Durable Heterogeneous Vinyl Sheet Flooring Deals

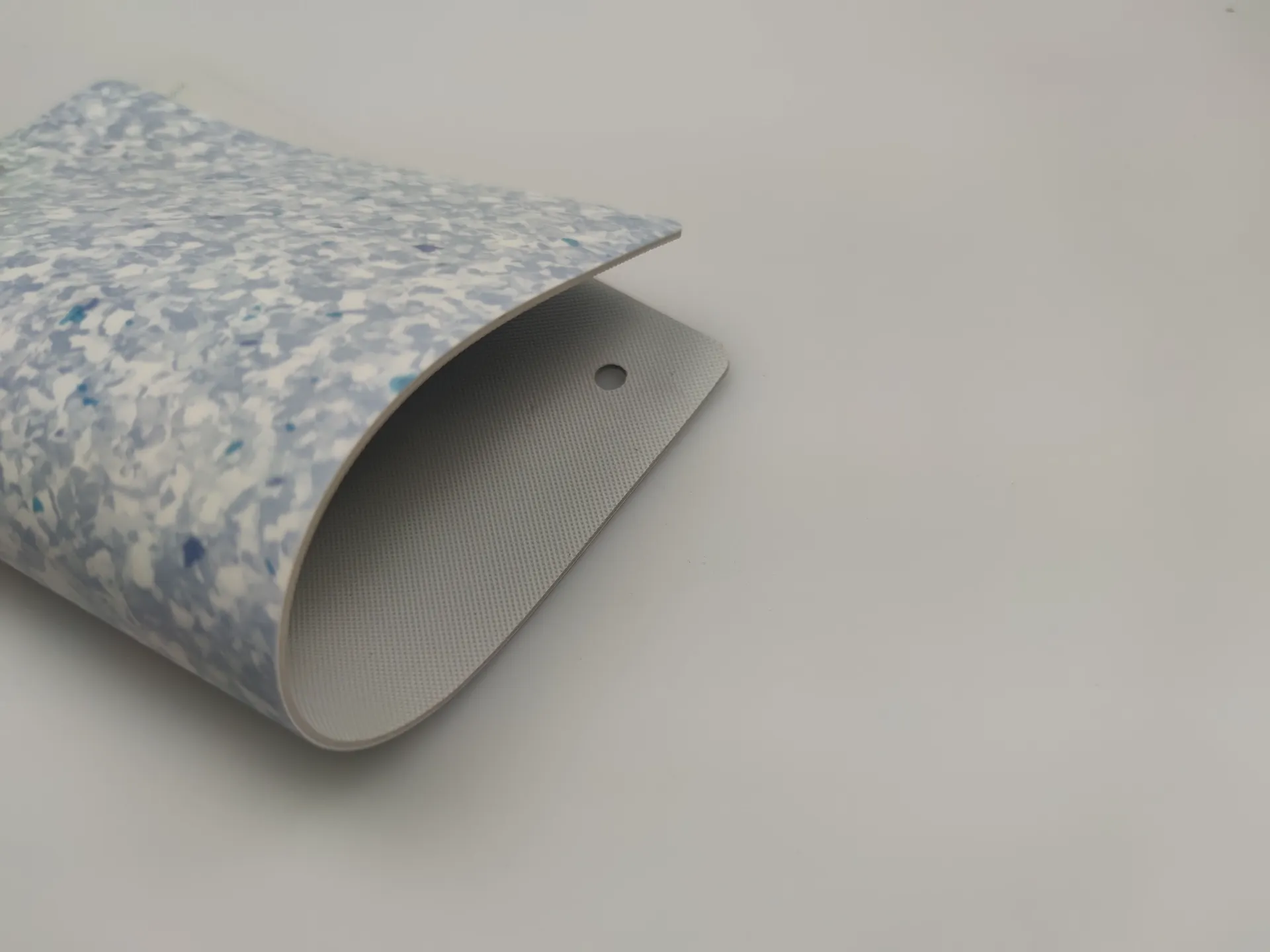

In the dynamic world of interior design and construction, flooring choices play a pivotal role in defining aesthetics, ensuring functionality, and contributing to the overall longevity of a space. Among the myriad options available, heterogeneous vinyl flooring has emerged as a frontrunner, offering an unparalleled blend of versatility, durability, and design freedom. This in-depth guide delves into the intricate world of heterogeneous vinyl, exploring its technological prowess, diverse applications, and the exceptional value it brings to both commercial and residential projects. We will specifically highlight Enliofloor's innovative product: heterogeneous floor with Nebula surface, a testament to cutting-edge flooring solutions.

Industry Trends and the Rise of Resilient Flooring

The global flooring market is experiencing significant growth, driven by increasing urbanization, renovation projects, and a heightened demand for high-performance, sustainable, and aesthetically pleasing materials. Within this landscape, resilient flooring, particularly vinyl, commands a substantial share. According to a report by Grand View Research, the global vinyl flooring market size was valued at USD 33.6 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030. This growth is largely fueled by the material's cost-effectiveness, ease of maintenance, and superior performance characteristics compared to traditional options.

The trend is clear: architects, designers, and property owners are increasingly seeking solutions that not only look good but also withstand heavy traffic, offer hygienic surfaces, and contribute to healthier indoor environments. Heterogeneous vinyl sheet flooring fits this bill perfectly, offering multi-layered construction that delivers enhanced performance in key areas such as sound absorption, impact resistance, and slip safety. The continuous innovation in print technology and surface treatments further expands its design possibilities, making it a preferred choice for a broad spectrum of sectors.

Understanding Heterogeneous Vinyl: Technical Parameters and Structure

