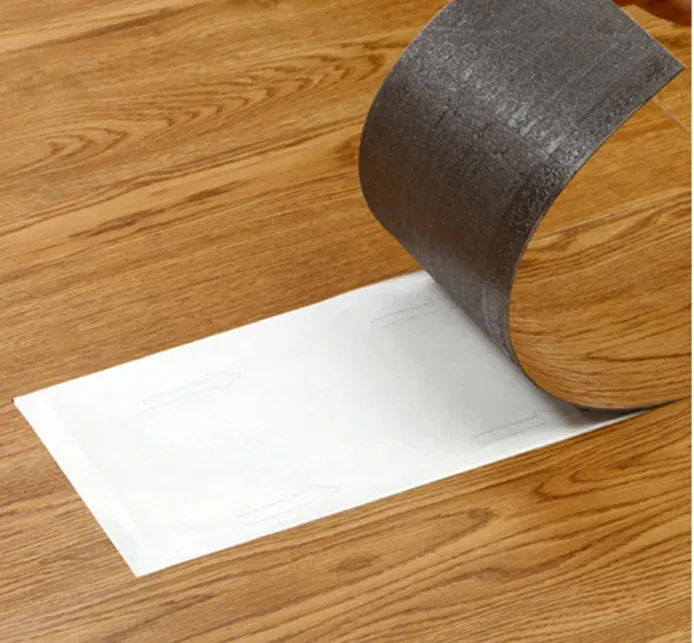

Dry Back LVT Flooring – Durable, Glue-Down, Waterproof

What Pros Really Think About Dry-Back LVT

If you’re comparing resilient surfaces, you’re probably eyeing Dry Back Lvt Flooring—the glue-down workhorse installers trust. It’s not flashy in the way click systems are, but it’s the steady, commercial-grade option that keeps retail, healthcare, and education environments humming. To be honest, I’ve seen a lot of products come and go; this segment just keeps gaining ground because it solves the boring, expensive stuff: stability, rolling loads, repairs, and lifecycle cost.

Quick trend check

Specifiers tell me the swing is back toward glue-down in high-traffic spaces. Why? Lower thermal movement, better point-load performance (think carts and hospital beds), and easier plank-by-plank replacement. Post-pandemic, low-VOC certifications and quiet underfoot acoustics are almost table stakes.

How it’s built (and tested)

A typical stack: stabilized backing → fiberglass or high-density core → printed film → transparent wear layer with PU topcoat. Thickness runs 2–5 mm, with wear layers around 0.3–0.7 mm. The glue-down format of Dry Back Lvt Flooring bonds flat to the subfloor, so dimensional stability is excellent when installed per ASTM and EN standards.

- Key standards: ASTM F1700 (solid vinyl tile), EN/ISO 10582, EN 13501-1 (fire), EN 13893/ISO 10582 slip, and FloorScore/SCS for VOCs.

- Expected service life: ≈10–20 years in commercial use (real-world use may vary).

- Origin (manufacturer base): #C3, No. 36 Xiangyuan Rd., Baiyun Dist., Guangzhou, China.

Product specs at a glance

| Construction | Heterogeneous PVC, PU-coated wear layer |

| Thickness | ≈2.0–5.0 mm |

| Wear layer | ≈0.3–0.7 mm (commercial options) |

| Sizes | Plank ≈152×914 mm; Tile ≈457×457 mm |

| Dimensional stability | ≤0.10% (EN ISO 23999) |

| Fire rating | Bfl-s1 (EN 13501-1) target |

| Slip resistance | R9–R10 typical (EN 13893) |

| Static load | ASTM F970 ≤0.005 in. indent @ 750 psi (typ.) |

| VOC | FloorScore certified; TVOC low-emitting |

From materials to floor: process flow

Materials are calendered, laminated under heat/pressure, and UV-cured. Patterns are digitally printed for realistic wood/stone looks. After conditioning, planks are cut and squared, then batch-tested: thickness, stain resistance, peel strength (adhesion), dimensional stability, and colorfastness (ISO 105-B02). Installers use pressure-sensitive or 2-part adhesives over a flat, dry subfloor (RH per ASTM F2170). Rolling load? This is where Dry Back Lvt Flooring shines.

Where it fits best

- Retail aisles, boutiques, and quick-serve dining (high footfall, fast repairs).

- Healthcare corridors, clinics, and labs (seam integrity, rolling loads).

- Education: classrooms, libraries, admin offices.

- Multifamily: kitchens, entries; plus back-of-house in hospitality.

Many customers say cleaning is “mop-and-go.” Stains from coffee and iodine usually release with neutral cleaner. I guess the biggest surprise is how quiet it feels under trolleys compared with some hard ceramics.

Vendor snapshot (what buyers compare)

| Vendor | Certifications | Lead Time | MOQ | Customization | Warranty |

| Enlio (origin: Guangzhou) | ISO 9001/14001, FloorScore, CE | ≈3–5 weeks | ≈500–1,000 m² | Prints, emboss, size, wear layer | Up to 10–15 yrs (use-case) |

| Vendor A | ISO, CE | ≈6–8 weeks | ≈1,500 m² | Limited SKUs | 5–10 yrs |

| Vendor B | FloorScore | ≈4–6 weeks | ≈1,000 m² | Color only | 8–12 yrs |

Customization and real-world results

- Design: bespoke wood/stone prints, EIR emboss up to ≈0.15 mm.

- Performance: select wear layer (0.3/0.5/0.7 mm), anti-bacterial topcoat options.

- Acoustic: underlayment packages to hit IIC/STC targets (project-specific).

Case study 1 (Retail, 1,800 m²): Boutique chain swapped cracked ceramics for Dry Back Lvt Flooring. Result: ≈25% faster nightly maintenance and fewer grout-stain complaints.

Case study 2 (Healthcare corridor, 3,200 m²): Glue-down spec won over click due to rolling beds. Post-occupancy testing showed indentations recovering within spec after 24h; iodine stains removed with neutral cleaner.

Why pick it (in plain words)

Advantages: dimensional stability, easy spot repairs, realistic looks, and proven test pedigree. However, subfloor prep matters—a lot. Get RH and flatness right, and Dry Back Lvt Flooring feels almost boringly reliable. Which is exactly what facilities teams want.

Authoritative citations

- ASTM F1700 – Standard Specification for Solid Vinyl Floor Tile.

- ISO 10582 – Resilient floor coverings — Heterogeneous poly(vinyl chloride) (PVC).

- EN 13501-1 – Fire classification of construction products and building elements.

- SCS Global Services – FloorScore Indoor Air Quality Certification (SCS-EC10.3).

- ASTM F2170 – Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025