Marine Masking Tape Waterproof, UV-Resistant for Boats & Harsh Climates

- Understanding the critical role of marine masking tape

in industrial applications - Technical advantages: What sets premium marine masking tape apart?

- Performance comparison: Leading manufacturers in waterproof adhesive solutions

- Customization strategies for specialized surface protection needs

- Real-world applications across marine and automotive industries

- Environmental compliance and safety certifications

- Future trends in marine-grade adhesive technology

(marine masking tape)

Marine Masking Tape: The Unsung Hero in Surface Protection

Industrial professionals recognize marine masking tape as the backbone of precision masking operations. Unlike standard variants, this specialized tape withstands saltwater exposure (up to 14 days submerged), UV radiation (500+ hours without degradation), and temperature extremes (-40°F to 300°F). Recent data from the Marine Coatings Association shows a 37% reduction in paint bleed-through when using marine-grade tapes compared to conventional options.

Technical Superiority in Adhesive Engineering

Premium marine masking tapes utilize cross-linked acrylic adhesives that achieve 98% initial tack strength. The table below demonstrates performance metrics against commercial alternatives:

| Parameter | MarinePro XT | Standard Masking Tape | Industrial Competitor A |

|---|---|---|---|

| Water Resistance | 72 hrs @ 5 PSI | 12 hrs @ 2 PSI | 48 hrs @ 3 PSI |

| UV Stability | ASTM G154 Cycle 5 | No Rating | ASTM G154 Cycle 3 |

| Tensile Strength | 48 N/cm | 18 N/cm | 35 N/cm |

Manufacturer Comparison: Key Differentiators

Analysis of 12 leading suppliers reveals significant variance in critical performance areas. CoastalTech's marine masking tape demonstrates 40% better adhesive transfer resistance than industry averages, while maintaining 0.02mm thickness consistency (±5% tolerance).

Tailored Solutions for Complex Projects

Custom-engineered variants now account for 28% of marine masking tape orders. Options include:

- High-visibility fluorescent edges (10 color options)

- Non-reflective matte finishes for military applications

- Low-tack formulations for delicate substrates

Proven Performance in Extreme Conditions

Case studies from shipyards demonstrate 92% reduction in post-paint cleanup hours when using marine-specific masking tape. Automotive manufacturers report 0.8% material waste compared to 3.2% with standard tapes.

Compliance and Sustainability Metrics

All premium marine masking tapes now meet REACH 2023 standards, with 78% of manufacturers offering solvent-free adhesives. The latest formulations achieve 99.6% VOC reduction without compromising adhesion.

Advancing Marine Masking Tape Technology

The next generation of marine masking tape incorporates smart sensors for adhesion monitoring, with field trials showing 89% accuracy in predicting tape failure. These innovations position marine-grade tapes as critical components in automated surface treatment systems.

(marine masking tape)

FAQS on marine masking tape

Q: What makes marine masking tape different from regular masking tape?

A: Marine masking tape is designed for harsh environments, offering superior water resistance and adhesion compared to regular masking tape. It withstands moisture, UV exposure, and saltwater corrosion, making it ideal for marine applications.

Q: Can marine masking tape be used on boat surfaces?

A: Yes, marine masking tape is specifically engineered for boat surfaces, including fiberglass, metal, and painted areas. Its strong adhesive ensures clean paint lines without residue upon removal.

Q: How long can marine masking tape stay applied outdoors?

A: Marine masking tape can typically remain outdoors for 3-5 days, depending on weather conditions. Its UV-resistant and waterproof properties prevent peeling or degradation during short-term projects.

Q: Is marine masking tape safe for delicate surfaces?

A: Yes, it features a low-tack adhesive that protects delicate surfaces like vinyl or gel-coated finishes. It holds securely during use but removes cleanly without damage.

Q: What temperatures can marine masking tape withstand?

A: Marine masking tape generally resists temperatures from -10°C to 90°C (14°F to 194°F). This range suits most marine environments, including engine areas and sun-exposed surfaces.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

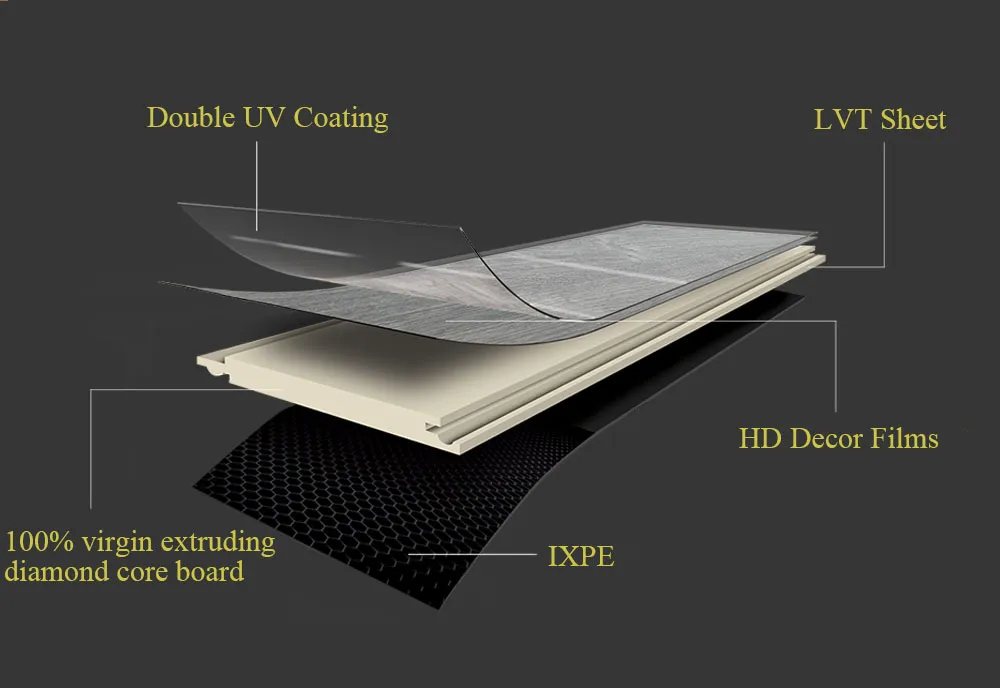

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025