Premium LVT Flooring: Durable, Waterproof & Stylish Vinyl

The Evolution of Advanced Resilient Flooring: Industry Trends in LVT and SPC

The global resilient flooring market is experiencing unprecedented growth, driven by increasing demand for durable, aesthetically versatile, and easy-to-maintain solutions across commercial and industrial sectors. Among these, lvt flooring stands out as a dominant force, offering a sophisticated blend of design flexibility and robust performance. Market analysis indicates a significant compound annual growth rate (CAGR) for luxury vinyl tile, projected to exceed 8% globally through 2028, reflecting its widespread adoption in various B2B environments. This surge is attributed to its advanced multi-layered construction, which provides superior resistance to wear, moisture, and impact, making it ideal for high-traffic areas.

Alongside traditional luxury vinyl tile, the emergence of rigid core alternatives like spc flooring has further diversified the market. Flooring spc, or Stone Plastic Composite, differentiates itself with an ultra-dense core layer, offering enhanced dimensional stability and even greater resistance to temperature fluctuations. Both LVT and SPC represent critical advancements in viny flooring technology, addressing the complex requirements of modern commercial spaces, from healthcare facilities and educational institutions to retail environments and corporate offices. Decision-makers looking to buy flooring solutions are increasingly prioritizing products that deliver long-term value, reduced lifecycle costs, and superior environmental performance.

These trends underscore a broader industry shift towards sustainable and high-performance materials. Manufacturers are continually innovating, incorporating recycled content, low-VOC formulations, and advanced surface treatments to meet stringent environmental standards and health certifications. This dedication to innovation ensures that resilient flooring solutions remain at the forefront of interior design and functional architecture, providing optimal environments for productivity and well-being.