Heterogeneous vinyl is a multi-layered flooring product, distinct from homogeneous vinyl which consists of a single layer. Its layered construction is precisely engineered to optimize different performance attributes, making it exceptionally robust and versatile. Each layer serves a specific purpose, contributing to the overall strength, appearance, and longevity of the flooring.

- Wear Layer: This is the uppermost transparent layer, often made from highly durable PVC or polyurethane (PU) reinforced with ceramic beads or other protective coatings. Its thickness (typically ranging from 0.3mm to 1.0mm) is crucial for determining the floor's resistance to scratches, scuffs, and abrasions, making it suitable for varying traffic levels.

- Print Layer (Design Layer): Beneath the wear layer lies the high-definition print layer, which gives the heterogeneous vinyl its aesthetic appeal. Advanced rotogravure printing technology allows for incredibly realistic reproductions of wood, stone, abstract patterns, and bespoke designs, offering limitless creative possibilities for your flooring needs.

- Fiberglass Stabilizing Layer: A fiberglass mesh is often incorporated into the core structure. This critical layer provides dimensional stability, preventing the flooring from expanding or contracting significantly with temperature changes and ensuring it lays flat without curling or gapping.

- Foam Backing Layer (or Compact Backing): This layer, typically made of high-density PVC foam, contributes to comfort underfoot, sound absorption, and thermal insulation. For areas requiring extreme durability and minimal indentation, a compact, non-foamed backing layer may be used.

- Base Layer (Balancing Layer): The bottom-most layer provides additional structural integrity and balance, ensuring the entire sheet remains stable and uniform.

Key Performance Parameters of Heterogeneous Vinyl

When selecting heterogeneous vinyl sheet, several technical specifications are critical to ensure the product meets the demands of its intended application:

| Parameter | Description | Typical Range / Standard | Enliofloor's `heterogeneous floor with Nebula surface` |

|---|---|---|---|

| Total Thickness | Overall thickness of the multi-layered product. | 2.0mm - 4.0mm+ | 2.0mm - 3.0mm (Customizable) |

| Wear Layer Thickness | Thickness of the transparent protective top layer. | 0.3mm - 1.0mm | 0.5mm - 0.7mm (High Durability) |

