Dry Back LVT Flooring - Durable, Glue-Down, Waterproof

Field Notes: Why dry back lvt flooring keeps winning commercial specs

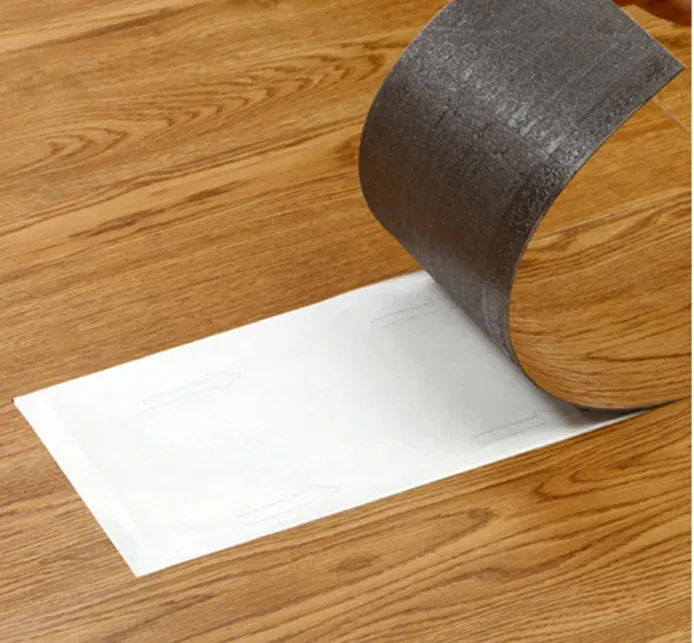

If you’ve been watching the flooring spec lists lately, you’ve probably noticed the swing back toward glue-down LVT in busy spaces. To be honest, it’s not hype. Installers tell me adhesives have improved, facilities teams like the repairability, and designers are getting richer textures without the price tag of hardwood or stone. In short: dry back lvt flooring has matured.

What it’s made of (and why that matters)

LVT is a multi-layer construction: PVC base for stability, a resilient core, a printed décor film, and a UV/PU wear layer. Typical thickness runs 2–5 mm; wear layers are commonly 0.3 mm (light commercial) to 0.5 mm (full commercial). The glue-down format keeps ingress/egress transitions slim and rolling loads quiet. Manufacturing is straightforward—calendering, print film alignment, hot-press lamination, UV-cured topcoat, precision cutting, and then dimensional stability/indent testing before boxing. Real-world service life? Around 10–20 years depending on wear layer, maintenance, and traffic.

Typical specs (lab-tested, field-proven)

| Parameter | Spec (≈ typical) | Standard |

|---|---|---|

| Total thickness | 2.0–5.0 mm | ASTM F1700 / EN ISO 10582 |

| Wear layer | 0.3 / 0.5 mm options | ASTM F1700 Type A |

| Dimensional stability | ≤0.10% | EN ISO 23999 |

| Residual indentation | ≤0.10 mm | EN ISO 24343-1 |

| Static load | ≤0.005 in @ 750 psi | ASTM F970 |

| Slip resistance | R10; DS ≥0.3 | DIN 51130 / EN 13893 |

| Fire / smoke | Bfl-s1 | EN 13501-1 |

| Indoor air quality | FloorScore / GREENGUARD Gold | SCS / UL |

Where it shines

Retail (quiet underfoot), hospitality corridors (tight seams), education (easy to replace a plank), healthcare admin and waiting areas, and multifamily amenity spaces. Many customers say maintenance is “mop-simple,” though I’ll add: the best results come with a sensible entry matting program and neutral cleaners.

Vendors at a glance

| Vendor | Wear layer | Certs | Customization / MOQ | Lead time | Notes |

|---|---|---|---|---|---|

| Enlio — Dry Back LVT Flooring (Origin: #C3, No. 36 Xiangyuan Rd., Baiyun Dist., Guangzhou, China) | 0.3 / 0.5 mm | CE, FloorScore, ISO 9001/14001 | Print/emboss/size; MOQ ≈ 500–1,000 m² | ≈ 3–6 weeks | Good value; quick color matching |

| Brand A (Global) | 0.3 / 0.55 mm | FloorScore, EPD | Limited emboss; MOQ ≈ 1,500 m² | 6–10 weeks | Large color library |

| Brand B (Regional) | 0.3 / 0.5 mm | GREENGUARD | Custom print small runs ≈ 300 m² | 3–5 weeks | Fast sampling, fewer SKUs |

Installation, testing, and the little things

Subfloors should meet ASTM F710. Moisture testing via ASTM F2170 (RH) or F1869 (MVER) is not optional—seriously, this is where projects live or die. Use pressure-sensitive or hard-set adhesives per traffic; roll with a 50–75 kg roller; maintain 18–27°C. Slip resistance typically lands R10; wear resistance often scores Group T (EN 660-2). VOC claims? Look for FloorScore or GREENGUARD Gold certificates on the exact SKU.

Customization and real-world stories

Customization can include plank size (e.g., 152.4×914.4 mm), emboss-in-register, matte urethane, and color tweaks. One Guangzhou boutique gym chose dry back lvt flooring for the low profile under heavy racks—no trip edges. A Middle East hotel refreshed three corridors in 48 hours; the night crew lifted and replaced a stained section the following week with zero fuss. A U.S. retail chain reported fewer telegraphing issues after tightening their skim-coat spec—small change, big difference, surprisingly.

Bottom line: when you need durable looks, fast repairs, and predictable costs, dry back lvt flooring is hard to beat—as long as moisture, prep, and adhesive are treated like the critical path they are.

Citations

- ASTM F1700: Standard Specification for Solid Vinyl Floor Tile

- ASTM F710: Preparing Concrete Floors to Receive Resilient Flooring

- ASTM F2170: RH in Concrete Floor Slabs and ASTM F1869: MVER

- EN ISO 10582: Heterogeneous PVC floor coverings

- EN ISO 23999: Dimensional stability

- FloorScore Certification Program

- UL GREENGUARD Certification

- EN 13501-1: Fire classification of construction products

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025