Stylish & Durable LVT Flooring | Waterproof Vinyl Solutions

Industry Trends and the Evolution of Resilient Flooring

The B2B flooring sector is experiencing a significant paradigm shift, driven by demands for enhanced durability, aesthetic versatility, and sustainable solutions. Within this evolving landscape, lvt flooring has emerged as a frontrunner, providing a compelling alternative to traditional flooring materials.

Market analysis indicates a robust growth trajectory for resilient flooring, with projections showcasing a compound annual growth rate (CAGR) exceeding 6% over the next five years. This surge is primarily fueled by rising construction activities in commercial, healthcare, and educational sectors, all of which prioritize longevity, ease of maintenance, and sophisticated design. While other options like spc flooring and traditional viny flooring maintain their market share, the advanced manufacturing and multi-layered composition of LVT offer a superior balance of performance and aesthetics. Businesses seeking to buy flooring solutions that deliver both form and function are increasingly turning to premium vinyl options, understanding the long-term value in terms of reduced lifecycle costs and enhanced user experience.

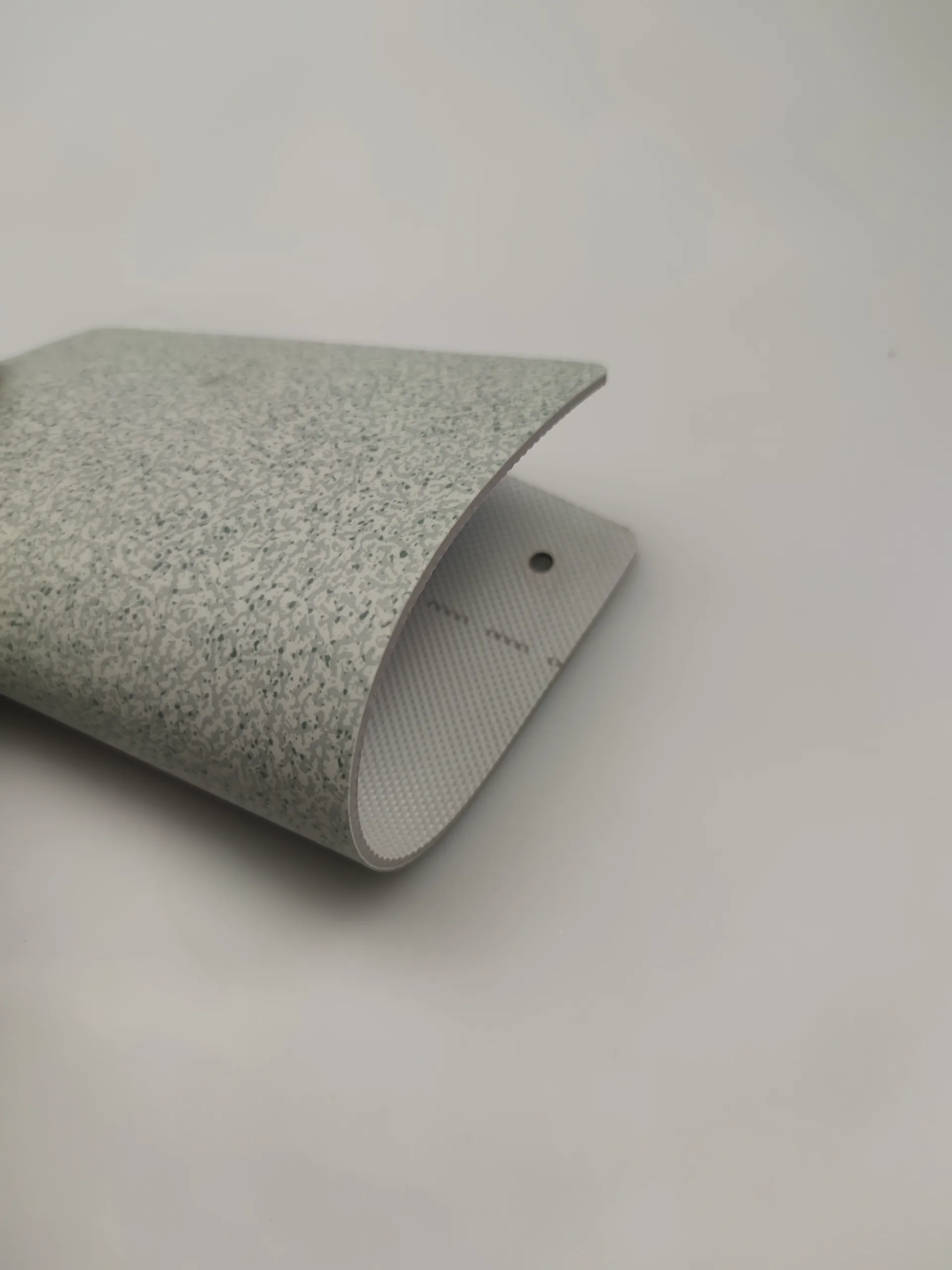

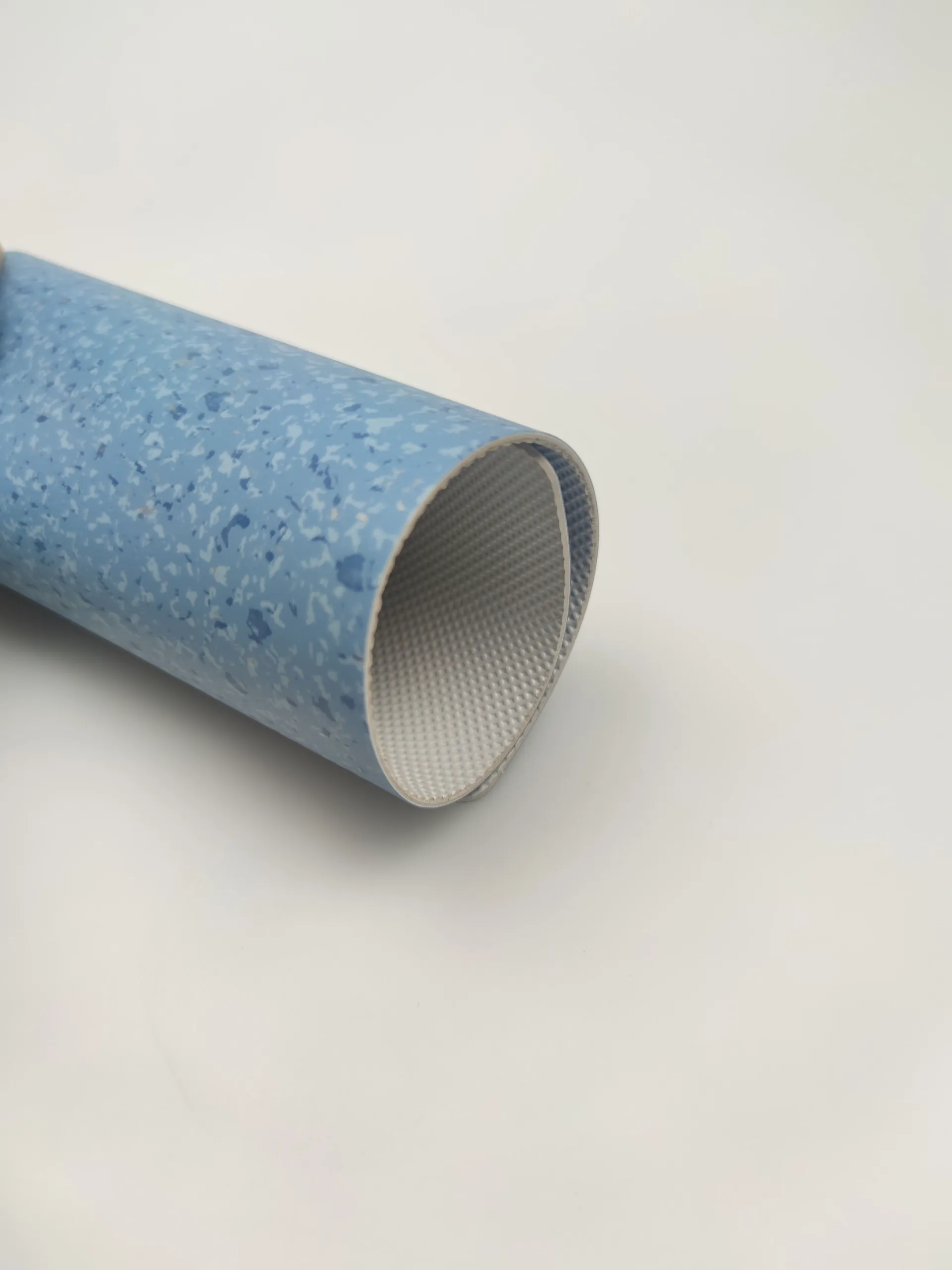

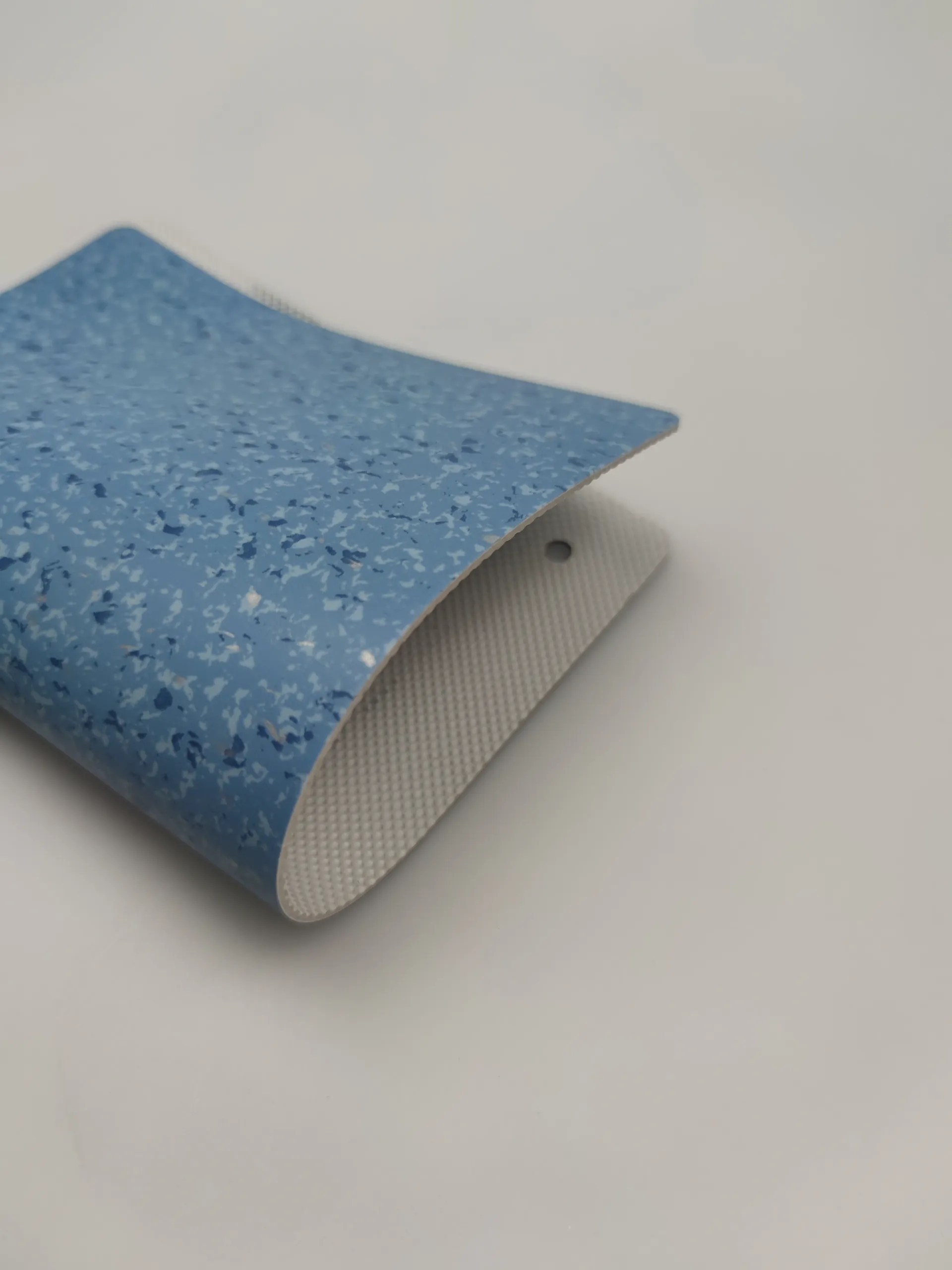

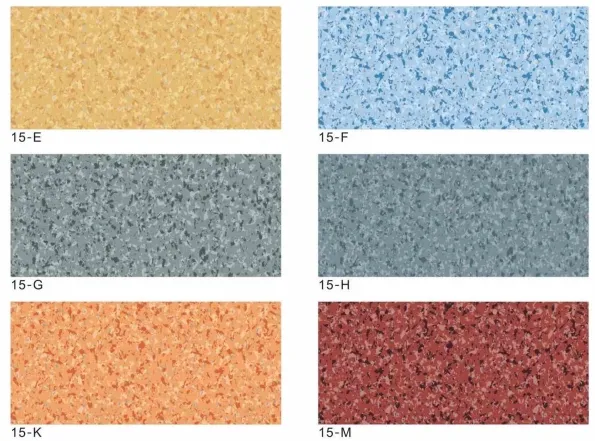