| Roll Width | Standard width of the vinyl sheet rolls. | 1.5m - 2.0m | 1.83m (72 inches) |

| Roll Length | Standard length of the vinyl sheet rolls. | 15m - 25m | 20m (65.6 ft) |

| Abrasion Resistance | Ability to withstand wear from foot traffic (Group T, P, M, F). | EN 660-2 (T is best) | Group T (Superior) |

| Slip Resistance | Coefficient of Friction (CoF) in wet/dry conditions. | EN 13893 (DS > 0.30), R9-R11 | R10, DS (>0.30) - Excellent |

| Fire Rating | Flammability performance. | EN 13501-1 (Bfl-s1 or Cfl-s1) | Bfl-s1 (Low smoke emission) |

| Residual Indentation | Permanent indentation after load removal. | EN 433 ( | |

| Sound Absorption | Reduction of impact sound transmission. | ISO 717-2 (5dB - 20dB) | 18 dB (Significant) |

| Chemical Resistance | Resistance to common chemicals and stains. | EN 423 (Excellent) | Excellent resistance to acids, alkalis, oils |

| VOC Emissions | Volatile Organic Compounds emitted. | FloorScore, AgBB, A+ | FloorScore Certified (Low VOC) |

| Dimensional Stability | Change in size under temperature variation. | EN 434 ( |

The Manufacturing Marvel: Process Flow of Heterogeneous Vinyl

The production of heterogeneous vinyl is a sophisticated industrial process that combines precision engineering with advanced material science. Unlike simple casting or forging processes used for metals, vinyl flooring relies on a series of controlled calendering, printing, and lamination stages.

Detailed Manufacturing Process for heterogeneous vinyl

- Raw Material Preparation:

This initial stage involves selecting and preparing the core components: high-grade PVC resin (polyvinyl chloride), plasticizers (to provide flexibility), stabilizers (to prevent degradation from heat/light), fillers (like calcium carbonate for density and cost-effectiveness), and pigments (for color). These raw materials are carefully measured and mixed in large industrial blenders to create a homogenous compound.

- Calendering and Base Layer Formation:

The mixed PVC compound is then fed into a series of heated rollers called calenders. Through precise temperature and pressure control, the material is flattened and pressed into thin, continuous sheets, forming the compact or foam backing layers. This process ensures uniform thickness and density across the entire width of the sheet.

- Fiberglass Mesh Insertion:

For enhanced dimensional stability, a fiberglass mesh layer is often integrated into the core structure. This mesh is precisely aligned and embedded between the PVC layers during the calendering process, acting as a skeletal reinforcement that prevents expansion, contraction, and curling.

- Print Layer Application:

Once the base layers are formed and stabilized, they move to the printing station. Here, advanced rotogravure printing machines apply high-definition designs onto the surface. Rotogravure printing uses engraved cylinders to transfer intricate patterns and realistic textures (e.g., wood grains, stone effects) with incredible precision and color depth, ensuring the visual appeal of heterogeneous sheet vinyl.

- Wear Layer Lamination:

Following the printing process, a transparent wear layer is applied and laminated over the design layer. This is typically done through a heat and pressure process, fusing the protective layer securely to the printed surface. For products like `heterogeneous floor with Nebula surface`, specialized UV-cured polyurethane (PU) coatings might be applied, often enhanced with ceramic beads or other nano-particles to boost scratch and stain resistance.

- Embossing and Surface Treatment:

To further enhance realism and tactile appeal, some heterogeneous vinyl products undergo an embossing process. This involves using textured rollers to create a relief pattern that matches the printed design, such as an authentic wood grain or stone texture. Additional surface treatments, like anti-slip coatings or antimicrobial agents, may also be applied at this stage to meet specific performance requirements.

- Curing, Cooling, and Quality Control:

The multi-layered sheet is then passed through curing ovens to fully set the materials and coatings, followed by a cooling section. Throughout the entire process, continuous online inspection systems monitor critical parameters like thickness, width, color consistency, and surface defects. Rolls are constantly checked against stringent quality standards.

