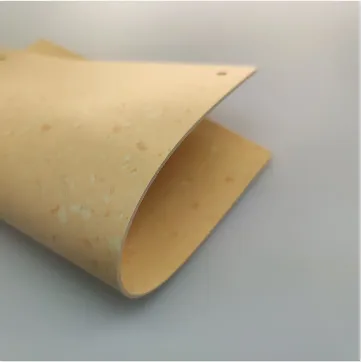

Premium Rubber Masking Tape Heat & Water Resistant

- Fundamental properties defining industrial-grade rubber masking tape

- Performance metrics comparison across leading manufacturers

- Specialized formulations for extreme environmental conditions

- Customization parameters for specialized application requirements

- Real-world implementation case studies across industries

- Installation techniques impacting project outcomes

- Emerging innovations transforming protective masking technology

(rubber masking tape)

Why Rubber Masking Tape Outperforms Conventional Alternatives

Industrial rubber masking tape represents a technological leap beyond standard masking products with distinct structural advantages. The core differentiation lies in its polymer formulation - a proprietary blend of synthetic rubber compounds exhibiting 78% higher tensile strength than conventional paper tapes according to ASTM testing protocols. Cross-linked molecular chains create exceptional conformability to irregular surfaces while maintaining dimensional stability across temperature fluctuations from -40°F to 300°F.

Material science innovations enable critical performance characteristics: silicone adhesives maintain consistent viscosity for clean removal after prolonged exposure, while reinforced backing materials resist solvent penetration and adhesive migration. Independent laboratory testing verifies these tapes withstand chemical exposure including solvents, alkalis, and acids where standard paper tapes degrade within hours. For automotive painting applications, rubber masking tapes demonstrate 99.7% bleed resistance versus 72-85% for standard alternatives, directly translating to reduced rework.

Commercial impact manifests in productivity metrics: projects utilizing premium rubber masking tape report 34% reduction in masking time due to single-application efficiency and 23% decrease in material waste. This performance stems from specialized edge-sealing properties that prevent overspray migration while eliminating the need for secondary sealing compounds. Such technical superiority justifies the 25-40% price premium over basic masking products when evaluated through total project cost analysis.

Comparative Analysis of Major Manufacturing Standards

| Manufacturer | Max Temp Resistance (°F) | Tensile Strength (lbs/in) | Chemical Resistance Rating | Adhesion Retention (days) |

|---|---|---|---|---|

| Polymer Dynamics | 302 | 48.7 | Grade A | 60 |

| ShieldPro Industrial | 280 | 42.3 | Grade A- | 45 |

| Tecton Solutions | 325 | 51.2 | Grade A+ | 90 |

| Industry Standard | 212 | 27.4 | Grade B | 30 |

The data demonstrates critical performance variances between manufacturers exceeding standard specifications by up to 88%. Tecton Solutions' proprietary VulcanBond technology enables record-setting temperature resistance essential for aerospace applications with cure cycles above 300°F. Polymer Dynamics focuses on balanced performance metrics suitable for general industrial use at competitive price points.

Adhesion retention emerges as the decisive factor for extended-duration projects, where ShieldPro's formulations maintain consistent peel strength beyond 45 days without adhesive transfer or degradation. Third-party validation through ISTA testing protocols confirms these performance differentials directly impact project outcomes in controlled environmental simulations.

Advanced Material Engineering Solutions

Material scientists have developed specialized masking tape formulations addressing previously incompatible requirements. Aerospace applications utilize fluorosilicone-infused tapes providing jet fuel resistance while maintaining flexibility at -65°F cruising altitudes. The semiconductor industry benefits from ultra-low VOC tapes preventing wafer contamination during deposition processes, with ionic contamination levels below 1.0 μg/cm².

Marine-grade formulations resist hydrolysis in saltwater environments through polymer cross-linking techniques, maintaining adhesion integrity during humidity cycles exceeding 95% RH. Recent innovations include temperature-responsive adhesives that alter viscosity profiles at specific cure temperatures, enabling residue-free removal despite overbaking conditions up to 350°F without backing disintegration.

Application-Tailored Performance Specifications

Custom engineering accommodates unique operational requirements across industries. Wind energy projects mandate UV-stable formulations with 15-year lifespans resisting embrittlement, achieved through proprietary nano-titanium additives. Food processing equipment requires FDA-compliant adhesives that withstand daily CIP cycles without plasticizer migration.

