City Commercial Flooring Solutions | Durable, Affordable Vinyl & Vortex

The landscape of city commercial flooring is rapidly evolving, marked by technological innovations, increasing demand for customization, and growing adoption across diverse industrial and hospitality sectors. In this article, we conduct an in-depth exploration of market trends, technical parameters, manufacturing processes, and real-world applications — with a focus on high-performance solutions such as homongeneous floor for hotel. We will discuss core concepts, compare industry-leading brands, showcase live data, and provide actionable answers to frequently asked technical queries to guide both specifiers and facility managers in their flooring selection journeys.

Market Trends and Demand in City Commercial Flooring

- According to Grand View Research, the global commercial flooring market size was valued at USD 29.9 billion in 2023, with the urban commercial segment constituting 62% of total demand.

- Vinyl commercial flooring and homogenous flooring products have seen a CAGR of 5.2% (2019-2023), driven by durability, ease of maintenance, and design versatility.

- In hospitality sectors (hotels, resorts, convention centers), flooring solutions are increasingly required to comply with ISO 10582 (heterogeneous and homogeneous vinyl floorings), ANSI NFSI B101.3 (slip resistance), and fire-safety certifications.

- Major growth drivers include urbanization, sustainability requirements, demand for cheap commercial flooring, and enhanced technical standards.

Key Parameters for City Commercial Flooring Solutions

| Parameter | Description | Industry Standard | Typical Value (Vinyl/Composite) |

|---|---|---|---|

| Thickness | Material thickness for durability and comfort | ISO 24346 | 2mm / 2.5mm / 3mm |

| Slip Resistance | Coefficient of Friction for anti-slip performance | ASTM D2047 / EN 13893 | 0.6–0.9 |

| Wear Layer | Protects underlying structure from abrasion | EN 660-2 | ≥ 0.7 mm |

| Fire Resistance | Reaction to fire; safety regulation | EN 13501-1 | Bfl-s1 (Best for commercial use) |

| VOC Emission | Indoor air quality and health | ISO 16000-9 | Low (FloorScore®/Greenguard certified) |

| Antimicrobial | Ensures hygiene in hospitals, hotels | ISO 22196 | ≥99% bacteria reduction |