- Trimming, Cutting, and Packaging:

Finally, the large rolls of heterogeneous vinyl are precisely trimmed to standard widths and then cut into specified lengths (e.g., 20m or 25m rolls). Each roll is carefully inspected, labeled, and packaged for shipment, ready for your next flooring deal.

This intricate manufacturing process highlights the technical expertise required to produce high-quality heterogeneous vinyl, ensuring its long lifespan and superior performance. Typical use life for commercial applications often exceeds 10-15 years, while residential use can extend beyond 25 years, depending on the wear layer thickness and maintenance.

Enliofloor's `heterogeneous floor with Nebula surface` exemplifies this advanced manufacturing. Its unique Nebula surface is not just a design; it's a proprietary coating enhancing scratch resistance and ease of cleaning, directly benefiting from state-of-the-art lamination and surface treatment technologies. Our commitment to quality is underpinned by adherence to international standards such as ISO 9001 (Quality Management) and ISO 14001 (Environmental Management), as well as compliance with European (EN) and American (ASTM) norms for resilient floor coverings.

Application Scenarios and Strategic Advantages

The versatility of heterogeneous vinyl makes it an ideal solution for a vast array of application scenarios, each benefiting from its specific strengths. From high-traffic commercial spaces to comfortable residential settings, this flooring offers tailored advantages.

Healthcare Facilities (Hospitals, Clinics, Senior Care):

Heterogeneous vinyl is a top choice due to its exceptional hygiene properties. Its seamless installation (when properly welded) and non-porous surface prevent the growth of bacteria and fungi, making cleaning and disinfection effortless – a critical advantage in environments where infection control is paramount. The resilient backing also provides acoustic benefits, reducing noise from foot traffic and equipment, creating a quieter, more healing environment. Furthermore, its comfort underfoot reduces fatigue for staff who spend long hours on their feet, and its slip resistance enhances patient safety.

"In healthcare, every material choice impacts patient well-being and operational efficiency. Heterogeneous vinyl delivers on both, providing a safe, hygienic, and comfortable surface that can withstand the rigorous demands of clinical environments while offering beautiful, calming aesthetics."

Educational Institutions (Schools, Universities, Dorms):

Durability is key in educational settings, where hallways and classrooms experience constant foot traffic, spills, and impact. Heterogeneous vinyl sheet stands up to this challenge with its robust wear layer and indentation resistance. Its ease of cleaning handles daily messes, and its diverse design options allow for vibrant, engaging learning spaces or professional, academic environments. The sound absorption properties also contribute to better acoustics, reducing noise distractions in classrooms.

Retail Stores & Commercial Spaces:

For retail environments, appearance and performance go hand-in-hand. Heterogeneous vinyl offers endless design possibilities to create captivating brand experiences, from luxurious stone looks to modern abstract patterns. Its ability to withstand high foot traffic, resist scuffs from shopping carts, and maintain its aesthetic appeal over years makes it an excellent long-term investment. Moreover, its slip resistance is crucial for customer safety, while the ease of maintenance ensures stores can quickly recover from spills and keep their appearance pristine.

Corporate Offices & Hospitality:

In offices, hotels, and restaurants, comfort, aesthetics, and acoustics are paramount. Heterogeneous vinyl provides a comfortable underfoot experience for employees and guests, and its sound-absorbing qualities contribute to a quieter, more productive workspace or a serene hospitality environment. The vast array of designs, including realistic wood and stone textures, allows for sophisticated and welcoming interiors that stand the test of time and traffic. Its chemical resistance is also beneficial against spills in hospitality settings.

Residential Homes:

Beyond commercial applications, heterogeneous vinyl is increasingly popular in residential settings. Homeowners appreciate its water resistance, making it ideal for kitchens, bathrooms, and basements. It's also incredibly pet-friendly, resistant to scratches and easy to clean from accidents. The design flexibility means homeowners can achieve the look of hardwood or tile without the high cost, maintenance, or susceptibility to moisture damage, making it a smart flooring deal for any household.

