Enlio Commercial Waterproof Flooring - Durable & Easy Clean

The Imperative of High-Performance Commercial Waterproof Flooring in Modern Infrastructure

In demanding commercial and industrial environments, the selection of robust and resilient flooring is paramount. Among the most critical considerations is resistance to moisture, chemicals, and heavy traffic. This is where commercial waterproof flooring emerges as a foundational element for operational integrity and long-term asset protection. From healthcare facilities to high-traffic transportation hubs, the ability of flooring to withstand spills, cleanings, and accidental inundations without degradation is essential for safety, hygiene, and aesthetic longevity. This article delves into the technical intricacies, market trends, and application versatility of advanced waterproof flooring solutions, providing a comprehensive guide for B2B decision-makers.

Modern commercial waterproof flooring solutions are engineered to meet stringent performance requirements, offering not just water resistance but also superior durability, chemical resistance, ease of maintenance, and enhanced safety features. These characteristics are indispensable in environments where operational continuity and stringent hygiene standards are non-negotiable. Understanding the core technologies and material science behind these systems is crucial for selecting an optimal solution that aligns with specific operational demands and compliance regulations.

Industry Trends and Market Dynamics in Waterproof Flooring

The global market for commercial waterproof flooring is experiencing significant growth, driven by increasing construction activities, rising awareness of hygiene and safety, and advancements in material science. Key trends shaping the industry include:

- Sustainability Focus: A growing demand for environmentally friendly products, leading to innovations in recycled content, low VOC emissions, and cradle-to-cradle certified flooring solutions.

- Enhanced Aesthetics and Design Versatility: Beyond purely functional aspects, clients increasingly seek flooring that combines superior performance with appealing designs, textures, and color options to complement interior aesthetics.

- Technological Integration: Development of smart flooring solutions with integrated sensors for monitoring traffic, temperature, or even structural integrity, although still nascent in the waterproof segment.

- Specialized Performance: Increasing demand for flooring with specific properties such as anti-microbial surfaces for healthcare, anti-static for data centers, or extreme chemical resistance for industrial processing plants.

- Rapid Installation Systems: Innovations in installation methods, including click-and-lock systems or adhesive-free options, to minimize downtime in commercial settings.

Vinyl-based solutions, particularly heterogeneous vinyl and heterogeneous sheet vinyl, continue to dominate the market due to their excellent balance of performance, cost-effectiveness, and design flexibility. The market anticipates further evolution with bio-based polymers and advanced composite materials offering even greater durability and environmental credentials.

Technical Specifications and Material Science

Understanding the composition and properties of commercial waterproof flooring is fundamental to its effective deployment. These advanced materials are engineered to resist water ingress, prevent microbial growth, and withstand mechanical stresses inherent in commercial use.

Heterogeneous Vinyl vs. Homogeneous Vinyl

While both types of vinyl flooring offer excellent waterproofing, their structural composition dictates their performance characteristics.

- Homogeneous Vinyl: Composed of a single layer of material throughout its thickness, offering uniform wear and pattern resilience. Ideal for extremely heavy traffic areas where durability and long-term appearance retention are critical, such as the homongeneous floor for airports and railway stations.

- Heterogeneous Vinyl: Multi-layered structure comprising a backing layer (often recycled PVC), a design layer with printed patterns, and a clear wear layer for protection. This construction allows for greater design versatility and improved acoustic properties. The thicker wear layer determines its durability for high-traffic environments, making heterogeneous sheet vinyl a popular choice for diverse commercial applications.

Key Technical Parameters

| Parameter | Description | Typical Value / Standard |

|---|---|---|

| Wear Layer Thickness | Crucial for durability against abrasion. Thicker layers mean longer service life. | 0.3mm to 1.0mm (EN 660-2) |

| Overall Thickness | Total thickness of the flooring material. Affects comfort, sound absorption, and installation. | 2.0mm to 4.0mm |

| Residual Indentation | Ability to recover from static or dynamic loads. Lower values indicate better performance. | < 0.1mm (EN 433) |

| Dimensional Stability | Resistance to expansion or contraction due to temperature/humidity changes. Prevents gapping. | < 0.4% (EN 434) |

| Slip Resistance | Coefficient of Friction (CoF) measured in wet and dry conditions. Critical for safety. | R9-R11 (DIN 51130) |

| Fire Classification | Material's reaction to fire, crucial for building safety codes. | Bfl-s1 (EN 13501-1) |

| Chemical Resistance | Ability to resist degradation from common chemicals, disinfectants, and cleaning agents. | No visible damage after exposure (EN 423) |

These parameters collectively define the performance profile of a commercial waterproof flooring solution, ensuring it meets the rigorous demands of its intended application.