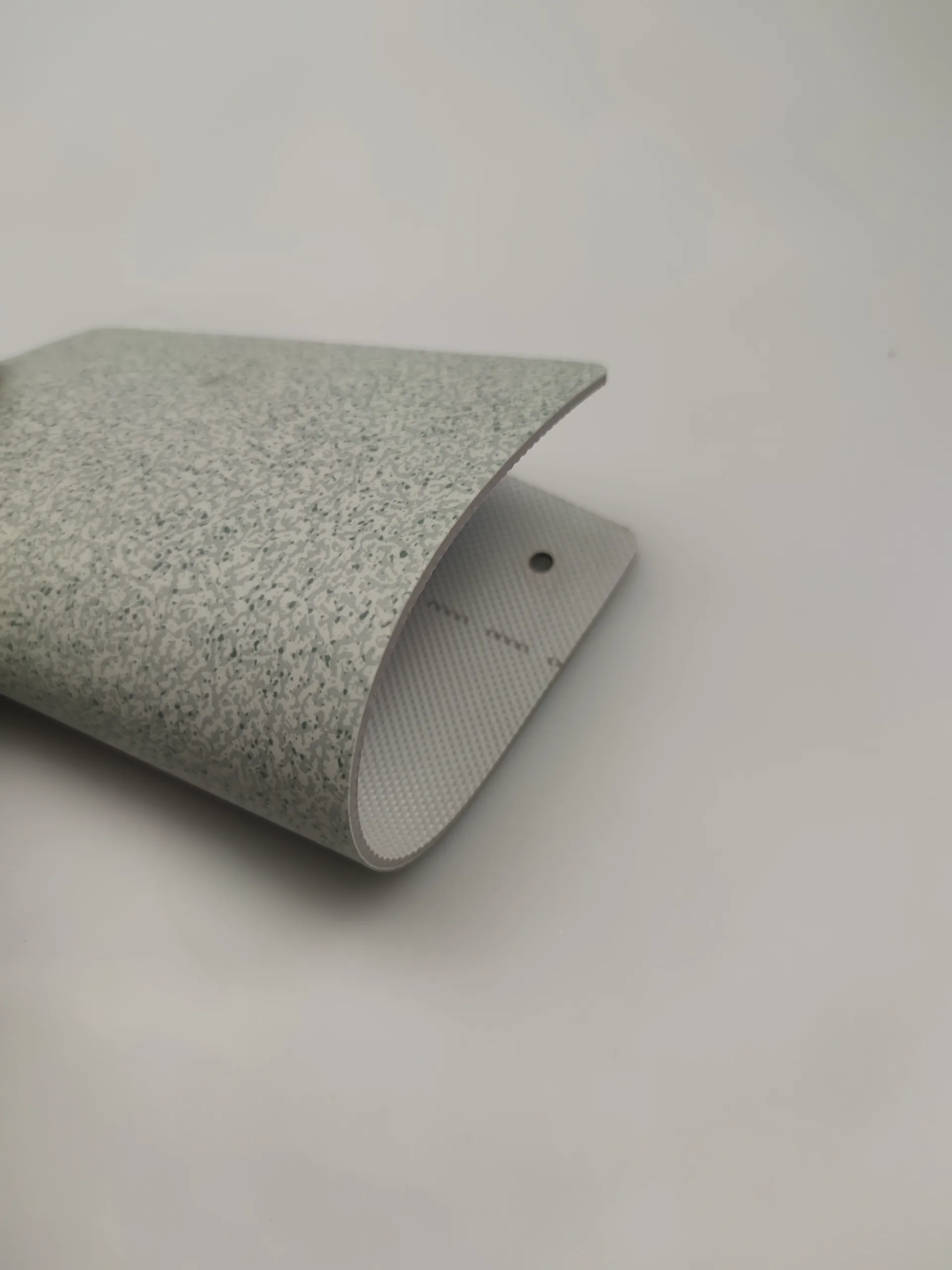

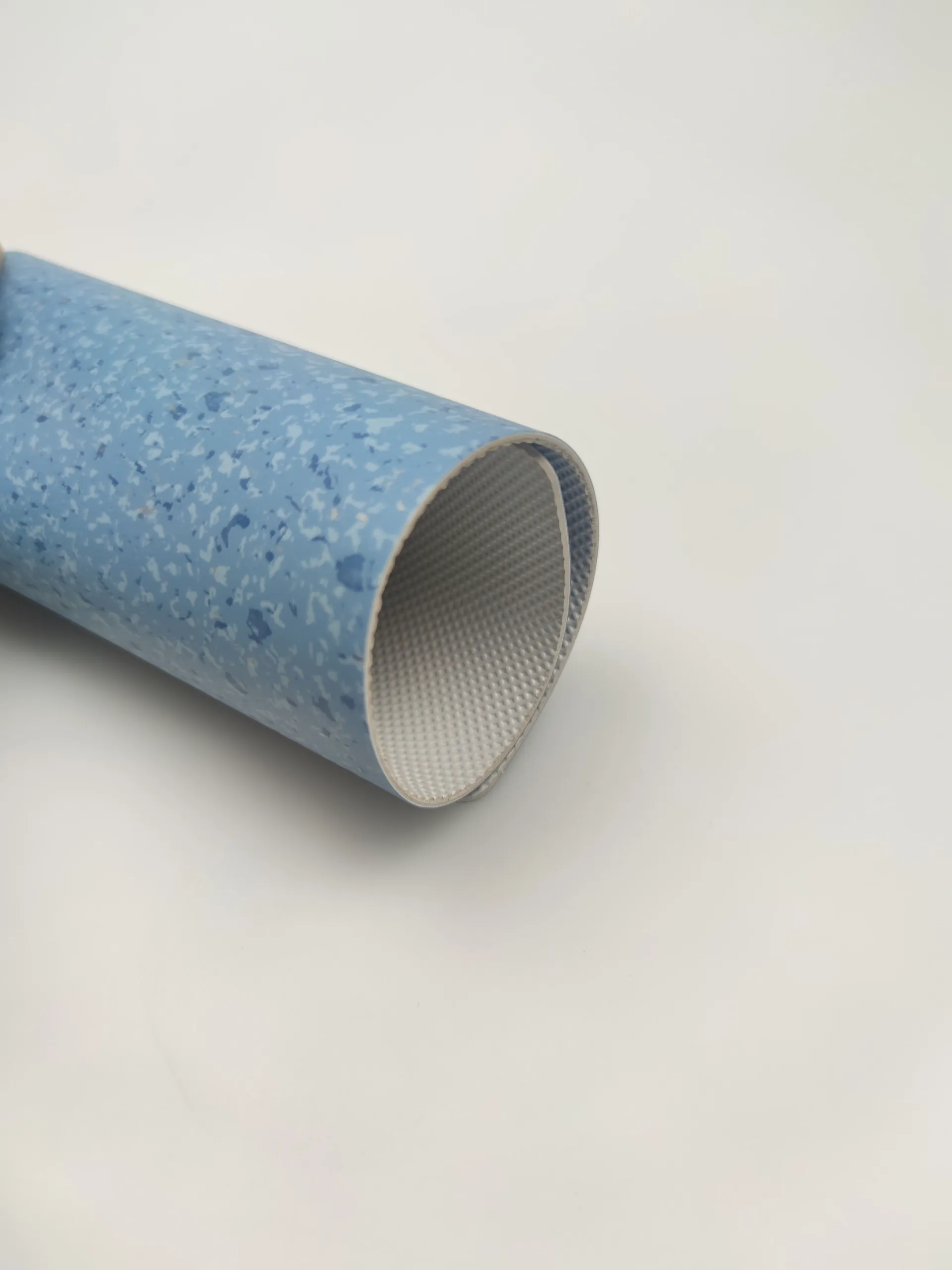

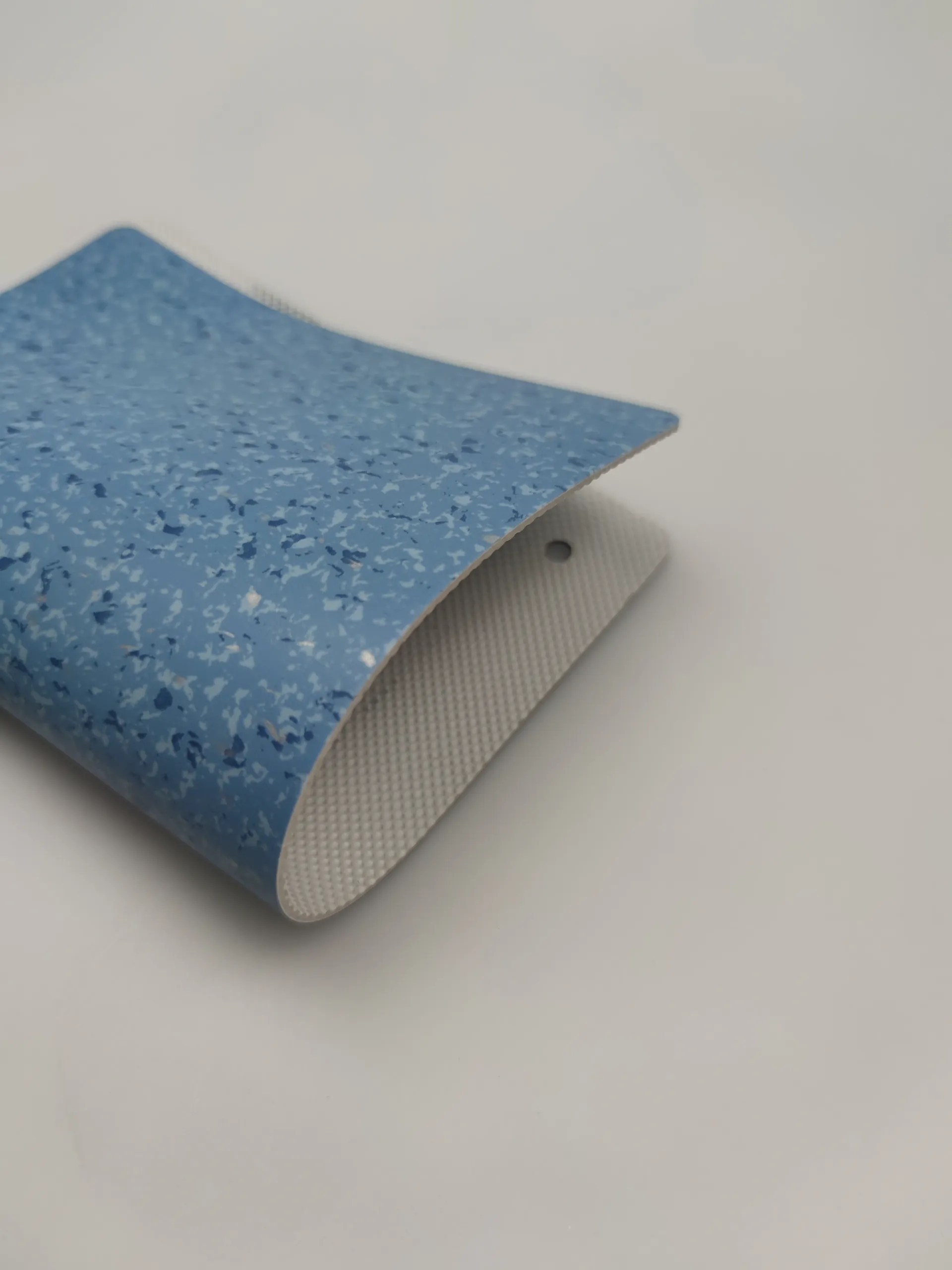

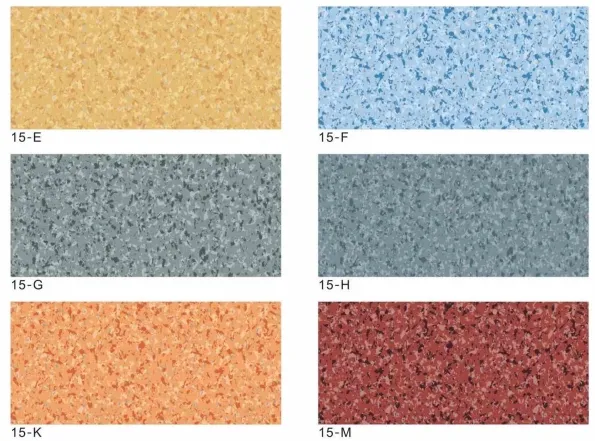

Understanding Heterogeneous Floor with Starrism Surface: The Core of LVT Technology

The "heterogeneous floor with Starrism surface" represents a pinnacle in modern lvt flooring engineering. Heterogeneous vinyl refers to a multi-layered vinyl floor that combines different compositions and designs to achieve specific functional and aesthetic properties. Unlike homogeneous vinyl, which is a single layer of uniform composition, heterogeneous floors are meticulously constructed with distinct layers, each serving a critical purpose. The Starrism surface further elevates this design by incorporating advanced treatments or materials that enhance visual appeal, tactile sensation, and surface performance, often translating to superior scuff, stain, and slip resistance.

Manufacturing Process Flow of Advanced LVT Flooring

The production of high-performance lvt flooring like the heterogeneous floor with Starrism surface involves a precise, multi-stage manufacturing process, ensuring both structural integrity and aesthetic excellence. This process is designed to optimize material properties and integrate advanced technologies.

- Raw Material Sourcing & Preparation: High-grade virgin PVC resins, plasticizers, stabilizers, and fillers are carefully selected. These materials are compounded to create the foundational vinyl compositions for various layers, ensuring optimal flexibility, stability, and environmental compliance.

- Base Layer Production (Backing): The lowest layer, typically a robust PVC composite, is manufactured through calendering. This process involves passing the compounded vinyl material through a series of heated rollers to create a continuous, uniform sheet, providing foundational stability and adhesion to the subfloor.

