Durable LVT Vinyl Flooring | Easy Click & Herringbone Styles

Understanding the Modern Evolution of lvt vinyl: Trends and Innovations

The flooring industry is currently undergoing a significant transformation, driven by demands for sustainability, enhanced durability, and aesthetic versatility. Within this dynamic landscape, lvt vinyl has emerged as a frontrunner, captivating both residential and commercial sectors with its unparalleled blend of practicality and design appeal. Recent industry trends highlight a sustained growth in demand for luxury vinyl products, with market analyses projecting continued expansion fueled by innovations in manufacturing processes and material science. Manufacturers are increasingly focusing on eco-friendly compositions, such as phthalate-free formulations and recycled content, aligning with global sustainability initiatives and consumer preferences for healthier indoor environments. Furthermore, advancements in digital printing technology have enabled LVT to replicate the intricate textures and visual nuances of natural materials like hardwood, stone, and ceramic with astonishing realism, offering designers unprecedented creative freedom without the maintenance drawbacks of traditional flooring. The shift towards easier, more efficient installation methods, particularly through sophisticated click-lock systems, is also a pivotal trend, reducing labor costs and installation times for projects of all scales. This evolution positions LVT not just as an alternative, but as a superior solution for a wide array of demanding applications, reflecting a mature product category that continues to innovate to meet the complex needs of modern architecture and interior design.

Technological breakthroughs are consistently reshaping the capabilities of lvt floor tiles. For instance, the development of enhanced wear layers, often incorporating ceramic bead or diamond dust particles, significantly extends the product's lifespan and resistance to scratches, scuffs, and abrasions, making it ideal for high-traffic environments. Acoustic backing layers are another notable innovation, designed to dramatically reduce impact sound transmission, a crucial consideration in multi-story buildings and commercial spaces like healthcare facilities and educational institutions where noise reduction is paramount. The increasing sophistication of interlocking mechanisms, particularly in click lvt flooring, has democratized installation, allowing for floating installations over various subfloors without the need for messy adhesives, thereby simplifying renovation projects and offering immediate foot traffic after installation. Moreover, the integration of anti-microbial treatments directly into the wear layer provides an added layer of hygiene, especially valuable in sensitive environments such as hospitals, clinics, and schools. These continuous innovations underscore LVT's adaptability and its commitment to meeting stringent performance criteria, solidifying its position as a go-to choice for specifiers and end-users seeking long-term value and superior performance. The market's embrace of these advancements reflects a collective recognition of LVT's inherent advantages in an increasingly demanding built environment.

The Advanced Manufacturing Process of Luxury Vinyl Tiles

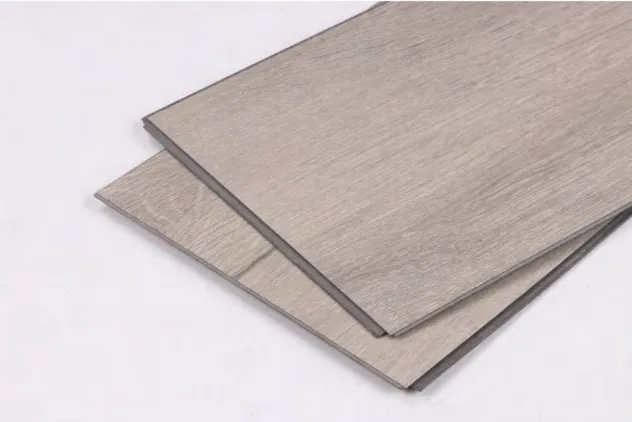

The creation of high-quality lvt vinyl involves a sophisticated multi-stage manufacturing process, ensuring both aesthetic appeal and robust performance. This process begins with the careful selection and blending of raw materials, primarily polyvinyl chloride (PVC) resins, plasticizers, stabilizers, and fillers, which form the core layers. Unlike traditional manufacturing methods for metals, LVT production relies heavily on calendering and pressing techniques. The initial step, often referred to as calendering, involves heating the raw compound and passing it through a series of heated rollers to form precise, thin sheets. These sheets are then laminated together under high pressure and temperature to create a stable, dense backing layer, which provides structural integrity and dimensional stability to the final product. This meticulous lamination prevents common issues like warping and gapping, ensuring a long-lasting and aesthetically pleasing floor. The choice of materials and the precise control over their thermal processing are critical to achieving the desired physical properties, including flexibility, resistance to indentation, and overall durability.

