Heterogeneous Vinyl Sheet: Durable, Stylish Flooring Solutions

Understanding Heterogeneous Vinyl: An In-Depth Analysis for B2B Professionals

In the dynamic landscape of commercial and industrial flooring, the choice of material significantly impacts operational efficiency, long-term costs, and aesthetic appeal. Among the myriad options, heterogeneous viny stands out as a high-performance solution, engineered to meet stringent demands across diverse sectors. Unlike its homogeneous counterpart, which consists of a single layer of uniform composition, heterogeneous viny is multi-layered, providing superior functional and aesthetic attributes. This advanced construction allows for a greater degree of customization in terms of design, texture, and performance characteristics, making it an ideal choice for environments requiring both durability and visual sophistication. The strategic layering typically includes a transparent wear layer, a printed decorative film, a dimensionally stable fiberglass reinforcement layer, and a robust backing layer, each contributing to the overall integrity and performance of the floor covering. This comprehensive article delves into the technical intricacies, application benefits, and market positioning of this essential flooring material.

The demand for sophisticated flooring solutions continues to rise, driven by evolving standards in hygiene, safety, and sustainable building practices. Heterogeneous vinyl sheet, often referred to as heterogeneous sheet vinyl, addresses these demands by offering exceptional resistance to heavy foot traffic, chemical spills, and indentation, coupled with ease of maintenance and superior acoustic properties. Its versatility makes it suitable for a broad spectrum of applications, from healthcare and educational facilities to retail environments and corporate offices. This in-depth analysis will provide B2B decision-makers and technical professionals with the insights necessary to make informed procurement decisions, highlighting industry trends, technical specifications, and real-world application advantages of this advanced flooring.

The Manufacturing Process of Heterogeneous Vinyl Flooring

The production of heterogeneous viny involves a sophisticated, multi-stage manufacturing process designed to create a resilient, multi-layered flooring solution. This process ensures the integration of distinct performance characteristics into each layer, culminating in a product that delivers exceptional durability, aesthetic appeal, and functional superiority. Understanding these steps is crucial for appreciating the technical excellence embedded in every square meter of heterogeneous vinyl.

Detailed Process Flow:

- Raw Material Preparation: The process begins with the careful selection and blending of raw materials. Key components include PVC resin (Polyvinyl Chloride), plasticizers for flexibility, stabilizers to enhance heat and light resistance, pigments for color, and various fillers to optimize mechanical properties. For the "heterogeneous floor with Stariver surface," specialized polymers are often integrated to achieve the desired surface finish and enhanced durability. All materials undergo strict quality checks to meet environmental and performance standards.

- Backing Layer Extrusion/Calendering: The foundational layer, typically composed of recycled or virgin PVC compounds, is formed through a precise extrusion or calendering process. This layer provides dimensional stability and structural integrity to the entire sheet. Advanced calendering techniques ensure a consistent thickness and density, crucial for long-term performance and adhesion to the subfloor.

- Fiberglass Reinforcement (Stabilizing Layer) Application: A critical step involves the integration of a fiberglass scrim or non-woven fiberglass mat between the backing layer and the decorative film. This fiberglass layer acts as a vital reinforcement, significantly improving the flooring's dimensional stability, preventing shrinkage, and enhancing resistance to temperature fluctuations. This is a key differentiator for high-quality heterogeneous sheet vinyl, ensuring the product remains flat and stable over its lifespan.

- Decorative Film Printing: High-resolution digital or rotogravure printing techniques are employed to create the decorative film. This film replicates various natural materials like wood or stone, or intricate abstract patterns, ensuring superior aesthetic versatility. The "Stariver surface" implies a particular focus on visual depth and perhaps textural fidelity, achieved through advanced printing and embossing capabilities.

- Wear Layer Application: A transparent wear layer, typically made from pure PVC, is applied over the decorative film. This layer is the primary protector against abrasion, scratches, stains, and indentation. Its thickness and composition (e.g., presence of ceramic beads or advanced polymer coatings like PUR) directly correlate with the product's durability and service life. For extreme traffic areas, wear layers can range from 0.5mm to 1.0mm or more, classified as T-group for very high abrasion resistance per EN 660-2.

- Surface Treatment/Finishing: A final surface treatment, such as a UV-cured polyurethane (PUR) or acrylic coating, is often applied to the wear layer. This enhances scratch resistance, simplifies cleaning, and can provide specific properties like improved slip resistance (e.g., R9-R11 ratings based on EN 13893 standards) or antimicrobial protection. The Stariver surface likely benefits from an advanced, resilient topcoat that offers superior longevity and ease of maintenance.

