Heterogeneous viny flooring – durable, stylish, hygienic

Heterogeneous floor with Nebula surface: a field report from real-world projects

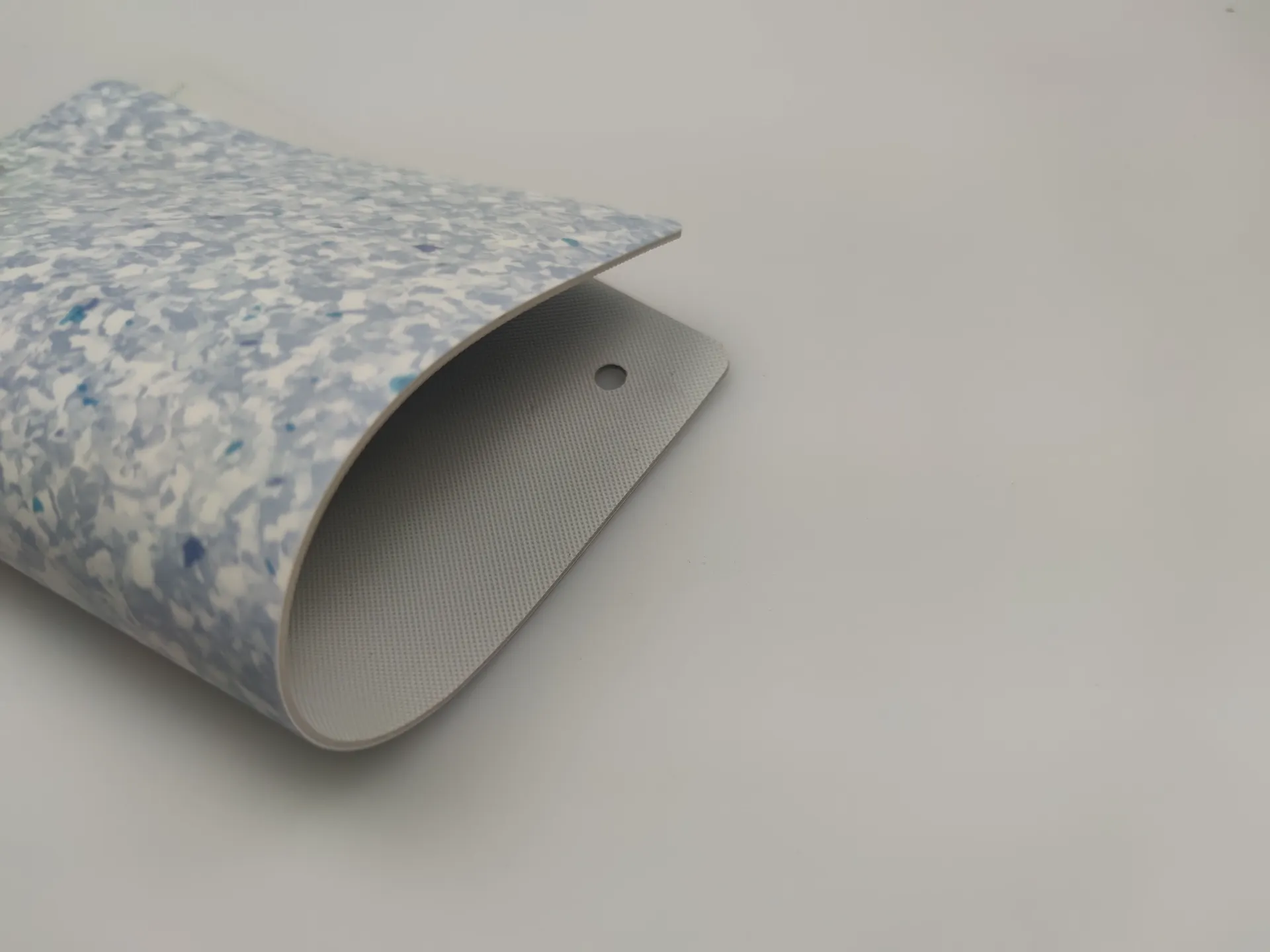

If you’ve been tracking commercial interiors, you’ve probably noticed resilient sheet sweeping hospitals, schools, and transit hubs. The quiet hero: Heterogeneous Viny. To be honest, what looked like “just vinyl” ten years ago is now an engineered system—multi-layered, acoustically tuned, and surprisingly tough.

