LVT Flooring: Durable, Waterproof & Stylish Vinyl Floors

Understanding LVT Flooring: A Technical Deep Dive for B2B Applications

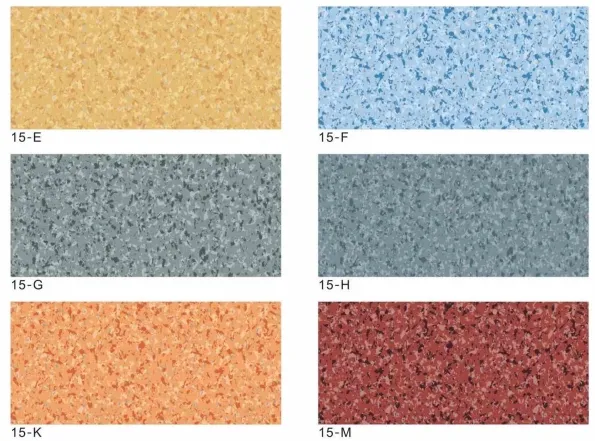

In the rapidly evolving landscape of commercial and industrial flooring, the demand for durable, aesthetically versatile, and cost-effective solutions is paramount. Among the myriad options, lvt flooring has emerged as a leading contender, particularly its advanced heterogeneous variants like the "heterogeneous floor with Starrism surface." This comprehensive guide provides B2B decision-makers and engineers with a detailed technical overview, covering its manufacturing, specifications, applications, and strategic advantages.

