Premium Heterogeneous Vinyl Flooring: Durable & Diverse Designs

The Evolution of High-Performance Flooring: Industry Trends in heterogeneous viny

The B2B flooring market is currently experiencing a significant shift towards materials that offer superior durability, aesthetic versatility, and advanced functional properties. In this landscape, heterogeneous viny has emerged as a frontrunner, particularly its advanced forms like the heterogeneous floor with Stariver surface. Key industry trends indicate a growing demand for flooring solutions that not only withstand extreme conditions but also contribute to a healthier, more sustainable built environment.

Decision-makers in sectors ranging from healthcare to heavy industrial facilities are prioritizing products that combine low lifecycle costs with high-performance attributes. This includes enhanced slip resistance, superior acoustic damping, robust chemical resistance, and minimal maintenance requirements. The emphasis on indoor air quality (IAQ) and eco-friendly manufacturing processes further drives innovation, pushing manufacturers to develop materials that are phthalate-free, low-VOC, and recyclable. Furthermore, the digital integration of building information modeling (BIM) is influencing product specifications, requiring detailed technical data and verifiable performance metrics to facilitate smarter project planning and execution.

This article delves into the technical intricacies, application advantages, and market positioning of advanced heterogeneous vinyl flooring solutions, providing critical insights for procurement and engineering professionals.

