Innovations in Carpet Production and Sustainable Manufacturing Practices for the Future

The Art and Industry of Carpet Manufacture

Carpets have been an essential part of human civilization for centuries, serving both functional and aesthetic purposes. From the luxurious Persian rugs of ancient times to modern synthetic carpets, the art of carpet manufacture has evolved significantly, reflecting cultural trends, technological advancements, and economic factors. This article explores the intricate process of carpet manufacture, the materials used, and the craftsmanship involved, highlighting the balance between tradition and innovation in this timeless industry.

History and Evolution

The history of carpet weaving can be traced back to ancient civilizations, with evidence dating as far back as the 5th century B.C. in Persia. These early carpets were handwoven from natural fibers like wool, cotton, and silk, featuring intricate designs and vibrant colors. Over time, the popularity of carpets spread across Europe, Asia, and North America, influencing various styles and techniques. Today, carpet manufacture combines both traditional methods and modern technology, allowing for greater efficiency and increased production capacity.

Materials Used in Carpet Manufacture

The choice of materials is one of the most critical aspects of carpet manufacturing. Traditionally, wool has been the primary material for high-quality carpets due to its durability, resilience, and natural insulating properties. Wool carpets can withstand heavy foot traffic while maintaining their appearance over time. In addition, wool is a sustainable choice, as it is a renewable resource.

Synthetic fibers, such as nylon, polyester, and polypropylene, have gained popularity in modern carpet manufacturing. These materials offer advantages such as stain resistance, colorfastness, and lower costs. They are ideal for residential and commercial spaces where durability and maintenance are key concerns. However, the growth of eco-conscious consumerism has led to a rise in demand for sustainable products, prompting manufacturers to explore recycled materials and environmentally friendly processes.

The Manufacturing Process

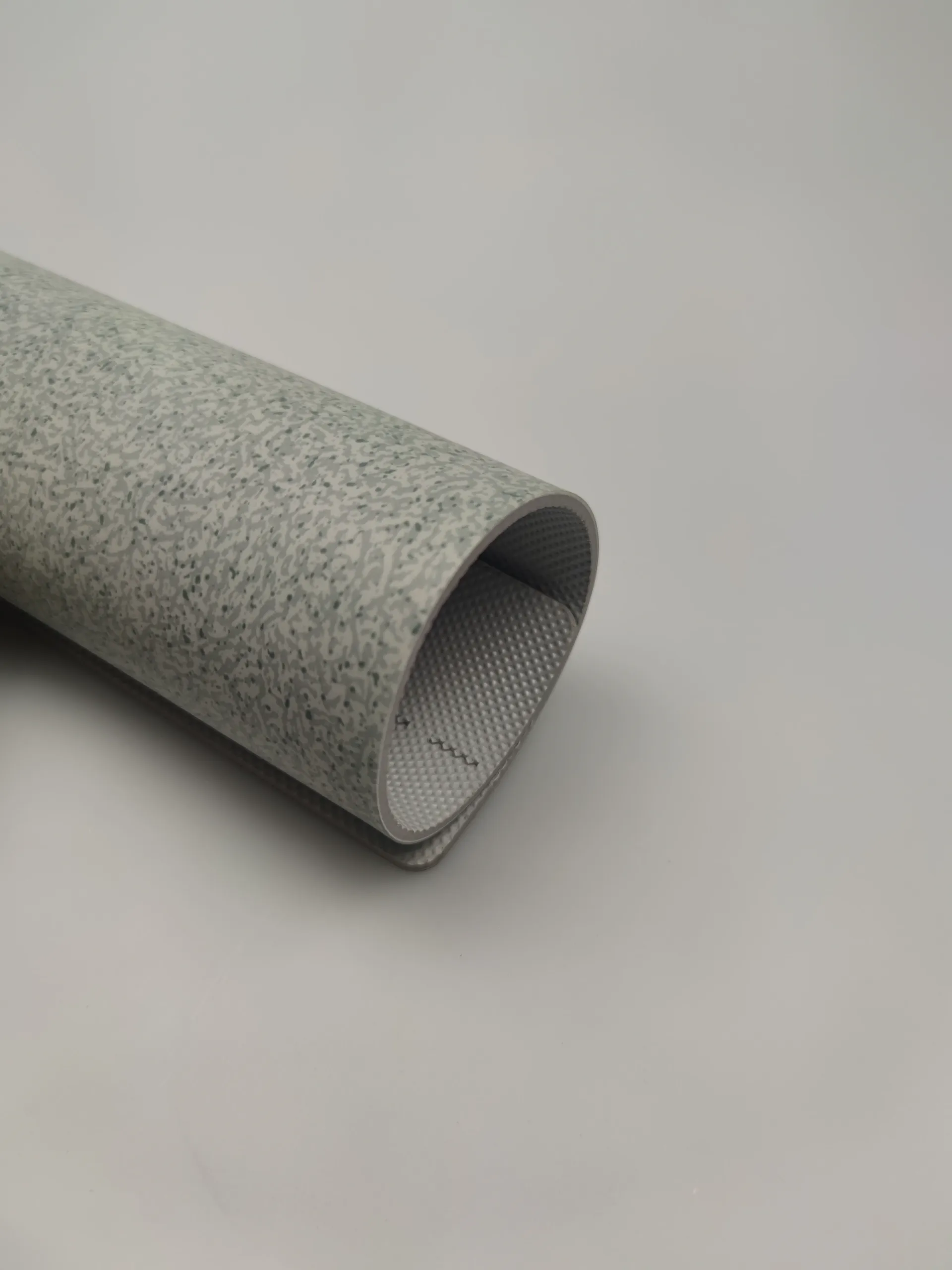

carpet manufacture

The carpet manufacturing process involves several steps, each requiring precision and expertise. The initial stage is the selection of materials, followed by dyeing the fibers to achieve the desired colors. Yarn is then spun from the dyed fibers, which can be woven or tufted into carpets.

Weaving is a traditional method that involves interlacing yarns to create intricate patterns and textures. Techniques such as hand-knotting and flatweave require immense skill and can take months to complete for a single piece. These carpets are often considered works of art due to the time and craftsmanship involved.

Tufting, on the other hand, is a more modern technique that uses a tufting machine to punch yarn into a backing material. This method allows for faster production and is commonly used for wall-to-wall carpeting. The tufted carpets can then be finished with latex backing to enhance durability and stability.

Quality Control and Finishing Touches

Quality control is paramount in the carpet manufacturing process. Each stage is closely monitored to ensure that the final product meets industry standards. After production, carpets undergo finishing processes such as shearing, to create a smooth surface, and treatments to enhance stain resistance.

Finally, carpets are inspected for any imperfections and packaged for distribution. The journey from raw material to final product illustrates the combination of artistry and technology that defines modern carpet manufacture.

Conclusion

Carpet manufacture is a vibrant blend of history, artistry, and innovation. As consumer preferences shift towards sustainability and unique designs, the industry continues to adapt while honoring traditional techniques. Whether handwoven or machine-made, carpets remain a cherished element in homes and public spaces, enhancing comfort and beauty in our everyday lives. As we move forward, the future of carpet manufacture promises exciting developments that honor the past while embracing the possibilities of modern technology.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025