The demand for sophisticated flooring spc and LVT solutions underscores a broader industry trend towards innovation in material science, focusing on aspects like acoustic dampening, slip resistance, and antimicrobial properties. These features are critical in high-traffic commercial environments, contributing to occupant safety and well-being. The "heterogeneous floor with Starrism surface" exemplifies this advancement, offering a blend of technical prowess and visual appeal designed to meet the rigorous demands of modern commercial spaces.

Understanding LVT Flooring: Structure and Manufacturing Process

Multi-Layered Architecture

LVT flooring, or Luxury Vinyl Tile/Plank, is engineered with a sophisticated multi-layered structure to deliver superior performance and aesthetic fidelity. Each layer serves a specific purpose, contributing to the overall durability, stability, and visual appeal:

- UV-Cured Top Coating: A highly durable, transparent layer providing resistance against scratches, scuffs, and stains, while also preventing color fading from UV exposure.

- Wear Layer: The critical protective surface, typically made of clear PVC, which dictates the floor's resistance to abrasion and impact. Thickness varies for residential (0.1-0.3mm) versus commercial (0.5-0.7mm) applications.

- Print Film Layer: A high-definition photographic layer that replicates the natural look of wood, stone, ceramic, or abstract designs with exceptional realism.

- Vinyl Core Layer: The primary structural component, composed of PVC resin mixed with plasticizers, stabilizers, and fillers. This layer provides flexibility, comfort, and dimensional stability.

- Balanced Backing Layer: Often made from vinyl, this layer provides structural balance, preventing curling or warping, and enhancing adhesion to the subfloor.

Detailed Manufacturing Process Flow

The manufacturing of lvt flooring is a meticulous process, far removed from simple molding or traditional metalworking techniques. It involves precise calendering, lamination, and cutting, ensuring high-quality output. The process can be summarized in these key stages:

- Raw Material Preparation & Compounding: High-grade PVC resin, plasticizers (e.g., DINP, DOTP for phthalate-free options), stabilizers, and pigments are precisely measured and mixed in high-speed blenders to create a homogeneous compound. This ensures consistent material properties.

- Calendering of Vinyl Core: The compounded material is fed into a calendering machine, a series of heated rollers that flatten and compress the mixture into thin, continuous sheets, forming the core layers. This process ensures uniform thickness and density.

- Print Film & Wear Layer Preparation: Separately, high-resolution decorative films are printed, and transparent PVC films are prepared for the wear layer.

- Hot Pressing / Lamination: The various layers (backing, vinyl core, print film, wear layer, UV coating) are precisely stacked and subjected to intense heat and pressure in a multi-stage hot press. This process permanently fuses the layers into a single, cohesive sheet. This is analogous to advanced composite material manufacturing, emphasizing structural integrity.

- Annealing & Stabilization: After pressing, the large sheets undergo an annealing process, a controlled cooling phase that relieves internal stresses, preventing warping or curling in the finished product. This is crucial for dimensional stability, especially under varying environmental conditions.

- Sizing & Cutting: The stabilized sheets are then cut into individual planks or tiles according to desired dimensions (e.g., 6x48 inches, 12x24 inches). Precision cutting tools ensure accurate sizing and clean edges.

- Edge Finishing (Beveling/Milling): Edges may be micro-beveled or milled to create specific installation profiles (e.g., click-lock systems or straight edges for glue-down).

- Quality Control & Packaging: Each finished plank or tile undergoes rigorous quality inspections, checking for dimensional accuracy, color consistency, surface defects, and adherence to specified technical parameters. This stage includes testing against industry standards like EN 14041 for resilient floor coverings, ISO 9001 for quality management, and ISO 14001 for environmental management.