- Curing and Quality Control: The layered material undergoes curing processes, often involving heat and pressure, to ensure optimal adhesion between layers and overall material integrity. Rigorous quality control checks are performed at various stages, inspecting for dimensional accuracy, color consistency, wear layer thickness, and adherence to performance specifications. This includes testing against international standards such as ISO 9001 for quality management and ISO 14001 for environmental management, ensuring the product's compliance and reliability.

- Cutting and Packaging: The finished heterogeneous vinyl sheet is then cut into specified widths and lengths, typically rolled onto cores, and carefully packaged for shipment. Proper packaging protects the product during transit and storage, ensuring it arrives in pristine condition.

This meticulous manufacturing sequence ensures that heterogeneous viny offers a service life typically ranging from 15 to 25 years or more, depending on the wear layer thickness and application environment. Its inherent advantages, such as superior dimensional stability due to fiberglass reinforcement, excellent indentation recovery, and enhanced resistance to moisture and common chemicals, make it an ideal solution for target industries including healthcare (e.g., operating rooms, patient wards), education (e.g., classrooms, corridors), retail (e.g., high-traffic aisles), and commercial facilities (e.g., offices, public spaces) where durability, hygiene, and aesthetic flexibility are paramount. The "heterogeneous floor with Stariver surface" specifically leverages these processes to deliver a product known for its resilience and premium finish.

