Heterogeneous Viny: Durable, Stylish Sheet Flooring Deals

Understanding Heterogeneous Vinyl Flooring in B2B Applications

In the demanding landscape of commercial and industrial environments, the selection of appropriate flooring is paramount, impacting not only aesthetics but also operational efficiency, safety, and long-term cost of ownership. Among the advanced solutions available, heterogeneous viny stands out as a highly engineered material designed to meet stringent performance criteria. Unlike its homogeneous counterpart, heterogeneous vinyl comprises multiple distinct layers, each contributing specific functionalities, culminating in a product that offers superior dimensional stability, advanced acoustic properties, and remarkable durability. This multi-layered construction allows for unparalleled design flexibility and specialized technical attributes, making it an ideal choice for a diverse range of B2B sectors seeking optimal functionality and aesthetic longevity for their flooring deal.

This article delves into the intricate details of heterogeneous vinyl, specifically focusing on its manufacturing, technical specifications, diverse application scenarios, and the compelling advantages it offers to professional specifiers and procurement teams. We will explore industry trends, provide data-backed insights, and examine how customized solutions can be tailored to meet unique project demands, ensuring that your flooring investment yields maximum value and performance.

The Advanced Manufacturing Process of Heterogeneous Vinyl

The production of heterogeneous viny is a sophisticated, multi-stage process that leverages advanced polymer engineering and precision manufacturing techniques. This intricate process ensures that each layer contributes optimally to the final product's performance characteristics.

Process Flow:

- 1. Core Layer (Backing) Production: This foundational layer typically consists of high-density polyvinyl chloride (PVC) mixed with plasticizers, stabilizers, and fillers. It provides dimensional stability and structural integrity. The materials are precisely compounded and then processed through calendering, a technique involving multiple heated rollers that flatten and densify the material into a continuous sheet of specified thickness. This ensures a robust base for the subsequent layers.

- 2. Fiberglass Reinforcement (Optional but common): For enhanced dimensional stability and resistance to thermal expansion/contraction, a fiberglass scrim or mesh is often embedded within or directly above the backing layer. This critical step minimizes movement and ensures the flooring maintains its form over time, especially in environments with fluctuating temperatures.

- 3. Print Layer Application: A highly detailed decorative film, printed with various designs, patterns, or colors, is then applied over the core layer. This layer utilizes advanced rotogravure or digital printing techniques, allowing for realistic wood, stone, abstract, or bespoke patterns. The quality of this layer is crucial for the aesthetic appeal of the heterogeneous sheet vinyl.

- 4. Wear Layer Lamination: A transparent, high-performance wear layer, typically made from pure PVC, is laminated over the print layer. This layer is the primary defense against abrasion, scratches, and stains. Its thickness directly correlates with the flooring's durability and service life. For example, in high-traffic commercial settings, a wear layer of 0.5mm to 0.8mm is common.

- 5. Surface Treatment (PU/PUR Reinforcement): The final step often involves applying a polyurethane (PU) or polyacrylate (PUR) surface treatment. This factory-applied finish enhances stain resistance, simplifies cleaning, and can provide additional benefits like improved slip resistance or antimicrobial properties.

- 6. Curing, Trimming, and Quality Control: The entire composite material is then cured under controlled conditions, trimmed to exact dimensions, and rolled. Throughout the process, rigorous testing is conducted according to international standards such as ISO 24343 (for dimensional stability), EN 433 (for residual indentation), and EN 13893 (for slip resistance) to ensure product consistency and performance.

Service Life and Target Industries:

With proper installation and maintenance, high-quality heterogeneous vinyl sheet can achieve a service life of 10-20 years or more in commercial settings. Its robustness and specialized properties make it ideal for a wide array of target industries, including healthcare (hospitals, clinics), education (schools, universities), retail (supermarkets, boutiques), corporate offices, and even light industrial sectors.

Advantages in Typical Application Scenarios:

In healthcare environments, the seamless installation and sealed surfaces of heterogeneous vinyl contribute significantly to hygiene, preventing microbial growth and facilitating easy disinfection. For educational facilities, its sound absorption properties (typically reducing impact sound by 15-20 dB) help create quieter learning environments, while its durability withstands heavy foot traffic and daily wear. In retail, the vast design flexibility allows for custom branding and attractive store layouts, enhancing the customer experience. Its resilience and anti-slip characteristics also provide a safer environment, reducing the risk of accidents.