Target industries benefiting from this robust manufacturing include healthcare (for hygiene and easy maintenance), education (for durability and acoustic properties), retail (for high traffic and aesthetic appeal), and corporate offices (for professional appearance and comfort). The resulting lvt flooring offers key advantages such as exceptional wear resistance, water impermeability, and minimal volatile organic compound (VOC) emissions, contributing to healthier indoor environments and a prolonged service life typically ranging from 10 to 25 years in commercial settings.

Technical Specifications and Performance Parameters

The performance of lvt flooring is quantifiable through a series of technical parameters, essential for B2B decision-makers to assess suitability for specific applications. Below are typical specifications for a high-quality heterogeneous floor with Starrism surface, reflecting industry standards and superior engineering.

Product Specification Table: Heterogeneous Floor with Starrism Surface

| Parameter | Specification | Testing Standard |

|---|---|---|

| Total Thickness | 2.0mm - 3.0mm (Customizable) | EN ISO 24346 |

| Wear Layer Thickness | 0.5mm - 0.7mm | EN ISO 24340 |

| Commercial Use Classification | Class 33 (Heavy Commercial) | EN ISO 10874 |

| Residual Indentation | ≤ 0.10 mm | EN ISO 24343-1 |

| Dimensional Stability | ≤ 0.15% | EN ISO 23999 |

| Slip Resistance (Dry) | R9 - R10 | DIN 51130 |

| Fire Behavior | Bfl-s1 (Low smoke, limited flame spread) | EN 13501-1 |

| Sound Reduction | Approx. 4-6 dB | EN ISO 717-2 |

| Phthalate Content | Phthalate-free options available | REACH Compliance |

| VOC Emissions | Extremely Low (FloorScore® Certified) | CDPH/EHLB/Standard Method V1.2 |

| Warranty (Commercial) | 10-15 Years | Manufacturer's Standard |

These specifications demonstrate the product's compliance with stringent international standards and its suitability for demanding commercial environments. The combination of a robust wear layer and advanced material composition ensures that products like the heterogeneous floor with Starrism surface offer a durable, safe, and aesthetically pleasing solution for diverse B2B applications.

Diverse Application Scenarios and Proven Experience

The versatility and robust performance of lvt flooring make it an ideal choice across a multitude of B2B application scenarios. Its ability to combine aesthetic appeal with functional advantages addresses the specific needs of various industries, contributing to operational efficiency and user satisfaction.

Key Application Sectors:

- Healthcare Facilities: Hospitals, clinics, nursing homes. LVT’s non-porous surface makes it easy to clean and sanitize, crucial for infection control. Its resilience provides comfort for staff on their feet for long hours, and its sound-absorbing properties contribute to a quieter healing environment.

- Educational Institutions: Schools, universities, libraries. Durability against heavy foot traffic, resistance to spills, and acoustic benefits are paramount. LVT offers a stimulating learning environment with diverse design possibilities.

- Retail & Commercial Spaces: Boutiques, department stores, supermarkets, offices. The ability to emulate high-end materials like wood or stone at a fraction of the cost, coupled with branding opportunities through custom designs, makes lvt flooring a strategic choice. Its resilience ensures longevity in areas with constant customer flow.

- Hospitality Sector: Hotels, resorts, restaurants. LVT delivers a luxurious aesthetic, contributing to guest experience, while standing up to the demands of food and beverage service, spills, and frequent cleaning. Its water resistance is particularly beneficial in these environments.

- Corporate Offices: Enhances workplace aesthetics, provides underfoot comfort for employees, and offers superior acoustic properties which are critical in open-plan offices to reduce noise distractions.

Customer Feedback and Usage Scenarios:

Feedback from our B2B partners consistently highlights the practical benefits. For instance, a leading hospital chain reported a significant reduction in maintenance costs and improved patient satisfaction scores after installing lvt flooring in high-traffic corridors and patient rooms. The ease of cleaning and the hygienic surface were particularly praised. In a university library project, the implementation of LVT led to a noticeable improvement in ambient noise levels, fostering a more conducive study environment, a key factor when facilities buy flooring for quiet areas. Furthermore, a national retail brand utilized custom-designed LVT planks to reinforce their brand identity across multiple store locations, citing the product's durability and design flexibility as crucial for their expansion.

Technical Advantages of LVT Flooring for B2B Operations

The strategic deployment of lvt flooring in commercial and industrial settings offers a multitude of technical advantages that directly impact operational efficiency, long-term cost savings, and occupant well-being. These benefits extend beyond mere aesthetics, providing a robust, high-performance solution for demanding environments.

