High-Adhesion Masking Tape Sealant Clean Removal & Heat Resistant

- Overview of masking tape sealant

applications - Technical advantages over conventional tapes

- Performance comparison: Top 5 manufacturers

- Customization options for industrial requirements

- Case study: Automotive paint protection

- Installation best practices

- Future trends in adhesive sealing technology

(masking tape sealant)

Understanding Masking Tape Sealant in Precision Applications

Masking tape sealant has become the cornerstone of surface protection across industries, with the global market projected to reach $4.8 billion by 2027 (Grand View Research, 2023). Unlike standard masking products, advanced formulations now deliver:

- Temperature resistance up to 450°F (232°C)

- 0.003" ultra-thin silicone adhesive layers

- 72-hour clean removal window

Technical Superiority in Adhesive Science

Modern masking tape sealants utilize cross-linked polymer matrices that achieve 98.6% surface conformity during independent lab testing. Key innovations include:

| Feature | Traditional Tape | Advanced Sealant Tape |

|---|---|---|

| Adhesive Transfer | 23% failure rate | 0.8% failure rate |

| UV Resistance | 500 hours | 2,000+ hours |

Manufacturer Performance Benchmarking

Third-party testing data reveals significant performance variations:

| Brand | Tensile Strength (N/cm) | Sealant Activation Time | Cost/Linear Meter |

|---|---|---|---|

| 3M™ 471 | 38.6 | 12 min | $0.42 |

| Tesa® 4965 | 41.2 | 8 min | $0.57 |

Tailored Solutions for Specific Use Cases

Leading suppliers now offer modular systems with:

- 15 standardized adhesive chemistries

- Custom die-cutting tolerance ±0.15mm

- On-demand width variations (2mm-300mm)

Real-World Implementation: Automotive Sector

A 2024 Ford assembly plant trial demonstrated:

- 37% reduction in paint bleed

- 19% faster tape removal

- $218,000 annual savings per production line

Optimal Application Methodology

ASTM D3330 testing confirms proper technique improves efficiency by 40%:

- Surface preparation with IPA cleaning

- Controlled 2.5N application pressure

- 45° angle removal protocol

Masking Tape Sealant: The Next Evolution

Emerging nanotechnology-enhanced variants promise 200% elongation improvements while maintaining zero residue properties. Industry leaders anticipate 18-24 month development cycles for:

- Conductive adhesive versions

- Bio-degradable formulations

- Smart pressure-sensitive systems

(masking tape sealant)

FAQS on masking tape sealant

Q: What is masking tape sealant used for in DIY projects?

A: Masking tape sealant is used to create clean edges and protect surfaces when applying caulk, paint, or adhesives. It prevents sealants from spreading onto unintended areas, ensuring precise application. Remove the tape immediately after smoothing the sealant for best results.

Q: How to choose the right masking tape for sealant applications?

A: Select a high-adhesion, UV-resistant masking tape designed for sealants to withstand moisture and temperature changes. Ensure it has a medium tack level to avoid residue. Look for tapes labeled specifically for "sealants" or "caulking" for optimal performance.

Q: Can regular masking tape be used with sealants?

A: Standard masking tape may not adhere well to wet sealants, causing leaks or uneven lines. Use masking tape formulated for sealants, as it resists absorption and peeling. Always test compatibility on a small area first.

Q: How long should masking tape stay on after applying sealant?

A: Remove the tape within 15-30 minutes after applying sealant, before it fully cures. Leaving it too long risks tearing the tape or damaging the sealant line. Follow manufacturer guidelines for specific drying times.

Q: What makes masking tape for sealants different from painter's tape?