What’s special about Finequin under Enlio’s umbrella?

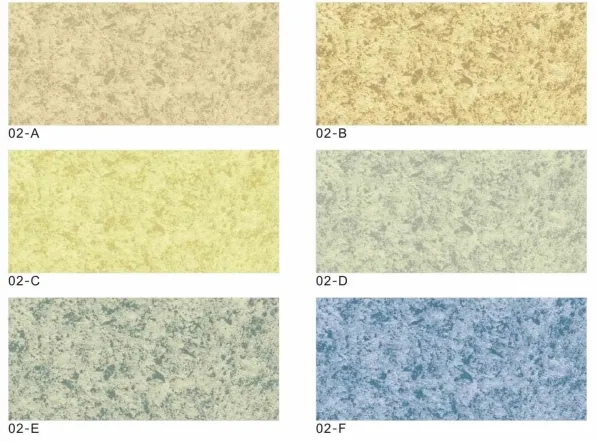

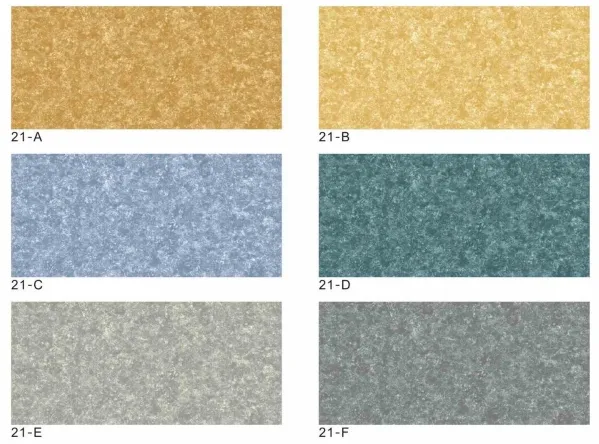

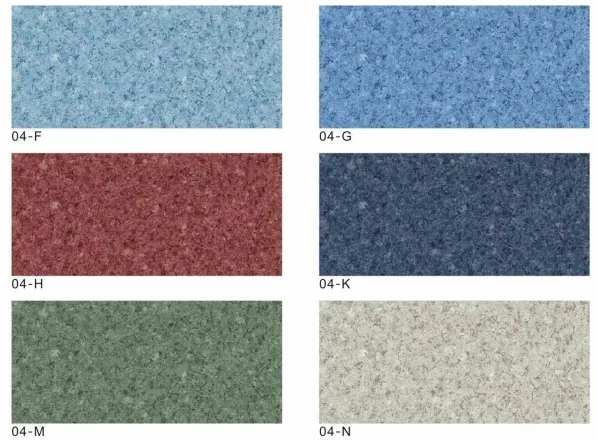

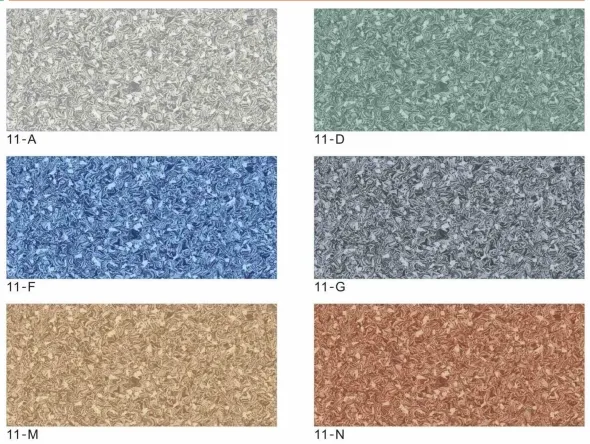

Enlio’s Finequin series—specifically the heterogeneous floor with Nebula surface—leans into durability, easy cleaning, sound reduction, and slip resistance. In fact, each SKU is tuned for a use-case; labs want chemical resistance, corridors need indentation control, clinics care about VOCs. It seems that Enlio has aimed this line squarely at high-traffic, low-fuss facilities.