- Core Layer Formation: For heterogeneous LVT, the core layer, often a blend of PVC and other materials, is precisely calendered or pressed onto the base layer. This layer contributes significantly to the floor's dimensional stability and impact resistance.

- Print Film Application: A high-definition photographic print film, which replicates the visual aesthetics of natural materials like wood, stone, or abstract designs, is meticulously applied. This layer is crucial for the floor's aesthetic appeal and is typically bonded with heat and pressure.

- Wear Layer Lamination: A transparent, highly durable PVC wear layer is applied over the print film. This layer, varying in thickness depending on the product's intended application (e.g., 0.3mm for light commercial, 0.7mm for heavy commercial), is essential for protecting the design layer from scratches, scuffs, and abrasions.

- Starrism Surface Treatment & UV Coating: The unique Starrism surface is then applied, often through specialized coating and curing processes. This may involve advanced PU (polyurethane) or ceramic bead coatings that enhance stain resistance, ease of cleaning, and overall longevity. A UV-cured topcoat provides additional protection against fading and chemical damage.

- Finishing, Cutting & Quality Control: The continuous sheet is then cooled, trimmed, and cut into individual planks or tiles according to precise dimensions (e.g., 6”x48” planks, 18”x18” tiles). Each batch undergoes rigorous quality control checks, adhering to international standards like ISO 10582 and EN 685, assessing parameters such as dimensional stability, wear resistance, indentation resistance, and slip properties. This ensures a service life optimized for demanding commercial environments.

Target industries benefiting from this precise manufacturing include healthcare facilities, educational institutions, retail spaces, corporate offices, and hospitality venues, where floors require exceptional durability, hygiene, and aesthetic appeal. Advantages in typical application scenarios include enhanced acoustic comfort, superior chemical resistance (e.g., to disinfectants in hospitals), and long-term cost-effectiveness due to minimal maintenance and extended lifespan.

Technical Specifications and Performance Parameters of Advanced LVT

The performance of lvt flooring is defined by a meticulous set of technical specifications and rigorous adherence to international testing standards. Understanding these parameters is crucial for B2B decision-makers and engineers to specify the correct product for their project's demands, ensuring optimal functionality and longevity. Key structural components include the backing layer, core layer, print layer, wear layer, and protective coatings, each engineered to contribute to the overall resilience and aesthetic fidelity.

Typical Product Specifications: Heterogeneous Floor with Starrism Surface

| Parameter | Specification (Example) | Standard/Significance |

|---|---|---|

| Overall Thickness | 2.0mm - 5.0mm | Determines structural integrity and sound absorption. |

| Wear Layer Thickness | 0.3mm - 0.7mm | Crucial for durability, abrasion, and scratch resistance (EN 660-2). |

| Dimensional Stability | ≤ 0.15% (after heat exposure) | Resistance to expansion/contraction (EN 434). Critical for preventing gapping. |

| Residual Indentation | ≤ 0.10 mm | Ability to recover from static load (EN 433). Important for heavy furniture/equipment. |

| Slip Resistance (DS) | R9 - R10 (Dry) | Ensures safety in public areas (EN 13893 / DIN 51130). |

| Fire Resistance | Bfl-s1 (EU) / Class A (US) | Reaction to fire, critical for commercial buildings (EN 13501-1 / ASTM E648). |

| Chemical Resistance | Excellent (e.g., to dilute acids, alkalis, oils) | Resistance to common spills and cleaning agents (ISO 26987). |

| Sound Absorption | Up to 5 dB reduction (ΔLw) | Contributes to acoustic comfort in commercial settings (ISO 717-2). |

| Environmental Credentials | Low VOC, Phthalate-Free (Optional) | Compliance with indoor air quality standards (e.g., FloorScore, AgBB). |

These specifications ensure that lvt flooring not only meets but often exceeds the demanding requirements of commercial and institutional applications. Adherence to standards such as ISO 9001 for quality management and ISO 14001 for environmental management further reinforces the product's reliability and manufacturer's commitment to excellence. For industries where hygiene and longevity are paramount, such as healthcare or food service, specialized surface treatments and anti-bacterial properties are often integrated and tested against relevant industry benchmarks.