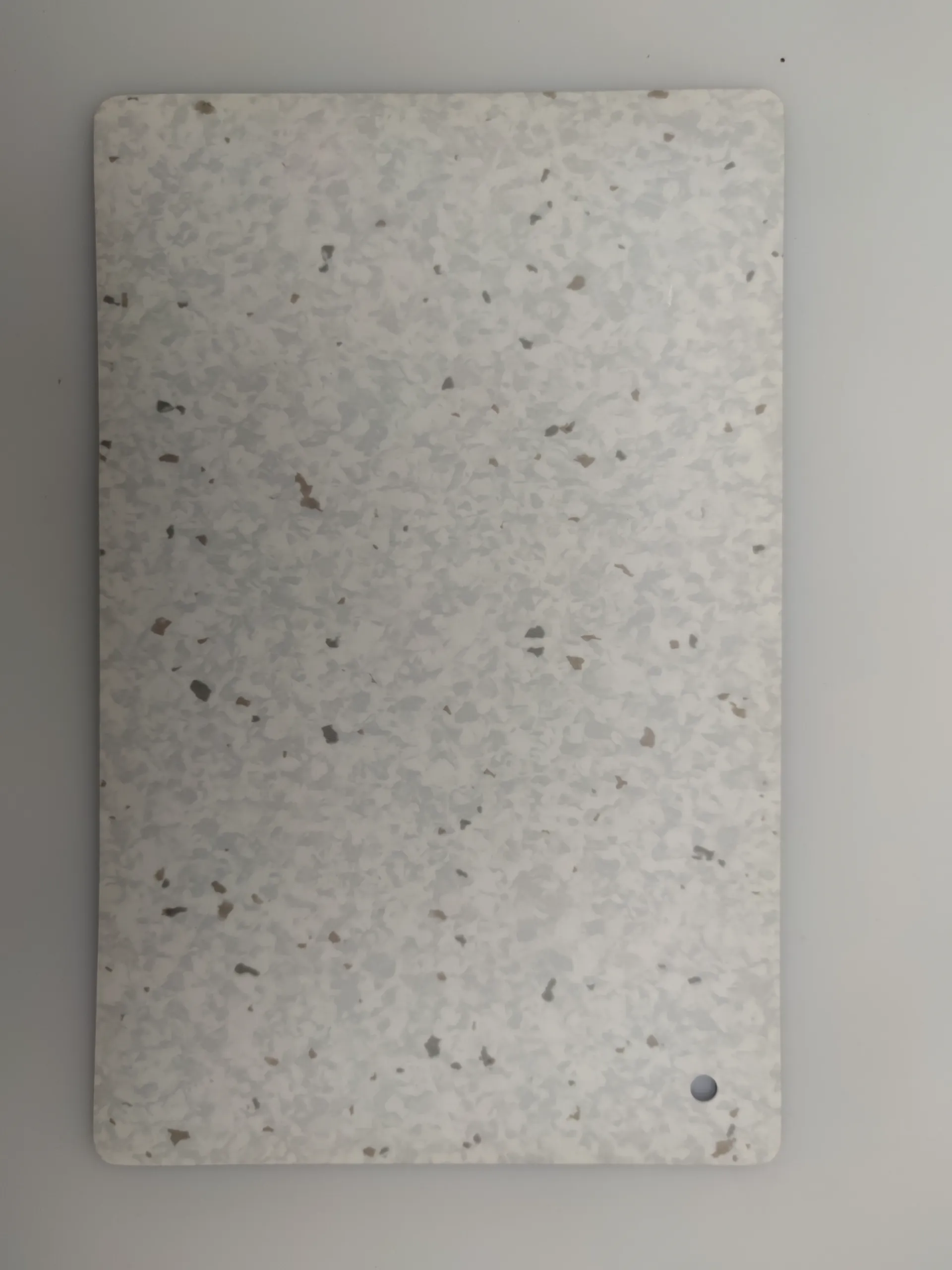

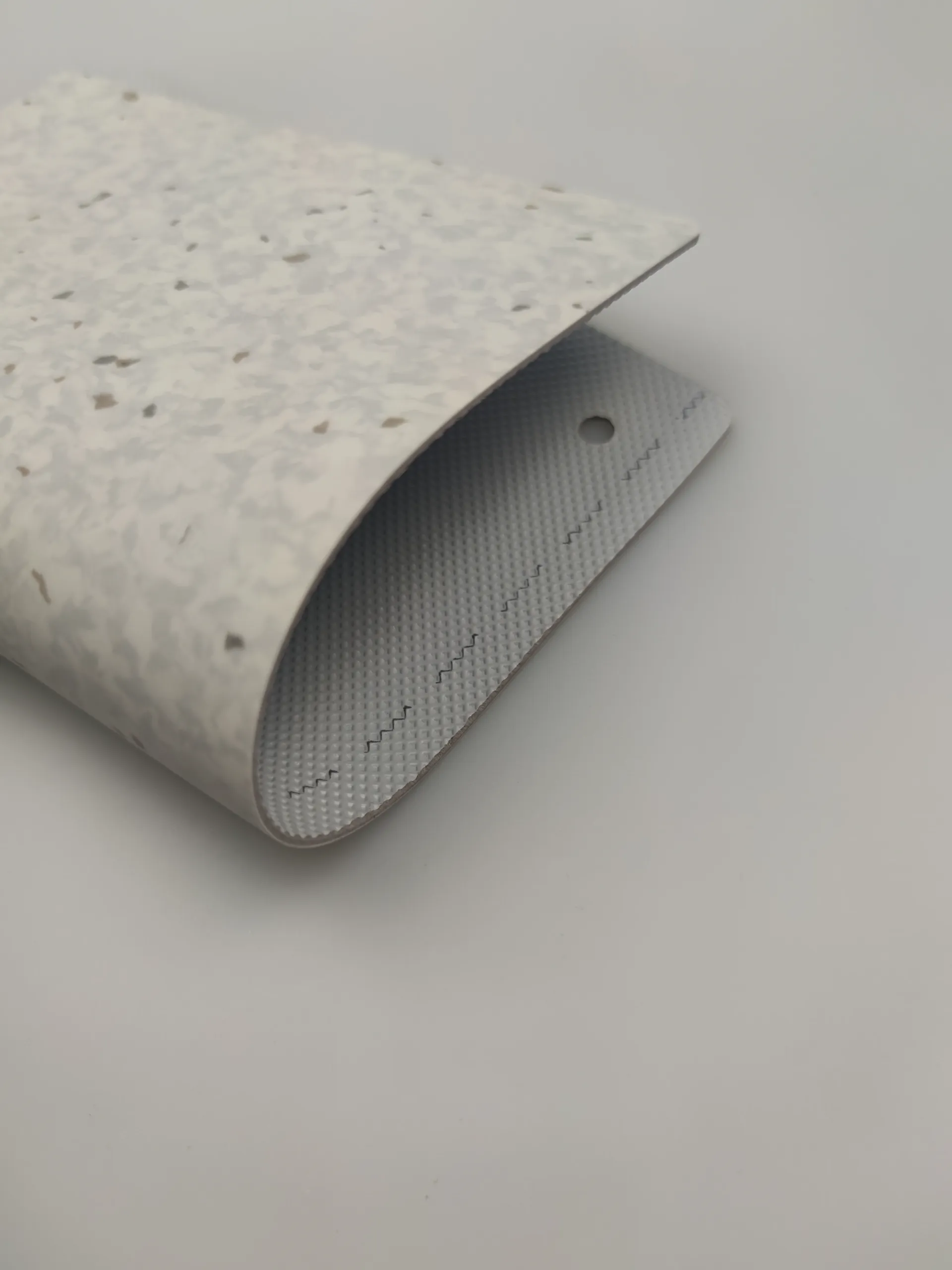

Fig 1: Illustrative cross-section of heterogeneous vinyl sheet construction.

Technical Specifications and Composition of High-Performance Heterogeneous Vinyl

The performance of heterogeneous viny is directly attributable to its meticulous layered structure and the precise technical specifications applied during its manufacture. Understanding these parameters is essential for B2B stakeholders in evaluating product suitability and ensuring compliance with project requirements. The "heterogeneous floor with Stariver surface" exemplifies how advanced engineering contributes to superior flooring performance.