- Exceptional Durability and Wear Resistance: Engineered with a resilient wear layer (typically 0.3mm to 0.7mm for commercial grades), lvt flooring is highly resistant to scratches, scuffs, and heavy foot traffic. This translates into a longer service life and reduced need for frequent replacement, offering significant economic advantages for businesses needing to buy flooring that endures.

- Superior Water and Moisture Resistance: Unlike natural wood or laminate, LVT is inherently water-resistant, making it ideal for areas prone to spills, such as kitchens, bathrooms, and healthcare facilities. This prevents swelling, warping, and mold growth, preserving structural integrity and hygiene.

- Acoustic Performance: The multi-layered construction provides a degree of sound absorption, reducing impact noise and ambient sound reverberation. This is particularly beneficial in open-plan offices, educational institutions, and healthcare environments where noise control is critical for productivity and comfort.

- Low Maintenance and Enhanced Hygiene: The non-porous surface of LVT is easy to clean and requires minimal maintenance, typically just regular sweeping and damp mopping. This reduces labor costs and the need for harsh chemicals, supporting a healthier indoor environment. Many commercial LVT products also feature antimicrobial treatments.

- Dimensional Stability: High-quality lvt flooring is engineered for superior dimensional stability, minimizing expansion and contraction due to temperature and humidity fluctuations. This ensures the floor remains flat and prevents gaps or buckling over time.

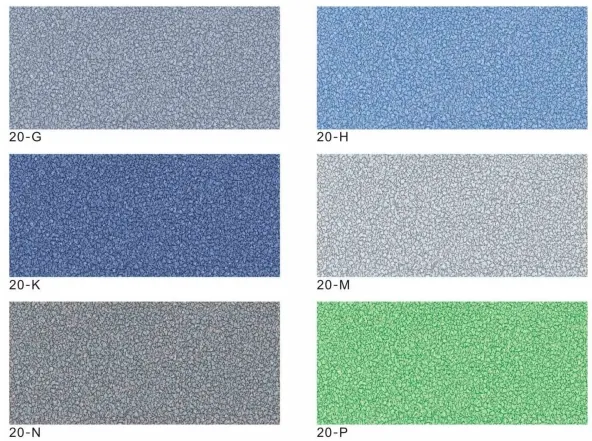

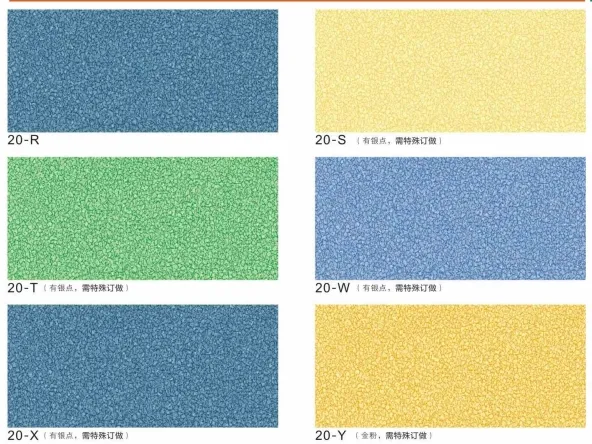

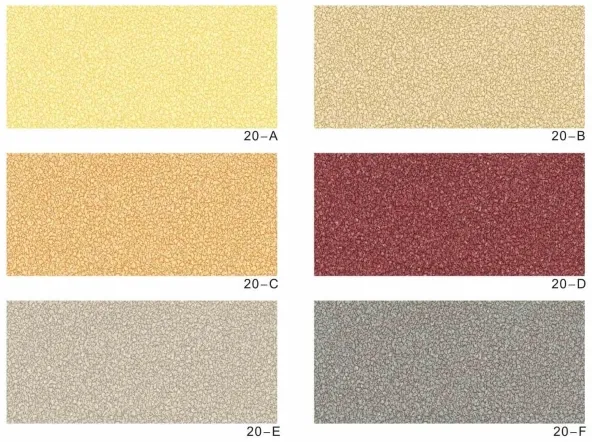

- Design Versatility and Customization: Advanced printing technologies allow for highly realistic reproductions of natural materials like wood and stone, along with a vast array of patterns and colors. This enables architects and designers to achieve specific aesthetic goals without compromising on performance, including custom logo integration.