Following the formation of the base layer, the decorative print film is applied. This film is meticulously designed using advanced digital printing techniques to replicate natural textures such as wood grains, stone patterns, or abstract designs with high fidelity and vibrant colors. On top of the print film, a transparent wear layer is then applied. This is arguably the most critical component for the product's longevity, as it directly resists scratches, scuffs, and stains. High-quality LVT wear layers are often enhanced with UV-cured urethane coatings, sometimes infused with ceramic beads or aluminum oxide particles, further boosting abrasion resistance and simplifying maintenance. After the wear layer, a protective UV coating is typically applied to prevent discoloration from sunlight and provide an easy-to-clean surface. The assembly of these layers is then consolidated under heat and pressure in a laminating press. For click lvt flooring, precision CNC (Computer Numerical Control) machining is utilized to create the intricate interlocking edge profiles, ensuring a tight, seamless fit for floating installations. Rigorous inspection standards, including those aligned with ISO 9001 for quality management and ASTM F1700 for material specifications, are maintained throughout the process to guarantee product consistency, dimensional stability, and performance. The typical lifespan of a well-manufactured LVT product, particularly those designed for commercial use, can range from 15 to 30 years, depending on the wear layer thickness and maintenance regimen, offering a superior return on investment.

Technical Parameters and Performance Benchmarks of LVT Vinyl

Understanding the technical specifications of lvt vinyl is crucial for B2B procurement decisions, ensuring that the selected product aligns precisely with the demands of the intended application. Key parameters include total thickness, wear layer thickness, dimensional stability, indentation resistance, slip resistance, and fire resistance. The total thickness of LVT planks or tiles typically ranges from 2mm to 8mm, with thicker products often incorporating an integrated underlayment for enhanced acoustic properties and comfort underfoot. The wear layer thickness, measured in mils or millimeters, is a direct indicator of durability, with commercial-grade applications typically requiring a wear layer of 20 mil (0.5mm) or greater to withstand heavy foot traffic and abrasive forces. Dimensional stability, assessed by standards like EN 434, ensures that the flooring maintains its original size and shape under varying temperature and humidity conditions, preventing gapping or buckling, especially critical for systems like herringbone click lvt flooring where precise alignment is paramount.

Beyond these foundational metrics, specialized LVT products may offer enhanced features such as acoustic dampening properties, measured in decibels (dB), vital for noise reduction in multi-level commercial settings. Chemical resistance, particularly to common household and commercial cleaning agents, is also a significant consideration for healthcare and laboratory environments, tested via ISO 26987. The inherent water resistance of lvt floor tiles makes them an ideal choice for areas prone to moisture, such as bathrooms, kitchens, and basements, vastly outperforming laminate or natural wood in such scenarios. For commercial environments, resistance to castor chair use (EN 425) is an important indicator of durability for office spaces. Understanding these specific technical parameters allows buyers to make informed decisions, ensuring the LVT product selected will not only meet but exceed performance expectations for its intended operational lifespan, thereby minimizing future maintenance and replacement costs. The comprehensive testing against international standards underpins the reliability and high performance of modern LVT solutions.

Versatile Application Scenarios for LVT Vinyl Flooring

The adaptability and robust performance of lvt vinyl make it suitable for an exceptionally broad range of application scenarios, from high-traffic commercial environments to sophisticated residential interiors. In the commercial sector, LVT is extensively utilized in retail stores, where its durability, ease of maintenance, and ability to mimic high-end materials provide an ideal balance of aesthetics and functionality. Hospitality venues, including hotels and restaurants, benefit from LVT’s acoustic properties and resistance to spills and stains, contributing to a comfortable and pristine guest experience. Healthcare facilities, such as hospitals and clinics, prioritize LVT for its hygienic properties, ease of cleaning, and the availability of anti-microbial treatments, alongside its resilience to heavy equipment and constant foot traffic. Educational institutions, from K-12 schools to universities, choose LVT for its noise reduction qualities, durability in hallways and classrooms, and vibrant design options that can enhance learning environments. Corporate offices are increasingly adopting LVT for its professional appearance, sound absorption, and ease of installation, particularly with click lvt flooring systems that minimize disruption during renovations.