Application Scenarios & Technical Advantages

The inherent technical advantages of lvt flooring make it an exceptional choice across a diverse array of B2B application scenarios. Its engineered resilience and design versatility address critical functional and aesthetic needs in demanding environments.

Key Application Industries:

- Healthcare Facilities: Hospitals, clinics, nursing homes. LVT’s non-porous surface, ease of cleaning, and resistance to disinfectants are vital for infection control. Its acoustic properties help reduce noise, contributing to a calmer healing environment.

- Education Sector: Schools, universities, daycares. Durability against heavy foot traffic, impact resistance from dropped items, and low maintenance requirements are key. Safety is enhanced by superior slip resistance, and comfort underfoot for staff and students.

- Retail Environments: Boutiques, supermarkets, shopping malls. LVT provides expansive design flexibility to create inviting brand-specific aesthetics, while its extreme wear resistance handles constant footfall and display movements.

- Corporate & Office Spaces: Open-plan offices, meeting rooms, corridors. Offering superior acoustics, easy rolling for office chairs, and diverse design options, LVT fosters productive and attractive workspaces.

- Hospitality & Leisure: Hotels, restaurants, event venues. The ability to replicate luxurious natural materials at a fraction of the cost, combined with water resistance and easy maintenance, makes it ideal for areas prone to spills and high traffic.

Technical Advantages:

- Exceptional Durability: The multi-layered construction, especially with robust wear layers and advanced surface treatments, provides outstanding resistance to scratches, scuffs, and indentation, significantly extending the product's service life in high-traffic commercial settings.

- Superior Water Resistance: Composed primarily of PVC, LVT is inherently water-resistant, making it suitable for areas prone to moisture, spills, and cleaning, offering a distinct advantage over natural wood or laminate.

- Enhanced Hygiene & Ease of Maintenance: The non-porous surface prevents bacterial growth and moisture absorption, making it incredibly easy to clean and sanitize. This reduces maintenance costs and ensures a hygienic environment, critical for healthcare and education sectors.

- Acoustic Performance: LVT contributes positively to indoor acoustics by absorbing impact sound, reducing ambient noise levels, and creating quieter, more comfortable spaces.

- Design Versatility: With high-definition print films and embossing techniques, LVT can flawlessly mimic the appearance and texture of natural materials like hardwood, ceramic, or stone, providing unparalleled design flexibility without the associated costs or maintenance.

- Cost-Effectiveness & Lifecycle Value: While initial installation costs are competitive, the long lifespan, minimal maintenance requirements, and excellent durability of LVT lead to significant long-term savings, offering a superior total cost of ownership compared to many traditional flooring options.

These advantages collectively position lvt flooring as a strategic investment for B2B projects seeking durable, aesthetically pleasing, and functionally superior flooring solutions.

Vendor Comparison: Choosing the Right Resilient Flooring Partner

Selecting the appropriate flooring vendor is as critical as choosing the right product. For B2B clients, factors such as product quality, adherence to certifications, customization capabilities, and robust after-sales support significantly influence project success. When evaluating options to buy flooring, a comparative analysis between different types of resilient vinyl, particularly lvt flooring and spc flooring, is essential.

LVT vs. SPC Flooring: A Comparative Analysis

While both LVT and SPC fall under the umbrella of viny flooring, their core compositions lead to distinct performance characteristics, making each suitable for different commercial applications.

