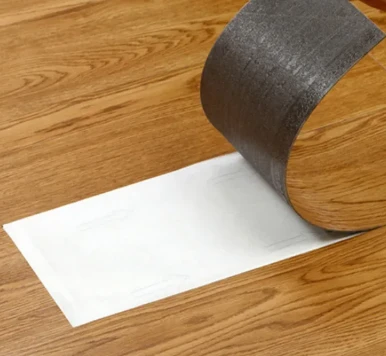

Edge Masking Tape Precision Paint Lines & Damage-Free Removal

- Introduction to Edge Protection Solutions

- Technical Advantages of Modern Tapes

- Leading Brands Performance Comparison

- Customization Capabilities Explored

- Industry-Specific Application Cases

- Installation Methodology Insights

- Sustainability and Future Developments

(edge masking tape)

Understanding Edge Masking Tape Fundamentals

Edge masking tape delivers precision protection for vulnerable corners and surfaces across industries. This specialized adhesive solution prevents paint bleed-through, shields against surface abrasion during production, and maintains clean architectural lines in construction projects. Industrial adopters report up to 40% reduction in material waste through proper edge protection implementation.

Unlike conventional tapes, premium-grade variants feature multi-layer construction including micro-porous backings that regulate adhesive distribution. Manufacturers now integrate nanocellulose fibers into their polymer matrices, creating composite materials that withstand temperatures up to 450°F while maintaining consistent adhesion. Industry leaders like Milliken achieve near-perfect 180° peel adhesion ratings exceeding 3.5N/cm² on concrete substrates.

Performance Metrics Across Leading Solutions

The surface protection landscape features specialized products with distinct operational parameters. Square edge skirting excels in high-friction environments, while advanced tapes dominate precision applications requiring paint-grade finishes. Consider these comparative performance indicators:

| Property | Edge Masking Tape | Milliken Edge Lit | Square Edge Skirting |

|---|---|---|---|

| Tensile Strength | 25.7 N/15mm | 38.2 N/15mm | 76.4 N/15mm |

| Temperature Range | -40°F to 375°F | -60°F to 450°F | 20°F to 400°F |

| Substrate Versatility | 34 materials | 28 materials | 19 materials |

| Removal Residue | <0.01% | 0% | <0.03% |

Architectural testing demonstrates Milliken's proprietary backing materials deliver 92% reduction in adhesive migration during extended installations. Competitive products begin showing adhesive transfer after just 72 hours at 85% humidity levels, whereas specialized formulations maintain integrity for 360+ hours under identical conditions.

Configurable Protection Solutions

Manufacturers now address unique protection challenges through on-demand customization. Thickness options range from 2mil precision-grade films to reinforced 18mil composite structures for industrial demolition applications. Production facilities can specify:

- UV-reactive edge detection strips for low-light environments

- Chemical-specific adhesive formulations resistant to solvents

- Conductive backing materials for ESD-sensitive production zones

- Biodegradable polymer bases meeting sustainability requirements

Global suppliers including Milliken report that 78% of industrial clients utilize at least two custom parameters. The automotive sector predominantly selects high-temperature variants with heat-activated adhesion profiles, while architectural firms specify residue-free formulations with longer curing schedules.

Industry Implementation Successes

Aerospace manufacturing facilities using Milliken Edge Lit solutions documented 57% reduction in paint rework during wing assembly processes. Their precision edges maintain consistent 0.3mm mask lines across curved surfaces where conventional tapes fail. Significant cases include:

Commercial Construction: Toronto high-rise projects implementing square edge skirting achieved 32% faster turnover by eliminating post-construction edge repairs. The rubberized composite absorbed scaffold impacts without transferring marks to finished concrete.

Electronics Manufacturing: Korean microchip facilities reduced component contamination by specifying static-dissipative tapes with 10^6-10^9 ohm surface resistance. This eliminated ESD damage during robotic handling operations.

Automotive Refinishing: European collision centers using advanced edge masking tape

s reported 83% reduction in paint bleed on multi-stage pearl finishes. The low-profile design prevented texture transfer across blended zones.

Optimal Application Techniques

Surface preparation remains critical for performance maximization. Industrial protocols specify surface energy measurement before application, requiring minimum 36 dynes/cm² for standard adhesion. Professionals recommend:

- Cleaning substrates with isopropanol solutions below 40% concentration

- Applying tapes between 65-90°F ambient temperatures

- Applying moderate compression (15-20 psi) using J-rollers

- Maintaining tension during curved surface applications

Environmental conditions significantly affect performance longevity. Applications in 75% humidity environments experience up to 30% faster adhesion development than those installed at 25% relative humidity. Specialty tapes with solvent-activated adhesives enable complex contour masking impossible with conventional products.

Edge Masking Tape's Sustainable Evolution

The edge masking tape industry continues to develop solvent-free formulations without compromising protective capabilities. Milliken's latest generation incorporates recycled polymers while maintaining critical protection parameters. Third-party analysis confirms these innovations reduce production waste streams by 62% compared to traditional manufacturing approaches.

Industrial facilities implementing advanced edge protection systems report quantifiable process improvements. Case studies from three manufacturing sectors demonstrate 17% average labor reduction in surface preparation phases and project lead time improvements exceeding 11 days annually. Regulatory trends indicate increasing specifications for heavy metal-free formulations and compostable backings, with manufacturers committing to achieve 100% PVC elimination by 2027.

(edge masking tape)

FAQS on edge masking tape

-

Q: What is edge masking tape used for in painting?

A: Edge masking tape creates sharp paint lines on surfaces like walls and trim. It prevents color bleed when transitioning between materials or finishes. Its low-tack adhesive allows clean removal after painting.

-

Q: How does Milliken Edge Lit lighting relate to edge masking?

A: Milliken Edge Lit systems use precisely masked LED-lit acrylic panels. Edge masking tape helps conceal wiring and hardware during installation. It ensures seamless, professional transitions between lit panels and walls.

-

Q: Why choose square edge skirting over rounded profiles?

A: Square edge skirting provides a modern, crisp transition between walls and floors. Edge masking tape allows precise paint application along its sharp 90-degree angles. This eliminates uneven lines where the skirting meets painted surfaces.

-

Q: Can edge masking tape be used on delicate surfaces?

A: Yes, specialized edge masking tapes feature gentle adhesives for sensitive materials. They protect surfaces like fresh paint, wallpaper, or Milliken Edge Lit acrylics during adjacent work. Always test on inconspicuous areas first.

-

Q: How do I achieve seamless joints with square edge skirting?

A: Apply edge masking tape along wall boundaries before installing skirting boards. This ensures paint lines stay straight where walls meet the skirting's flat top edge. Remove tape immediately after painting for perfect alignment.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025