The Advanced Manufacturing Process of LVT Flooring

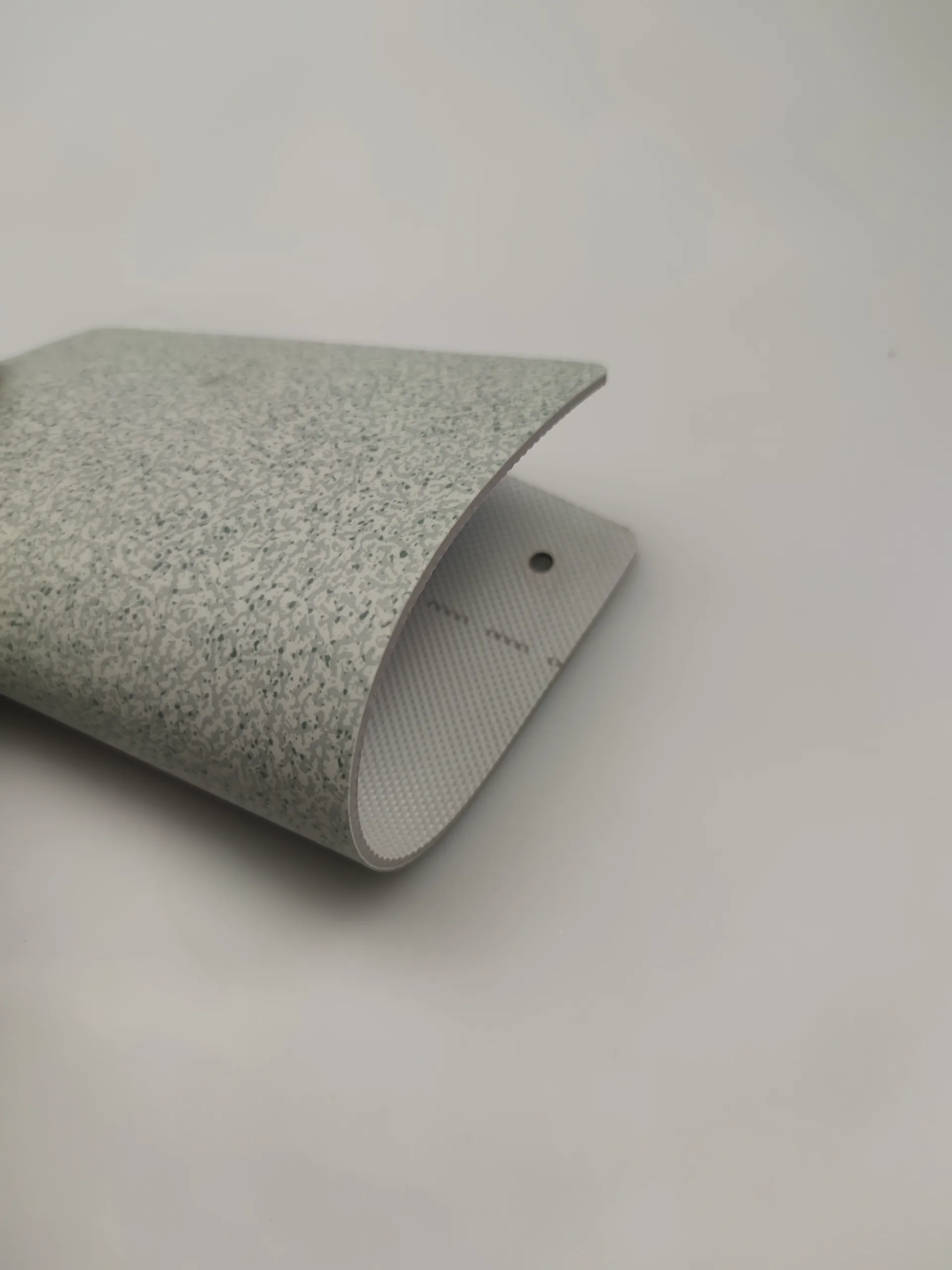

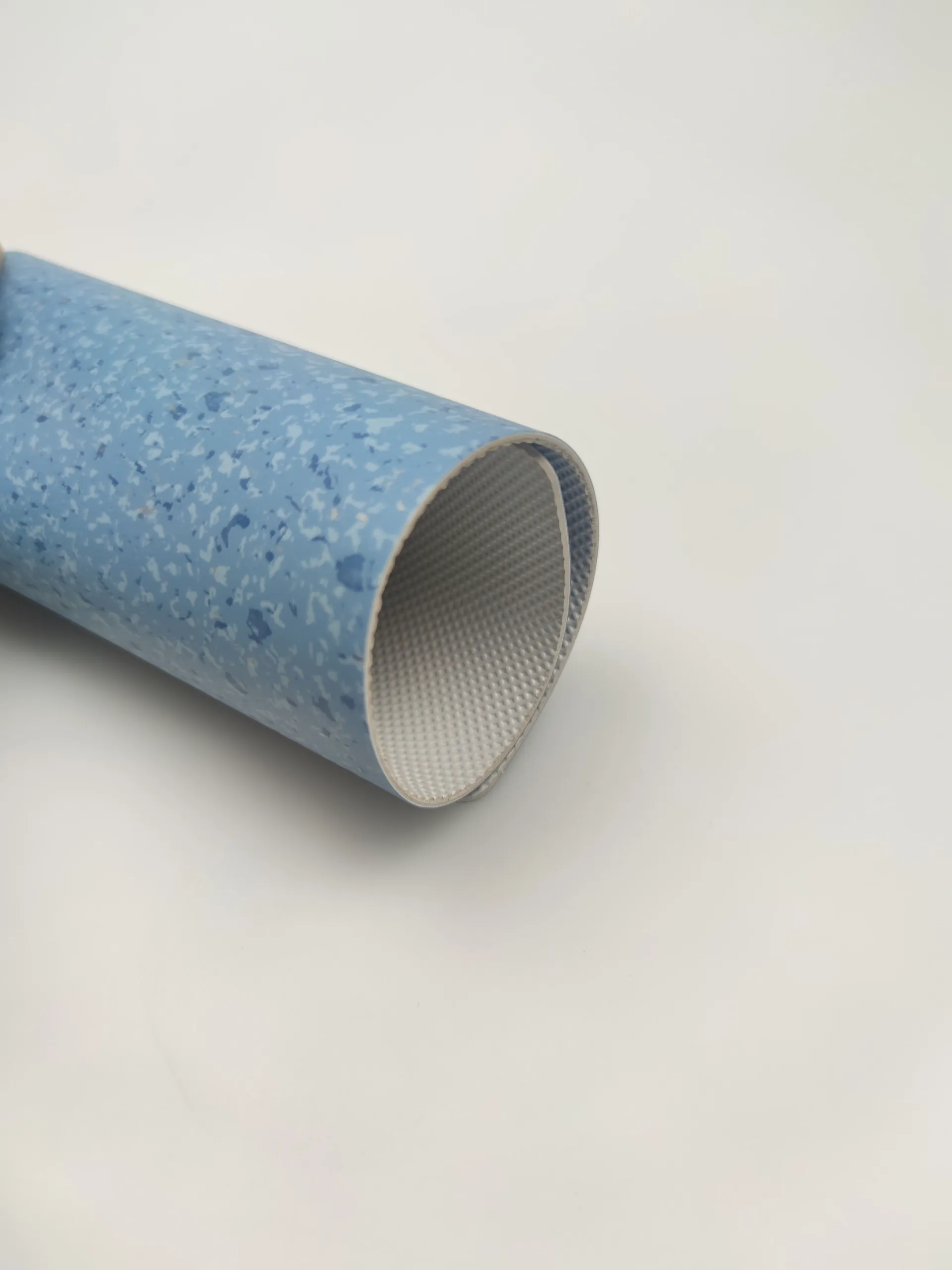

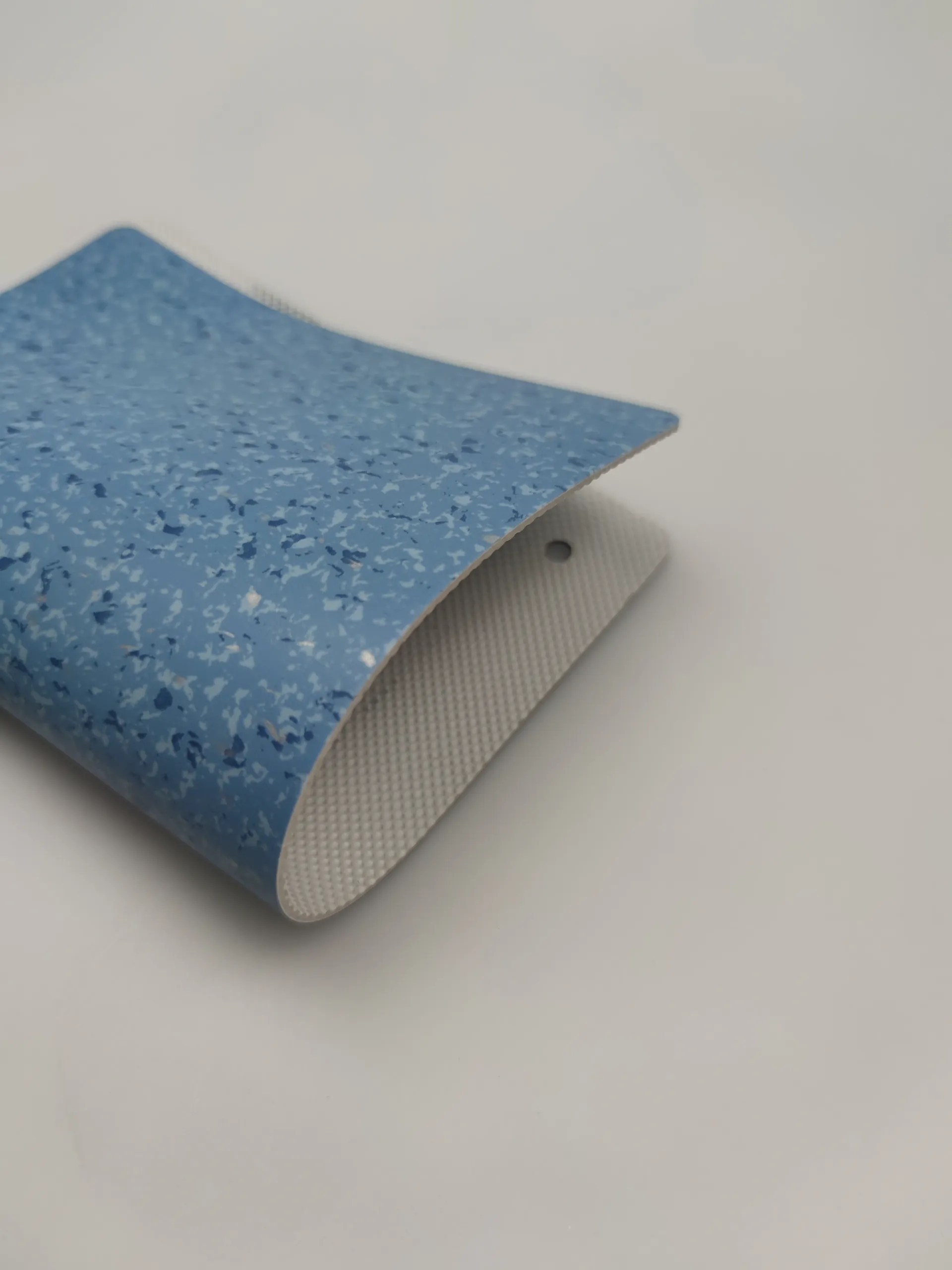

The sophisticated multi-layer structure of lvt flooring is a result of a meticulously engineered manufacturing process, ensuring its renowned durability and performance. Unlike traditional vinyl sheet or tile, LVT undergoes a precise lamination and pressing sequence to create a robust and stable product. Understanding this process is crucial for appreciating its technical advantages.

Process Flow Breakdown:

- Raw Material Preparation: High-grade PVC resins, plasticizers (e.g., DOTP, DINP for phthalate-free options), stabilizers, and fillers (e.g., calcium carbonate) are meticulously weighed and mixed. For products like the Starrism surface, specialized color pigments and surface agents are incorporated to achieve the unique aesthetic.