Understanding the Structure and Manufacturing of Heterogeneous Viny

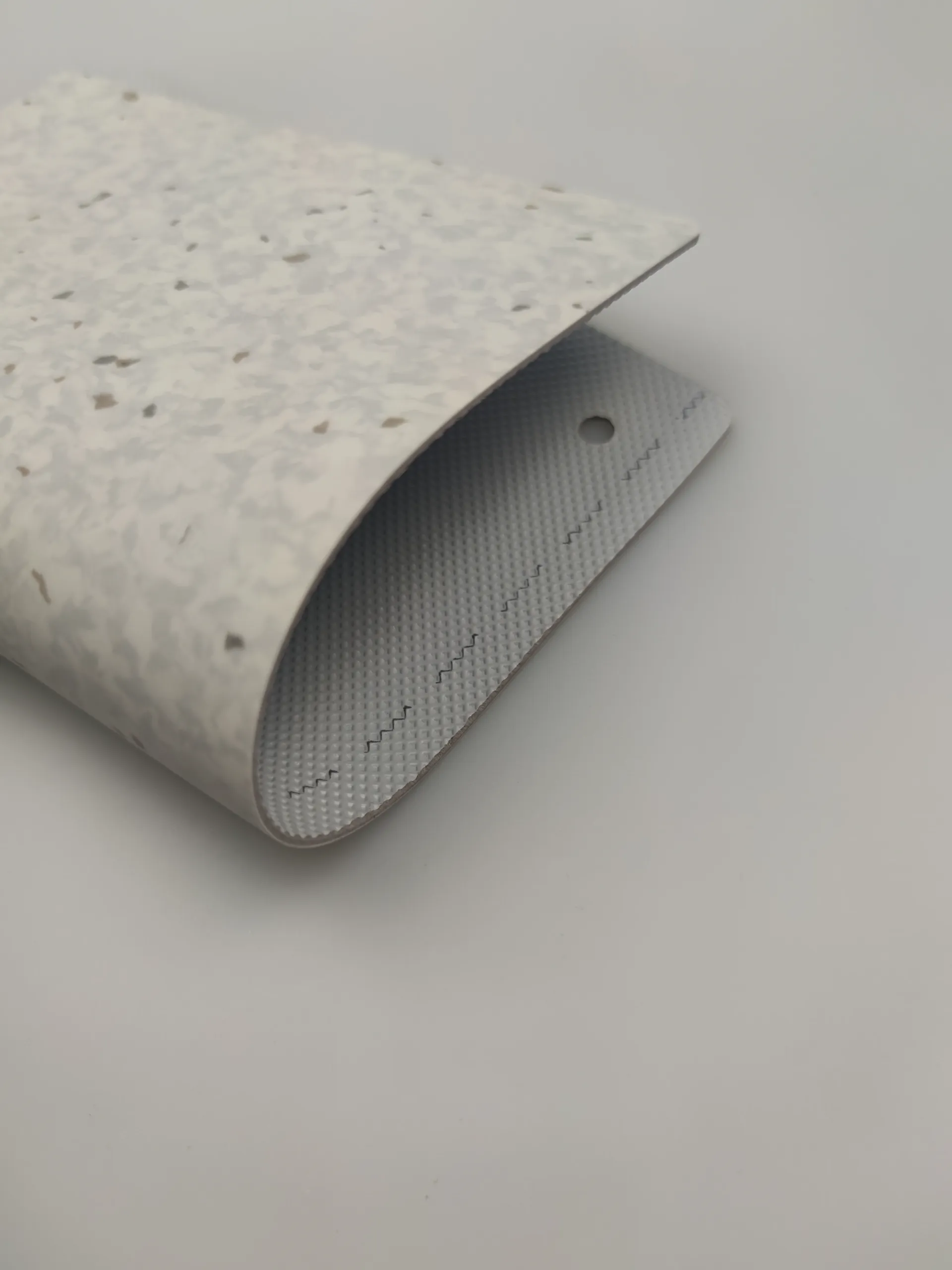

Heterogeneous viny refers to a multi-layered vinyl flooring product, distinct from homogeneous vinyl due to its composite structure. Each layer serves a specific function, engineered to deliver optimal performance characteristics. A typical heterogeneous vinyl sheet consists of a compact backing layer, a fiberglass reinforcement layer for dimensional stability, a printed decorative layer, and a clear wear layer, often enhanced with a specialized surface treatment like Stariver.

Manufacturing Process Flow: From Raw Material to Finished Product

The manufacturing of high-quality heterogeneous vinyl sheet involves a meticulously controlled process to ensure consistent product integrity and performance. The primary materials include polyvinyl chloride (PVC) resins, plasticizers (increasingly bio-based or non-phthalate), stabilizers, fillers (e.g., calcium carbonate), pigments, and reinforcing agents like fiberglass.

- Raw Material Blending: PVC resin, plasticizers, stabilizers, and fillers are precisely measured and mixed to create the base compound. This step is critical for achieving desired flexibility, density, and chemical resistance.

- Base Layer Extrusion/Casting: The compound is then extruded or cast into a dense, compact backing layer, forming the foundation of the sheet. This layer contributes significantly to the flooring's indentation resistance and overall robustness.

- Fiberglass Reinforcement: A fiberglass scrim or mesh is integrated into the structure, often laminated between two PVC layers. This reinforcement is paramount for dimensional stability, minimizing expansion and contraction under varying temperature and humidity conditions, a key advantage for large-scale installations.

- Print Layer Application: High-resolution designs and colors are applied to the surface, creating the aesthetic appeal. Modern techniques allow for intricate patterns, including wood, stone, or abstract designs, with exceptional clarity.

- Wear Layer Application: A transparent wear layer, typically made of pure PVC, is then applied over the print layer. The thickness of this layer (e.g., 0.5mm, 0.7mm) directly correlates with the product's durability and suitability for heavy traffic areas.

- Surface Treatment (Stariver Surface): For enhanced performance, a specialized surface treatment, such as the Stariver surface technology, is applied. This involves advanced coating formulations that improve scratch resistance, reduce maintenance efforts, and provide superior resistance to scuffing and staining.

- Curing and Finishing: The multi-layered sheet undergoes a curing process, often involving heat, to bond the layers permanently. It is then cooled, trimmed, and rolled.

- Quality Control & Testing: Throughout the process, rigorous testing is conducted. This includes adherence to international standards such as ISO 10582 for heterogeneous polyvinyl chloride floor coverings, EN 649, ASTM F1303, and CE certification for health, safety, and environmental protection. Tests cover parameters like indentation resistance, dimensional stability, slip resistance (e.g., R9-R11), fire resistance (e.g., Bfl-s1), chemical resistance, and abrasion resistance.

This structured approach ensures that each roll of heterogeneous sheet vinyl meets stringent performance criteria, providing a service life often exceeding 15-20 years in appropriate applications, reducing overall lifecycle costs for target industries like healthcare, education, retail, and light industrial.

Visual representation of heterogeneous vinyl layer structure.