| Feature | LVT (Luxury Vinyl Tile) | SPC Flooring (Stone Plastic Composite) |

|---|---|---|

| Core Composition | PVC and plasticizers; more flexible. | Stone powder (limestone) and PVC; rigid and dense. |

| Dimensional Stability | Good, but can be susceptible to extreme temperature fluctuations. | Excellent; highly stable against temperature and humidity changes. |

| Comfort Underfoot | Softer, more flexible, generally more comfortable. | Firmer, often requires an underlayment for added comfort. |

| Impact Resistance | Good. | Excellent due to rigid core. |

| Installation Method | Glue-down, loose lay, or click-lock. | Primarily click-lock (floating installation). |

| Subfloor Imperfections | Requires very smooth subfloor. | More forgiving of minor subfloor imperfections. |

| Cost | Mid to high range. | Mid to high range, generally comparable to LVT. |

| Best Application | Commercial (offices, retail, healthcare), moderate temperature fluctuations. | Commercial (high traffic, large areas, varying temperatures), sunrooms, basements. |

For those prioritizing a more cushioned feel or specific aesthetic flexibility with glue-down options, lvt flooring remains an excellent choice. When faced with significant temperature swings, direct sunlight exposure, or demanding industrial settings requiring maximum rigidity, flooring spc may present a more robust solution. A reputable vendor, such as Enlio, provides comprehensive guidance to match product specifications with project requirements, leveraging deep industry expertise and a diverse product portfolio.

Customized Solutions and Real-World Application Case Studies

In the B2B sector, standardized products often fall short of meeting unique project demands. Leading providers of lvt flooring understand this, offering comprehensive customized solutions that extend beyond off-the-shelf options. This includes tailoring wear layer thicknesses, selecting specific print films for bespoke designs, incorporating branded elements, and custom cutting to precise dimensions, ensuring the flooring perfectly aligns with architectural visions and functional requirements.

Application Case Studies:

Case Study 1: Major Metropolitan Hospital Renovation

Challenge: A large hospital required a durable, hygienic, and aesthetically calming flooring solution for its patient rooms, corridors, and waiting areas. The existing flooring was prone to staining, difficult to clean, and offered poor acoustic performance, impacting patient recovery and staff comfort.

Solution: Enlio’s heterogeneous floor with Starrism surface, featuring a 0.7mm wear layer and a specialized anti-bacterial coating, was specified. Custom wood-look planks were selected to create a warm, inviting atmosphere, moving away from sterile aesthetics. The flooring's superior chemical resistance was a critical factor for maintaining strict disinfection protocols.

Outcome: The hospital reported a significant improvement in hygiene scores, reduced maintenance time by 20%, and positive feedback from both patients and staff regarding the enhanced comfort and reduced noise levels. The lvt flooring also contributed to lower lifecycle costs due to its longevity and ease of care.

Case Study 2: High-End Retail Chain Expansion

Challenge: A luxury fashion retailer sought a flooring solution that could withstand heavy foot traffic, showcase product displays effectively, and align with their brand's sophisticated aesthetic across new store openings nationwide. The previous flooring choice struggled with scuff marks and rapid wear in high-traffic zones.

Solution: A bespoke design of large format stone-effect lvt flooring was created, incorporating a high-performance Starrism surface for enhanced scratch and stain resistance. The pattern was custom-sized to minimize seams and create a seamless, elegant appearance.

Outcome: The new lvt flooring dramatically improved the stores' aesthetic appeal and durability. Stores reported a 30% reduction in surface damage complaints and a marked improvement in overall store presentation, reinforcing the brand image and customer experience. The ease of spot cleaning also contributed to maintaining impeccable store conditions.

Case Study 3: University Sports Complex Flooring

Challenge: A university needed a resilient flooring for its new sports complex changing rooms and administrative offices that could withstand heavy athletic shoe traffic, moisture, and frequent cleaning, while also being comfortable and visually appealing.

Solution: Enlio provided a heavy-duty heterogeneous LVT with a textured Starrism surface for enhanced slip resistance in wet areas and a comfortable, wood-grain finish for office zones. The robust wear layer and waterproof core made it ideal for both high-humidity and high-impact areas.

Outcome: The installation resulted in a highly functional and attractive environment. The facilities management team praised the floor's ability to resist scuffing and staining, even from sports equipment, and noted improved safety due to its excellent slip resistance. The flooring contributed to a clean, modern, and durable facility.