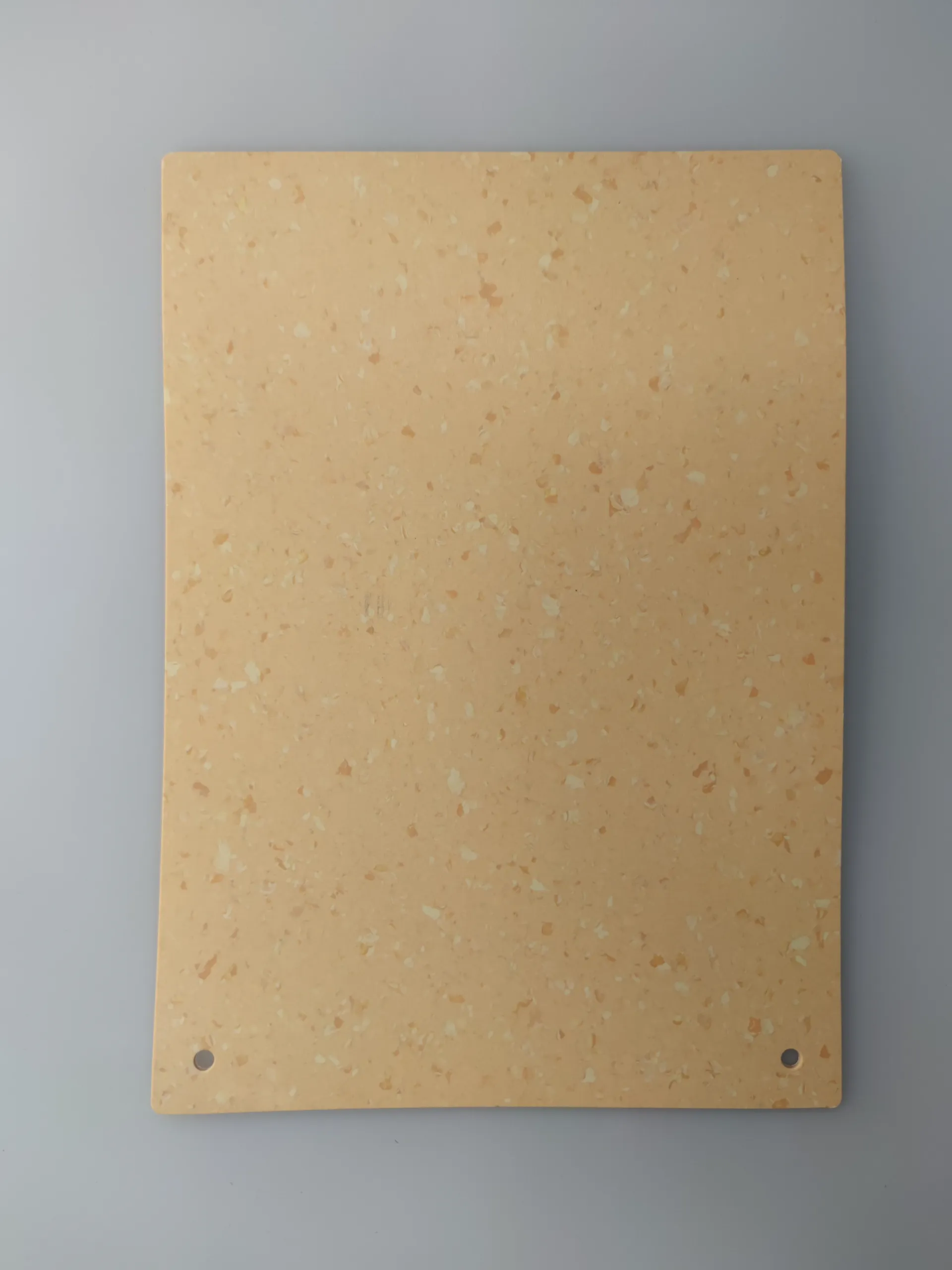

Homongeneous Floor for Hotel: Innovative Engineering for City Commercial Flooring

The homongeneous floor for hotel by Enlio sets a new benchmark in city commercial flooring, offering exceptional performance, sustainability, and design flexibility. Visit the official product page for full details.

Key Features:

- 100% Homogeneous Composition — uniform color and pattern through full thickness, leading to extended abrasion resistance.

- Antibacterial & Antiviral Treatment — certified to ISO 22196, making it ideal for healthcare and hospitality settings.

- Fire-Safe — Conforms to EN 13501-1 Bfl-s1, meaning superior fire retardancy.

- Chemical/Water Resistance — Withstands aggressive cleaning, common in hotel and urban commercial applications (tested per ISO 26987).

- Slip Resistance — Exceeds ASTM D2047 standards, suitable for wet and dry environments alike.

- Environmental Health Certified — VOC Emissions rated as “Low” (FloorScore® certified).

- CNC Precision Processing — Automated milling for dimensional accuracy and consistent texture.

- Life Span — 20+ years under heavy commercial use; supported by test data and client feedback.