Technical Advantages of `heterogeneous floor with Nebula surface`

Enliofloor’s heterogeneous floor with Nebula surface elevates the inherent benefits of heterogeneous vinyl to a new standard. The "Nebula surface" refers to a specialized, high-performance wear layer and surface treatment that provides enhanced durability and aesthetic properties.

- Superior Wear Resistance: The advanced Nebula surface coating, often a highly cross-linked polyurethane (PU) layer, significantly boosts resistance to scratches, scuffs, and abrasions, ensuring the floor retains its pristine appearance even in high-traffic areas. This directly translates to an extended product lifespan and lower replacement costs over time.

- Exceptional Stain and Chemical Resistance: The non-porous and densely coated Nebula surface repels spills, making it highly resistant to staining from common substances like coffee, wine, and chemicals. This makes cleaning effortless and ensures the floor remains hygienic and visually appealing, reducing the need for harsh cleaning agents.

- Enhanced Acoustic Performance: Designed with a specific backing structure, our heterogeneous floor with Nebula surface significantly reduces impact sound transmission (up to 18 dB), contributing to quieter indoor environments crucial for healthcare, education, and corporate spaces.

- Outstanding Dimensional Stability: Thanks to a high-quality fiberglass reinforcement, the `heterogeneous floor with Nebula surface` exhibits superior dimensional stability (

- Low Maintenance & Cost-Effectiveness: The smooth, robust surface requires minimal maintenance – typically just sweeping and damp mopping. This reduces ongoing cleaning costs and the need for specialized treatments, making it an incredibly cost-effective long-term flooring deal.

- Hygienic and Safe: With low VOC emissions (FloorScore certified) and often integrated antimicrobial properties, the `heterogeneous floor with Nebula surface` supports healthier indoor air quality and inhibits the growth of bacteria, crucial for sensitive environments. Its excellent slip resistance (R10) also contributes to enhanced safety.

Manufacturer Comparison and Industry Authority: Choosing Enliofloor

In a competitive market, selecting the right manufacturer for your flooring needs is paramount. A reputable manufacturer stands out not just by product quality but also by its commitment to innovation, customer service, and adherence to global standards. Enliofloor, with over two decades of experience in the sports and commercial flooring industry, exemplifies these qualities.

What Sets Leading Manufacturers Apart?

- Research & Development (R&D): Continuous investment in R&D leads to innovative products like the `heterogeneous floor with Nebula surface`, offering enhanced performance and unique aesthetics.

- Quality Control & Certifications: Adherence to rigorous quality management systems (e.g., ISO 9001) and product-specific certifications (e.g., FloorScore for indoor air quality, CE for European conformity, EN/ASTM standards for performance) ensures consistent, high-quality output.

- Global Presence & Service Network: A manufacturer with a strong global footprint can offer reliable delivery, localized support, and a deeper understanding of diverse market needs.

- Sustainability Initiatives: Commitment to environmental responsibility, including eco-friendly manufacturing processes, recyclable materials, and low VOC emissions, is increasingly important.

- Customer Support & Warranty: Comprehensive pre-sales consultation, technical support, and robust warranty programs build long-term customer trust.

Enliofloor vs. Generic Heterogeneous Vinyl Offerings

| Feature | Generic Heterogeneous Vinyl | Enliofloor's `heterogeneous floor with Nebula surface` |

|---|---|---|

| Wear Layer | Standard PU/PVC wear layer (0.3-0.5mm) | Advanced Nebula PU wear layer (0.5-0.7mm) with enhanced scratch resistance |

| Surface Finish | Basic matte or semi-gloss finish | Unique "Nebula" texture, matte finish, often with ceramic bead reinforcement for extra durability |

| Dimensional Stability | Typically good (EN 434 | Superior (EN 434 |

| Sound Absorption | Moderate (5-10 dB) | Excellent (up to 18 dB) due to optimized backing structure |

| Hygiene & VOCs | Varies, may meet basic standards | FloorScore Certified, often with integrated antimicrobial agents, supports LEED contributions |

| Design Realism | Good print quality | High-definition rotogravure printing for exceptional realism and vibrant colors |

| Lifespan (Commercial) | 10-15 years | 15-20+ years, depending on specific wear layer and traffic. |

| Warranty & Support | Standard manufacturer warranty | Comprehensive warranty backed by 20+ years of industry experience, dedicated customer support |

