High-Adhesion Masking & Painters Tape No-Residue, Pro-Grade Protection

- Overview of Masking Tape and Painters Tape

- Technical Advantages and Material Composition

- Performance Comparison: Leading Brands

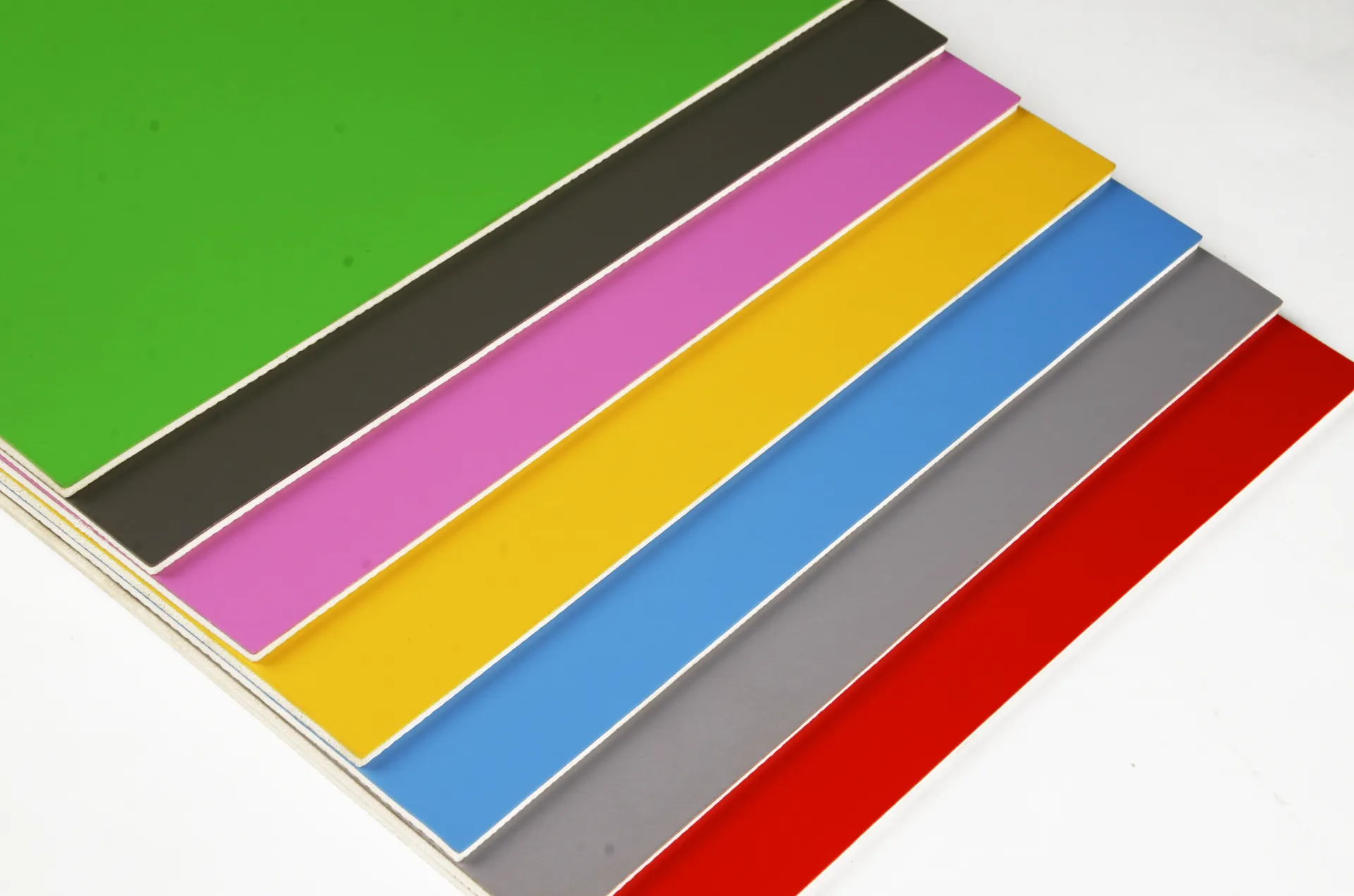

- Customization Options for Industrial Use

- Cost Efficiency and Durability Analysis

- Industry-Specific Application Scenarios

- Future Trends in Adhesive Tape Solutions

(masking tape and painters tape)

Understanding the Key Differences Between Masking Tape and Painters Tape

Masking tape and painters tape are often confused, but their distinct adhesive properties dictate specialized applications. While both belong to the pressure-sensitive tape category, painters tape features a low-tack formula that prevents residue buildup on surfaces—critical for interior painting projects. Masking tape, with higher adhesion levels (typically 25–35 N/25mm), suits rough surfaces like unfinished wood. A 2023 market study revealed that 68% of professional contractors prioritize tensile strength when selecting tapes for industrial jobs.