Manufacturing Process of Commercial Waterproof Flooring

The production of high-performance commercial waterproof flooring involves sophisticated processes designed to impart durability, dimensional stability, and aesthetic appeal. While specific techniques vary between manufacturers and product types (e.g., homogeneous vs. heterogeneous), the general flow for PVC-based flooring, such as heterogeneous vinyl sheet, typically follows these stages:

1. Raw Material Preparation and Compounding

- Polymer Selection: Primarily polyvinyl chloride (PVC) resin for its inherent water resistance, flexibility, and cost-effectiveness.

- Additives: Incorporation of plasticizers for flexibility, stabilizers for UV and heat resistance, fillers (e.g., calcium carbonate) for bulk and rigidity, pigments for color, and anti-microbial agents.

- Compounding: These raw materials are precisely weighed, mixed, and compounded under heat and pressure to create a homogeneous melt, which is then extruded into granules or sheets.

2. Base Layer Formation (Calendaring or Coating)

- Calendaring: The compounded PVC mixture is fed through a series of heated rollers (calenders) that progressively flatten and smooth the material into a continuous sheet of specified thickness. This forms the foundational layer, often the backing or core layer for heterogeneous products.

- Coating: Alternatively, a liquid PVC paste (plastisol) can be spread onto a carrier web and then heated in an oven to gelatinize and solidify, forming a uniform layer.

3. Design Layer Printing (for Heterogeneous Products)

- A high-resolution gravure or digital printing press applies the desired pattern (wood, stone, abstract, etc.) onto the base layer. Advanced printing technologies ensure vivid colors and realistic textures.

4. Wear Layer Application

- A clear PVC film or a liquid polyurethane (PU) coating is applied over the design layer. This wear layer is crucial for protecting the pattern from abrasion, scratches, and stains. Multiple passes or thicker films enhance durability.

- For homogeneous flooring, the entire thickness acts as the wear layer, often with an integrated PU or UV-cured surface treatment for enhanced resistance.

5. Curing and Embossing

- The layered product passes through curing ovens to properly bond the layers and achieve desired material properties.

- Optional embossing plates can be used to create surface textures (e.g., wood grain, slate) that align with the printed design, adding realism and slip resistance.

6. Cooling, Trimming, and Quality Control

- The continuous sheet is cooled, trimmed to precise dimensions, and then rolled or cut into planks/tiles.

- Testing Standards: Throughout the process, rigorous testing is conducted in accordance with international standards such as ISO (e.g., ISO 10582 for flexible PVC sheet flooring), EN (e.g., EN 649 for homogeneous and heterogeneous poly(vinyl chloride) floor coverings), and ASTM to verify parameters like dimensional stability, wear resistance, indentation, slip resistance, and fire classification. These tests ensure the final product meets specified service life expectations, often exceeding 15-20 years in typical commercial applications.