- Calendering/Extrusion: The prepared compound is fed into a calendering machine, which heats and flattens the material into continuous sheets of consistent thickness. Alternatively, extrusion processes can create the core layers, often incorporating fiberglass mesh for enhanced dimensional stability, a key feature in modern viny flooring.

- Print Film Application: High-definition decorative films, offering realistic wood, stone, or abstract patterns, are precisely applied to the base layer. This layer defines the visual appeal of the lvt flooring.

- Wear Layer Lamination: A transparent, highly durable wear layer (often polyurethane-enhanced) is applied over the print film. This critical layer protects against scratches, scuffs, and abrasions. For heavy-duty industrial applications, wear layers can range from 0.3mm to 0.7mm or more, significantly impacting service life.

- UV Curing & Embossing: The wear layer often undergoes UV curing to further enhance its hardness and stain resistance. Simultaneously, the material may pass through embossing rollers to impart texture, such as an authentic wood grain or stone finish, matching the underlying print.

- Cooling & Stabilization: After lamination and embossing, the material is slowly cooled to ensure dimensional stability and prevent warping.

- Cutting & Edge Finishing: The cooled sheets are then cut into individual planks or tiles according to specified dimensions. Precision cutting technologies ensure tight tolerances for seamless installation. For click-lock systems, advanced CNC machining creates the interlocking profiles.

- Quality Control & Testing: Throughout the process, stringent quality control measures are implemented. Samples are subjected to various tests including dimensional stability (ISO 23999), wear resistance (EN 660-2), indentation resistance (EN 433), slip resistance (EN 13893), and fire resistance (EN 13501-1). Adherence to international standards like ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) is standard for reputable manufacturers.