Beyond these core commercial applications, lvt floor tiles are also gaining significant traction in specialized environments. For instance, specific formulations of LVT with enhanced slip resistance are ideal for wet areas like commercial kitchens, laundromats, and even certain light industrial settings where safety is paramount. The modularity of LVT, particularly when considering various sizes and shapes, enables creative designs such as bespoke patterns or directional cues, useful in large public spaces like airports and convention centers. While not typically associated with petrochemical or heavy metallurgy, LVT's robust nature makes it suitable for office and administrative areas within these larger industrial complexes, where a resilient, easy-to-maintain, and aesthetically pleasing floor is desired without the harsh chemical exposures. Moreover, the ease of installation associated with lvt click flooring clearance solutions makes it an attractive option for quick, cost-effective renovations in existing structures or for temporary installations requiring rapid deployment and removal. This widespread applicability underscores LVT's strategic value as a versatile and high-performance flooring solution across the B2B spectrum.

Evaluating LVT Vinyl Manufacturers: A Comparative Analysis

Choosing the right manufacturer for lvt vinyl is a critical decision that impacts project longevity, compliance, and overall cost-efficiency. Manufacturers differentiate themselves through various factors, including their material sourcing, production technologies, range of certifications, and commitment to R&D. Leading manufacturers typically adhere to stringent quality control protocols, often holding ISO 9001 certification for quality management systems and ISO 14001 for environmental management, signifying a commitment to both product excellence and sustainable practices. The origin of raw materials, such as virgin PVC versus recycled content, can influence both performance and environmental footprint. Top-tier producers invest heavily in advanced calendering and embossing techniques that yield superior realism in design and enhanced tactile sensations, often employing synchronous registered embossing to perfectly align texture with visual patterns. Companies like Enlio, for instance, specialize in high-performance Click LVT Flooring solutions, focusing on robust click systems and wear layers suitable for demanding sports and commercial applications, distinguishing themselves from those primarily targeting residential or light commercial markets.

Beyond manufacturing prowess, a manufacturer's reputation is built on its adherence to global standards and industry leadership. Certifications such as Floorscore ensure low VOC (Volatile Organic Compound) emissions, contributing to better indoor air quality – a non-negotiable for many commercial and institutional projects. CE marking (Conformité Européenne) indicates compliance with European health, safety, and environmental protection standards. When evaluating vendors for projects requiring large volumes or specialized designs, such as intricate herringbone click lvt flooring layouts, assessing their capability for custom solutions and project support is paramount. This includes their ability to provide bespoke colors, patterns, and plank dimensions, as well as comprehensive technical assistance, installation guides, and post-sales support. A key differentiator for reliable manufacturers is their transparent communication regarding product specifications, testing data, and comprehensive warranty programs, often extending for 15-25 years for commercial applications, reflecting confidence in their product’s longevity and performance under strenuous conditions. This rigorous evaluation ensures a partnership that delivers not just a product, but a complete, reliable, and high-value flooring solution.

Tailored LVT Vinyl Solutions and Project Implementation

Recognizing that no two projects are identical, leading suppliers of lvt vinyl offer comprehensive custom solutions tailored to specific architectural, design, and performance requirements. This customization extends beyond standard product lines to encompass bespoke designs, specialized wear layer treatments, and unique dimensional specifications for lvt floor tiles. For instance, a high-traffic retail space might require an exceptionally thick wear layer for maximum abrasion resistance, while a healthcare facility may prioritize advanced anti-microbial properties and enhanced slip resistance. Design customization involves creating unique color palettes, custom patterns, or even integrating corporate logos directly into the flooring, achievable through advanced digital printing and cutting technologies. This level of bespoke manufacturing ensures that the flooring not only meets stringent technical demands but also perfectly aligns with the brand identity and aesthetic vision of the project. Furthermore, project implementation often includes detailed consultation from experienced technical teams, offering guidance on subfloor preparation, installation methodologies, and ongoing maintenance protocols to maximize the lifespan and performance of the LVT installation.