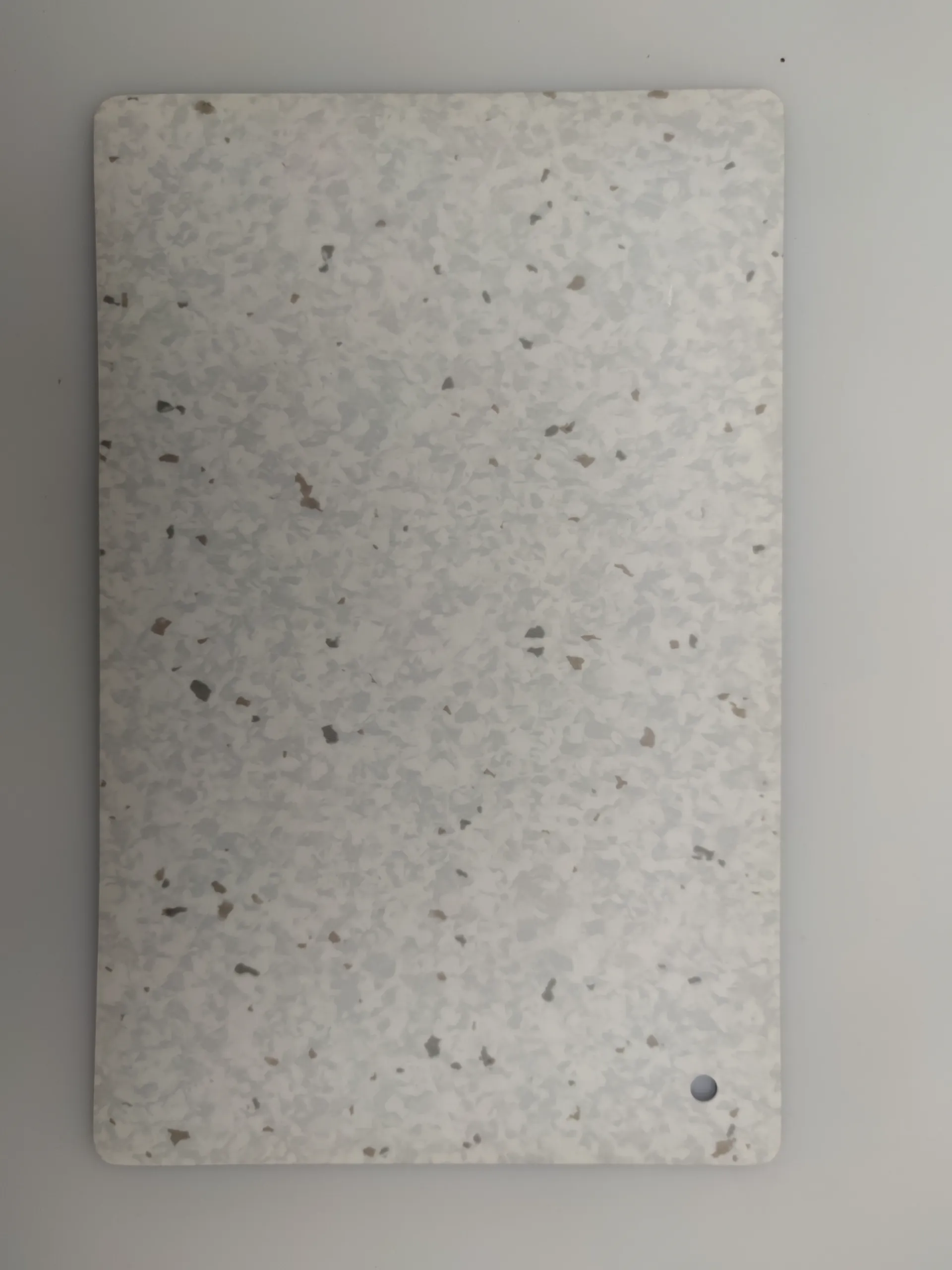

Technical Specifications: Enlio's Heterogeneous Floor with Stariver Surface

Understanding the precise technical parameters is crucial for specifying the correct flooring solution for demanding B2B environments. Enlio's heterogeneous floor with Stariver surface exemplifies advanced engineering in heterogeneous vinyl sheet, offering a balanced combination of durability, safety, and aesthetic appeal. Below is a detailed table outlining key specifications:

Product Specification Table

| Parameter | Specification (Stariver Surface) | Standard/Method |

|---|---|---|

| Product Type | Heterogeneous Vinyl Floor Covering | EN ISO 10582 |

| Total Thickness | 2.0 mm / 3.0 mm (typical) | EN 428 |

| Wear Layer Thickness | 0.5 mm / 0.7 mm | EN 429 |

| Format | Rolls (e.g., 2m x 20m) | Manufacturer Specific |

| Weight | ~2800 g/m² - 3200 g/m² | EN 430 |

| Slip Resistance | R9 - R10 (Dry) | EN 13893 (DS) / DIN 51130 |

| Fire Resistance | Bfl-s1 (low smoke emission) | EN 13501-1 |

| Dimensional Stability | ≤ 0.15% | EN 434 |

| Indentation Resistance | Residual Indentation ≤ 0.10 mm | EN 433 |

| Abrasion Group | T (Very Heavy Commercial/Light Industrial) | EN 660-2 |

| Chemical Resistance | Excellent against diluted acids, alkalis, oils | EN 423 |

| Acoustic Insulation | ΔLw ~ 17 dB (for 2.0mm) | EN ISO 717-2 |

| Anti-bacterial/fungal | Yes | ISO 22196 |

| Underfloor Heating Compatibility | Suitable (Max 27°C surface temp) | Manufacturer Guidelines |

These parameters underscore the robust engineering of this flooring type, making heterogeneous viny an optimal choice for areas requiring stringent performance and hygiene standards.

Technical Advantages of Heterogeneous Sheet Vinyl

The multi-layered composition of heterogeneous vinyl sheet grants it a distinct set of technical advantages that are highly valued in commercial and industrial settings:

- Superior Dimensional Stability: The integrated fiberglass reinforcement layer significantly mitigates issues of expansion and contraction due to temperature fluctuations, ensuring a long-lasting, smooth floor surface without gapping or buckling. This is critical in large installations where subfloor movement needs to be minimized.

- Enhanced Wear Resistance: A thick, transparent wear layer, especially when fortified with advanced surface treatments like Stariver, offers exceptional resistance to abrasion, scratches, and scuff marks. This extends the aesthetic and functional life of the flooring, even in high-traffic environments.

- Outstanding Indentation Recovery: The dense backing layer and robust composition provide excellent resistance to permanent indentation from heavy static loads or rolling traffic, maintaining a pristine surface appearance over time.

- Excellent Chemical Resistance: The non-porous surface and PVC composition make it highly resistant to a wide range of chemicals, including acids, alkalis, oils, and common cleaning agents. This advantage is paramount in healthcare, laboratories, and manufacturing facilities where spills are frequent.

- Hygienic and Easy to Maintain: The seamless installation (when hot-welded) and non-porous nature of heterogeneous sheet vinyl prevent the ingress of dirt, bacteria, and moisture. This facilitates easy cleaning and disinfection, crucial for sterile environments. The Stariver surface further reduces the need for aggressive cleaning chemicals and waxing, contributing to lower maintenance costs and energy saving.

- Acoustic Comfort: The multi-layered structure provides good sound absorption properties, reducing impact sound and ambient noise within a space. This is a significant benefit for educational institutions, offices, and healthcare facilities.

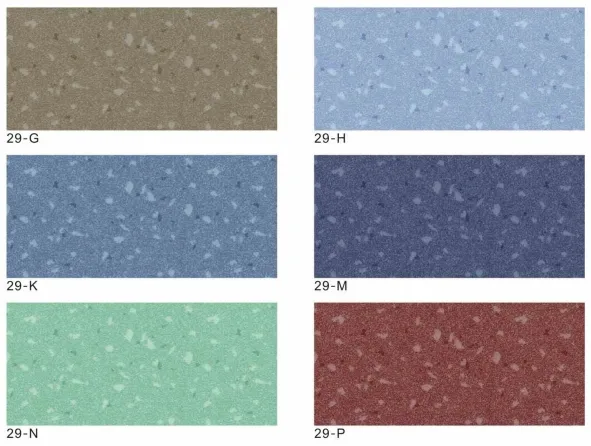

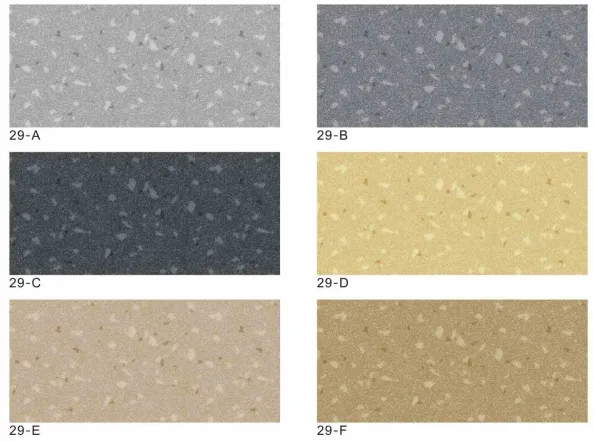

- Design Flexibility: The print layer allows for an almost limitless array of designs, colors, and patterns, enabling architects and designers to achieve specific aesthetic goals without compromising on performance.