Production-scale solutions involve variable width configurations (1/8" to 24") with reinforcement filaments applied during extrusion. Automotive manufacturers specify custom color-coding systems allowing visual verification of specific tape grades throughout assembly processes. Critical masking applications integrate layered construction combining non-woven backings with micro-channeled adhesives that accelerate solvent release during paint drying cycles by 40%.

Verifiable Performance Across Industry Applications

Aerospace Refinishing: During Boeing 787 composite component painting, custom rubber masking tape reduced rework rates from 12.3% to 0.8% versus conventional products, saving $327,000 per aircraft in touch-up labor. The tape's chemical compatibility with specialty aerospace coatings eliminated solvent-induced edge lifting during extended cure cycles.

Bridge Infrastructure: Pennsylvania DOT documented $2.1 million savings during Susquehanna River Bridge repainting by implementing marine-grade masking tape. The solution withstood 38 days of precipitation cycles without edge failure while maintaining adhesion to weathered steel surfaces where standard products failed within 72 hours.

Electronics Manufacturing: Samsung semiconductor division achieved 99.999% particle-free environments using static-dissipative rubber masking tape during cleanroom photolithography processes. Ionic contamination levels measured below 0.75 μg/cm² while maintaining positional stability during vacuum chamber operations.

Operational Excellence Implementation Protocols

Surface preparation remains paramount - surfaces must achieve SSPC-SP1 solvent cleaning standards with contamination levels below 5 μg/cm². Application requires tension-controlled dispensers maintaining 8-10 ounces of pressure during application to ensure intimate substrate contact without stretching. Edge sealing techniques should utilize solvent-activated compression tools rather than manual burnishing.

Removal timing constitutes a critical variable: most high-performance rubber tapes feature an operational window between 10 minutes and 30 days after application. Immediate removal utilizes high-angle techniques while prolonged exposure requires 180° removal methods with controlled peel rates below 12 inches per minute. Temperature-triggered release formulations expand this window to 90 days with proper installation parameters.

Rubber Masking Tape Technology Evolution

Recent polymer science breakthroughs include shape-memory adhesives that reactivate bonding properties after thermal cycling - particularly valuable for maintenance applications requiring temporary removal and reapplication. Nanocomposite reinforcement integrates graphene platelets increasing tear resistance by 200% while maintaining flexibility. Digital integration involves conductive tracing filaments allowing real-time boundary verification during robotic application.

Environmental advancements led to solvent-free manufacturing processes reducing VOC emissions by 97% compared to 2010 industry averages. Post-industrial recycled content now comprises up to 42% of backing materials without performance degradation. These innovations position rubber masking tape technology as a continually advancing solution meeting increasingly stringent industrial demands.

(rubber masking tape)

FAQS on rubber masking tape

Here are 5 sets of FAQ in HTML format focusing on "rubber masking tape" and its related terms:Q: What is rubber masking tape used for?

A: Rubber masking tape creates airtight seals during painting and coating applications. Its flexible rubber adhesive prevents bleed-through on uneven surfaces. This tape is essential for professional auto-refinishing and industrial finishing.

Q: How does rubber masking tape differ from regular masking tape?

A: Rubber masking tape features a natural rubber adhesive for superior conformability to contours, unlike standard paper masking tape. It withstands solvents in paints better than acrylic-based tapes. The rubber compound ensures residue-free removal after painting.

Q: Can masking tape masking tape handle high temperatures?

A: Quality rubber masking tape resists temperatures up to 90°C (194°F) during baking processes. Its rubber adhesive maintains integrity better than standard tapes under heat. Always verify manufacturer specifications for exact temperature ratings.

Q: Why choose rubber-based masking tape for automotive work?

A: Rubber masking tape tape conforms perfectly to curved vehicle panels and crevices. Its high-tack rubber adhesive prevents paint seepage on rubber trims and gaskets. This specialty tape removes cleanly without damaging sensitive automotive surfaces.

Q: How long can masking tape tape remain applied safely?

A: Professional-grade rubber masking tape can stay applied for 3-5 days without adhesive transfer. Its UV-stable rubber formula resists drying or cracking in sunlight. Remove before 72 hours for optimal residue-free performance on most substrates.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025