pisos vct AI Vibration Control with gpt-4-turbo

pisos vct (Vinyl Composition Tile) remains a dominant solution in heavy-duty flooring demands—combining durability with versatile design. This guide spotlights the latest technology advancements, industry trends, and detailed comparisons amongst leading brands, including tarkett vct, mohawk vct, johnsonite vct, enlio johnsonite vct, and enlio tarkett vct ii. Special attention is given to the high-performance heterogeneous floor with nora surface—a product setting new standards for efficiency, safety, and longevity.

The global pisos vct market—valued at USD 2.68 billion in 2023—is projected to reach USD 3.12 billion by 2029 (MRFR Report), driven by resource-efficient manufacturing and rising adoption in healthcare, education, industrial, and public infrastructure. Demand is surging for:

- Low maintenance, anti-bacterial surfaces

- LEED-compliance (environmental standards)

- Customizable designs and fast installation

- Superior fire resistance and slip safety

| Brand | Model/Variation | Thickness (mm) | Wear Layer (mm) | ISO/ANSI Standard | Service Life (Years) | Fire Rating | Slip Resistance (DIN 51130) | Notable Feature |

|---|---|---|---|---|---|---|---|---|

| tarkett vct | Standard Excelon | 2.0–3.2 | 0.8 | ISO 10581, ASTM F1066 | 12–17 | Bfl–s1 | R10 | High abrasion, colourfast |

| mohawk vct | Performance Series | 2.0 | 0.7 | EN 649, ISO 9001 | 10–15 | Bfl–s1 | R9 | Stain-block formula |

| johnsonite vct | SolidTone™ | 2.5–3.2 | 0.75 | AATCC 134, ISO 14001 | 15–20 | Cfl–s1 | R10 | Extended warranty |

| enlio johnsonite vct | EP VCT | 2.0 | 0.8 | ISO 9001:2015, ISO 14001 | ≥15 | Bfl–s1 | R10 | Antibacterial certified |

| enlio tarkett vct ii | Tarkett II | 2.0–2.5 | 0.7–0.8 | ISO 10581, EN 14041 | 14–18 | Bfl–s1 | R10 | Easy-maintenance UV cure |

All grades of pisos vct share key technical advantages: rigid composite structure, advanced PVC/wear-resistant layers, and compliance with strict standards (ISO 10581, ASTM F1066). Their "R10" slip rating indicates higher occupational safety (R9-R10 recommended for industrial settings per DIN 51130). Service lifespans up to 20 years are not uncommon, supported by high-wear surface compounds and UV-stable pigments.

(PVC, Limestone Fillers, Pigments)

(Extrusion/Calendering)

(Press Moulding/Casting)

(CNC)

(ISO/ANSI)

The manufacturing workflow utilizes CNC for tight dimensional control, ensuring tile consistency and edge-perfect installations. Each batch is tested for:

- Thickness accuracy (±0.1 mm, ISO 10581)

- Fire resistance (EN 13501-1 Bfl–s1)

- Dimensional stability (≤0.13%, ASTM F1066)

- Colorfastness (AATCC 134/Gray Scale ≥ 4)