Industry Trends and Market Dynamics

The market for resilient flooring, particularly heterogeneous viny, is continuously evolving, driven by technological advancements, aesthetic preferences, and an increasing focus on sustainability and health. Current trends indicate a strong demand for products that offer a blend of high performance, environmental responsibility, and versatile design.

- Sustainability and Circular Economy: There's a growing emphasis on flooring solutions with lower environmental impact. Manufacturers are increasingly focusing on using recycled content, reducing VOC emissions (Volatile Organic Compounds) to meet standards like EN 16516, and developing products that are fully recyclable at the end of their life cycle. This aligns with global efforts toward a circular economy and green building certifications such as LEED and BREEAM.

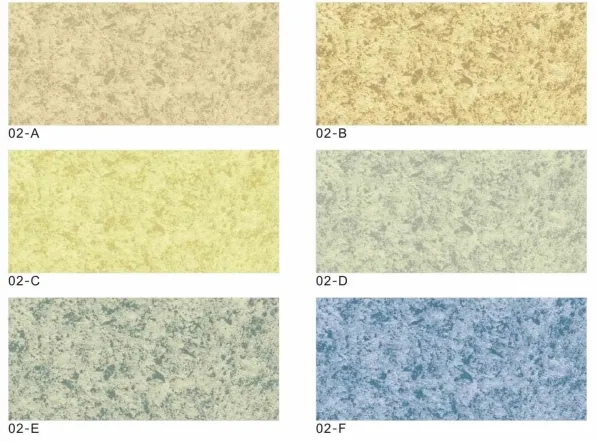

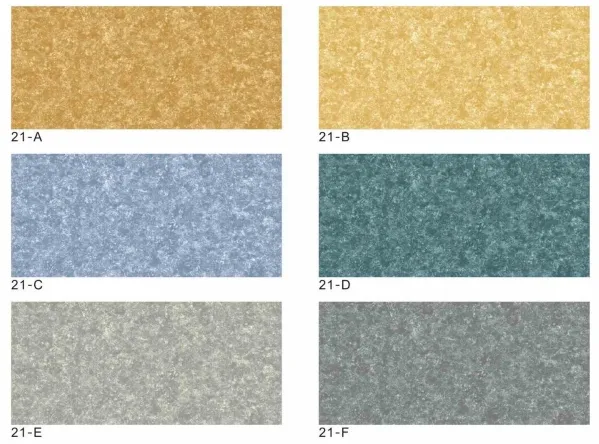

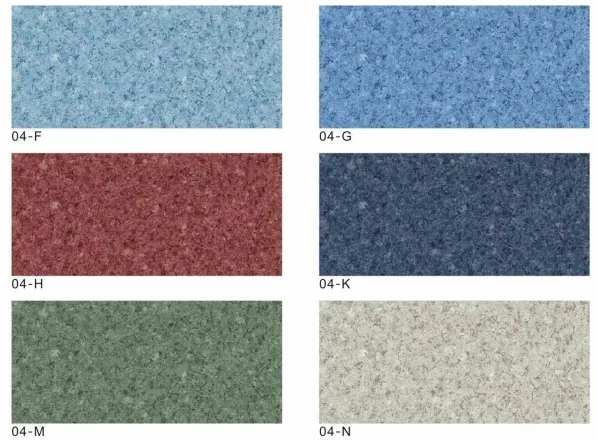

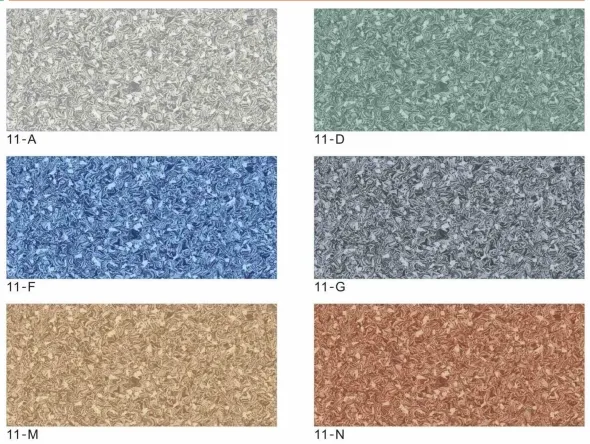

- Advanced Aesthetics and Customization: Beyond traditional wood and stone replications, modern heterogeneous sheet vinyl offers sophisticated abstract patterns, metallic finishes, and digital print capabilities that allow for bespoke designs. This trend caters to architects and interior designers seeking to create unique, branded environments.