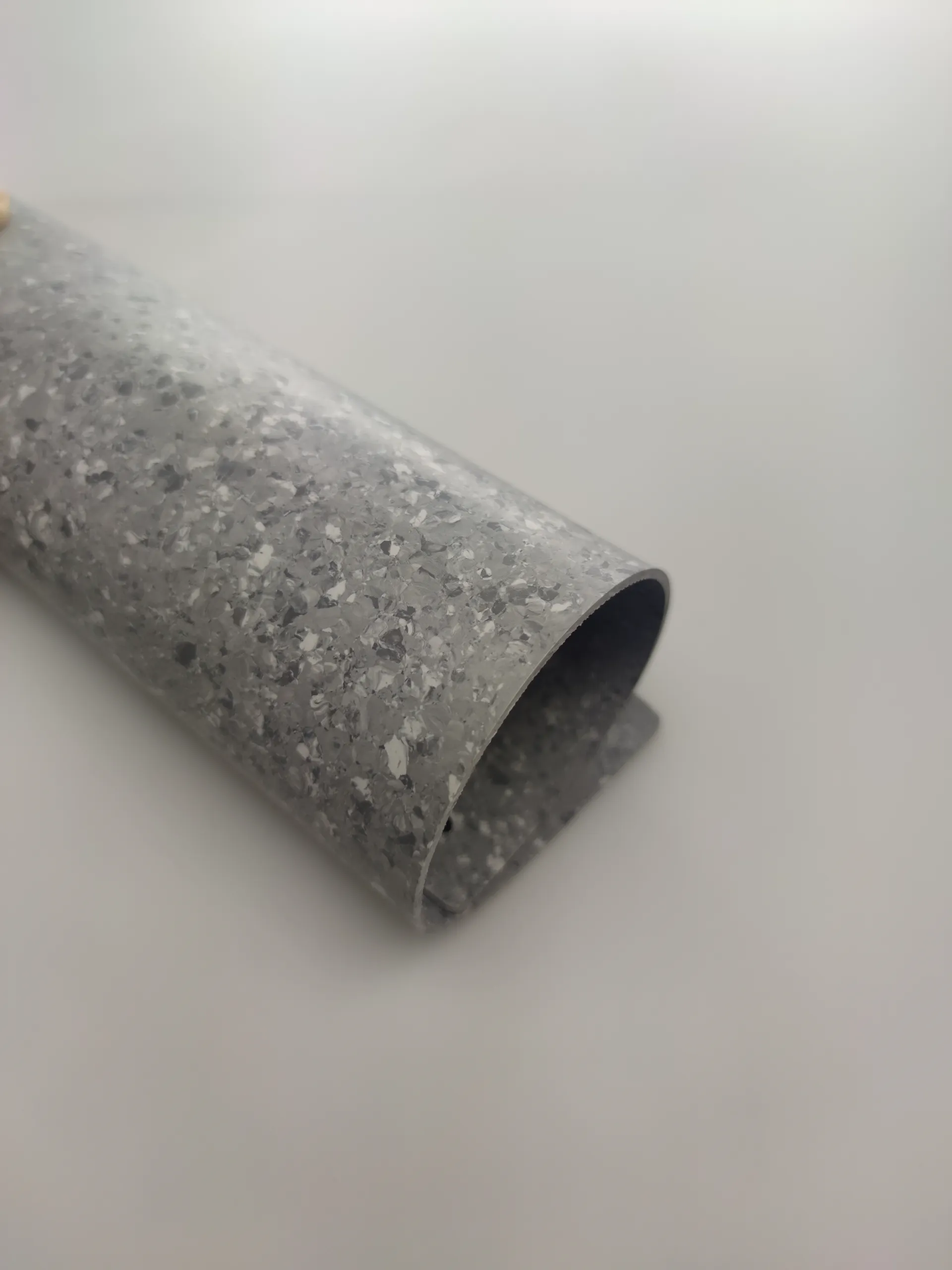

Example of advanced heterogeneous sheet vinyl installation demonstrating versatility.

This meticulous manufacturing process ensures that commercial waterproof flooring products, including specialized options like enlio commercial waterproof flooring, deliver consistent, high-quality performance in diverse industrial and commercial environments.

Technical Advantages in Diverse Application Scenarios

The inherent properties of high-quality commercial waterproof flooring translate into significant advantages across a multitude of sectors:

- Superior Water and Moisture Resistance: The primary advantage. Impermeable surfaces prevent water penetration, protecting subfloors from damage, mold growth, and structural weakening. This is critical in areas prone to spills or high humidity.

- Exceptional Durability and Wear Resistance: Engineered wear layers, especially in heterogeneous vinyl sheet, withstand heavy foot traffic, rolling loads, and abrasion, significantly extending the service life compared to conventional flooring. Products like those offered by Enlio are designed to maintain their integrity for decades.

- Chemical and Stain Resistance: The non-porous surface of vinyl flooring repels a wide range of chemicals, disinfectants, and staining agents, making it easy to clean and sanitize. This is invaluable in healthcare, laboratories, and food processing facilities.

- Enhanced Hygiene and Anti-Microbial Properties: The seamless installation (especially with sheet goods and welded seams) prevents dirt, moisture, and pathogens from accumulating, facilitating thorough cleaning and contributing to a sterile environment. Many products incorporate anti-microbial treatments directly into the wear layer.