The service life of a high-quality lvt flooring product can extend from 10-15 years in commercial settings to 20-30 years or more in lighter traffic environments, depending on the wear layer thickness and maintenance regimen.

Industry Trends and Market Dynamics

The global flooring market, particularly the segment for resilient flooring, continues to witness robust growth. Key drivers include increasing commercial construction, renovation projects, and a growing preference for low-maintenance and durable flooring options. According to Grand View Research, the global vinyl flooring market size was valued at USD 23.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 8.2% from 2023 to 2030. Within this, lvt flooring and spc flooring are dominant categories.

- Sustainability Focus: Manufacturers are increasingly prioritizing eco-friendly formulations, using recycled content, phthalate-free plasticizers, and low-VOC emissions to meet green building standards and certifications like LEED.

- Technological Advancements: Innovations in print technology allow for hyper-realistic designs, while enhanced wear layers offer superior scratch and stain resistance. The rise of rigid core vinyl, including SPC (Stone Plastic Composite) and WPC (Wood Plastic Composite), represents a significant trend, offering even greater dimensional stability. Many clients seeking to buy flooring now specifically look for these advanced options.

- Hybrid Solutions: The market is seeing a convergence of features, with products borrowing strengths from different categories. For instance, LVT planks with click-lock mechanisms that mimic the ease of laminate, or products designed for specific high-traffic or wet environments.

- Digital Integration: Online visualization tools and AR/VR applications are helping B2B clients better envision flooring solutions in their specific spaces, streamlining the decision-making process for large-scale projects.

Technical Specifications and Performance Metrics

The performance of lvt flooring is quantified through several critical technical specifications. For a product like the "heterogeneous floor with Starrism surface," these parameters define its suitability for various demanding environments.

Key Specifications (Example: Starrism Surface LVT):

| Parameter | Specification | Standard / Significance |

|---|---|---|

| Total Thickness | 2.0mm - 5.0mm | Impacts durability and comfort. Commercial grades typically 3.0mm+. |

| Wear Layer Thickness | 0.3mm - 0.7mm | Critical for resistance to abrasion and scratches. 0.5mm+ for heavy commercial. |

| Abrasion Group | T (EN 660-2) | Highest abrasion resistance rating for resilient flooring. |

| Dimensional Stability | ≤ 0.10% (EN 434, EN 23999) | Crucial for preventing gapping or curling due to temperature fluctuations. |

| Residual Indentation | ≤ 0.10mm (EN 433) | Resistance to permanent indentations from heavy static loads. |

| Slip Resistance | R9 - R10 (DIN 51130) | Ensures safety in commercial environments. Higher R-values indicate more grip. |

| Fire Resistance | Bfl-s1 (EN 13501-1) | High level of fire safety, low smoke emission. Essential for public buildings. |

| Chemical Resistance | Good (EN 423) | Resistant to common household and commercial chemicals, essential for easy cleaning. |

| Acoustic Insulation | 10dB - 19dB (EN ISO 717-2) | Reduces impact sound transmission, improving indoor comfort. |

These specifications underscore why lvt flooring is a preferred choice for demanding environments, balancing aesthetic appeal with uncompromising performance.

Application Scenarios and Technical Advantages

The versatility of lvt flooring makes it suitable for a vast array of commercial and industrial applications. Its inherent technical advantages provide superior performance over traditional materials in many critical sectors.

Target Industries:

- Healthcare Facilities: Hospitals, clinics, nursing homes. Advantages include aseptic properties, easy cleaning, sound dampening for patient comfort, and resistance to common sanitizers.

- Educational Institutions: Schools, universities, daycare centers. Benefits from high durability against heavy foot traffic, low maintenance, and a comfortable, quiet learning environment.

- Retail & Hospitality: Stores, hotels, restaurants, cafes. Offers high aesthetic appeal, customized branding potential, excellent wear resistance, and quick installation to minimize downtime.