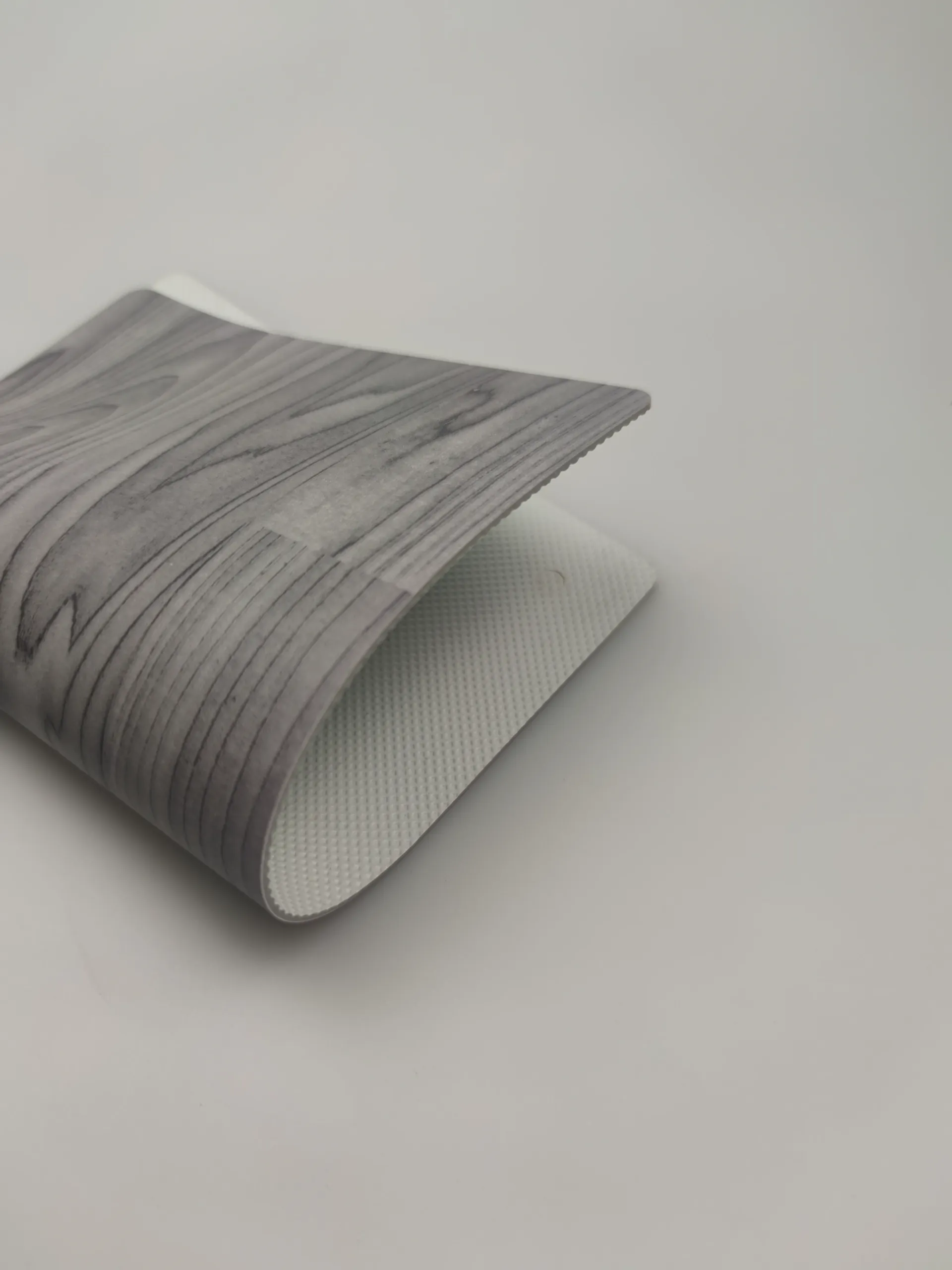

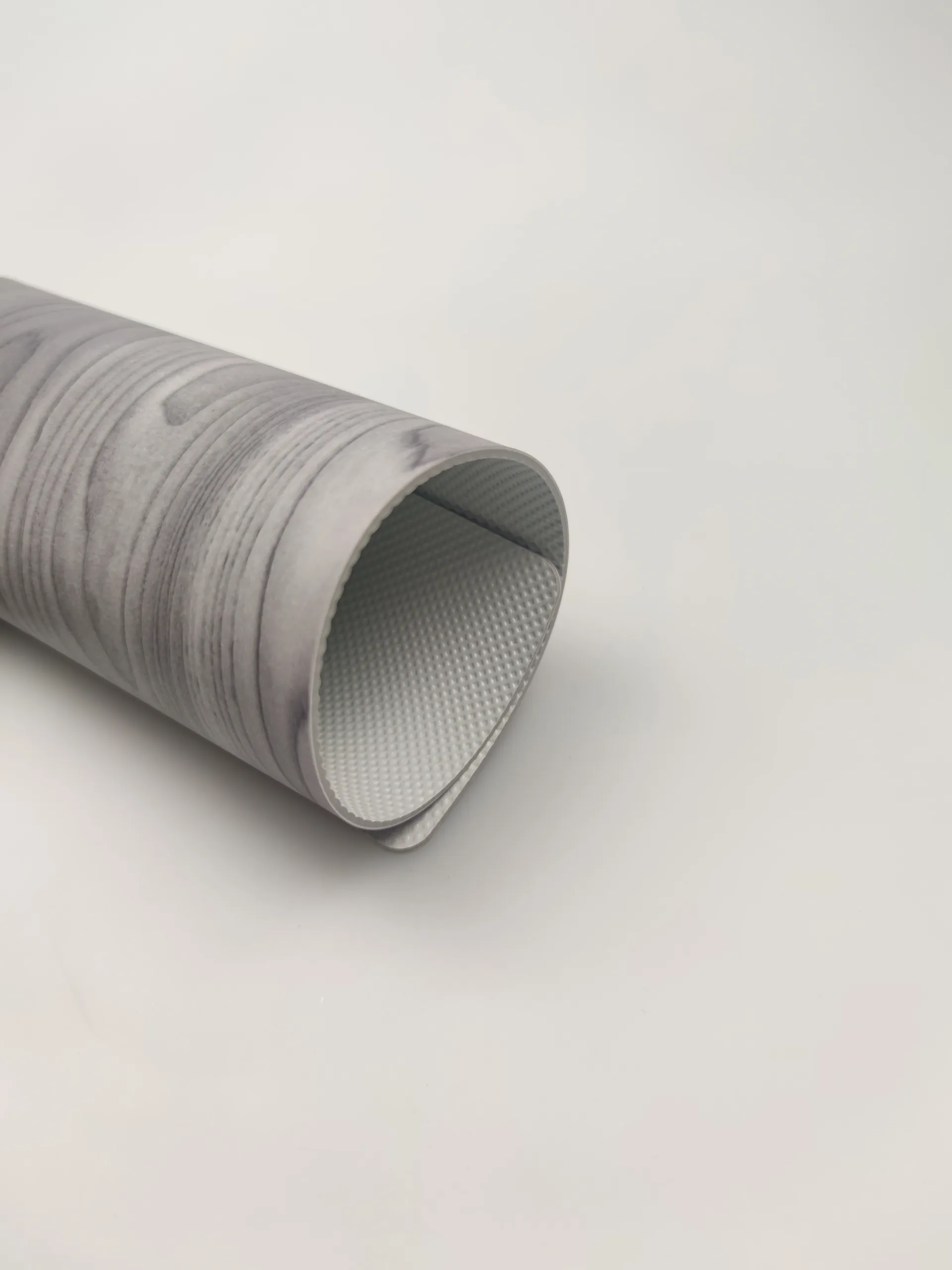

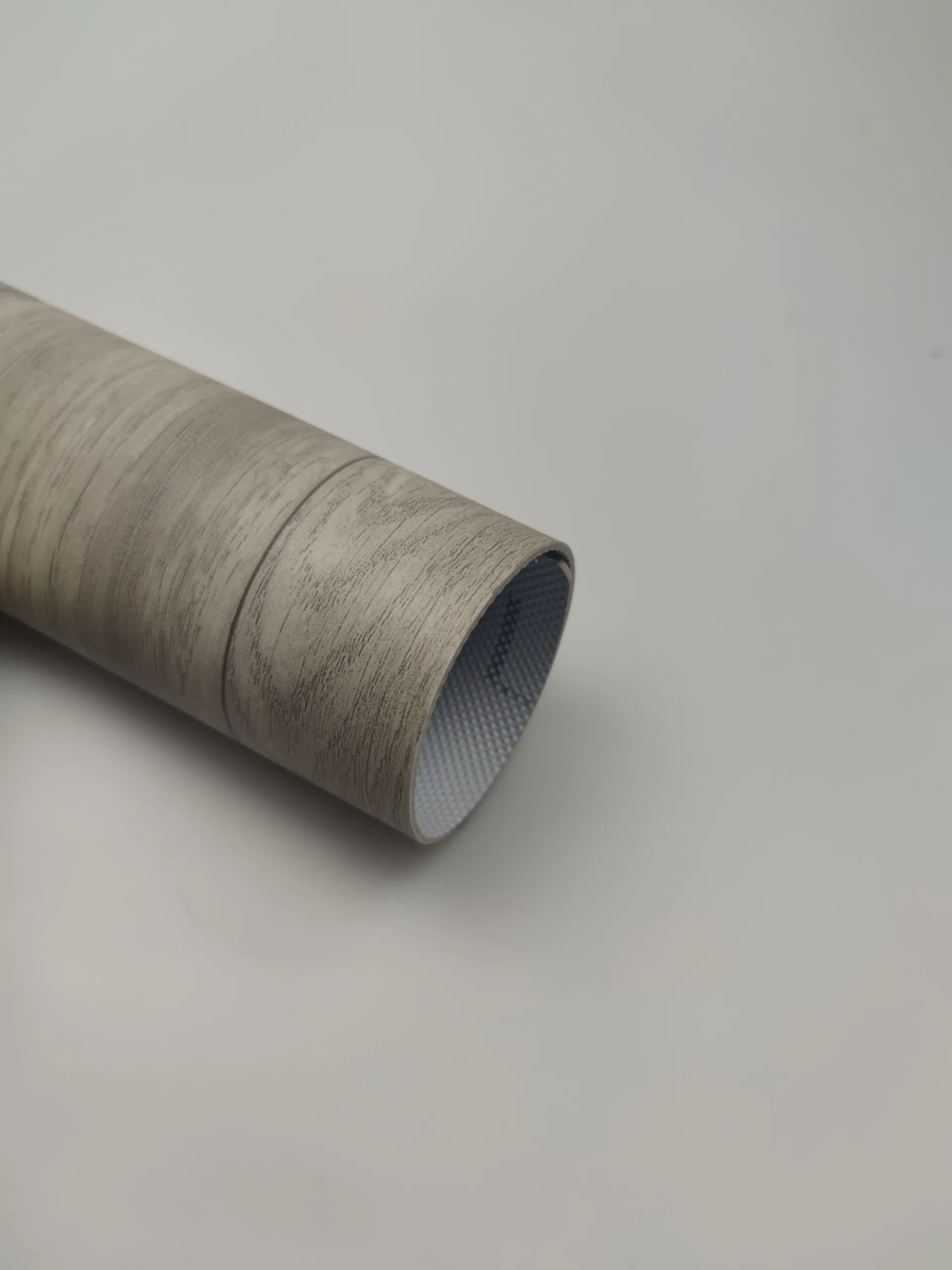

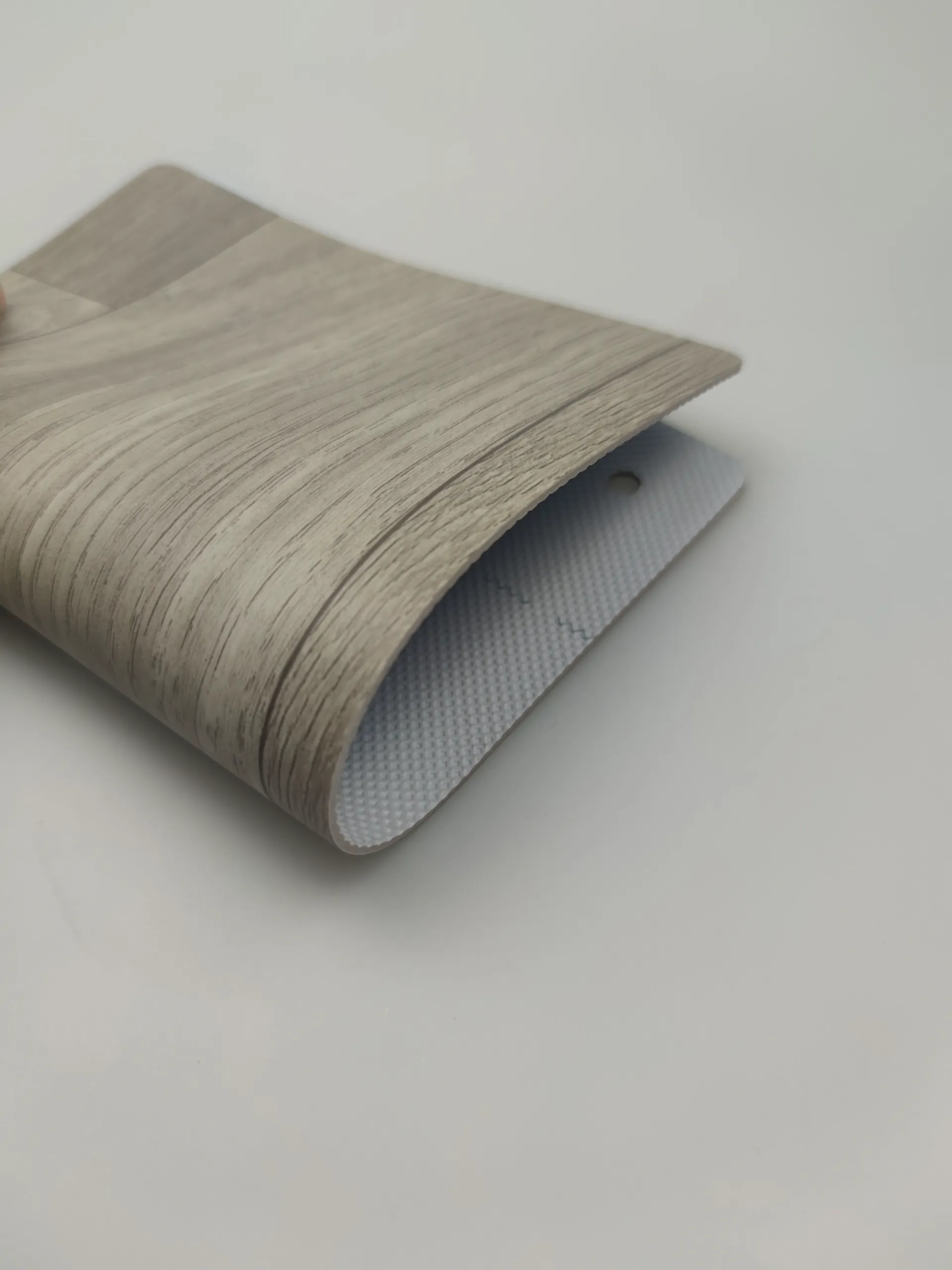

Enlio’s heterogeneous floor with nora surface brings a multi-layered approach to high-performance flooring, leveraging both VCT and rubber technology advantages. Integrated Nora® surface delivers extreme abrasion resistance, shock absorption, and premium anti-slip—meeting the strictest standards for industrial, public, and medical settings.

| Specification | Value | Test Standard | |

|---|---|---|---|

| Physical | Total Thickness | 2.0 / 3.0 mm | EN 428 |

| Wear Layer | 0.8 mm | EN 429 | |

| Density | 1.45 g/cm³ | ISO 1183 | |

| Performance | Abrasion Loss | < 0.06 g | EN 660-2 |

| Fire Class | Bfl–s1 | EN 13501-1 | |

| Slip Resistance | R10 | DIN 51130 | |

| Environmental | TVOC Emission | <10 μg/m³ (72h) | ISO 16000-6 |

| Antibacterial | Yes (99.9% E.coli/Klebsiella Pneumonia) | ISO 22196 | |

| Brand | Origin | ISO Certification | Innovation | Warranty | Main Sector |

|---|---|---|---|---|---|

| tarkett vct | France/US | ISO 9001, 14001 | Eco-binder, Digital print | 15 yrs | Healthcare, Education |