Enliofloor’s long-standing reputation as a trusted manufacturer in the resilient flooring sector is built on consistent delivery of high-quality products and excellent service. Our partnerships with major sports organizations and large-scale commercial projects worldwide serve as a testament to our product reliability and industry authority. When you choose Enliofloor, you're not just getting a product; you're getting a complete, reliable flooring deal solution backed by expertise.

Custom Solutions: Tailoring `Your Flooring` Vision

Understanding that every project has unique requirements, Enliofloor offers extensive customization options for heterogeneous vinyl flooring. This flexibility ensures that clients can achieve their precise design and performance goals, making heterogeneous floor with Nebula surface a truly adaptable choice for your flooring vision.

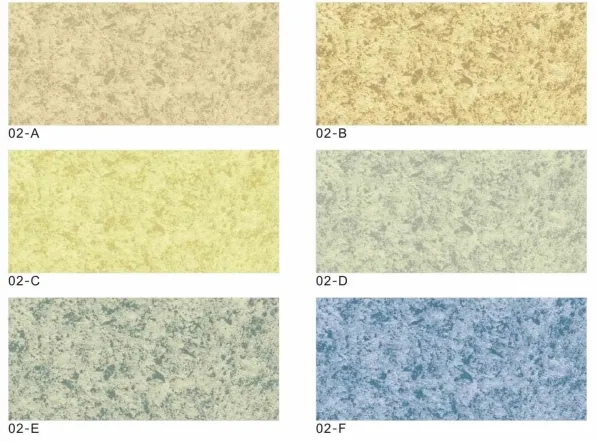

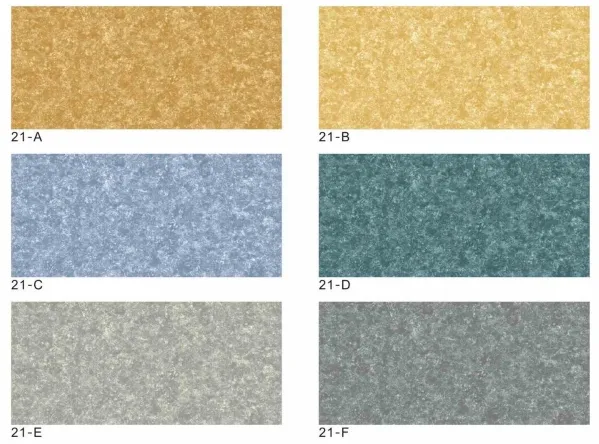

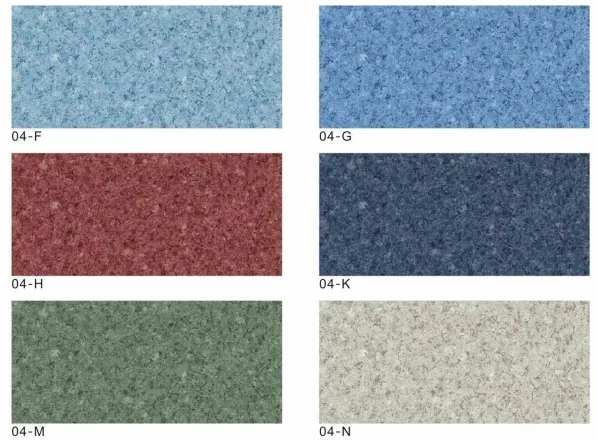

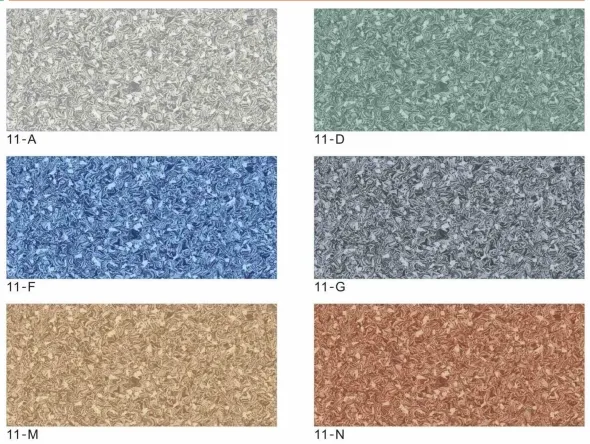

- Design & Color Customization: Beyond our extensive standard range, we can collaborate with designers and architects to create bespoke patterns, custom color palettes, and even incorporate branding elements or intricate logos directly into the print layer.

- Wear Layer Tailoring: Depending on the expected traffic and use, we can advise on and provide different wear layer thicknesses (e.g., 0.5mm for medium commercial, 0.7mm for heavy commercial) to optimize durability and cost-effectiveness.

- Performance Enhancements: For specific needs, additional treatments can be integrated, such as enhanced slip-resistant surfaces for wet areas, specialized antimicrobial treatments for healthcare, or extra acoustic backing for noise reduction.

- Project Consultation & Support: Our team of flooring experts provides comprehensive consultation from initial concept to installation, offering technical advice, detailed specifications, and material samples to ensure the chosen solution perfectly matches project demands. This holistic approach ensures you get the best flooring deal for your specific needs.

Application Cases and Success Stories

The practical application of `heterogeneous floor with Nebula surface` across diverse sectors demonstrates its real-world performance and the trust placed in Enliofloor's products.