Beyond product customization, the success of large-scale click lvt flooring projects hinges on robust logistical and technical support. Experienced LVT providers often offer integrated project management services, from initial design consultation and material specification to delivery scheduling and on-site technical assistance. For example, a major hospitality chain undertaking a multi-site renovation would benefit significantly from a supplier capable of managing complex logistics, ensuring timely delivery of specific lvt click flooring clearance batches to various locations while maintaining consistent quality and color matching across all sites. Case studies highlight instances where expert technical support during installation significantly reduced project timelines and mitigated potential issues, such as proper acclimation of materials and troubleshooting unforeseen subfloor conditions. Companies that provide comprehensive warranty support and readily available after-sales service also instill greater confidence, ensuring long-term satisfaction and minimizing operational disruptions. The ability to seamlessly integrate custom solutions with reliable project execution is a hallmark of a truly valuable LVT partner for B2B enterprises.

Frequently Asked Questions (FAQs) about LVT Vinyl Flooring

What is the typical lead time for large orders of lvt vinyl?

For standard lvt vinyl products, typical lead times for large commercial orders generally range from 4 to 8 weeks, depending on the manufacturer's production schedule and stock availability. However, for custom designs or specialized specifications like bespoke herringbone click lvt flooring patterns, the lead time may extend to 10-14 weeks to accommodate design, prototyping, and manufacturing. It is always recommended to consult directly with your supplier during the planning phase to confirm exact delivery schedules, especially for time-sensitive projects. Expedited shipping options may be available at an additional cost, though these are typically assessed on a case-by-case basis depending on the order volume and destination.

What kind of warranty can I expect for commercial lvt floor tiles?

Reputable manufacturers typically offer extensive commercial warranties for lvt vinyl products, usually ranging from 15 to 25 years against manufacturing defects, excessive wear, and delamination under normal commercial use. The specifics of the warranty, including coverage for wear layer performance and structural integrity, depend on the product line and wear layer thickness. For example, a high-performance click lvt flooring with a 28 mil wear layer designed for heavy commercial traffic would generally carry a longer and more comprehensive warranty than lighter residential grades. It's crucial to review the manufacturer's specific warranty document, as proper installation and maintenance procedures are often prerequisites for warranty validity.

Is LVT vinyl suitable for high-moisture environments?

Yes, lvt vinyl is inherently water-resistant, making it an excellent choice for areas prone to moisture, such as commercial kitchens, bathrooms, laundry rooms, and basements. Its multi-layered construction and PVC composition prevent water absorption, minimizing the risk of swelling, warping, or mold growth typically associated with wood or laminate flooring in such conditions. While the product itself is highly water-resistant, proper subfloor preparation and the use of appropriate adhesives (for glue-down installations) or a robust click-lock system (for click lvt flooring) are crucial to ensure that moisture does not penetrate underneath the planks and compromise the subfloor. Always ensure the subfloor is clean, dry, and level before installation to maintain performance.

What certifications should I look for when purchasing lvt vinyl?

When sourcing lvt vinyl, look for certifications that attest to product quality, environmental sustainability, and indoor air quality. Key certifications include Floorscore (for low VOC emissions), CE marking (for compliance with European health and safety standards), ISO 9001 (for quality management systems), and ISO 14001 (for environmental management systems). Some products may also carry specific fire ratings (e.g., Bfl-s1 as per EN 13501-1) or slip resistance ratings, which are critical for commercial applications. These certifications provide independent verification that the product meets stringent performance and safety criteria, giving buyers confidence in their investment.

Authoritative References

- ASTM International. (2020). ASTM F1700-20 Standard Specification for Solid Vinyl Tile.

- International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems — Requirements.

- European Committee for Standardization. (2013). EN 14041:2013 Resilient, Textile and Laminate Floor Coverings — Essential Characteristics.

- Resilient Floor Covering Institute (RFCI). (Ongoing). Floorscore Certification Program for Indoor Air Quality.

-

Waterproof Advantages of SPC Flooring Vinyl in KitchensAug.06,2025

-

SPC Hybrid Waterproof Flooring Thickness GuideAug.06,2025

-

Leveling Subfloor Before My Floor SPC InstallAug.06,2025

-

How Mesh Deck Skirting Improves Outdoor Pest ControlAug.06,2025

-

Choosing the Right Commercial Flooring for Your Business NeedsAug.06,2025

-

Choosing the Best Residential Flooring: A Comprehensive Guide to Style, Durability, and ComfortAug.06,2025