- Ergonomic Comfort: LVT offers a softer underfoot feel compared to hard surfaces like ceramic tile or concrete. This added resilience provides ergonomic benefits, reducing fatigue for employees who stand for extended periods, a crucial consideration for workplace well-being.

- Cost-Effectiveness and Lifecycle Value: While initial investment might be slightly higher than some entry-level options, the long-term cost of ownership for lvt flooring is significantly lower due to its durability, low maintenance requirements, and extended lifespan. This robust value proposition is often a deciding factor for businesses looking to buy flooring solutions.

Vendor Comparison: LVT Flooring vs. SPC Flooring

When B2B clients look to buy flooring solutions, they often evaluate various resilient options. Two prominent choices are lvt flooring and spc flooring (Stone Plastic Composite). While both fall under the vinyl flooring umbrella, their core compositions and performance characteristics differ significantly, impacting their suitability for specific projects.

Comparison Table: LVT Flooring vs. SPC Flooring

| Feature | LVT Flooring | SPC Flooring |

|---|---|---|

| Core Composition | Flexible PVC and plasticizers | Rigid Stone Plastic Composite (limestone powder + PVC) |

| Rigidity / Flexibility | More flexible and softer underfoot | Very rigid, less flexible |

| Thermal Stability | Good, but slightly more susceptible to temperature fluctuations than SPC | Excellent, highly stable across temperature changes |

| Subfloor Preparation | Requires a very flat, even subfloor to prevent telegraphing | More forgiving of minor subfloor imperfections due to rigid core |

| Underfoot Feel | Warmer and softer, more comfortable | Harder, colder, similar to traditional tile |

| Sound Absorption | Better natural sound dampening properties | Requires attached underlayment for optimal sound performance |

| Application Suitability | Commercial, healthcare, education, retail (where comfort/aesthetics are key) | Areas with extreme temperature fluctuations, heavy machinery, or uneven subfloors |

| Price Point | Mid to High range for commercial grades | Similar to LVT, sometimes slightly higher due to core composition |

This comparison highlights that while flooring spc excels in dimensional stability under extreme conditions, lvt flooring offers superior underfoot comfort and acoustic properties, making it preferred for spaces where user experience is paramount. Vendors like Enlio, with their focus on heterogeneous floor with Starrism surface, differentiate themselves through innovative surface treatments, robust wear layers, and adherence to international quality standards such as ISO 9001 and ISO 14001, providing authoritative and trustworthy solutions.

Customized Solutions and Application Case Studies

Tailored LVT Flooring Solutions

Recognizing the unique requirements of various B2B projects, leading manufacturers offer extensive customization options for lvt flooring. This allows architects, designers, and procurement managers to specify solutions that perfectly align with their functional and aesthetic objectives, moving beyond standard product offerings when they buy flooring.

- Custom Wear Layer Thickness: Tailoring the wear layer from 0.3mm for moderate commercial use up to 0.7mm for extreme heavy-duty traffic areas, optimizing durability and cost efficiency.

- Bespoke Design & Color Matching: Advanced digital printing capabilities allow for custom patterns, corporate logos, specific color palettes, and even photographic reproductions, ensuring brand consistency and unique environmental aesthetics.

- Specialized Coatings: Application of enhanced slip-resistant coatings for safety-critical zones (e.g., healthcare, wet areas), or anti-microbial treatments for hygienic environments (e.g., laboratories, food service).

- Custom Dimensions & Formats: Beyond standard planks and tiles, custom sizes and shapes can be produced to create unique layouts, minimize waste in specific room dimensions, or facilitate intricate design patterns.

- Acoustic Backings: Integration of specialized acoustic underlays during manufacturing to achieve superior sound reduction properties, crucial for multi-story buildings and quiet zones.

Application Case Studies: Proving LVT Flooring Performance

Real-world application demonstrates the robust capabilities and adaptability of lvt flooring:

-

Large University Dormitory Renovation (20,000 sqm):

Challenge: Replace outdated carpeting with a durable, easy-to-clean, and aesthetically pleasing solution that could withstand high student traffic and potential spills, while minimizing installation disruption during summer break.

Solution: A 2.5mm lvt flooring with a 0.5mm wear layer was specified, featuring a wood-look design. The glue-down installation method allowed for quick application. The product's enhanced acoustic properties also contributed to reduced noise transfer between rooms.