- Corrosion Resistance: Unlike some metallic or more porous flooring options, PVC-based heterogeneous vinyl is inherently resistant to moisture and many corrosive substances, making it ideal for wet areas or environments with chemical exposure.

Example of homogeneous vinyl (left) versus heterogeneous vinyl (right) showing layered structure.

Application Scenarios and Target Industries

The robust performance and versatile design of heterogeneous viny make it suitable for a broad spectrum of commercial and industrial applications. Its ability to meet stringent regulatory requirements while providing aesthetic flexibility positions it as a preferred choice across various sectors.

- Healthcare Facilities: Hospitals, clinics, laboratories, and eldercare homes require flooring that is extremely hygienic, easy to clean, slip-resistant, and comfortable underfoot. The anti-bacterial properties, chemical resistance, and seamless installation (via hot welding) of heterogeneous vinyl sheet minimize infection risks and facilitate rigorous cleaning protocols. Its acoustic properties also contribute to a quieter healing environment.

- Educational Institutions: Schools, universities, and daycare centers benefit from flooring that can withstand heavy foot traffic, spills, and impact. The durability, stain resistance, and ease of maintenance of heterogeneous vinyl contribute to long-term cost savings and a conducive learning environment.

- Retail and Commercial Spaces: High-end retail stores, supermarkets, offices, and public buildings demand flooring that is both aesthetically pleasing and capable of enduring continuous customer traffic. The design versatility, coupled with superior wear resistance and low maintenance, makes it an ideal choice for creating inviting and durable spaces.

- Light Industrial and Manufacturing: Areas requiring good chemical resistance, indentation resistance, and easy cleaning, such as pharmaceutical production lines, clean rooms, and light assembly areas, find heterogeneous viny to be a highly functional solution. Its corrosion resistance is particularly advantageous in environments exposed to various industrial liquids.

- Hospitality Sector: Hotels, restaurants, and conference centers benefit from flooring that offers both elegance and resilience. The design options, combined with acoustic comfort and ease of cleaning, enhance guest experience and operational efficiency.

- Sports and Recreation: While specialized sports flooring exists, certain areas in gyms or multi-purpose halls can utilize robust heterogeneous vinyl for its durability and impact resistance. Enlio, known for its expertise in sports surfaces, applies similar rigorous quality standards to its commercial offerings like the Stariver surface.

In these scenarios, the long service life and low maintenance requirements of advanced heterogeneous sheet vinyl translate directly into significant energy saving and operational cost reductions over the lifecycle of the building.

Vendor Comparison: Differentiating High-Performance Heterogeneous Vinyl

When selecting a provider for heterogeneous vinyl, B2B decision-makers must evaluate vendors based on product innovation, technical specifications, certifications, and service reliability. While many manufacturers offer heterogeneous vinyl, advanced solutions like Enlio's heterogeneous floor with Stariver surface stand out due to specific technological enhancements.

Comparison Table: Enlio Stariver Surface vs. Standard Heterogeneous Vinyl

| Feature | Enlio Heterogeneous Floor (Stariver Surface) | Standard Heterogeneous Vinyl | Impact on TCO & Performance |

|---|---|---|---|

| Surface Treatment | Stariver Advanced PUR Treatment | Standard PUR or no specific treatment | Significantly enhanced scratch, stain, and scuff resistance; reduced maintenance costs (no waxing/polishing often needed). |

| Wear Layer Thickness Options | 0.5mm, 0.7mm for heavy commercial/light industrial | Typically 0.35mm - 0.5mm for commercial use | Longer lifespan in high-traffic areas, superior durability against mechanical wear. |

| Environmental Certifications | ISO 14001, CE, FloorScore/REACH compliant, Low VOC, Phthalate-free | May vary, often basic CE compliance | Ensures healthier indoor air quality, compliance with green building standards, and reduced environmental impact. |

| Dimensional Stability | ≤ 0.15% (Fiberglass reinforced) | ≤ 0.25% (May lack robust reinforcement) | Prevents gapping, curling, and buckling, ensuring a smooth, long-lasting installation. |

| Antimicrobial Properties | Integrated antimicrobial agents (ISO 22196) | Basic or none | Crucial for healthcare and educational settings, inhibiting bacterial growth. |

| Typical Warranty | 10-15 years commercial | 5-10 years commercial | Indicates manufacturer confidence in product longevity, reducing long-term replacement costs. |

Brands like Enlio focus on continuous innovation, integrating technologies such as Stariver to deliver superior Total Cost of Ownership (TCO) through extended lifespan and reduced maintenance. While 'hawk flooring' might be a generic term or a specific regional brand, the key differentiator remains the adherence to international standards and the incorporation of advanced surface treatments and structural enhancements.