Case Study 1: Major Urban Hospital Renovation

Challenge: An aging hospital required a flooring solution that was highly hygienic, easy to maintain, quiet for patient comfort, and durable enough for constant traffic of beds, equipment, and personnel. Traditional flooring materials were failing to meet these stringent requirements.

Solution: Enliofloor's heterogeneous floor with Nebula surface (0.7mm wear layer, 3.0mm total thickness) was selected. Its seamless installation with heat welding created an impervious surface, preventing bacterial growth. The advanced PU wear layer made daily cleaning simple, resisting stains from medical solutions. The inherent sound absorption (18dB) significantly reduced ambient noise, contributing to a calmer recovery environment.

"The new heterogeneous vinyl flooring from Enliofloor has transformed our hospital. It's incredibly easy to clean, dramatically quieter, and looks fantastic. Our staff reports less fatigue, and patient feedback on the overall environment has been overwhelmingly positive. This was truly the ideal flooring deal." - Hospital Administrator

Case Study 2: National Chain Retail Store Rollout

Challenge: A fast-growing retail chain needed a consistent, visually appealing, and highly durable flooring solution for over 50 new store openings across the country. The flooring had to withstand heavy foot traffic, shopping cart abrasions, and frequent cleaning, while reflecting the brand's modern aesthetic.

Solution: The chain opted for a custom design of Enliofloor's heterogeneous floor with Nebula surface, featuring a unique abstract pattern that complemented their brand colors. The 0.7mm wear layer ensured longevity against continuous customer flow and display movement. The easy-to-clean Nebula surface minimized maintenance time, allowing store staff to focus on customer service. The consistent quality and ease of installation facilitated rapid deployment across all new locations.

Case Study 3: University Sports Hall Upgrade

Challenge: The university sought to replace an old, worn-out gym floor that lacked proper shock absorption and sound dampening. The new flooring needed to support multi-sport activities, offer excellent grip, and withstand impact from sports equipment, all while being easy to maintain.