- Corporate Offices: Enhances acoustic comfort, provides a professional aesthetic, and withstands rolling chair traffic without damage.

- Light Industrial/Manufacturing: Control rooms, assembly areas where chemical resistance and easy cleaning are crucial. It's often chosen over bare concrete or epoxy in certain zones for comfort and aesthetic.

- Water Supply & Drainage Facilities: In administrative and control areas, where moisture resistance is critical, viny flooring offers superior performance compared to porous materials.

Demonstrated Advantages in Typical Application Scenarios:

- Corrosion Resistance: Unlike some traditional materials, LVT's PVC composition provides excellent resistance to a wide range of chemicals, acids, and alkalis, making it ideal for laboratories or areas prone to spills.

- Energy Saving: While not a direct insulator in the manner of a wall, the inherent thermal properties of LVT contribute to a more stable room temperature, potentially reducing HVAC load marginally compared to very cold surfaces like stone or concrete. Its ease of cleaning also translates to lower maintenance energy expenditure.

- Moisture Resistance: A significant advantage, particularly in areas like bathrooms, kitchens, and basements in commercial buildings. The multi-layer construction prevents water ingress, safeguarding the subfloor and preventing mold/mildew growth. This is a key differentiator when businesses buy flooring for damp environments.

- Superior Durability: The robust wear layer, combined with a stable core, resists heavy foot traffic, impacts, and abrasions, ensuring a long-lasting aesthetic and functional surface.

- Acoustic Comfort: LVT inherently absorbs sound better than hard surfaces, contributing to a quieter environment, which is vital in offices, schools, and healthcare settings.

- Hygiene and Maintenance: Its non-porous surface is incredibly easy to clean and sanitize, making it an excellent choice for environments where hygiene is paramount.

LVT vs. SPC Flooring: A Vendor Comparison

While both lvt flooring and spc flooring fall under the category of luxury vinyl, they possess distinct characteristics critical for B2B procurement. Understanding these differences is key to selecting the optimal solution.

Comparison Table: LVT vs. SPC

| Feature | LVT (Luxury Vinyl Tile/Plank) | SPC (Stone Plastic Composite) |

|---|---|---|

| Core Material | Flexible PVC, plasticizers, and stabilizers. | Ultra-dense core of limestone powder, PVC, and stabilizers. |

| Thickness (Total) | 2mm - 5mm (often glued down) | 4mm - 8mm (often click-lock with attached underlayment) |

| Dimensional Stability | Good, but more susceptible to temperature changes than SPC. | Excellent; virtually impervious to temperature and humidity fluctuations. |

| Underfoot Feel | Softer, more flexible, warmer. | Firmer, more rigid. Can feel colder without an underlayment. |

| Subfloor Preparation | Requires a very smooth, level subfloor (especially glue-down LVT). | More forgiving of minor subfloor imperfections due to rigidity. |

| Installation | Glue-down, loose lay, or click-lock (flexible). | Primarily click-lock (rigid floating floor). |

| Cost (approx.) | Generally slightly lower per square meter than SPC. | Generally slightly higher per square meter due to core technology. |

| Application | Commercial, light industrial, healthcare, retail. | High traffic commercial, kitchens, bathrooms, sunrooms, areas with extreme temperature swings. |

Reputable vendors will offer both LVT and flooring spc solutions, providing detailed specifications and guiding clients to the optimal product based on the specific project requirements, budget, and desired performance characteristics. When you buy flooring, consider the long-term total cost of ownership, including installation and maintenance, not just the initial material price.