Layered Structure and Material Science:

- Wear Layer: Typically 0.3mm to 1.0mm thick, composed of clear PVC. This layer is often enhanced with ceramic particles, PUR (polyurethane) coatings, or other high-performance additives to boost abrasion resistance (e.g., T-group classification per EN 660-2), chemical resistance, and ease of maintenance. The Stariver surface benefits from a high-density, highly resistant wear layer, offering exceptional longevity.

- Printed Design Layer: A high-fidelity printed film that provides the aesthetic appeal and visual texture, protected permanently beneath the wear layer.

- Fiberglass Reinforcement: A woven or non-woven fiberglass scrim, typically integrated between the decorative film and the core layer. This critical layer prevents shrinkage and expansion, ensuring dimensional stability (e.g., ≤0.4% per EN 434). This is vital for preventing gaps and curls over time, especially in large installations.

- Core Layer / Cushion Layer (Optional): A dense PVC layer, sometimes foamed, providing additional comfort underfoot, enhanced sound absorption, and improved thermal insulation. This significantly contributes to acoustic performance (e.g., impact sound reduction ≥17dB per EN ISO 717-2).

- Backing Layer: The bottom layer, usually a denser PVC, provides structural integrity and ensures secure adhesion to the subfloor. It often incorporates recycled content, aligning with sustainability goals.

Key Product Specifications for Heterogeneous Floor with Stariver Surface:

| Parameter | Specification (Heterogeneous Floor with Stariver Surface) | Relevant Standard |

|---|---|---|

| Total Thickness | 2.0mm - 4.0mm (standard 2.5mm for commercial applications) | EN ISO 24346 |

| Wear Layer Thickness | 0.5mm - 0.7mm | EN ISO 24340 |

| Abrasion Resistance (Wear Group) | T (Very High) | EN 660-2 |

| Dimensional Stability | ≤ 0.4% | EN 434 |

| Residual Indentation | ≤ 0.10 mm | EN ISO 24343-1 |

| Slip Resistance | R9 - R10 (depending on surface texture) | EN 13893 / DIN 51130 |

| Impact Sound Reduction | ≥ 17 dB (for cushion-backed variants) | EN ISO 717-2 |

| Fire Resistance | Bfl-s1 (low smoke, non-flammable) | EN 13501-1 |

| VOC Emissions | Very Low (A+ rating, FloorScore certified) | ISO 16000-6 / AgBB / French A+ |

| Chemical Resistance | Good to Excellent (resistant to dilute acids, alkalis, oils, common disinfectants) | EN ISO 26987 |

Fig 2: Advanced surface and backing layers contribute to the durability of heterogeneous viny.

These specifications underscore the robust engineering behind high-quality heterogeneous vinyl sheet. The "Stariver surface" is designed to excel in these areas, providing a reliable and long-lasting flooring solution that maintains its aesthetic and functional integrity even under demanding commercial conditions.

Industry Trends and Market Dynamics for Heterogeneous Sheet Vinyl

The market for resilient flooring, particularly heterogeneous sheet vinyl, is experiencing sustained growth, driven by several key industry trends. Decision-makers in B2B sectors must remain cognizant of these shifts to ensure their investments align with future-proof solutions. The versatility and performance attributes of this multi-layered flooring position it strongly within these evolving dynamics.

Key Market Drivers:

- Healthcare Infrastructure Expansion: Globally, significant investments in new hospitals, clinics, and elderly care facilities are fueling demand for hygienic, durable, and easy-to-clean flooring. Heterogeneous vinyl sheet with antimicrobial properties and superior chemical resistance is a preferred choice in these critical environments.

- Sustainability and Green Building Initiatives: Increasing emphasis on environmentally friendly building materials, low VOC emissions, and lifecycle assessments (LCAs) is shaping product development. Manufacturers are innovating to produce heterogeneous vinyl with higher recycled content and clearer certifications (e.g., FloorScore, REACH compliance), addressing growing ecological concerns.

- Technological Advancements in Design: Digital printing technology has revolutionized the aesthetic possibilities of heterogeneous vinyl sheet, allowing for realistic reproductions of wood, stone, and bespoke patterns, meeting the sophisticated aesthetic demands of modern commercial interiors.

- Demand for Enhanced Performance: Beyond aesthetics, there's a growing need for flooring that offers improved acoustic comfort, superior slip resistance, and better ergonomic properties, especially in workspaces and educational settings where employee and user well-being are prioritized.

- Cost-Effectiveness and Lifecycle Value: While initial costs can vary, the long service life, low maintenance requirements, and excellent durability of heterogeneous vinyl provide a compelling total cost of ownership, making it an attractive long-term investment for discerning businesses.