Product snapshot (typical configuration)

| Construction | Multi-layer PVC with PUR, printed film, glass-fiber reinforcement, compact or foam backing |

| Total thickness | ≈ 2.0 mm (other gauges on request) |

| Wear layer | ≈ 0.50 mm transparent PVC + UV-cured PUR |

| Roll size | 2.0 m × 20 m (around 40 m²/roll) |

| Weight | ≈ 2.8–3.0 kg/m² |

| Slip rating | R10 (DIN 51130); DS (EN 13893) |

| Acoustic comfort | ≈ 6–10 dB (ISO 10140), real-world use may vary |

| Fire | Bfl-s1 (EN 13501-1) |

| Indentation | ≤ 0.10 mm (EN ISO 24343-1) |

| VOC | Low-VOC, tested to ISO 16000 series |

| Service life | 10–15 years in heavy commercial; maintenance dependent |

| Origin | #C3, No. 36 Xiangyuan Rd., Baiyun Dist., Guangzhou, China |

Process flow (how it’s made)

- PVC resin + plasticizers (phthalate-free options), stabilizers, pigments.

- Calendered base layers + printed film; glass-fiber scrim for dimensional stability.

- Hot-pressed lamination; embossed Nebula surface for micro-texture and traction.

- UV-cured PUR topcoat to boost stain, scratch, and cleaning performance.

- Quality checks: abrasion (EN 660-2, Group T), indentation (EN ISO 24343-1), castor chair (EN 425), fire (EN 13501-1), acoustics (ISO 10140), VOC (ISO 16000).

Heterogeneous Viny fits healthcare corridors, classrooms, retail aisles, labs, transit concourses, and light sports/multi-use halls. Many customers say the Nebula surface hides traffic patterns better than flat-finish floors, which I’ve also noticed during site walks.

Vendor comparison (quick buyer’s view)

| Vendor | Pros | Watch-outs | Certs/Warranty | Lead time |

|---|---|---|---|---|

| Enlio Finequin (Nebula) | Balanced spec; easy cleaning; dependable slip + acoustics | Colorways curated; deep customization on request | ISO 9001/14001; CE; 10-year commercial | ≈ 2–4 weeks |

| Vendor A (Budget Import) | Low upfront cost | Variable QC; softer wear layer | Basic docs; 5–7 years | ≈ 4–6 weeks |

| Vendor B (Premium EU) | Extensive palettes; strong branding | Higher price point | EN/ISO portfolio; 10–15 years | ≈ 3–5 weeks |

Customization

- Wear layer: 0.35–0.70 mm depending on traffic class.

- Backing: compact for carts; foam for comfort/acoustics.

- Color/print: Nebula patterns with custom tones for branding.

- Seams: heat-weldable rods to maintain hygiene envelope.

Field notes and case snippets

- City Clinic: switched to Heterogeneous Viny with Nebula surface; cleaning team reported 20–25% faster mopping versus waxed VCT.

- Middle School: foam-back option reduced corridor noise ≈ 7–8 dB; principal called it “a calmer hallway.”

- Retail chain: after 12 months, abrasion still within Group T tolerance; carts didn’t telegraph much indentation.

As one facility manager told me—somewhat surprised—“It just holds up. We don’t think about it, and that’s the point.”

Standards and compliance

Designed to meet EN ISO 10582 for heterogeneous PVC, tested to EN 13501-1 for fire, ISO 10140 for acoustics, and ISO 16000 for VOC. Slip performance validated against DIN 51130 and EN 13893; abrasion to EN 660-2. The boring—but necessary—stuff that keeps specifiers comfortable.

Authoritative citations

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025