Precision manufacturing line for heterogeneous vinyl flooring.

Customized Solutions and Application Case Studies

The flexibility of heterogeneous viny extends beyond standard product offerings. Manufacturers like Enlio work closely with clients to provide customized solutions that meet unique project requirements, from specific color matching and intricate pattern designs to tailored performance characteristics for highly specialized environments.

Customization Capabilities:

- Bespoke Aesthetics: Custom print layers allow for company logos, specific color palettes, or unique graphic patterns to be incorporated, reinforcing brand identity within a space.

- Enhanced Performance Layers: For extreme environments, adjustments can be made to wear layer thickness, slip resistance ratings (e.g., R11 for wet areas), or even additional acoustic backing layers.

- Specific Material Formulations: While maintaining core properties, minor adjustments to raw material blends can optimize characteristics like static dissipation or enhanced chemical resistance for niche applications.

Application Case Studies & Customer Feedback:

Case Study 1: Major Regional Hospital Network, Healthcare Sector

Challenge: The hospital required a flooring solution for high-traffic corridors and patient rooms that could withstand constant foot and rolling equipment traffic, rigorous cleaning protocols, and provide excellent hygiene and acoustic comfort.

Solution: Enlio's heterogeneous floor with Stariver surface (2.0mm total, 0.7mm wear layer) was installed across 15,000 m². The specific formulation was chosen for its ISO 22196 compliant antimicrobial properties, superior chemical resistance to hospital-grade disinfectants, and Bfl-s1 fire rating.

Outcome: After 3 years, the flooring shows minimal signs of wear and tear. The Stariver surface has significantly reduced maintenance time by 25% compared to previous flooring, contributing to lower operational costs. Facilities Manager feedback: "The Enlio Stariver floor has exceeded our expectations. Its durability and ease of sanitation are critical for patient safety and our operational efficiency. The acoustic dampening has also been noticeably better."

Case Study 2: National University Campus, Education Sector

Challenge: The university sought a durable, aesthetically versatile, and low-maintenance flooring for lecture halls, libraries, and administrative offices across its expanding campus, requiring a vibrant yet resilient solution.

Solution: Custom designs of Enlio's heterogeneous sheet vinyl were supplied, integrating the university's color scheme into the print layer. The 2.0mm thick material with a 0.5mm wear layer offered the required balance of durability and comfort for student and staff areas.

Outcome: The installation in 20,000 m² of space has proven highly successful. The flooring provides excellent sound reduction, which is vital in lecture environments. The facility team reports that the floors are robust against heavy student traffic and general wear, requiring only routine cleaning. "The ability to customize the design with our institutional colors was a huge plus," stated the Project Coordinator. "And the performance in high-traffic zones has been flawless."

Seamless heterogeneous vinyl installation in a commercial setting.

Ensuring Quality: Certifications, Authoritative References, and Trustworthiness

For B2B procurement, certifications and verifiable data are paramount indicators of product quality and supplier trustworthiness. Enlio's commitment to excellence in heterogeneous viny is underpinned by adherence to rigorous international standards and transparent operational practices.

Authoritative References & Certifications:

- ISO 9001:2015: Certified Quality Management System, ensuring consistent product and service delivery.

- ISO 14001:2015: Certified Environmental Management System, demonstrating commitment to sustainable manufacturing processes.

- CE Marking: Compliance with European health, safety, and environmental protection standards for products sold within the EEA.

- EN 14041: Declaration of Performance in accordance with the Construction Products Regulation (CPR).

- ASTM F1303: Standard Specification for Sheet Vinyl Floor Covering, fully compliant.

- FloorScore Certification: Validates low VOC emissions, contributing to better indoor air quality.

- REACH Compliance: Adherence to European regulations on the Registration, Evaluation, Authorisation, and Restriction of Chemicals.

- ISO 22196: Measurement of antibacterial activity on plastic surfaces.