According to a report by Grand View Research, the global vinyl flooring market size was valued at USD 33.1 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. Within this, the commercial segment, where heterogeneous vinyl sheet is dominant, accounts for a significant share due to its suitability for heavy traffic and specific performance requirements. Regions like Asia Pacific and North America are leading in market growth, driven by rapid urbanization and infrastructural development. This growth trajectory underscores the strategic importance of investing in high-quality heterogeneous vinyl solutions.

The innovation cycle for this flooring material is accelerating, with manufacturers focusing on integrating smart features such as embedded sensors for maintenance scheduling or enhanced anti-microbial treatments that last the lifetime of the floor. The "heterogeneous floor with Stariver surface" is designed to align with these trends, offering a blend of aesthetic innovation and robust performance tailored for the evolving commercial environment.

Application Scenarios and Technical Advantages of Heterogeneous Vinyl

Key Technical Advantages of Heterogeneous Vinyl Flooring:

- Exceptional Durability and Wear Resistance: The multi-layered construction, particularly the robust wear layer and fiberglass reinforcement, provides outstanding resistance to abrasion, impact, and heavy rolling loads. This translates to a significantly longer service life compared to many other flooring options, reducing the frequency and cost of replacement.

- Superior Hygienic Properties: The non-porous surface of heterogeneous viny prevents the growth of bacteria and fungi, making it ideal for environments requiring strict hygiene protocols. It is also highly resistant to stains and chemical spills, facilitating easy cleaning and disinfection, which is critical in healthcare settings.

- Enhanced Acoustic Performance: The layered structure, often incorporating a cushioned backing, provides excellent sound absorption, reducing impact noise and improving overall acoustic comfort in busy spaces. This is especially beneficial in educational, office, or healthcare settings where noise reduction is paramount.

- Dimensional Stability: The integrated fiberglass layer effectively minimizes expansion and contraction due to temperature fluctuations, ensuring the floor remains flat and gap-free over its lifespan. This prevents common issues like curling or lifting edges, maintaining a seamless appearance.

- Design Versatility: High-definition printing allows for an almost limitless array of designs, colors, and patterns, offering aesthetic flexibility to match any interior design scheme. The "Stariver surface" specifically enhances this with its premium visual quality and textural realism.

- Ease of Maintenance: The smooth, sealed surface requires minimal effort to clean, often just sweeping and damp mopping, contributing to lower operational costs over time. This makes it a practical choice for facilities with demanding cleaning schedules.

- Comfort Underfoot: While highly durable, the inherent flexibility and optional cushion layers provide a degree of comfort underfoot, reducing fatigue for staff who spend long hours standing, improving overall workplace ergonomics.

Typical Application Environments:

- Healthcare Facilities: Hospitals, clinics, laboratories, and nursing homes benefit immensely from the hygienic, chemical-resistant, and easy-to-clean properties of heterogeneous sheet vinyl. Its ability to be heat-welded creates seamless, impervious surfaces crucial for infection control and maintaining sterile environments.

- Educational Institutions: Schools, universities, and daycare centers require flooring that can withstand heavy traffic, offer good acoustics, and be easy to maintain. This type of vinyl flooring provides these attributes along with vibrant design possibilities to create stimulating learning environments.

- Retail and Commercial Spaces: High-traffic retail stores, supermarkets, offices, and hotels benefit from the durability, aesthetic appeal, and cost-effectiveness of this flooring. It withstands constant footfall and the movement of display units, maintaining its appearance over years.

- Pharmaceutical and Light Industrial Settings: Areas requiring controlled environments and resistance to certain chemicals find this flooring suitable. Its low VOC emissions are also beneficial in such contexts, contributing to worker safety and product integrity.

- Public and Institutional Buildings: Libraries, museums, government offices, and transport hubs rely on flooring that combines long-term durability with public safety features like slip resistance and easy maintenance for large-scale operations.

Fig 3: Heterogeneous vinyl sheet delivering durability and aesthetics in a modern commercial space.

These broad applications underscore the adaptability and superior performance of this flooring solution as a preferred choice for demanding B2B environments. The "heterogeneous floor with Stariver surface" is specifically engineered to excel in these very scenarios, offering unmatched reliability and visual appeal.

Vendor Comparison and Customized Solutions

Selecting the right supplier for heterogeneous vinyl flooring is as critical as choosing the product itself. The market features numerous manufacturers, each with distinct offerings and service models. A thorough vendor comparison, alongside an understanding of customization options, empowers B2B clients to optimize their flooring investments.