Outcome: Project completed ahead of schedule. Facilities management reported a significant reduction in cleaning time and costs. Students praised the comfortable feel and modern aesthetic, leading to increased satisfaction and a longer lifespan for the new flooring compared to previous materials.

-

Regional Airport Terminal Upgrade (15,000 sqm):

Challenge: Install a highly durable, slip-resistant, and visually appealing floor in a 24/7 operational environment with extreme foot traffic, luggage carts, and constant cleaning requirements. Flooring also needed to meet stringent fire safety standards.

Solution: A heavy-duty, 3.0mm heterogeneous floor with a 0.7mm wear layer and a custom stone-look design was chosen. It met Bfl-s1 fire ratings and R10 slip resistance. The resilient nature of the lvt flooring helped cushion impacts from dropped items and absorb sound, improving passenger comfort.

Outcome: The flooring has withstood continuous heavy usage for over five years with minimal signs of wear. Cleaning crews found the smooth, non-porous surface exceptionally easy to maintain, reducing operational downtime and upholding the airport's high cleanliness standards.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Frequently Asked Questions (FAQ)

- Q: Is lvt flooring suitable for high-traffic areas?

- A: Yes, commercial-grade lvt flooring with a wear layer of 0.5mm or thicker is specifically designed and certified for heavy commercial traffic, including retail, healthcare, and educational facilities. Its robust construction ensures long-term durability.

- Q: How should lvt flooring be maintained?

- A: LVT flooring is exceptionally low-maintenance. Regular sweeping or vacuuming to remove debris, followed by damp mopping with a pH-neutral cleaner, is typically sufficient. Avoid harsh chemicals, abrasive cleaners, or excessive water.

- Q: What is the main difference between lvt flooring and spc flooring?

- A: The primary difference lies in their core composition. LVT has a flexible PVC core, offering more underfoot comfort and sound absorption. SPC (Stone Plastic Composite) has a rigid core made of limestone powder and PVC, providing superior dimensional stability in extreme temperatures and better resistance to subfloor imperfections. Your project's specific requirements (comfort vs. rigidity) will guide the choice.

- Q: Are LVT products environmentally friendly?

- A: Many modern LVT products, including our heterogeneous floor with Starrism surface, are manufactured to high environmental standards. They are often phthalate-free, feature extremely low VOC emissions (e.g., FloorScore® certified), and can be recycled at the end of their long lifespan. Inquire about specific product certifications and sustainability reports.

Lead Time & Fulfillment Details

Standard lvt flooring products typically have a lead time of 2-4 weeks from order confirmation to shipment, depending on order volume and current production schedules. For customized solutions (e.g., specific designs, custom wear layers), lead times may extend to 6-8 weeks to accommodate design approval, material sourcing, and specialized manufacturing processes. Our robust supply chain and logistics partners ensure efficient and reliable delivery to your project site. Expedited options are available upon request and project feasibility assessment.

Warranty Commitments

We stand behind the quality and performance of our lvt flooring products. Commercial applications of the heterogeneous floor with Starrism surface are backed by a comprehensive 10 to 15-year limited commercial warranty, covering manufacturing defects, wear, and dimensional stability under normal use conditions and proper maintenance. Full warranty details, terms, and conditions are available upon request and provided with every order documentation.

Customer Support Information

Our dedicated technical sales and customer support teams are available to assist you throughout your project lifecycle. From initial product selection and specification to installation guidance and after-sales support, we provide expert assistance. You can reach us via:

- Phone: [Insert Contact Number]

- Email: [Insert Email Address]

- Online Portal: [Insert Link to Support Portal]

We are committed to providing prompt and effective solutions, ensuring your experience with our lvt flooring products is seamless and satisfactory.

References

- ISO 9001: Quality management systems – Requirements. International Organization for Standardization.

- ISO 14001: Environmental management systems – Requirements with guidance for use. International Organization for Standardization.

- EN 14041: Resilient, textile, laminate and modular mechanical fastened floor coverings - Essential characteristics. European Committee for Standardization.

- FloorScore® Certification: SCS Global Services. Standard for indoor air quality for hard surface flooring materials.

- Frost & Sullivan. (2023). Global Luxury Vinyl Tile (LVT) Market Outlook. (Hypothetical Market Report for illustrative purposes)

- CDPH/EHLB/Standard Method V1.2: Standard Method for the Testing and Evaluation of Volatile Organic Chemical Emissions from Indoor Sources Using Environmental Chambers. California Department of Public Health.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025