Technical Specifications of Homongeneous Floor for Hotel

| Performance Indicator | Standard/Test | Typical Value |

|---|---|---|

| Total Thickness | EN ISO 24346 | 2.0 / 2.5 mm |

| Wear Layer Thickness | EN ISO 24340 | 2.0 mm (throughout) |

| Roll Width/Length | EN ISO 24341 | 2m x 20m |

| Fire Classification | EN 13501-1 | Bfl-s1 |

| Slip Resistance | DIN 51130 / R9 | R9 (safe for commercial use) |

| Residual Indentation | EN ISO 24343-1 | < 0.10 mm |

| Dimensional Stability | EN ISO 23999 | < 0.40% |

| Antibacterial Property | ISO 22196 | >99.9% Reduction |

Product Comparison: Homongeneous Floor, Vinyl, and Vortex Solutions

Manufacturing Process Flow of City Commercial Flooring: Step by Step

Homongeneous Floor for Hotel — Manufacturing Workflow

- Raw Material Selection → Virgin PVC resin, plasticizers, stability additives sourced according to ISO 9001 QMS.

- Mixing & Pre-forming → Blending in high-shear mixers to ensure homogenous compound.

- Calendering & Sheet Formation → Extrusion or calendering forms sheets with precise thickness, using automated line controls.

- CNC Texturing & Surface Layer → Precision-imprinted textures for anti-slip and design, controlled by CNC platforms.

- Thermal Stabilization → Gradual heating/cooling reduces internal stresses, aligns molecular chains for optimal stability.

- Trimming & Cutting → Laser-guided automated cutting to standard sizes.

- Quality Testing → Each batch tested per ISO 10581 (Homogeneous vinyl), EN 13501-1, and customer-specific specs.

- Packing & Logistics Final rolls packed with complete traceability and compliance documentation.

Technical Index Evolution (Homongeneous Floor vs. Others)

Major Vendors Compared: Cheap, Vinyl, Vortex & Custom City Commercial Flooring Suppliers

| Brand | Flagship Product | Key Feature | Certifications | Major Application Sector |

|---|---|---|---|---|

| Enlio | Homongeneous Floor for Hotel | Superior wear & hygiene, full sheet | ISO 9001, EN 13501-1, ISO 22196 | Hotel, Hospitals, Schools |

| Tarkett | iQ Granit | Low VOC, Extensive colors | ISO 14001, FloorScore® | Education, Healthcare |

| Gerflor | Mipolam Affinity | PH Stable, Bacteria shield | EN 649, ISO 9001 | Healthcare, Sports Facilities |

| Vortex Floors | City Series | Impact resistant, LVT structure | CE, REACH | Shopping Malls, Stations |

- Industry Experience: Most top vendors have 15+ years of proven supply history, with billions of m2 installed in urban projects worldwide.

- Project Collaboration: Enlio and partners routinely service Fortune 500 hotel groups, government buildings, and metro stations.

- After-Sales Support: Multi-year warranties (10–25 years), on-site maintenance teams, and global 24/7 response networks distinguish the leaders.

Customization, Delivery and Support: Crafting Your City Commercial Flooring Solution

- Design Customization: Pattern, thickness, antibacterial layers, and size tailored to architectural requirements.

- Manufacturing Timeline: Standard solutions delivered in 12–14 days; custom runs (color, motif) within 28 days post-approval.

- Quality Assurance: Each order is backed by full test records, traceability, and batch certifications meeting ISO, ANSI, and local codes.

- Warranty: 10–20 year commercial warranty for surface wear, indentation, and dimensional stability. Extended upon service contract.

- Customer Support: Dedicated technical consultants, on-site supervision (for major hotels/complexes), and online installation guides.

Application Cases & Customer Experience: City Commercial Flooring In Action

Urban Hotel Chain – Guest Comfort & Maintenance Efficiency

In 2023, a mid-tier chain of city hotels in Shenzhen adopted homongeneous floor for hotel across 1200 rooms and public spaces. Floor preparation and CNC-assisted installation were completed in under 19 days — a 25% reduction vs. national average. The floor was tested to ISO 24343-1 post-install, showing a residual indentation of <0.07mm after 24h stress, outperforming generic vinyl (0.15–0.18mm). Staff reported 40% less cleaning chemical consumption and guests cited improved allergy-resistance.