Comparative Analysis: Heterogeneous Vinyl Providers

While many brands, including niche players like hawk flooring, offer vinyl solutions, not all heterogeneous products deliver the same level of performance, certifications, and customization. The table below provides a general comparison to illustrate key differentiators, highlighting why Enlio's "heterogeneous floor with Stariver surface" stands out in a competitive market:

| Feature/Aspect | Enlio (Stariver Surface Heterogeneous Floor) | Generic Premium Heterogeneous Vinyl | Standard Homogeneous Vinyl |

|---|---|---|---|

| Layer Structure | Multi-layered (Wear, Print, Fiberglass, Backing) with specialized Stariver surface treatment for enhanced visual depth and protection. | Multi-layered (Wear, Print, Fiberglass, Backing). | Single, uniform layer throughout thickness. |

| Wear Layer Performance | 0.5-0.7mm PUR-enhanced, T-group abrasion, superior stain/scratch resistance. Exceptionally durable. | 0.5-0.7mm, T-group abrasion, good stain/scratch resistance. | Full thickness wear, but often requires regular polishing/buffing to maintain appearance and performance. |

| Dimensional Stability | Excellent (Fiberglass reinforced, ≤0.4% per EN 434). Minimized expansion/contraction. | Very Good (Fiberglass reinforced, ≤0.4% per EN 434). | Good (Can be more prone to movement without dedicated reinforcement layer). |

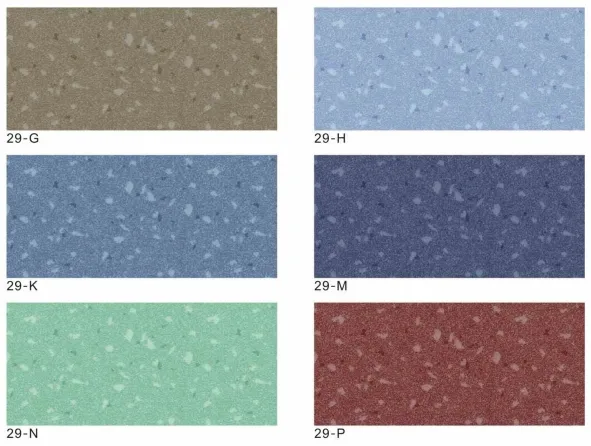

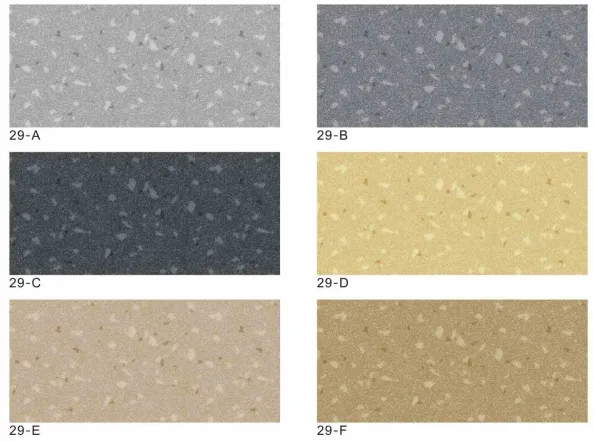

| Design & Aesthetics | High-fidelity prints, realistic textures, extensive pattern library, custom options for Stariver, premium look. | Wide range of realistic designs and colors. | Limited patterns, often speckled or plain, less visual depth or realism. |

| Hygienic Properties | Excellent (Non-porous, PUR-coated, often antimicrobial treated, seamlessly weldable). Ideal for healthcare. | Excellent (Non-porous, surface treated, seamlessly weldable). | Good (Non-porous, but typically requires more aggressive cleaning/maintenance to maintain hygiene). |

| Acoustic Comfort | Superior (≥17dB impact sound reduction for specific constructions). Significant noise dampening. | Very Good (Often ≥15dB impact sound reduction). | Moderate (Typically lower acoustic insulation without additional underlayment). |

| Total Cost of Ownership | Optimal (Higher initial investment, very low long-term maintenance & replacement costs due to longevity). | Very Good (Higher initial, low long-term maintenance). | Good (Lower initial, higher long-term maintenance due to waxing/buffing/stripping cycles). |

Customized Solutions and Design Flexibility:

One of the significant advantages of working with specialized manufacturers of heterogeneous vinyl flooring like Enlio is the availability of customized solutions. This flexibility extends beyond standard color palettes and patterns, allowing for truly bespoke flooring designs tailored to specific project requirements.

- Bespoke Design & Branding: For large-scale projects, manufacturers can create custom printed designs, incorporating corporate logos, specific color gradients, or unique thematic elements that align with brand identity or architectural vision. The "heterogeneous floor with Stariver surface" offers enhanced digital printing capabilities for unparalleled customization.

- Tailored Technical Performance: Depending on the application, specifications such as wear layer thickness, slip resistance ratings (e.g., R11 for kitchens or industrial zones), or specific antimicrobial treatments can be adjusted. This ensures the flooring perfectly matches the operational demands and safety requirements of the environment.