- Improved Safety (Slip Resistance): Specialized surface textures and coatings provide enhanced slip resistance, reducing the risk of accidents in wet conditions, a crucial factor in commercial kitchens, restrooms, and industrial zones.

- Acoustic Comfort: Multi-layered vinyl flooring can offer significant sound absorption properties, reducing impact noise and creating a more comfortable indoor environment in offices, educational institutions, and healthcare settings.

- Low Maintenance and Cost-Efficiency: The durable and stain-resistant nature of these floors minimizes the need for aggressive cleaning protocols or frequent repairs, leading to lower operational costs over the product's lifespan.

Application Scenarios and Target Industries

The robust characteristics of commercial waterproof flooring make it ideal for a vast array of target industries where durability, hygiene, and resistance to environmental factors are paramount.

- Healthcare Facilities: Hospitals, clinics, laboratories, and elderly care homes require sterile, easy-to-clean, and chemical-resistant surfaces. Seamless heterogeneous vinyl sheet with welded seams prevents bacterial growth and withstands frequent disinfection, supporting infection control protocols.

- Educational Institutions: Schools, universities, and daycare centers benefit from flooring that can handle heavy foot traffic, spills, and resist staining from various agents, while offering acoustic comfort.

- Retail and Hospitality: Restaurants, hotels, supermarkets, and showrooms demand aesthetically pleasing, yet highly durable and easily maintainable flooring that can withstand spills and heavy public traffic.

- Transportation Hubs: Airports, railway stations, and bus terminals, as exemplified by Enlio's homongeneous floor for airports and railway stations, require flooring that can endure extreme wear, heavy rolling loads, and resist constant cleaning and accidental spills, maintaining structural integrity and appearance under immense pressure.

- Industrial and Manufacturing: Light manufacturing, warehouses, and cleanrooms benefit from chemical and abrasion-resistant flooring that can support machinery and withstand industrial processes. Specific products offer anti-static properties for sensitive electronics manufacturing.

- Commercial Kitchens and Food Service: Areas with high moisture, grease, and heavy traffic require flooring that is not only waterproof but also highly slip-resistant and easy to sanitize, meeting stringent health codes.

- Sports Facilities and Gyms: Specialized waterproof vinyl flooring provides impact absorption, slip resistance, and durability for athletic activities and heavy equipment areas, making it ideal for locker rooms and fitness zones.

Innovative installation techniques ensuring seamless water resistance.

Vendor Comparison: Key Differentiators in Commercial Waterproof Flooring

When selecting a supplier for commercial waterproof flooring, discerning decision-makers evaluate vendors based on a comprehensive set of criteria beyond just initial cost. Key differentiators include:

- Product Portfolio Depth: A vendor offering a wide range of homogeneous, heterogeneous vinyl, and other specialized waterproof options can better meet diverse project requirements.

- Certifications and Compliance: Adherence to international standards (ISO 9001, ISO 14001, CE, ASTM, EN), as well as specific health and environmental certifications (e.g., FloorScore, REACH compliance), demonstrates commitment to quality and safety.

- R&D and Innovation: Manufacturers who invest in research and development often introduce advanced wear layers, anti-microbial technologies, and sustainable formulations, pushing the boundaries of performance.

- Customization Capabilities: The ability to provide bespoke colors, patterns, or specific technical properties tailored to unique project demands.

- Technical Support and Service: Comprehensive pre-sales consultation, detailed installation guides, post-sales support, and robust warranty programs.

Comparative Analysis: Key Waterproof Flooring Types

| Feature | Heterogeneous Vinyl Sheet | Homogeneous Vinyl | LVT/LVP (Waterproof Core) |

|---|---|---|---|

| Construction | Multi-layered (backing, print, wear layer) | Single, uniform layer | Multi-layered rigid core (WPC/SPC) with print and wear layer |

| Waterproofing | Excellent (seamless welding possible) | Excellent (seamless welding possible) | Excellent (interlocking systems, often no subfloor prep for moisture) |

| Durability | Very High (wear layer dependent) | Extremely High (uniform wear) | High (rigid core resists impact) |

| Design Versatility | Very High (realistic prints) | Moderate (chip/granule patterns) | Very High (realistic wood/stone looks) |

| Installation | Adhesive, professional required (seaming) | Adhesive, professional required (seaming) | Click-lock (DIY-friendly for smaller projects, professional for commercial scale) |

| Target Applications | Healthcare, Education, Retail, Offices | Heavy industrial, Hospitals (operating rooms), Airports, Railway Stations | Retail, Hospitality, Offices, Multi-family housing |

This comparison highlights that while all are effective commercial waterproof flooring options, their optimal deployment depends on specific project demands for aesthetics, traffic, and installation logistics.

