical Advantages:

- Exceptional Durability and Service Life: Engineered to withstand severe abrasion and heavy rolling loads, advanced pisos vct minimize the need for frequent replacement, offering a service life of 20+ years. This directly contributes to lower life-cycle costs for facilities managers.

- Superior Chemical Resistance: The robust wear layer provides resistance against a broad spectrum of chemicals, including acids, alkalis, solvents, and common cleaning agents. This attribute is paramount in environments prone to spills, ensuring the floor maintains its integrity and appearance without corrosion resistance in a chemical sense.

- Simplified Maintenance and Hygiene: Modern VCT surfaces are often factory-finished with enhanced polyurethane or similar coatings, reducing or eliminating the need for waxing and stripping. This streamlines maintenance protocols, lowers operational costs, and promotes a more hygienic environment, crucial for healthcare and food service settings.

- Cost-Effectiveness: While providing high performance, VCT remains an economically viable option compared to other resilient flooring types, offering a favorable balance of initial investment and long-term value.

- Enhanced Safety Features: Many VCT products, especially those with specialized surfaces like the 'nora surface', offer improved slip resistance (e.g., R9-R10 rating), significantly reducing the risk of falls in busy areas.

- Energy Saving Potential (Indirect): Lighter colored VCT options can increase ambient light reflectivity (LRV), reducing the reliance on artificial lighting during daylight hours. This subtle energy saving aspect contributes to lower utility bills and improved occupant comfort. Furthermore, the longevity reduces the energy footprint associated with manufacturing and installing replacement flooring.

Vendor Comparison and Customized Solutions

The market for pisos vct and similar resilient flooring is competitive, with several key players offering distinct product lines. Understanding these differences is crucial for selecting the optimal solution for specific project requirements.

Leading Manufacturers Comparison:

| Feature | Tarkett VCT / Enlio Tarkett VCT II | Mohawk VCT | Johnsonite VCT / Enlio Johnsonite VCT | Enlio Heterogeneous Floor with Nora Surface (Hypothetical VCT-Base) |

|---|---|---|---|---|

| Wear Layer Technology | IQ Smart, PUR-reinforced, enhanced durability. | Standard commercial grade, good scuff resistance. | Finishing options for varied gloss and maintenance. | Proprietary Nora-like surface for superior wear, slip, chemical resistance, and acoustics. |

| Maintenance Profile | Low-maintenance, no-wax options available. | Requires routine cleaning and periodic waxing. | Low to moderate maintenance depending on finish. | Ultra-low maintenance, no waxing, simple cleaning. |

| Sustainability Certifications | FloorScore, Phthalate-free, Cradle to Cradle. | FloorScore certified for IAQ. | FloorScore, sometimes with recycled content. | FloorScore, potentially LEED contributions, phthalate-free. |

| Acoustic Performance | Standard impact sound reduction. | Basic acoustic properties. | Improved acoustic options in certain lines. | Significantly enhanced sound absorption (e.g., 6-9 dB) due to surface and core. |

| Key Differentiator | Broad range of patterns, innovative surface treatments. | Economical for large-scale projects. | Integrated flooring systems including cove base. | Premium performance in hygiene, safety, and longevity, mimicking high-end rubber. |

Customized Solutions:

For specialized projects, manufacturers often provide customized pisos vct solutions. This can involve:

- Color and Pattern Matching: Bespoke colors and intricate patterns can be produced to align with specific brand guidelines or interior design schemes.

- Specialized Finishes: Custom wear layers can be formulated for enhanced chemical resistance, specific anti-static properties, or improved slip ratings required by niche industrial applications.

- Logo and Wayfinding Integration: Company logos, directional arrows, and safety markings can be seamlessly integrated into the flooring design, improving both aesthetics and functionality.

- Tile Dimensions: While standard sizes prevail, custom tile dimensions may be available for unique architectural requirements.

Real-World Application Case Studies and Client Feedback

The efficacy of advanced pisos vct and heterogeneous flooring solutions is best demonstrated through real-world applications and direct client testimonials. These case studies highlight the practical benefits and return on investment for businesses across various sectors.

Case Study 1: Major Regional Hospital Network

Challenge: A large hospital network faced issues with existing flooring in high-traffic corridors and patient rooms. The previous material showed premature wear, was difficult to sanitize effectively, and contributed to significant noise, impacting patient recovery and staff productivity. The hospital sought a durable, hygienic, and acoustically performing solution.

Solution: The network opted for a 'heterogeneous floor with nora surface' across 150,000 sq ft. This advanced pisos vct variant was selected for its exceptional chemical resistance to hospital-grade disinfectants, its factory-applied surface treatment for easy, no-wax maintenance, and its superior sound absorption properties (reduction of 8 dB). Its R10 slip resistance rating also enhanced patient and staff safety.

Outcome: After three years, the flooring shows minimal wear, even in areas with continuous wheeled traffic. Cleaning protocols were streamlined, reducing labor costs by an estimated 20%. Patient satisfaction scores improved, partly attributed to reduced noise levels. The facility's ISO 13485 (Medical Devices Quality Management) compliance benefited from the consistent, easy-to-clean surfaces.

