Durable Commercial Flooring: Waterproof SPC, Heavy Traffic

Hospitals Need Floors That Don’t Flinch: A Practical Insider’s Look

If you’ve ever managed a busy healthcare corridor at 2 a.m., you know why durable commercial flooring is not just a spec line—it’s an operational backbone. I recently revisited Puenie-branded homogeneous vinyl from Enlio’s healthcare lineup (product: “homongeneous floor for hospital”), and it reminded me how far resilient surfaces have come: quieter carts, tighter seams, better infection-control routines. Origin matters too—this line is manufactured at #C3, No. 36 Xiangyuan Rd., Baiyun Dist., Guangzhou, China.

Trends? Post-pandemic, specifiers want low-VOC sheets, heat-welded seams, integrated coves, and documented lifecycle; sustainability programs increasingly ask for EPDs and take-back. In fact, facilities teams tell me that reliable weld rods and indentation resistance now weigh as much as color.

What “Homogeneous” Really Buys You

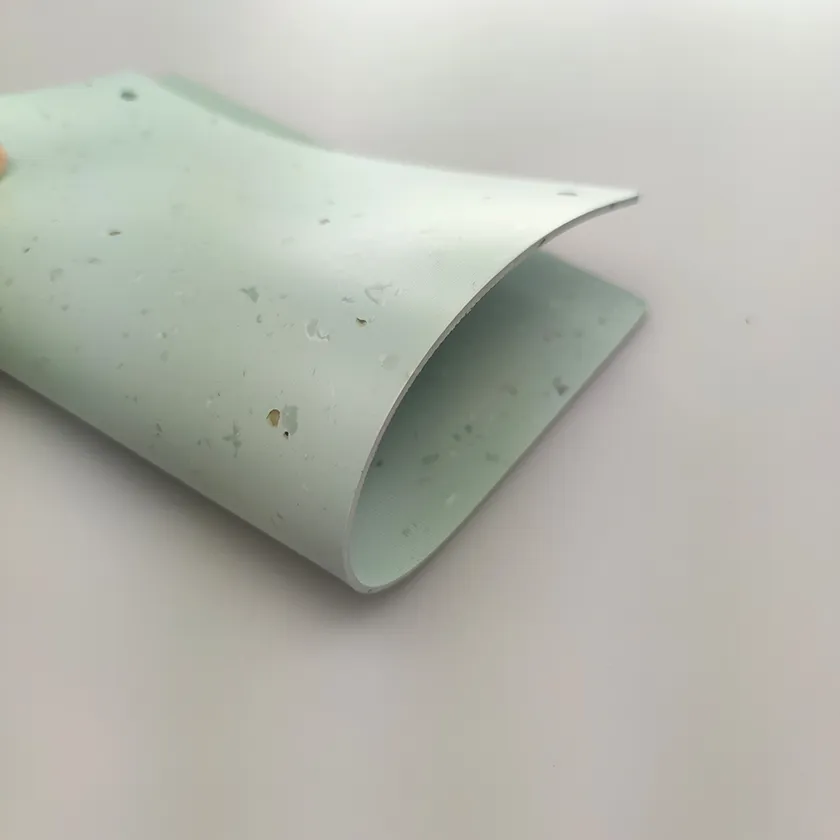

Enlio’s premium homogeneous vinyl (Puenie) is a single-layer through-chip sheet—same formulation top to bottom, so wear patterns are less visible and maintenance is simpler. To be honest, that consistency is a lifesaver in high-turnover spaces like med-surg floors and imaging suites.

Typical Product Specs (hospital sheet)

| Construction | Single-layer homogeneous PVC (through-chip) |

| Thickness | ≈ 2.0 mm (common healthcare spec) |

| Wear performance | EN 660-2 wear group T (lab-tested; real-world use may vary) |

| Indentation | Residual ≤ 0.10 mm (EN ISO 24343-1) ≈ typical for quality homogeneous sheet |

| Slip | DIN 51130 R9–R10 (application dependent); EN 13893 ≥ 0.3 DS |

| Fire | EN 13501-1 Bfl-s1 (indicative for hospital-grade vinyl) |

| Indoor air | Low-VOC per ISO 16000 series; FloorScore options typically available |

| Anti-static | ≤ 2 kV (EN 1815), standard antistatic class |

| Service life | 10–20 years with proper maintenance (traffic-dependent) |

Process & Quality Flow (how it’s made)

Materials: medical-oriented PVC resin, stabilizers, plasticizers (often phthalate-free options), pigments, and mineral fillers. Methods: mixing → calendering → hot-press consolidation → emboss (if any) → PUR or similar top treatment → cooling → trimming. Testing: EN ISO 10581 for homogeneous PVC specs, EN 660-2 wear, EN 13501 fire, EN 13893 slip, ISO 22196 antibacterial activity checks, and routine dimensional stability. Quick note: many healthcare tenders also request ASTM F970 (static load) and cleanroom outgassing data.

Where It Works (and why)

- Corridors, nurses’ stations, labs: rolling loads, constant cleaning.

- Patient rooms and imaging suites: hygiene, acoustics, comfort underfoot.

- Pharmacies and support areas: chemical resistance and tight welded seams.

- Education, retail back-of-house, transit hubs: the same durable commercial flooring criteria apply.

Vendor Snapshot (what buyers compare)

| Vendor | Strengths | Considerations |

|---|---|---|

| Enlio (Puenie homogeneous) | Hospital-focused colors, robust wear group T, welded-seam ecosystem | Verify VOC documentation for local green schemes |

| Global Brand A | Broad EPD/HPD library, strong global stock | Premium pricing in some regions |

| Global Brand B | Specialty options (ESD, acoustic backing) | Lead times for niche SKUs |

Customization & Install Notes

Colors and chip patterns can be tuned for wayfinding; matching weld rods and pre-formed coves smooth infection-control workflows. Installers usually heat-weld seams, flash-cove to 100–150 mm, then finish with a PUR maintenance layer. Many customers say the biggest win is predictable cleaning: neutral cleaner, auto-scrubber, and periodic polish—nothing exotic.

Field Stories (short and honest)

A 600-bed hospital in South China reported quieter night shifts after swapping cracked tiles for durable commercial flooring sheet—less grout, fewer trip edges. Another clinic chain cited reduced downtime: welded seams plus coved upstands made terminal cleans faster. Feedback wasn’t perfect (a chemotherapy prep room needed extra chair glides), but overall abrasion and stain resistance held up.

Compliance snapshot: look for EN ISO 10581 conformity, EN 660-2 wear group T, EN 13501-1 Bfl-s1 fire, EN 13893 slip, ISO 16000 low VOC, and—where required—ASTM F970 for static load. Always confirm current test reports.

Citations

- EN ISO 10581: Resilient floor coverings — Homogeneous poly(vinyl chloride) — Specifications. https://www.iso.org/standard/67807.html

- EN 660-2: Resilient floor coverings — Determination of wear resistance. https://standards.iteh.ai/catalog/standards/cen/8cf1e5c9-9d6d-4f7b-9b0e-7e2c5a5d9a3b/en-660-2

- EN 13501-1: Fire classification of construction products and building elements. https://standards.cen.eu

- EN 13893: Slip resistance for resilient floor coverings. https://standards.iteh.ai

- ISO 16000 series: Indoor air — VOC measurement. https://www.iso.org/committee/546318.html

- ASTM F970: Standard Test Method for Static Load Limit. https://www.astm.org/f0970

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025