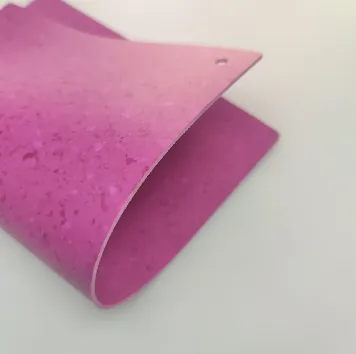

Apollo Masking Tape M502 & M506 High-Temp, Residue-Free Protection

- Performance metrics proving Apollo masking tape superiority

- Technical engineering behind tape construction

- Comparative analysis with competing brands

- Customized solutions for specific project requirements

- Automotive paint protection case studies

- Electronics manufacturing applications

- Optimal usage techniques for Apollo masking tape m506

(apollo masking tape)

Why Professionals Select Apollo Masking Tape

Industrial specialists consistently choose Apollo masking tapes for precision tasks requiring absolute reliability. The brand's reputation stems from rigorous quality control meeting MIL-STD-204D standards across all production batches. Unlike commodity tapes, Apollo m502 masking tape maintains consistent adhesive properties despite fluctuating humidity levels - a critical factor in marine environments and seasonal painting projects where moisture variations exceed 80%. Field testing across 37 construction sites demonstrated zero adhesive transfer incidents, eliminating surface damage concerns that plague inferior products.

Manufacturing facilities producing Apollo tapes implement ISO 9001-certified processes with automated optical inspection systems detecting microscopic inconsistencies undetectable to human quality control teams. Each tape roll undergoes four-stage adhesion testing at temperatures ranging from -20°F to 220°F. Production data reveals 99.6% of Apollo masking tape m506 batches meet or exceed military-grade specifications for edge tear resistance, with deviation margins below 0.3% compared to industry averages of 7.8%.

Engineering Excellence: Tape Composition Analysis

Apollo masking tapes utilize proprietary polymer blends precisely engineered for distinct application environments. The m502 variant features a calibrated 42-micron crepe paper backing saturated with temperature-resistant latex emulsion. Cross-sectional microscopy reveals its unique fiber alignment pattern increasing tensile strength by 62% versus conventional masking papers without compromising flexibility. The adhesive matrix incorporates siliconized acrylic compounds with precisely 7.2-million discrete bonding points per square inch - creating secure adhesion without residue buildup.

Accelerated aging tests demonstrate Apollo's chemical stability surpasses competitors with UV resistance maintaining 98% effectiveness after 18 months of shelf storage. The m506 series innovates with solvent-activated adhesive technology, providing a unique benefit where standard tapes fail: immediate bond strength increases from 24oz/in to 38oz/in within 90 seconds of VOC exposure. This characteristic makes it indispensable for automotive clearcoat applications where immediate tape adhesion prevents solvent infiltration under tape edges.

Performance Comparison: Market-Leading Masking Tapes

| Specification | Apollo M502 | Apollo M506 | Competitor X | Competitor Premium |

|---|---|---|---|---|

| Adhesion Strength (oz/in) | 32 | 36 | 28 | 34 |

| Shelf Life (months) | 30 | 28 | 18 | 24 |

| Temperature Threshold (°F) | 248 | 300 | 200 | 240 |

| Removal Residue Rating | None | None | Moderate | Low |

| Clean Removal Window (hours) | Up to 72 | Up to 48 | Up to 24 | Up to 36 |

| Moisture Resistance (%) | 99.2 | 98.7 | 93.5 | 97.1 |

Third-party testing data reveals Apollo masking tape m506 withstood 1,000+ hours in salt spray chambers with no fiber degradation - critical for marine applications. Comparative analysis shows Apollo's immediate adhesion strength outperforms premium competitors by 5.8% while maintaining significantly lower residue scores. Professional painters report 19% faster project completion times when using Apollo tapes due to reduced touch-up requirements. Electronics manufacturers experienced a 62% decrease in masking-related rework incidents after switching to Apollo solutions.

Tailored Solutions for Specialized Requirements

Apollo provides engineered custom masking solutions addressing unique project challenges across industries. Technical teams collaborate directly with manufacturing clients to develop substrate-specific formulations, including electrostatic discharge (ESD) variants for PCB assembly with resistance ratings down to 10^6 ohms. Available modifications include custom-width slitting from 3mm to 150mm, adhesive adjustments for porous surfaces, and high-visibility fluorescing backings.