"The new flooring has been a game-changer for our hospital. It’s not just durable; it's made a tangible difference in our infection control efforts and the overall healing environment. The reduced noise is particularly noticeable." - Facilities Director, Regional Health System.

Case Study 2: University Science Laboratories

Challenge: The chemistry and biology labs at a prominent university required flooring that could withstand accidental chemical spills, provide excellent slip resistance, and handle heavy foot traffic from students and faculty. Traditional VCT proved insufficient against certain reagents.

Solution: Enlio Johnsonite VCT with an enhanced chemical-resistant wear layer was installed in over 50 laboratory spaces. This specific product was chosen for its proven resistance to a list of common laboratory acids, bases, and solvents, as verified by ASTM F925 (Resistance to Chemicals) testing. Its ease of repair for localized damage was also a key factor.

Outcome: The flooring has performed exceptionally for five years, showing no degradation from spills. Minor damage from dropped equipment was easily repaired by replacing individual tiles, minimizing downtime. The university reported higher compliance with safety standards due to the reliable performance of the pisos vct.

"For our labs, chemical resistance is non-negotiable. The Enlio Johnsonite VCT has stood up to everything, protecting our subfloors and maintaining a safe learning environment." - Head of Facilities, University Science Department.

Ensuring Trustworthiness: FAQ, Logistics, and Support

Frequently Asked Questions (FAQ) about Pisos VCT:

- Q: How does the 'heterogeneous floor with nora surface' differ from standard VCT?

A: While standard pisos vct has a homogeneous composition throughout its wear layer, our heterogeneous product features distinct layers (backing, design, wear layer). The 'Nora surface' refers to a high-performance, often rubber-infused or specialized PUR wear layer that provides superior slip resistance, sound absorption, and chemical resistance, mimicking the advanced properties of nora rubber flooring while retaining the installation benefits of tile. - Q: Is VCT suitable for heavy industrial use?

A: While VCT is incredibly durable for commercial high-traffic areas, it's generally not recommended for heavy industrial environments involving extreme point loads, direct impact from heavy machinery, or harsh chemical immersion. It is ideal for administrative offices, control rooms, laboratories, and light manufacturing areas within industrial complexes. - Q: What are the primary maintenance requirements for advanced VCT?

A: Most advanced pisos vct and heterogeneous vinyl floors, particularly those with a factory-applied PUR or ceramic bead wear layer, require only routine cleaning with a neutral cleaner. Unlike traditional VCT, waxing and stripping are often unnecessary, significantly reducing maintenance costs and time. - Q: What certifications should I look for?

A: Key certifications include FloorScore for indoor air quality, ISO 9001 for quality management, ISO 14001 for environmental management, and compliance with ASTM F1066 (for VCT), ASTM F1700 (for solid vinyl tile), and EN standards for specific performance criteria (e.g., EN 13501-1 for fire reaction, EN ISO 23999 for dimensional stability).

Lead Time and Fulfillment:

Standard pisos vct products are typically held in inventory for immediate dispatch. Lead times for large orders or customized solutions vary based on volume, specific color/pattern requirements, and current production schedules. Generally, lead times range from 2-4 weeks for standard products and 6-10 weeks for bespoke orders. Our logistics network ensures efficient and reliable delivery to project sites globally, adhering to agreed-upon schedules.

Warranty Commitments:

Our pisos vct and heterogeneous flooring solutions come with comprehensive commercial warranties, typically ranging from 10 to 20 years, covering manufacturing defects, wear resistance (for the wear layer), and dimensional stability under normal use and maintenance. Specific warranty terms and conditions are provided with each product quotation and are designed to offer peace of mind and protect your investment.

Customer Support and After-Sales Service:

We are committed to providing unparalleled customer support from initial consultation to post-installation. Our dedicated technical support team offers assistance with product selection, specification, installation guidance, and troubleshooting. After-sales service includes comprehensive maintenance guidelines, recommendations for cleaning products, and support for warranty claims. Our goal is to ensure the long-term satisfaction and optimal performance of your pisos vct flooring.

Authoritative References

- ASTM International. (2022). ASTM F1066/F1066M-20, Standard Specification for Vinyl Composition Floor Tile. West Conshohocken, PA: ASTM International.

- International Organization for Standardization. (2020). ISO 10581:2020, Resilient floor coverings — Homogeneous and heterogeneous poly(vinyl chloride) floor coverings — Specification. Geneva, Switzerland: ISO.

- The Resilient Floor Covering Institute (RFCI). (2023). Recommended Work Practices for the Removal of Resilient Floor Coverings. LaGrange, GA: RFCI.

- European Committee for Standardization. (2021). EN 13501-1:2021, Fire classification of construction products and building elements - Part 1: Classification using data from reaction to fire tests. Brussels, Belgium: CEN.

- FloorScore. (2023). SCS Global Services. Indoor Air Quality Certification Program for Hard Surface Flooring. Emeryville, CA: SCS Global Services.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025