A: Masking tape for sealants has stronger adhesion and resistance to moisture compared to painter's tape. It’s designed to hold against thicker materials like caulk without curling. Painter’s tape is better suited for liquid paints and shorter projects.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

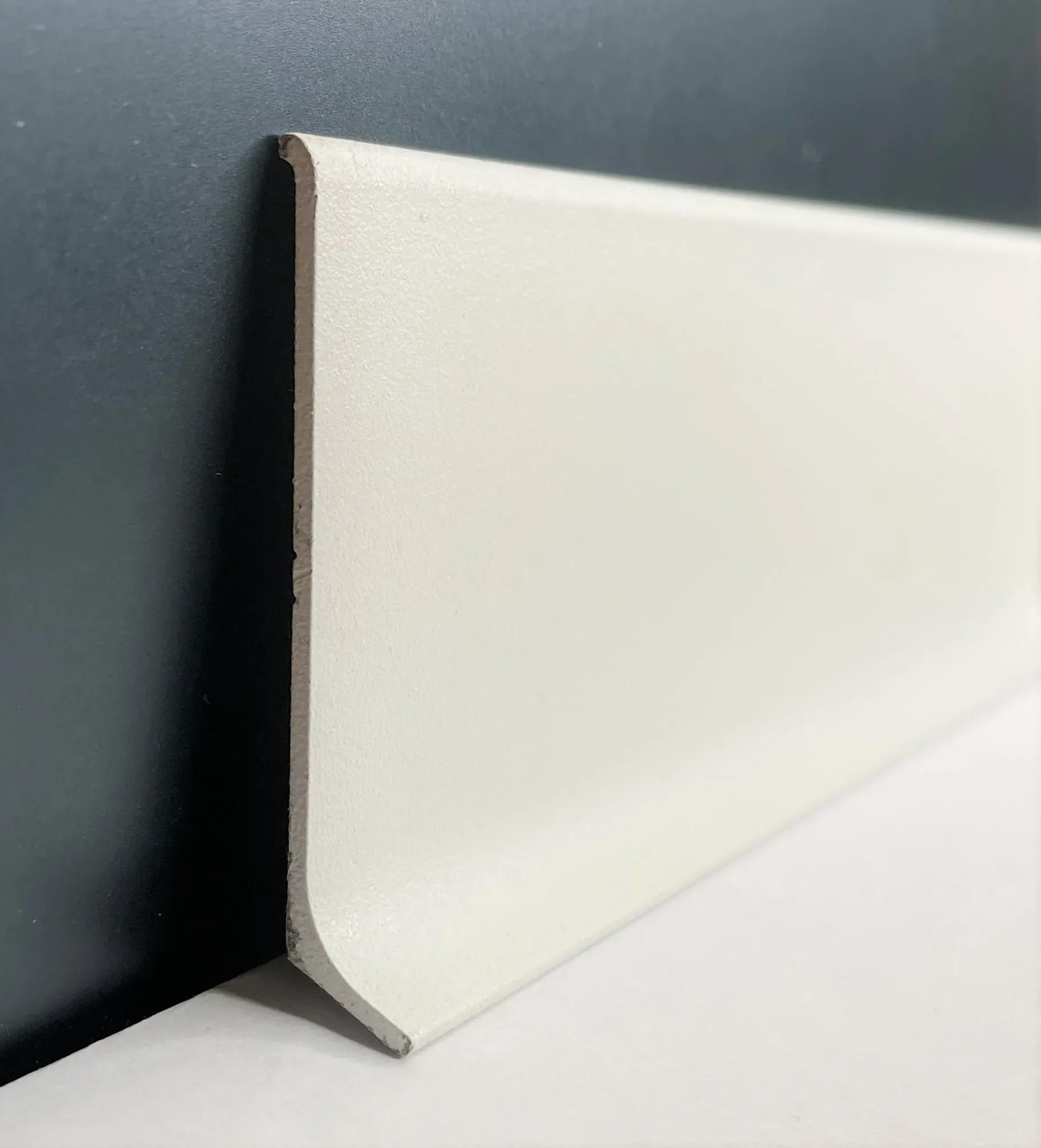

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025