- Integrated Smart Features: While nascent, discussions around integrating smart technologies into flooring (e.g., sensors for occupancy, foot traffic, or even environmental monitoring) are gaining traction. This could offer significant advantages in facility management and energy efficiency for commercial buildings.

- Enhanced Health and Well-being: In healthcare and education, demand for flooring with inherent antimicrobial properties, superior indoor air quality, and improved acoustic comfort is on the rise. Specialized surface treatments (e.g., PUR coatings) are being developed to deliver these benefits effectively.

These trends highlight the importance of choosing a flooring partner that not only provides robust products but also stays ahead of industry innovations, offering solutions that are future-proof and aligned with evolving B2B requirements for sustainable, high-performance heterogeneous vinyl sheet.

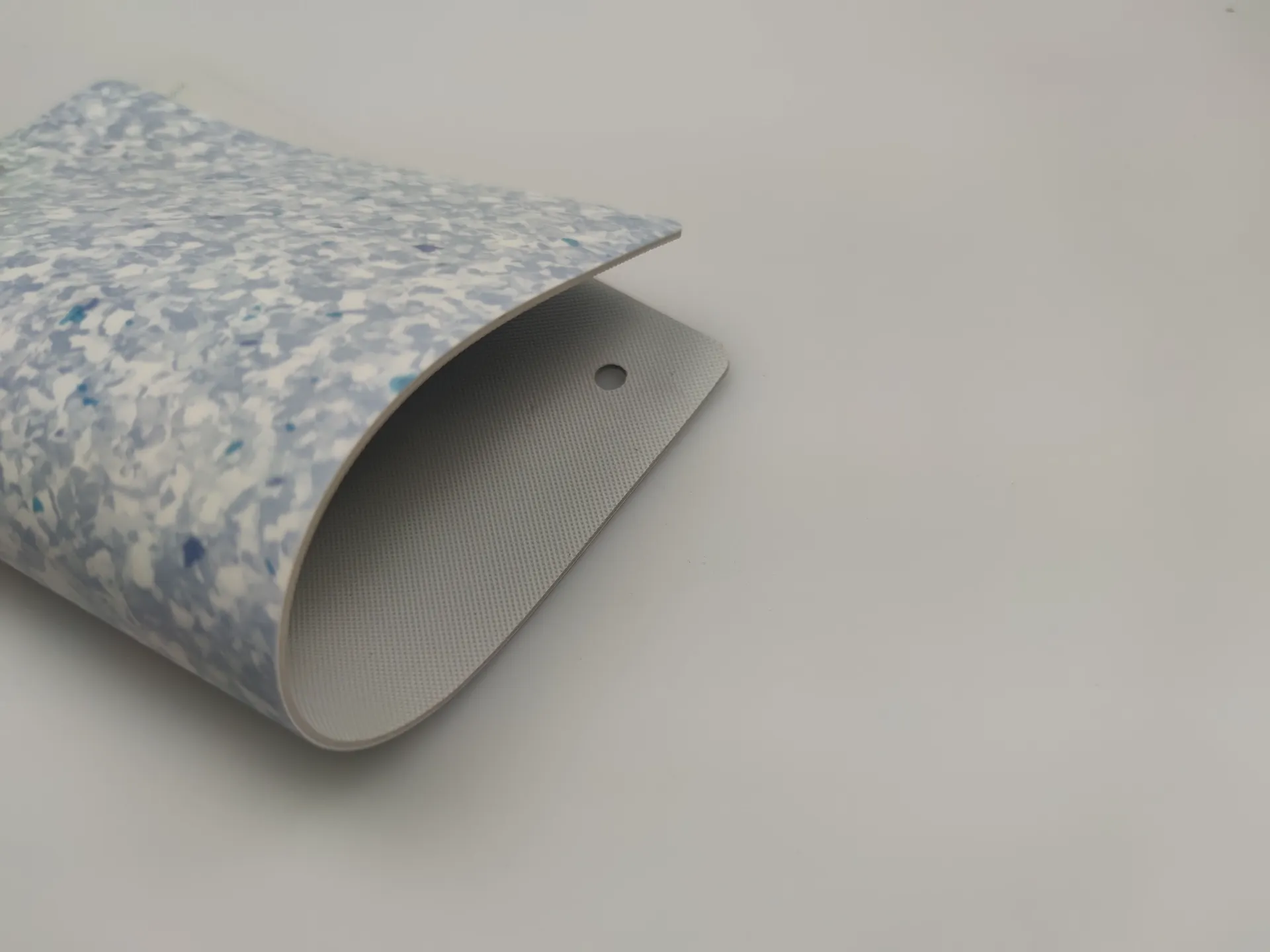

Technical Specifications: Heterogeneous Floor with Nebula Surface

The "heterogeneous floor with Nebula surface" is an exemplary product engineered for superior performance in demanding commercial environments. Its multi-layered structure and advanced surface treatment deliver exceptional durability, aesthetic appeal, and ease of maintenance. Below are key technical specifications that underscore its suitability for various applications.