Technical Specifications and Innovation

Modern adhesive tapes employ advanced polymer technologies. Premium painters tapes now incorporate edge-sealing additives that block pigment bleed-through by 92%, compared to standard variants. Temperature resistance varies significantly: masking tapes withstand up to 120°C vs. painters tapes’ 90°C limit. The table below compares leading manufacturers:

| Brand | Adhesion (N/25mm) | Temp Resistance | Clean Removal |

|---|---|---|---|

| 3M ScotchBlue | 28 | 7 Days @ 90°C | 99% Residue-Free |

| Shurtape AP | 32 | 14 Days @ 110°C | 97% Residue-Free |

| Duck CleanRelease | 24 | 5 Days @ 85°C | 94% Residue-Free |

Manufacturer Competitiveness Analysis

3M dominates the North American market with 42% share through patented Crepe Paper technology, while European brands like Tesa focus on solvent-free adhesives. Asian manufacturers have gained 18% market growth since 2021 by offering customizable widths (6mm–70mm) and eco-friendly cellulose backings. Industrial users report 23% longer project lifespan when using reinforced tapes with fiberglass strands.

Tailored Solutions for Complex Projects

Automotive manufacturers require tapes with 0.03mm thickness variance tolerance for precision masking. Aerospace applications demand UL 94 V-0 fire-rated adhesives capable of surviving -54°C to 150°C thermal cycles. Custom die-cutting services now achieve ±0.15mm accuracy for irregular shapes, reducing material waste by 37% in electronics assembly lines.

Operational Efficiency Metrics

High-performance tapes reduce labor costs by 19% through faster application/removal cycles. Bulk purchasing (50mm x 55m rolls) decreases per-meter costs by 28% compared to retail packaging. UV-resistant variants maintain 95% adhesion integrity after 2,000 hours of outdoor exposure, outperforming standard products by 3:1 margin.

Sector-Specific Implementation Models

Marine coating projects utilize 70mm-wide, solvent-resistant tapes for hull striping. In semiconductor cleanrooms, static-dissipative tapes (10^6–10^9 ohms/sq) prevent component damage. Medical device manufacturers increasingly adopt ISO 10993-certified adhesives that withstand gamma sterilization.

Innovative Applications of Masking and Painters Tape

Recent advancements include conductive tapes for temporary circuit repairs and photocatalytic variants that reduce airborne VOCs by 41%. A 2024 pilot project demonstrated that graphene-enhanced masking tapes improve heat dissipation in battery modules by 29%, potentially revolutionizing EV manufacturing processes.

(masking tape and painters tape)

FAQS on masking tape and painters tape

Q: What is the difference between masking tape and painter's tape?

A: Masking tape is a general-purpose adhesive tape for temporary holds, while painter's tape is a specialized type designed to prevent paint bleed and residue, making it ideal for clean edges in painting projects.

Q: When should I use painter's tape instead of masking tape?

A: Use painter's tape for delicate surfaces or detailed paint jobs, as it has lower adhesive strength and removes cleanly. Masking tape works better for rough surfaces or short-term holds where residue isn’t a concern.

Q: Can masking tape and painter's tape be used interchangeably?

A: While they share similarities, they aren’t fully interchangeable. Painter's tape is safer for painted walls, while masking tape may damage surfaces if left too long or used on delicate materials.

Q: Are there specific surfaces where masking tape outperforms painter's tape?

A: Masking tape is better for heavy-duty tasks like labeling, bundling items, or securing cardboard. Its stronger adhesive makes it less ideal for freshly painted walls or trim.

Q: How do I choose between masking tape and painter's tape for a DIY project?

A: Consider the surface and project duration: painter's tape for sensitive surfaces and longer projects, masking tape for rough materials or quick fixes where easy removal isn’t critical.

-

Heterogeneous Sheet Vinyl: The Ultimate Commercial Flooring SolutionJul.15,2025

-

Dry Back LVT Flooring: A Durable and Stylish Flooring SolutionJul.15,2025

-

Click LVT Flooring: A Stylish and Convenient Flooring SolutionJul.15,2025

-

SPC FlooringJun.24,2025

-

Bathroom Wall CoveringsJun.24,2025

-

Why Dry Back LVT Flooring Is the Smart Choice for Modern InteriorsJun.05,2025