Innovative Laser Safe Masking Tape for Enhanced Precision and Protection in Various Applications

Laser Safe Masking Tape A Game-Changer in Precision Crafting and Production

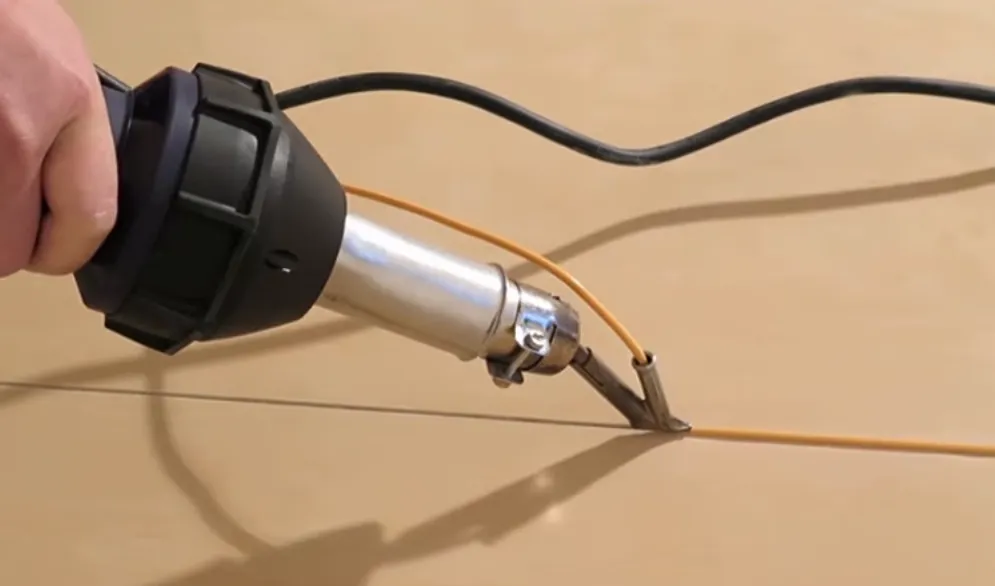

In the world of precision crafting and production, the importance of accurate materials cannot be overstated—especially when dealing with lasers. As technology advances and laser cutting, engraving, and marking become more widespread, the need for effective masking during these processes has grown. Enter laser safe masking tape, a specialized solution designed to meet high standards of precision and safety for all laser-related tasks.

Understanding Laser Safe Masking Tape

Laser safe masking tape is crafted specifically to withstand the intense energy and heat generated by laser applications. Traditional masking tapes can often combust or leave behind residue when exposed to laser beams, which can tarnish or even damage the underlying material. In contrast, laser safe masking tape is composed of materials that do not burn and do not produce harmful fumes during the laser process. This tape is typically made from high-quality, heat-resistant substrates, ensuring that it can protect surfaces without compromising the integrity of the design or application.

Key Benefits of Using Laser Safe Masking Tape

1. Surface Protection One of the primary purposes of masking tape in laser applications is to protect surfaces from unwanted marks or burns. Laser safe masking tape acts as a barrier, ensuring that material remains clean and unblemished post-laser work. This is particularly vital when working with high-value materials such as wood, acrylic, and metals.

2. Clean Release After the laser process is complete, removing the tape should ideally leave no residue or damage behind. Laser safe masking tape is designed for a clean release, so users do not have to worry about sticky remnants or the need for additional cleaning.

laser safe masking tape

3. Versatility Whether you are engaged in crafting, manufacturing, or industrial applications, laser safe masking tape is versatile enough to accommodate a variety of materials. Its adherence and protective qualities make it suitable for different projects, from delicate art pieces to robust engineering applications.

4. Easy to Handle A quality masking tape is user-friendly. Laser safe masking tape is easy to cut, peel, and apply. This feature enables crafters and industrial users alike to work efficiently and effectively, speeding up the overall production process without compromising quality.

5. Environmentally Friendly Options Many manufacturers are now producing eco-friendly laser safe masking tapes, which allow users to make sustainable choices without sacrificing performance. These tapes can often be recycled, aligning with modern eco-conscious practices.

Industry Applications

Laser safe masking tape is widely used across various industries. In the crafting community, hobbyists and professionals alike rely on it for creating intricate designs in woodworks or personalizing gifts using laser engraving. In manufacturing, businesses utilize this tape to delineate specific areas during laser cutting processes, enhancing precision and minimizing waste. Similarly, in signage production, the tape helps ensure clean edges and minimal distortion in design during the laser cutting phase.

Conclusion

With the continual rise of laser technology in crafting, manufacturing, and design, the relevance of laser safe masking tape cannot be ignored. It provides essential protection while delivering superior performance without compromising safety. As more creators and industries tap into the potential of laser applications, the demand for reliable and effective materials like laser safe masking tape will only increase. Investing in this specialized tape not only enhances the quality of the work but also significantly improves workflow, allowing artisans and manufacturers to push the boundaries of what is possible with laser technology.

-

Waterproof Advantages of SPC Flooring Vinyl in KitchensAug.06,2025

-

SPC Hybrid Waterproof Flooring Thickness GuideAug.06,2025

-

Leveling Subfloor Before My Floor SPC InstallAug.06,2025

-

How Mesh Deck Skirting Improves Outdoor Pest ControlAug.06,2025

-

Choosing the Right Commercial Flooring for Your Business NeedsAug.06,2025

-

Choosing the Best Residential Flooring: A Comprehensive Guide to Style, Durability, and ComfortAug.06,2025