Product Specification Table: Heterogeneous Floor with Nebula Surface

| Parameter | Specification | Testing Standard |

|---|---|---|

| Total Thickness | 2.0 mm - 4.0 mm (typical 2.5 mm) | EN ISO 24346 |

| Wear Layer Thickness | 0.5 mm - 0.8 mm | EN ISO 24340 |

| Abrasion Group | T (highest commercial classification) | EN ISO 10582 |

| Dimensional Stability | ≤ 0.40 % | EN ISO 23999 |

| Residual Indentation | ≤ 0.10 mm | EN ISO 24343-1 |

| Slip Resistance (R-Value) | R9 - R10 (suitable for general use) | DIN 51130 |

| Fire Resistance | Bfl-s1 (low flammability, low smoke) | EN 13501-1 |

| Sound Reduction (Impact) | 15 dB - 19 dB | EN ISO 717-2 |

| Chemical Resistance | Excellent against dilute acids, alkalis, oils | EN ISO 26987 |

| Light Fastness | ≥ 6 (Blue Wool Scale) | EN ISO 105-B02 |

| Anti-static Properties | ≤ 2 kV (Body Voltage Test) | EN 1815 |

The Nebula surface treatment is specifically engineered to provide an enhanced matte finish, reducing glare and creating a sophisticated aesthetic while simultaneously boosting scratch and scuff resistance. Its non-porous nature makes it exceptionally easy to clean and maintain, crucial for environments where hygiene is paramount. These comprehensive specifications confirm the product's high-performance capabilities and compliance with international quality and safety benchmarks, making it a reliable choice for any demanding commercial environment and ensuring an excellent flooring deal.

Versatile Application Scenarios

The adaptability and robust performance characteristics of heterogeneous viny make it a preferred flooring solution across a broad spectrum of commercial and public sector environments. Its ability to combine aesthetic appeal with critical functional attributes ensures suitability for diverse demands.

- Healthcare Facilities: From hospital wards and operating theaters to clinics and nursing homes, the need for sterile, easy-to-clean, and durable flooring is paramount. Heterogeneous vinyl's seamless installation, chemical resistance, and often integrated antimicrobial properties make it an excellent choice. Its sound-absorbing qualities also contribute to a quieter, more comforting environment for patients and staff.

- Educational Institutions: Schools, universities, and daycare centers experience constant heavy foot traffic and require flooring that can withstand rigorous daily use while being easy to maintain. Heterogeneous sheet vinyl provides robust resistance to scuffs and spills, offers sound reduction for improved learning environments, and comes in a wide array of designs to create engaging spaces.

- Retail and Commercial Spaces: In shops, supermarkets, showrooms, and office buildings, flooring contributes significantly to brand image and customer experience. Heterogeneous vinyl's aesthetic versatility allows for custom branding and high-impact designs, while its superior wear resistance ensures it retains its appearance even in high-traffic areas, directly influencing a positive perception of your flooring.

- Hospitality Sector: Hotels, restaurants, and conference centers benefit from flooring that combines luxury aesthetics with practical durability. Heterogeneous vinyl offers luxurious finishes, acoustic comfort for guest rooms and public areas, and resistance to spills and stains common in food service.

- Light Industrial and Public Buildings: Areas like laboratories, cleanrooms, and municipal buildings require flooring that can endure specific demands such as chemical exposure, heavy static loads, or rigorous cleaning protocols. Specialized heterogeneous vinyl sheet with enhanced chemical resistance and anti-static properties fulfills these requirements, ensuring operational continuity and safety.

The adaptability across these diverse sectors underscores the strategic value of heterogeneous vinyl as a comprehensive, long-term flooring solution for B2B enterprises.

