Exploring the Best PVC Welding Rods for Durable and Reliable Plastic Welding Applications

Understanding PVC Welding Rods Properties, Applications, and Benefits

Welding is a crucial process in various manufacturing and construction industries, and among the many welding materials available, PVC (Polyvinyl Chloride) welding rods have gained immense popularity. PVC is a versatile and widely used plastic that finds applications in pipes, fittings, and other components due to its durability and resistance to corrosion. This article explores the properties, applications, and benefits of PVC welding rods.

Properties of PVC Welding Rods

PVC welding rods are generally made from high-quality PVC material that possesses several advantageous properties. One of the primary characteristics of PVC is its excellent chemical resistance. This makes it an ideal choice for welding in environments where exposure to harsh chemicals is prevalent, such as in chemical processing plants or wastewater treatment facilities.

Another important property of PVC is its UV resistance. Unlike some plastics that degrade under the sun's UV rays, PVC maintains its structural integrity when exposed to sunlight. This feature is particularly beneficial in outdoor applications, where welded structures are subjected to varying weather conditions.

In terms of mechanical properties, PVC has a good tensile strength, making it suitable for applications where strength is essential. Furthermore, PVC welding rods are lightweight and easy to handle, which simplifies the welding process and enhances productivity.

Applications of PVC Welding Rods

PVC welding rods are widely employed in various applications across different industries. One of the most common uses is in the fabrication and repair of PVC piping systems. These systems are often used in plumbing, drainage, and irrigation projects. The use of PVC welding rods ensures a strong, leak-free bond between pipes and fittings, enhancing the overall reliability of the system.

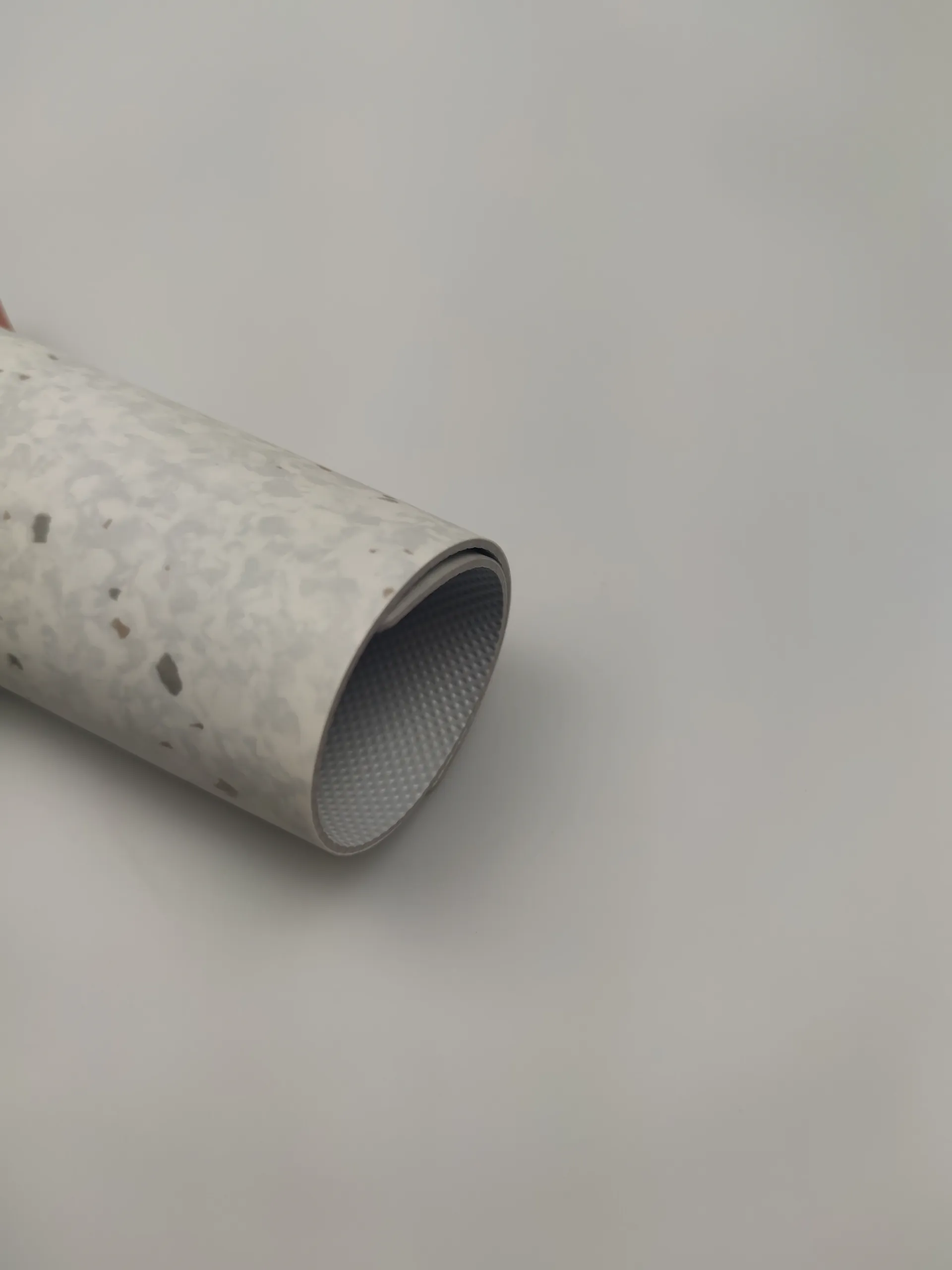

welding rod pvc

In addition to plumbing, PVC welding rods are also utilized in manufacturing signage and displays. The durability and weather resistance of PVC make it an ideal material for outdoor signage, where longevity and visibility are necessary.

Another application can be found in the construction and assembly of PVC furniture and fixtures, where welding provides an aesthetic appeal and structural strength. Moreover, in medical applications, PVC welding rods are used in the production of medical devices and components due to their non-toxic properties.

Benefits of Using PVC Welding Rods

One of the significant benefits of using PVC welding rods is their cost-effectiveness. Compared to other materials, PVC tends to be more affordable, making it a preferred choice for budget-conscious projects. Additionally, the welding process using PVC rods is generally quicker and requires less specialized equipment, which can further reduce project costs and lead times.

Another advantage is the ability to create strong, durable welds that can withstand significant stress and strain. This ensures the longevity of welded products, reducing the need for repairs or replacements over time.

Moreover, PVC welding rods contribute to environmental sustainability. PVC is recyclable, and using welding methods minimizes waste compared to mechanical fastening systems, which often require additional materials like bolts or screws.

Conclusion

PVC welding rods are an essential component in various industries, providing the necessary strength, durability, and resistance to chemical and environmental factors. Their broad range of applications and benefits, from affordability to sustainability, make them a popular choice among engineers, builders, and manufacturers. As industries continue to evolve and demand high-quality materials, PVC welding rods will undoubtedly play a vital role in meeting those needs.

-

modern-interior-solutions-with-durable-pvc-material-skirtingAug.22,2025

-

elevating-outdoor-spaces-with-premium-wood-material-skirtingAug.22,2025

-

Waterproof Advantages of SPC Flooring Vinyl in KitchensAug.06,2025

-

SPC Hybrid Waterproof Flooring Thickness GuideAug.06,2025

-

Leveling Subfloor Before My Floor SPC InstallAug.06,2025

-

How Mesh Deck Skirting Improves Outdoor Pest ControlAug.06,2025