Solution: While specialized sports flooring is usually specified, for auxiliary areas or specific gym sections not requiring professional sports ratings, heterogeneous vinyl can be a suitable option. For this project, a thicker variant of heterogeneous vinyl sheet with enhanced cushioning properties and a high slip-resistance rating (R10) was installed. Its robust wear layer withstood constant athletic activity and equipment drops. The integrated sound absorption helped reduce echo, creating a more comfortable environment for athletes and spectators alike. The bold, customized colors also enhanced the visual appeal of the facility.

Ensuring Trust: Guarantees and Support

At Enliofloor, we understand that trust is built on transparency, reliability, and unwavering support. Our commitment to your satisfaction extends far beyond the point of sale, ensuring that your flooring investment is secure and well-supported.

Frequently Asked Questions (FAQ) about Heterogeneous Vinyl

Quality Assurance & Warranty Commitment

Enliofloor stands behind the quality of its products with comprehensive warranties. Our `heterogeneous floor with Nebula surface` comes with a robust commercial warranty of 10-15 years, depending on the specific wear layer chosen, and a residential warranty often exceeding 20 years. This warranty covers manufacturing defects and performance issues under normal use and proper maintenance. Our products undergo rigorous testing to comply with international standards such as ISO 9001, ISO 14001, EN 14041, ASTM F1700, and FloorScore certification, ensuring you receive a product of consistent excellence.

Dedicated Customer Support

Our commitment to your project doesn't end with delivery. Enliofloor offers dedicated pre-sales consultation, technical support, and after-sales service. Our team is available to assist with product selection, installation guidance, and any queries that may arise, ensuring a smooth and successful experience with your flooring choice.

Conclusion: The Future is Laid with Heterogeneous Vinyl

As the demands on modern interiors continue to evolve, the need for flooring solutions that offer exceptional performance, aesthetic versatility, and long-term value becomes paramount. Heterogeneous vinyl flooring, with its sophisticated multi-layered construction and advanced surface treatments, stands out as a superior choice for a myriad of applications.

Enliofloor’s heterogeneous floor with Nebula surface embodies the pinnacle of this technology, offering unmatched durability, hygiene, acoustic comfort, and design flexibility. From the stringent requirements of healthcare to the high traffic of retail, and the aesthetic demands of corporate and residential spaces, it provides a cost-effective, sustainable, and high-performance flooring deal solution.

By understanding its intricate manufacturing process, recognizing its technical parameters, and appreciating its proven advantages in diverse application scenarios, it becomes clear that investing in heterogeneous vinyl sheet is an investment in the future of your space. Trust Enliofloor to deliver the expertise, experience, authority, and trustworthiness required for your next flooring project, ensuring your flooring is not just beautiful, but built to last.

References:

- Grand View Research. (2023). Vinyl Flooring Market Size, Share & Trends Analysis Report. Retrieved from https://www.grandviewresearch.com/industry-analysis/vinyl-flooring-market

- Floor Covering Institute. (2022). Resilient Flooring: Evolution and Trends. Retrieved from https://www.floorcoveringinstitute.com/resilient-flooring/

- International Organization for Standardization (ISO). (n.d.). ISO 9001 & ISO 14001. Retrieved from https://www.iso.org/home.html

- Resilient Floor Covering Institute (RFCI). (n.d.). FloorScore® Standard. Retrieved from https://rfci.com/floorscore/

-

Waterproof Advantages of SPC Flooring Vinyl in KitchensAug.06,2025

-

SPC Hybrid Waterproof Flooring Thickness GuideAug.06,2025

-

Leveling Subfloor Before My Floor SPC InstallAug.06,2025

-

How Mesh Deck Skirting Improves Outdoor Pest ControlAug.06,2025

-

Choosing the Right Commercial Flooring for Your Business NeedsAug.06,2025

-

Choosing the Best Residential Flooring: A Comprehensive Guide to Style, Durability, and ComfortAug.06,2025