Technical Advantages of Heterogeneous Vinyl

The inherent multi-layered construction of heterogeneous viny bestows it with a suite of technical advantages that are critical for high-performance commercial and industrial applications. These advantages collectively contribute to a superior total cost of ownership and enhanced operational safety.

- Superior Durability and Wear Resistance: The presence of a dedicated, high-performance wear layer, typically 0.5mm to 0.8mm thick, provides exceptional resistance against abrasion, scratches, and scuffs. This makes heterogeneous vinyl far more resilient in high-traffic areas compared to many other flooring types, maintaining its appearance over extended periods.

- Excellent Dimensional Stability: Reinforced by a compacted backing layer and often incorporating fiberglass scrim, heterogeneous vinyl exhibits minimal expansion and contraction with temperature fluctuations. This characteristic prevents gapping, curling, and buckling, ensuring a smooth, continuous surface that is crucial for maintaining hygiene and operational integrity.

- Advanced Acoustic Properties: The multi-layered structure significantly contributes to impact sound reduction, often by 15-20 dB. This is a critical advantage in environments like healthcare facilities, educational institutions, and corporate offices where noise reduction enhances comfort, concentration, and privacy.

- Exceptional Hygiene and Ease of Maintenance: The dense, non-porous surface, often enhanced with a PUR treatment, resists dirt, stains, and bacterial growth. Its seamless installation capability in sheet format further eliminates crevices where pathogens could harbor, making cleaning and disinfection straightforward and highly effective. This is invaluable in environments demanding strict sanitary standards.

- Design Versatility: The dedicated print layer allows for an almost unlimited range of designs, colors, and patterns, from realistic wood and stone aesthetics to intricate custom graphics. This flexibility empowers architects and designers to create visually compelling and brand-aligned spaces without compromising on performance.

- Chemical and Stain Resistance: Many formulations of heterogeneous sheet vinyl offer excellent resistance to a wide range of chemicals, including dilute acids, alkalis, and common cleaning agents. This protects the floor from damage and discoloration due to spills, a common concern in commercial settings.

These advantages collectively position heterogeneous vinyl as a highly resilient, aesthetically versatile, and functionally superior choice for demanding B2B flooring applications, directly addressing the core needs of durability, safety, and operational efficiency.

Vendor Comparison and Selection Criteria

Selecting the right supplier for heterogeneous vinyl sheet is as crucial as selecting the product itself. B2B decision-makers must evaluate vendors not just on price, but on a holistic range of factors including product quality, certifications, customization capabilities, and after-sales support.

Key Vendor Evaluation Metrics:

- Product Portfolio & Innovation: Does the vendor offer a diverse range of heterogeneous vinyl options, including specialized products (e.g., anti-static, acoustic, extreme heavy duty)? Are they investing in R&D for new surface treatments or sustainable formulations?

- Quality Certifications: Look for international standards such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and product-specific certifications like CE marking (EU conformity), FloorScore (IAQ), and compliance with European (EN) or ASTM standards for performance.

- Customization Capabilities: Can the vendor provide custom colors, patterns, or specific technical attributes (e.g., higher slip resistance, specific thickness) to match unique project requirements?

- Technical Support & Expertise: Do they offer comprehensive pre-sales consultation, technical specifications, installation guides, and post-sales support? A strong technical team can be invaluable for complex projects.

- Lead Times & Logistics: Evaluate the vendor's ability to meet project deadlines, handle large orders, and manage international shipping logistics efficiently for your flooring.

- Warranty & After-Sales Service: Understand the warranty terms, coverage, and the responsiveness of their customer support for any issues that may arise post-installation.

Vendor Comparison Table (Illustrative):

| Feature/Criterion | Enlio Floor (Nebula Surface) | Competitor A (Premium Grade) | Competitor B (Standard Grade) |

|---|---|---|---|

| Wear Layer Thickness | 0.7mm - 0.8mm (High) | 0.6mm - 0.7mm (High) | 0.4mm - 0.5mm (Medium) |

| Surface Treatment | PUR Nebula Coating (Enhanced Scratch/Stain) | PURShield (Standard PU) | Acrylic Sealant |

| Acoustic Performance (dB) | 17 dB (Excellent) | 15 dB (Good) | 10 dB (Standard) |

| Certifications | ISO 9001, 14001, CE, FloorScore | ISO 9001, CE | CE |

| Customization Options | Extensive (Color, Pattern, Technical) | Moderate (Color, limited Pattern) | Limited (Standard colors only) |

| Warranty (Commercial) | 15 Years | 10-12 Years | 5-7 Years |

This comparison highlights that while several vendors offer heterogeneous vinyl sheet, the nuances in wear layer technology, surface treatments, and support services can significantly impact the long-term performance and value of your investment.