Customized Solutions and Vendor Flexibility

For large-scale commercial projects, off-the-shelf flooring solutions may not always meet unique branding, aesthetic, or functional requirements. Leading manufacturers of commercial waterproof flooring offer extensive customization options, including:

- Bespoke Colors and Patterns: Matching corporate branding guidelines or specific interior design palettes. This can involve custom pigment mixing or digital printing for unique graphic elements.

- Tailored Technical Properties: Adjusting wear layer thickness, adding enhanced anti-slip properties (e.g., specialized grit inclusions), or integrating specific anti-static or acoustic dampening layers to meet highly specialized operational demands.

- Modular vs. Sheet Formats: Offering products in various formats, such as rolls of heterogeneous sheet vinyl for large, seamless installations or tiles/planks for modularity and easier replacement.

- Project-Specific Logistics and Packaging: Custom roll lengths, pallet configurations, and labeling to streamline large-scale deployments and reduce waste.

Partnerships with vendors like Enlio, who have a strong R&D department and flexible manufacturing capabilities, can unlock solutions precisely engineered for complex project specifications, ensuring optimal performance and aesthetic integration.

Application Case Studies: Proving Performance

Case Study 1: International Airport Terminal Renovation

Challenge: A major international airport required a flooring solution for its bustling terminals, concourses, and baggage claim areas that could withstand immense daily foot traffic (millions annually), heavy rolling luggage, occasional fluid spills, and rigorous cleaning schedules, all while maintaining a premium aesthetic. The existing flooring suffered from rapid wear and water damage, leading to frequent, costly repairs and operational disruptions.

Solution: The project specified a robust homogeneous vinyl flooring, similar to the Enlio homongeneous floor for airports and railway stations, known for its uniform wear layer and extreme durability. The chosen product featured a 2.5mm thickness with a high-performance PU surface treatment for enhanced scratch and stain resistance. Over 50,000 square meters of this specialized flooring were installed.

Outcome: After three years of continuous operation, the flooring demonstrated negligible signs of wear, excellent resistance to scuffing and indentation from baggage carts, and retained its original color and sheen. The seamless installation, achieved through expert heat welding, completely eliminated water ingress issues, significantly reducing maintenance costs and ensuring uninterrupted passenger flow. The client reported a 40% reduction in annual flooring repair expenditures.

Case Study 2: State-of-the-Art Hospital Operating Theatres

Challenge: A new wing for a regional hospital, including surgical suites and intensive care units, needed a flooring solution that met stringent sterile environment requirements, provided exceptional chemical resistance against disinfectants, offered anti-microbial properties, and ensured high slip resistance for staff safety, all while being completely waterproof.

Solution: An advanced heterogeneous sheet vinyl flooring, specifically designed for healthcare environments (such as a premium enlio commercial waterproof flooring product), was selected. This product featured a 0.7mm pure PVC wear layer, an integrated anti-microbial treatment, R10 slip resistance, and a flexible sheet format to allow for seamless coving up walls, ensuring a fully sealed "wet room" environment.

Outcome: The flooring exceeded expectations in maintaining hygiene standards. Its resistance to iodine, blood, and potent cleaning agents ensured the floor remained pristine and functional. Staff feedback highlighted the improved underfoot comfort and reduced slip incidents. The seamless, waterproof installation was critical in achieving and maintaining infection control, contributing to a safer and more efficient medical environment.

Certifications and Authoritative Validation

Credibility in the commercial waterproof flooring sector is underpinned by adherence to rigorous international standards and independent certifications. Leading manufacturers proudly display certifications such as:

- ISO 9001: Quality Management Systems, ensuring consistent product quality.

- ISO 14001: Environmental Management Systems, reflecting sustainable manufacturing practices.

- CE Marking: Conformity with European health, safety, and environmental protection standards.