- Specialized Formulations: For areas requiring enhanced static control (ESD flooring for electronics manufacturing or data centers) or specific chemical resistance (for laboratories or industrial plants), specialized PVC formulations and conductive layers can be integrated into the heterogeneous vinyl sheet.

- Acoustic Backing Options: For projects where noise reduction is a paramount concern, options for thicker cushion layers or integrated acoustic backings can be provided, significantly boosting impact sound insulation and creating quieter spaces.

Partnering with a manufacturer capable of delivering these customized solutions for heterogeneous vinyl flooring ensures that the flooring not only meets aesthetic and functional requirements but also contributes to the overall success and longevity of the facility. This strategic approach is especially valuable for large institutions or multi-site rollouts seeking a consistent, high-performance solution.

Real-World Application Case Studies

The theoretical advantages of heterogeneous vinyl flooring are best illustrated through successful real-world applications. These case studies demonstrate how the "heterogeneous floor with Stariver surface" and similar products address complex flooring challenges in demanding environments, offering tangible benefits to clients.

Case Study 1: Major Regional Hospital Renovation

Client: St. Jude Medical Center, Midwest USA

Challenge: The hospital required a flooring solution for its high-traffic corridors, patient rooms, and surgical prep areas. Key requirements included superior hygiene, resistance to heavy rolling equipment (e.g., hospital beds, trolleys), chemical resistance to disinfectants, and excellent acoustic properties to minimize patient disturbance. The existing homogeneous vinyl was showing significant wear and required constant, costly maintenance.

Solution: Enlio's heterogeneous floor with Stariver surface (4.0mm total thickness, 0.7mm wear layer, PUR-enhanced) was selected. Its non-porous, seam-weldable surface, combined with an integrated antimicrobial treatment, provided a critical barrier against infection. The enhanced wear layer and fiberglass reinforcement ensured robust resistance to heavy loads and exceptional dimensional stability, crucial for a sterile and highly functional environment. The Stariver surface's advanced finish also provided an aesthetic upgrade, contributing to a more calming atmosphere.

Results: The hospital reported a significant reduction in cleaning and maintenance costs, with the new flooring resisting stains and scuffs far more effectively than previous installations. Patient and staff satisfaction improved due to reduced noise levels and a more aesthetically pleasing, clean, and safe environment. The project, completed over 15,000 sq meters, demonstrated the long-term value and operational benefits of high-quality heterogeneous vinyl sheet in a demanding healthcare setting.

Case Study 2: National University Science & Technology Campus

Client: National University of Applied Sciences, European Union

Challenge: The university needed durable, aesthetically appealing, and quiet flooring for its new research laboratories, lecture halls, and student common areas. Specific concerns included resistance to laboratory chemicals, heavy student traffic, and the need for a comfortable yet robust surface to minimize fatigue for researchers and students. They also prioritized low VOC emissions for a healthy indoor environment to meet stringent European building standards.

Solution: A custom solution using heterogeneous viny with enhanced chemical resistance properties and an integrated acoustic backing was chosen. The design team worked closely with the manufacturer to select specific patterns and colors that complemented the modern architectural style of the new campus buildings, while ensuring compliance with all technical requirements for a science facility. The "heterogeneous floor with Stariver surface" provided the necessary balance of technical performance, aesthetic flexibility, and sustainable features.

Results: The installation in over 10,000 sq meters of space resulted in a highly functional and visually appealing campus. The flooring excelled in chemical spill resistance in laboratories and significantly reduced noise transfer in lecture halls, enhancing the learning and research environment. The low VOC emission certification (A+) contributed significantly to the university's green building objectives, providing a healthier indoor environment for all occupants. This project showcased the adaptability and high-performance capabilities of specialized heterogeneous vinyl sheet in a complex educational setting.

Fig 4: Educational spaces transformed by the durable and aesthetic qualities of heterogeneous viny.

Commitment to Quality and Trustworthiness ()

Enlio's commitment to excellence in heterogeneous vinyl solutions is underpinned by stringent quality assurance protocols, comprehensive certifications, and robust customer support. This dedication ensures not only product reliability but also builds lasting trust with B2B partners, making us a dependable choice for your flooring needs.

Certifications and Adherence to Global Standards:

Our "heterogeneous floor with Stariver surface" adheres to and often exceeds international quality and environmental standards, reflecting our dedication to producing top-tier flooring solutions:

- ISO 9001:2015: Certified for Quality Management Systems, ensuring consistent product quality and customer satisfaction through rigorous process control.

- ISO 14001:2015: Certified for Environmental Management Systems, demonstrating our commitment to sustainable manufacturing practices and minimizing environmental impact.

- CE Marking: Conforming to European health, safety, and environmental protection standards for products sold within the European Economic Area, ensuring market readiness and safety.