| mohawk vct | USA | ISO 9001, EN 649 | StainGuard, Easy-fit | 12 yrs | Retail, Office |

| johnsonite vct | USA | ISO 14001 | ColorFind, extended warranty | 18 yrs | Industrial, Technical |

| enlio johnsonite vct | China | ISO 9001:2015/GB/T19001 | Antibacterial, Low VOC | 15 yrs | Industry, Transport |

| enlio tarkett vct ii | China/FR | ISO 10581 | Upgraded UV Layer | 16 yrs | Industrial, School |

| heterogeneous floor with nora surface | China (Enlio) | ISO 9001, 14001, EN 13501-1 | Multi-layer hybrid, Nora tech | 20 yrs | Petrochemical, Hospitals, Heavy Duty |

Each manufacturer—while ensuring rigorous fire, impact, and chemical resistance—differentiates through unique process/technology. The heterogeneous floor with nora surface sets a benchmark for combined durability (abrasion loss <0.06g), antimicrobial protection, and sustainability leadership (low TVOC emission <10 μg/m³).

- Tile Size: 300x300mm, 457x457mm, custom upon request

- Total Thickness: 2.0mm, 3.0mm

- Wear Layer: 0.7–0.8mm (high wear/high traffic)

- Colors: >40 colorways (single-tone, speckle-mix, digital print)

- Edge: Square/Bevel

- Surface: Smooth, texture, Nora® rubber grain

The heterogeneous floor with nora surface enables specification flexibility to match safety, performance, and branding requirements across facilities.

- Technical consulting & specification finalization (1–3 days)

- Material selection & approval of samples (2–7 days)

- Batch production (12–22 days)

- Quality inspection / ISO-compliant testing (1–2 days)

- Packaging & logistics (2–5 days, global express)

- After-sales support & maintenance consulting

- Petrochemical: Highly corrosive plant environments; floor demands ultra resistance to acids, solvents. (e.g. Sinopec refineries)

- Metallurgy: Heavy impact from equipment and loads; anti-slip critical for workplace safety.

- Water Treatment/Public Utilities: Wet, high-traffic scenarios—waterproof & antibacterial property essential.

- Education & Hospital: Strict hygiene, anti-bacterial, and color stability are paramount (Enlio customers: top hospitals, schools in Asia/Europe).

- Transport Terminals & Corridors: Heavy pedestrian, luggage trolleys, cleaning machines—need maximum wear/tear endurance.

- Warranty: Up to 20 years structural/wear guarantee on heterogeneous floor with nora surface.

- Quality Certifications: ISO 9001, 14001, EN 13501-1, EN 660-2, ISO 22196—all batches strictly tested before shipment.

- Technical Support: Industry consulting (~24/7 response), on-site assistance for installation/training, COA/test report access.

- Traceability: Each batch has unique lot number for origin and quality recall—fully digital, auditable by partners.

In summary, pisos vct—especially the latest hybrid iterations like heterogeneous floor with nora surface—stand at the forefront of industrial flooring technology. Through rigorous standards (ISO/EN), precision production, and continuous material innovation, these floors deliver long-life, safety, and sustainability. Manufacturer comparisons underline a broad spectrum of choice, while real-world cases spotlight proven success in demanding environments.

References (industry journals & forums):

1. Floor Trends Magazine: 2024 Flooring Market Update

2. ISO 10581: Resilient Floor Coverings—VCT Specification

3. Floor Focus: VCT Market Closing Gap on Ceramic

4. Market Research Future: Global Vinyl Composition Tile Market Report 2023-2029

-

SPC Vinyl FlooringJul.18,2025

-

Home SPC FlooringJul.18,2025

-

Heterogeneous Sheet Vinyl: The Ultimate Commercial Flooring SolutionJul.15,2025

-

Dry Back LVT Flooring: A Durable and Stylish Flooring SolutionJul.15,2025

-

Click LVT Flooring: A Stylish and Convenient Flooring SolutionJul.15,2025

-

SPC FlooringJun.24,2025