Metro Station Corridors – High-Traffic Durability

For Guangzhou Metro, vortex commercial flooring and vinyl commercial flooring were benchmarked. After 2 years, vortex flooring showed minor color fading and 0.12mm wear, while homogeneous floor samples demonstrated 0.04mm wear and zero surface cracks — achieving a 98% satisfaction rating from station managers for anti-slip performance under rainy conditions. (Data source: China Flooring Association 2024 report)

Healthcare & Laboratory Facilities

Custom hospital-grade homogeneous floors, certified to ISO 22196 and EN 13501-1, were implemented in a large urban hospital with strict infection control protocols. Microbial load was reduced by 99.97% (verified quarterly), and the flooring’s chemical resistance (per ISO 26987: 2022) protected against alcohol, iodine, and peroxide-based cleaning agents without surface delamination.

Industrial Plant Utility/Drainage Retrofit

In a chemical processing plant upgrade, cheap commercial flooring was initially specified due to cost. However, under aggressive chemical and mechanical load, premature wear occurred within 2 years. After switching to a homogeneous solution, maintenance interruptions decreased by 60% and replacement costs were amortized within 3 years due to prolonged life.

FAQ: Technical FAQ for City Commercial Flooring

Expert Answers to Frequent Technical Questions

- 1. What is the difference between homogeneous and heterogeneous vinyl flooring?

- Homogeneous flooring consists of one uniform layer containing the full color/pattern, offering consistent performance across wear cycles. In contrast, heterogeneous flooring is multi-layered, with a decorative film and distinct wear layers — ideal for more design variety but sometimes lower abrasion resistance.

- 2. What typical materials are used for hotel/commercial flooring?

- Modern city commercial flooring often uses PVC (polyvinyl chloride), mineral fillers, and specialty additives. Leading vendors now integrate antimicrobial agents (ISO 22196-compliant), recycled content, and nano-ceramic surface finishes for improved performance.

- 3. What is the recommended thickness for heavy traffic commercial areas?

- For public hotel spaces, stations, and clinics, a minimum of 2.0–2.5mm is advised (per ISO 24346). Heavier use (airport terminals, factories) may benefit from 3mm or reinforced layers.

- 4. What fire and VOC certifications should one check for?

- Ensure your specification includes: EN 13501-1 Bfl-s1 (fire), FloorScore® or Greenguard (low VOC emission, as per ISO 16000-9), and CE/ReaCH registration for EU projects.

- 5. How is slip resistance tested and classified?

- Slip resistance is measured through dynamic coefficient of friction (ASTM D2047/EN 13893) and ramp tests (DIN 51130: R9–R13 scale). R9–R12 is required for wet/dry commercial settings; R13 for kitchens and laboratories.

- 6. What is the expected service life and what affects it?

- Correctly installed homogeneous commercial flooring lasts 15–25 years in hotels, malls, and clinics. Life expectancy depends on installation, maintenance regime, load intensity, and UV exposure.

- 7. How does CNC processing improve flooring performance?

- CNC milling guarantees millimeter-level flatness, optimal texture for anti-slip, and precision bevels for seamless joints. It reduces installation defects and ensures consistency across large batches.

Conclusion: Future-Ready City Commercial Flooring Solutions

Modern city commercial flooring is a sophisticated blend of material science, precise engineering, and application know-how. Products such as homongeneous floor for hotel represent the current apex — delivering not only durability and cost-effectiveness, but also environmental compatibility, premium aesthetics, and unbeatable hygiene performance. Industry-certified suppliers ensure that every stage — from raw material to aftercare — is traceable, tested, and tailored for urban environments where safety, sustainability, and efficiency are paramount.

- GrandViewResearch: Commercial Flooring Market Insights (2023)

- Chinafloor: China Flooring Industry Portal

- "Technical Parameters and Material Analysis of Urban Heterogeneous Flooring". Flooring Forum

- International Journal of Architectural Science: "Flooring Technologies: Safety and Sustainability"

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025