- EN Standards Compliance: Full compliance with relevant European Norms, including EN 13845 (Resilient floor coverings – Heterogeneous smooth PVC floor coverings with foam layer), EN 13893 (Slip resistance), EN 13501-1 (Fire classification), and EN 717-1 (Formaldehyde emissions), among others, verifying product performance.

- FloorScore Certification: Ensuring that our products meet stringent indoor air quality requirements for VOC emissions, contributing to healthy indoor environments in schools, offices, and healthcare facilities.

- REACH Compliance: Adhering to the European Union regulation concerning the Registration, Evaluation, Authorisation, and Restriction of Chemicals, promoting product safety and environmental protection.

Lead Time and Fulfillment Details:

We understand the critical nature of project timelines. Our standard lead time for the "heterogeneous floor with Stariver surface" is typically 4-6 weeks for custom orders and 2-3 weeks for in-stock items, subject to order volume and destination. Expedited shipping options are available upon request to meet urgent project deadlines. We maintain a robust supply chain and a vast inventory of popular designs to ensure efficient fulfillment and minimize project delays. Our dedicated logistics team works diligently to coordinate global shipments, providing real-time tracking and dedicated support from order placement to final delivery, ensuring a seamless experience.

Warranty Commitments and After-Sales Support:

Our confidence in the durability and performance of our heterogeneous vinyl sheet is reflected in our comprehensive warranty programs. The "heterogeneous floor with Stariver surface" comes with a standard 10-year commercial warranty, covering manufacturing defects, excessive wear, and dimensional stability under normal use and maintenance conditions. Extended warranty options are available for specific project types or high-traffic installations, providing additional peace of mind.

Our dedicated after-sales support team is readily available to assist with any technical queries, installation guidance, or post-installation concerns. We provide detailed maintenance guidelines and access to our network of certified installers to ensure optimal long-term performance. For immediate assistance, clients can contact our support hotline at +XX-XXX-XXXX-XXXX or email support@enliofloor.com. We are committed to ensuring the long-term satisfaction and success of every project utilizing our flooring products.

Frequently Asked Questions (FAQ) about Heterogeneous Vinyl

Q1: What is the primary difference between heterogeneous and homogeneous vinyl flooring?

A: Homogeneous vinyl is a single layer of uniform composition and color throughout its thickness. Heterogeneous vinyl, on the other hand, is multi-layered, consisting of a transparent wear layer, a printed design layer, often a fiberglass reinforcement, and a backing layer. This layered construction allows for greater design versatility, enhanced dimensional stability, and specific performance characteristics in each layer, such as superior abrasion resistance in the wear layer.

Q2: Is heterogeneous vinyl suitable for high-traffic areas?

A: Absolutely. High-quality heterogeneous sheet vinyl, particularly products like the "heterogeneous floor with Stariver surface" with a robust wear layer (typically 0.5mm to 0.7mm), is engineered specifically for demanding, high-traffic commercial and industrial environments. Its multi-layered structure provides excellent resistance to abrasion, indentation, and heavy rolling loads, ensuring long-term performance.

Q3: How does heterogeneous vinyl contribute to indoor air quality?

A: Reputable manufacturers produce heterogeneous vinyl flooring with very low VOC (Volatile Organic Compound) emissions. Products that are FloorScore certified or have A+ ratings under European standards are verified to meet strict indoor air quality requirements, contributing to healthier building environments for occupants. Always check for relevant certifications for reassurance.

Q4: Can heterogeneous vinyl be installed over existing flooring?

A: In some cases, yes, but the subfloor must be thoroughly prepared. It needs to be clean, dry, flat, smooth, and structurally sound. Any imperfections in the existing subfloor will likely telegraph through the new heterogeneous vinyl sheet over time. Professional assessment and preparation are always recommended to ensure a flawless and durable installation.

Q5: What is the typical lifespan and maintenance for heterogeneous vinyl flooring?

A: With proper installation and maintenance, high-quality heterogeneous vinyl can last 15-25 years or more in commercial settings. Maintenance is generally low: regular sweeping/vacuuming and damp mopping with a neutral cleaner are usually sufficient. The robust wear layer and surface treatments (like PUR) often eliminate the need for waxing or polishing, significantly reducing long-term maintenance costs.

Authoritative References

- 1. ISO. (2023). International Organization for Standardization. Available at: www.iso.org

- 2. European Committee for Standardization (CEN). (2023). Available at: www.cencenelec.eu

- 3. Resilient Floor Covering Institute (RFCI). (2023). FloorScore Certification Program. Available at: www.rfci.com

- 4. Grand View Research. (2023). Vinyl Flooring Market Size, Share & Trends Analysis Report. Available at: www.grandviewresearch.com

- 5. European Chemicals Agency (ECHA). (2023). REACH Regulation. Available at: www.echa.europa.eu

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025