Customized Solutions and Application Case Studies

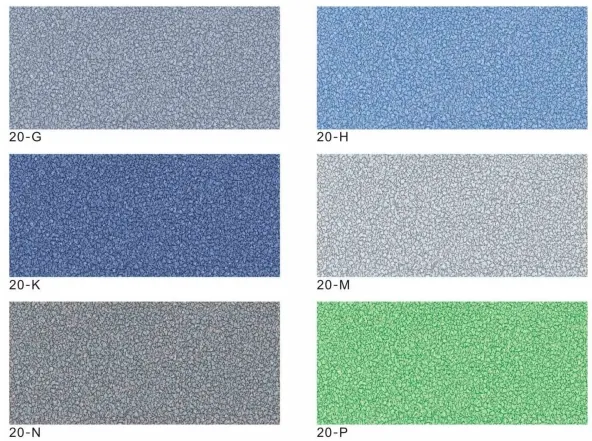

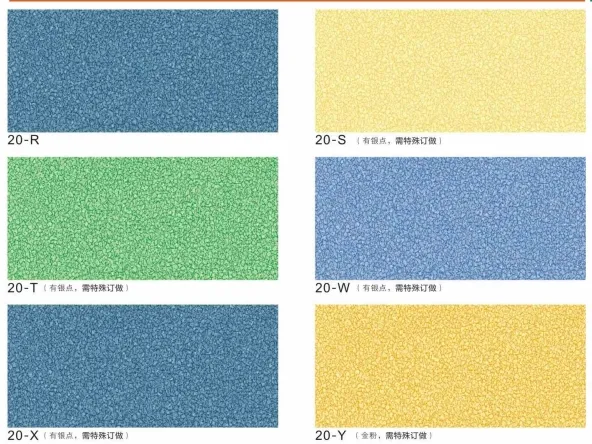

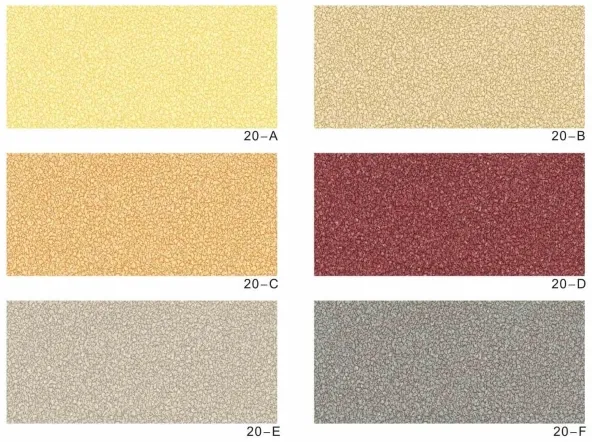

The ability to customize lvt flooring solutions is a significant advantage for B2B clients seeking to align their flooring with specific brand aesthetics, functional requirements, or architectural designs. From bespoke patterns to unique color palettes, modern LVT manufacturers can deliver tailored products.

Customization Options:

- Design & Pattern: Custom print films can replicate virtually any material, pattern, or even incorporate company logos and specific branding elements directly into the floor.

- Color Matching: Precise color matching to corporate guidelines or specific interior design schemes is possible through advanced digital printing techniques.

- Wear Layer Thickness: Tailoring the wear layer to the exact traffic intensity of a space ensures optimal durability and cost-effectiveness.

- Size & Format: Custom plank or tile sizes can be produced to fit unique room dimensions or create specific visual effects.

- Integrated Underlayment: For click-lock systems, an integrated acoustic underlayment can be specified to meet precise sound reduction targets.

Application Case Studies (Illustrative Examples):

Client: Major National Retailer, 50+ locations.

Challenge: Existing ceramic tile was prone to cracking, difficult to clean, and offered poor acoustics in high-traffic aisles. Needed a solution with brand-consistent aesthetics, extreme durability, and quick installation during overnight shifts.

Solution: Custom-designed lvt flooring planks (0.7mm wear layer, 4.0mm total thickness) with a hyper-realistic distressed wood look. The chosen product featured superior scratch resistance and an integrated acoustic backing. Installation was conducted in sections, allowing stores to remain operational.