Authoritativeness & Trustworthiness: Our Commitment to Quality

Building trust with B2B clients is paramount, especially when investing in critical infrastructure elements like flooring. Our commitment to expertise, authoritativeness, and trustworthiness is embedded in every stage of our operations, from product development to after-sales support.

Certifications and Quality Assurance

Our heterogeneous floor with Starrism surface, like all our lvt flooring solutions, undergoes stringent testing and carries certifications from recognized international bodies. These include:

- ISO 9001: Certification for Quality Management Systems, ensuring consistent product quality and customer satisfaction.

- ISO 14001: Certification for Environmental Management Systems, affirming our commitment to sustainable manufacturing practices.

- CE Mark: Conformance with European health, safety, and environmental protection standards.

- FloorScore®: Certification for indoor air quality, ensuring low VOC emissions and a healthy indoor environment.

- ASTM & EN Standards: Compliance with critical performance benchmarks for wear resistance, dimensional stability, fire resistance, and slip properties.

These certifications are not just badges; they represent our unwavering dedication to delivering reliable, high-performing products that meet global industry standards. Our long-standing partnerships with architects, contractors, and facility managers across various sectors globally testify to our consistent service and product excellence over numerous years.

Frequently Asked Questions (FAQ)

Q: Is LVT suitable for high-traffic commercial areas?

A: Absolutely. Our heterogeneous lvt flooring, especially with a robust wear layer (0.5mm - 0.7mm) and Starrism surface treatment, is engineered to withstand extreme commercial foot traffic, making it ideal for retail, healthcare, and education sectors.

Q: How does LVT compare to spc flooring in terms of water resistance?

A: Both LVT and SPC are highly water-resistant. LVT is composed primarily of PVC, making it inherently resistant to moisture. SPC's stone-polymer composite core offers exceptional dimensional stability even in very wet conditions, providing robust waterproof performance.

Q: What is the typical lead time for large B2B orders?

A: Lead times vary depending on order volume and customization requirements. For standard products, lead times typically range from 3-6 weeks. Custom orders may require additional time for production and quality checks. We provide precise lead time estimates upon order confirmation and strive for efficient fulfillment.

Q: What kind of warranty do you offer?

A: We offer comprehensive commercial warranties, typically ranging from 10 to 20 years, depending on the product's wear layer thickness and intended application. Our warranties cover manufacturing defects and performance under normal commercial use, reflecting our confidence in product durability.

Customer Support and After-Sales Service

Our commitment extends beyond product delivery. We offer dedicated customer support, providing technical assistance, installation guidance, and maintenance advice to ensure optimal performance throughout the floor's lifecycle. Our global network of representatives is ready to assist with any queries or challenges, reinforcing our reputation as a trusted partner in commercial flooring solutions.

Conclusion

The selection of commercial flooring is a critical decision impacting aesthetics, functionality, safety, and long-term operational costs. Advanced lvt flooring, particularly specialized heterogeneous solutions with enhanced surfaces like Starrism, offers an unparalleled combination of durability, design flexibility, and cost-effectiveness. By adhering to rigorous manufacturing processes, international quality standards, and providing robust customer support, we empower B2B clients to make informed choices that contribute significantly to the success and sustainability of their projects.

We invite you to explore how our innovative viny flooring solutions can transform your commercial spaces, providing an optimal balance of performance, design, and value.

References

- ISO 10582: Resilient floor coverings — Heterogeneous poly(vinyl chloride) floor coverings — Specifications. International Organization for Standardization.

- EN 685: Resilient, textile and laminate floor coverings — Classification. European Committee for Standardization.

- ASTM F1700: Standard Specification for Solid Vinyl Tile and Solid Vinyl Plank. ASTM International.

- Grand View Research. (2023). Luxury Vinyl Tile (LVT) Flooring Market Size, Share & Trends Analysis Report.

- FloorScore. Scientific Certification Systems, Inc. (SCS Global Services).

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025