- Strategic Partnerships: Enlio boasts a track record of successful partnerships with major construction firms, public institutions, and international distributors, reflecting years of trusted service and proven product performance.

Lead Time, Warranty, and After-Sales Support:

- Lead Time/Fulfillment: Standard orders for Enlio's heterogeneous floor with Stariver surface typically have a lead time of 2-4 weeks, depending on volume and customization. Expedited options are available for urgent projects. Our robust supply chain and manufacturing capacity ensure timely delivery and reliable fulfillment.

- Warranty Commitments: Enlio provides a comprehensive 10-15 year commercial warranty for its Stariver heterogeneous vinyl, subject to proper installation and maintenance as per manufacturer guidelines. This warranty covers manufacturing defects and premature wear under normal use.

- Customer Support: Our dedicated B2B support team offers extensive pre-sales consultation, technical assistance during installation, and comprehensive after-sales service. This includes detailed product data sheets, installation guides, maintenance protocols, and direct access to technical experts to address any inquiries or support needs.

Frequently Asked Questions (FAQ)

Q1: What is the primary difference between homogeneous and heterogeneous viny?

A1: Homogeneous vinyl is a single layer of material throughout its thickness, offering uniform wear characteristics. Heterogeneous viny, like Enlio's Stariver surface, is composed of multiple distinct layers (backing, fiberglass, print, wear layer) engineered for specific functions, providing enhanced dimensional stability, design versatility, and specialized surface performance attributes. This multi-layered approach often leads to superior performance in specific areas such as indentation recovery and reduced maintenance.

Q2: How does the Stariver surface technology enhance the flooring's performance?

A2: The Stariver surface is an advanced Polyurethane (PUR) treatment integrated into the wear layer. It significantly improves resistance to scratches, scuffs, stains, and chemical agents. This specialized treatment also creates a smoother, denser surface that repels dirt, making cleaning and maintenance significantly easier and reducing the need for waxing or polishing, thereby lowering operational costs.

Q3: Is Enlio's heterogeneous vinyl sheet suitable for environments with heavy rolling loads?

A3: Yes, Enlio's heterogeneous floor with Stariver surface is engineered with a dense backing layer and robust wear layer to offer excellent indentation resistance. For specific heavy rolling load applications, we recommend consulting our technical team to select the optimal product thickness and installation method to ensure long-term performance.

Q4: What are the environmental benefits of choosing Enlio's heterogeneous vinyl sheet?

A4: Our heterogeneous vinyl products are designed with sustainability in mind. They are typically phthalate-free, low-VOC (FloorScore certified), and manufactured under ISO 14001 environmental management systems. The long lifespan and low maintenance requirements also contribute to reduced material consumption and energy usage over the product's lifecycle.

Q5: How does Enlio support large-scale B2B projects?

A5: Enlio provides comprehensive support for large-scale projects, including technical consultation, customized product solutions (e.g., specific colors or performance needs), detailed project planning, reliable logistics and fulfillment, and robust after-sales support. Our experienced team works closely with architects, contractors, and facility managers from specification to completion, ensuring seamless integration and optimal performance of our heterogeneous vinyl solutions.

Conclusion: Strategic Choice for Modern Infrastructure

The selection of flooring in B2B environments is a strategic decision impacting operational efficiency, safety, and long-term cost. Heterogeneous viny, particularly advanced formulations like Enlio's heterogeneous floor with Stariver surface, represents a superior solution capable of meeting the rigorous demands of modern commercial and industrial infrastructure.

Its multi-layered construction, enhanced surface treatments, and compliance with global technical and environmental standards provide an unparalleled combination of durability, hygiene, aesthetic flexibility, and low total cost of ownership. For decision-makers prioritizing robust performance, sustainable practices, and long-term value, investing in high-quality heterogeneous sheet vinyl is a choice that yields significant returns.

Citations

- ISO 10582:2016. Resilient floor coverings - Heterogeneous polyvinyl chloride floor coverings - Specification. International Organization for Standardization.

- EN 14041:2004+AC:2006. Resilient, textile and laminate floor coverings - Essential characteristics. European Committee for Standardization.

- ASTM F1303-2017. Standard Specification for Sheet Vinyl Floor Covering with Backing. ASTM International.

- World Health Organization. Guidelines on Hand Hygiene in Health Care. 2009.

- The European Chemical Agency (ECHA). REACH Regulation (EC) No 1907/2006.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025