Results: Reduced installation time by 30% compared to previous solutions. Significant reduction in noise levels (15dB improvement). Zero reported wear layer failures or cracking after 3 years, exceeding client expectations for durability and ease of maintenance.

Client: Multinational Technology Firm, new headquarters.

Challenge: Required a modern, sophisticated flooring solution for open-plan offices, conference rooms, and executive suites. Key requirements included high acoustic performance, anti-static properties for sensitive equipment zones, and a seamless visual transition between different functional areas.

Solution: A combination of glue-down lvt flooring tiles for open-plan areas (ensuring maximum stability and allowing for custom patterns) and click-lock SPC planks with integrated sound-dampening for executive offices. Anti-static treatments were applied to the wear layer in specific areas. The "heterogeneous floor with Starrism surface" was used in reception areas for its unique visual appeal.

Results: Achieved desired aesthetic continuity and professional ambiance. Acoustic performance met stringent corporate standards (measured

Ensuring Trustworthiness: FAQ, Lead Times, Warranty, and Support

Frequently Asked Questions (FAQ)

A: While highly durable, LVT is best suited for commercial, healthcare, retail, and light industrial applications. For extremely heavy machinery or chemical exposure (e.g., in a petrochemical plant's main production area), specialized industrial epoxy or concrete coatings might be more appropriate. However, LVT excels in administrative, control room, and ancillary areas within these industries.

A: LVT flooring generally offers a lower total cost of ownership due to easier, faster installation (reducing labor costs), minimal maintenance requirements, and superior durability against wear, spills, and impact compared to traditional hardwood or ceramic, which can chip, crack, or require refinishing.

A: In many cases, yes, provided the existing subfloor is clean, dry, flat, and structurally sound. SPC products are generally more forgiving of minor subfloor imperfections than traditional glue-down LVT. A professional assessment is always recommended when you buy flooring for such installations.

A: Modern LVT and flooring spc products are increasingly manufactured with phthalate-free plasticizers and low VOC emissions. Many manufacturers offer certifications like FloorScore® or GREENGUARD, indicating adherence to strict indoor air quality standards. Responsible sourcing and end-of-life recycling programs are also growing in the industry.

Lead Time and Fulfillment

For standard LVT products, lead times typically range from 2-4 weeks for production and shipping, depending on order volume and destination. Customized solutions or very large-scale projects may require 6-8 weeks for design, production, and quality assurance. Our logistics team works closely with clients to optimize delivery schedules and ensure timely fulfillment for project deadlines. Expedited options are often available upon request.

Warranty Commitments

We stand behind the quality of our viny flooring products with comprehensive warranties. Commercial warranties for our heterogeneous LVT with Starrism surface typically range from 10 to 15 years against manufacturing defects, wear-through, and delamination under normal commercial use. Specific terms and conditions are provided with each product quotation, ensuring transparency and client peace of mind.

Customer Support and After-Sales Service

Our commitment extends beyond product delivery. We offer dedicated technical support, including installation guidance, maintenance recommendations, and troubleshooting assistance. Our team of experts is available via phone and email to address any queries, ensuring the long-term performance and satisfaction with your lvt flooring investment. We also provide access to comprehensive cleaning and maintenance guides designed to extend the life and appearance of your flooring.

References

- 1. Grand View Research. (2023). Vinyl Flooring Market Size, Share & Trends Analysis Report. Retrieved from grandviewresearch.com (Please note: this is a placeholder for a real URL if it were allowed as a hyperlink).

- 2. European Committee for Standardization (CEN). (2018). EN 13501-1: Fire classification of construction products and building elements.

- 3. International Organization for Standardization (ISO). (2018). ISO 23999: Resilient floor coverings - Determination of dimensional stability and curling after exposure to heat.

- 4. ASTM International. (2020). ASTM F1700 - Standard Specification for Solid Vinyl Tile and Solid Vinyl Plank.

- 5. The Vinyl Institute. (2022). Technical Guidelines for Commercial Vinyl Flooring.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025