- FloorScore®: Certification for indoor air quality, ensuring low VOC emissions.

- REACH Compliance: Adherence to European regulations concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals.

- ASTM F1700 / EN 649 / EN ISO 10582: Product-specific performance standards for resilient flooring.

These certifications provide independent verification of product performance, safety, and environmental responsibility, crucial for specifying engineers and procurement managers. Reputable suppliers, often with decades of service and a robust portfolio of partner clients (e.g., major airport authorities, national healthcare systems), offer extensive test data and detailed product sheets to support their claims.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Frequently Asked Questions (FAQ)

-

Q: Is all vinyl flooring considered waterproof?

A: While PVC itself is waterproof, the installation method and product construction are critical. Sheet vinyl with welded seams offers the most robust waterproof barrier. Click-lock LVT/LVP with waterproof cores (WPC/SPC) are highly water-resistant but may not be fully waterproof if subfloor moisture is an issue or if seams are compromised over time. Always specify genuine commercial waterproof flooring for critical areas.

-

Q: What is the typical service life of commercial waterproof flooring?

A: With proper installation and maintenance, high-quality commercial vinyl flooring can last 15-25 years, and often longer in less demanding areas. The thickness of the wear layer and the type of vinyl (homogeneous typically outlasts heterogeneous in extreme wear) are key factors.

-

Q: How does installation affect the waterproof qualities?

A: Professional installation is paramount. For sheet products, seamless installation with heat-welded seams is essential to create an impermeable barrier. Poorly prepared subfloors or inadequate adhesive application can compromise even the best flooring's performance. Always engage certified installers for commercial waterproof flooring projects.

Lead Time and Fulfillment Details

Standard lead times for high-volume commercial waterproof flooring orders typically range from 4-8 weeks, depending on product type, customization requirements, and order volume. For specialized or custom-engineered solutions, lead times may extend to 10-12 weeks to accommodate manufacturing and testing protocols. Reputable suppliers provide clear communication regarding production schedules, logistics, and shipping, often utilizing established global distribution networks to ensure timely delivery. Urgent requirements can sometimes be accommodated with expedited production, subject to additional costs and material availability.

Warranty Commitments

Leading manufacturers of commercial waterproof flooring offer comprehensive warranties, typically ranging from 10 to 20 years for commercial applications, covering manufacturing defects, wear-through, and performance under specified conditions. These warranties are usually contingent upon professional installation, adherence to manufacturer's maintenance guidelines, and appropriate product selection for the intended application. Detailed warranty certificates are provided with each purchase, outlining specific terms and conditions.

Customer Support Information

Exceptional customer support is a hallmark of trusted B2B suppliers. This includes:

- Dedicated Project Managers: Single point of contact for complex projects.

- Technical Consultation: Expert advice on product selection, subfloor preparation, and installation best practices.

- After-Sales Service: Support for troubleshooting, maintenance queries, and warranty claims.

- Training Programs: For installers and maintenance staff to ensure optimal product performance and longevity.

Contact details for sales, technical support, and general inquiries are readily available through official corporate channels, ensuring that clients can access assistance whenever needed.

Conclusion

The strategic selection of commercial waterproof flooring is a critical decision that impacts not only the initial investment but also the long-term operational costs, safety, and aesthetic appeal of any commercial or industrial facility. With advancements in materials science and manufacturing processes, modern solutions like advanced heterogeneous vinyl and robust homogeneous options offer an unparalleled combination of durability, hygiene, and design versatility. By prioritizing products from authoritative vendors who adhere to stringent quality standards and offer comprehensive support, businesses can ensure their flooring infrastructure is resilient, efficient, and capable of meeting the evolving demands of dynamic commercial environments.

References

- ASTM International. "Standard Specification for Resilient Tile Flooring." ASTM F1700-19.

- European Committee for Standardization. "Resilient floor coverings – Homogeneous and heterogeneous poly(vinyl chloride) floor coverings – Specification." EN 649:2011.

- International Organization for Standardization. "Resilient floor coverings – Flexible PVC floor coverings with foam layer backing – Specification." ISO 10582:2017.

- National Institute of Building Sciences (NIBS). "Whole Building Design Guide: Vinyl Flooring." WBDG.org.

- FloorScore Indoor Air Quality Certification Program. SCS Global Services.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025