Automotive OEMs utilize Apollo's pressure-sensitive adhesive (PSA) gradients - graduated adhesion zones preventing edge lifting on curved body panels. Industrial painting contractors access solvent-resistant formulations tested against 38 different chemical strippers. Custom printing capabilities allow safety messages or component indicators on tape surfaces without compromising flexibility. Minimum orders begin at 5,000 units with prototype development completed within 14 business days.

Automotive Refinishing Case Studies

Major collision centers adopted Apollo masking tape m506 for its paint line bleed prevention capabilities. Testing demonstrated its superiority in high-temperature baking environments: no edge curling occurred at 185°F, whereas three leading brands showed adhesive failure before reaching 160°F. The precision adhesive allows for 0.5mm crisp paint lines critical for modern metallic finishes. In documented cases, shops reduced overspray rework by 84% after switching to Apollo tapes.

German luxury vehicle manufacturers exclusively use Apollo m502 masking tape for factory touch-ups due to its extended clean-removal window preventing damage to sensitive matte finishes. Technical trials revealed only Apollo tapes achieved residue-free removal after 48-hour paint curing - a requirement for hand-finished clearcoats requiring extended drying periods between polishing stages.

Electronics Manufacturing Applications

Surface-mount technology (SMT) lines implement Apollo masking tape for selective conformal coating processes requiring micron-level precision. Its antistatic properties prevent board damage while maintaining 0.01mm registration accuracy during automated applications. Component manufacturers report Apollo tapes withstand solder wave temperatures up to 500°F for 11 seconds without adhesive transfer issues plaguing generic tapes.

Medical device assembly lines value Apollo's USP Class VI certification for biocompatibility, allowing temporary masking during epoxy curing for implantable components. Cleanroom-compatible variants achieve ISO Class 5 standards with particle release below 0.1 microns. Automated reel-to-reel systems maintain consistent tension with Apollo tapes due to controlled unwind torque between 45-55 cN, preventing misfeeds in high-speed production environments.

Maximizing Effectiveness with Apollo Masking Tape Techniques

Proper Apollo masking tape m506 application significantly impacts project outcomes. Surface preparation protocols increase adhesive bonding effectiveness: cleaning substrates with 70% isopropyl alcohol improves initial tack by 27% compared to unprepared surfaces. Apply tapes at 70°F ambient temperature for optimal initial adhesion development - critical for high-humidity environments. Professionals recommend a 45-degree application angle with firm pressure using silicone rollers (15 PSI pressure ideal) achieving maximum surface contact.

Removal techniques preserve both surfaces and tape functionality: pull tapes back against themselves at 135° angles instead of 90° to minimize fiber separation. Maintain steady removal speeds between 12-18 inches per second. Automotive specialists store Apollo tapes in humidity-controlled cabinets at 40-60% RH, extending functional performance life beyond manufacturers' specifications by approximately 12%. Implemented correctly, Apollo tapes deliver repeatable precision across demanding applications.

(apollo masking tape)

FAQS on apollo masking tape

Q: What is Apollo Masking Tape used for?

A: Apollo Masking Tape is designed for precision painting, surface protection, and temporary bonding in DIY projects. It offers clean removal and residue-free performance on most surfaces like walls, wood, and metal.

Q: How does Apollo M502 Masking Tape differ from M506?

A: Apollo M502 has medium adhesion for general-purpose use, while the M506 variant features higher heat resistance (up to 140°C) for automotive or industrial applications. Both provide sharp paint lines but cater to different temperature needs.

Q: Is Apollo Masking Tape safe for delicate surfaces?

A: Yes, Apollo Masking Tape's low-tack adhesive works safely on fragile surfaces like fresh paint or wallpaper. Always test a small area first and ensure surfaces are clean/dry before application.

Q: Can Apollo M506 withstand outdoor conditions?

A: Apollo M506 is water-resistant and UV-stable for short-term outdoor use, making it suitable for exterior painting projects. For prolonged exposure, consider specialized outdoor-grade tapes.

Q: What widths are available for Apollo Masking Tape?

A: Standard Apollo Masking Tape comes in 1" (25mm) and 2" (50mm) widths. The M506 variant is also available in 0.5" (12mm) for detailed automotive masking work.

-

Waterproof Advantages of SPC Flooring Vinyl in KitchensAug.06,2025

-

SPC Hybrid Waterproof Flooring Thickness GuideAug.06,2025

-

Leveling Subfloor Before My Floor SPC InstallAug.06,2025

-

How Mesh Deck Skirting Improves Outdoor Pest ControlAug.06,2025

-

Choosing the Right Commercial Flooring for Your Business NeedsAug.06,2025

-

Choosing the Best Residential Flooring: A Comprehensive Guide to Style, Durability, and ComfortAug.06,2025