Customized Solutions for Unique Project Requirements

One of the significant advantages of working with experienced manufacturers of heterogeneous viny is the capacity to develop customized solutions that perfectly align with specific project demands. Standard product lines, while versatile, may not always address every unique architectural, functional, or branding requirement.

Areas of Customization:

- Bespoke Design and Aesthetics: From custom color matching to replicating unique textures or incorporating specific corporate logos and patterns directly into the print layer, customization ensures that the flooring seamlessly integrates with the overall interior design vision and brand identity, making it truly your flooring.

-

Enhanced Technical Performance: Projects with extreme requirements might necessitate alterations to standard specifications. This could include:

- Increased Wear Layer Thickness: For ultra-heavy traffic zones where longevity is paramount.

- Higher Slip Resistance: For areas prone to moisture or requiring enhanced safety measures (e.g., R11 or R12 ratings).

- Specialized Anti-static or Conductive Properties: Critical for server rooms, laboratories, and manufacturing facilities handling sensitive electronics.

- Superior Acoustic Backing: For spaces demanding exceptional sound dampening beyond standard offerings.

- Specific Material Formulations: Custom blends of PVC, plasticizers, and stabilizers can be developed to achieve unique properties such as enhanced flexibility for intricate installations, specific chemical resistance profiles, or improved fire retardancy beyond standard classifications.

- Environmental & Health Compliance: For projects requiring adherence to very specific green building certifications or extremely low VOC emission targets, manufacturers can tailor formulations to meet these stringent requirements.

Engaging in a collaborative design process with a reputable manufacturer ensures that these bespoke requirements are accurately translated into the final product. This level of customization optimizes both the functional performance and the aesthetic integration of the heterogeneous vinyl sheet within complex B2B environments, providing a truly optimized flooring solution.

Application Case Studies: Heterogeneous Vinyl in Action

Real-world applications demonstrate the tangible benefits and versatility of heterogeneous vinyl sheet. These case studies highlight how its technical advantages translate into practical solutions for diverse B2B challenges.

Case Study 1: Major Regional Hospital Renovation

- Challenge: A 500-bed hospital needed durable, hygienic, and aesthetically pleasing flooring for its new wing, including patient rooms, corridors, and a rehabilitation center. Key concerns included infection control, noise reduction, and long-term maintenance costs.

- Solution: Over 15,000 square meters of heterogeneous floor with Nebula surface (3.0mm total thickness, 0.7mm wear layer, R10 slip resistance) were installed. The seamless welding technique provided an impermeable surface, critical for infection control.

- Outcome: The flooring significantly contributed to a quieter environment (18dB impact sound reduction), improving patient comfort. Its PUR surface treatment eased cleaning protocols, reducing daily maintenance time by 20% compared to previous flooring types. The durable wear layer minimized scuffing from gurneys and foot traffic, maintaining a pristine appearance months after installation. The aesthetic versatility allowed for different calming color palettes across departments.

Case Study 2: National Retail Chain Flagship Store

- Challenge: A prominent retail brand sought a high-impact, durable flooring solution for its flagship store, which experiences extremely high foot traffic (est. 10,000 visitors/day). The requirement was for a unique design that reflected the brand's modern image, coupled with exceptional wear resistance and easy cleaning.

- Solution: A customized heterogeneous viny design with a metallic abstract pattern and an extra-thick 0.8mm wear layer was specified. The flooring was installed using a specialized adhesive system to ensure maximum bond strength over the 5,000 square meters.

- Outcome: The customized pattern immediately became a focal point of the store's interior. After two years of operation, the flooring showed minimal signs of wear, exceeding the client's expectations for durability. The ease of cleaning contributed to maintaining the store's premium image, leading to a successful flooring deal that resonated with both operational and marketing objectives.

Case Study 3: University Science Laboratory

- Challenge: A university chemistry lab required flooring that offered superior chemical resistance, anti-static properties to protect sensitive equipment, and a sterile surface that could be easily decontaminated.

- Solution: A specialized, conductive heterogeneous vinyl sheet with enhanced chemical resistance properties was installed. The flooring was installed with conductive adhesive and copper strips connected to the building's grounding system to dissipate static electricity effectively.

- Outcome: The customized heterogeneous vinyl successfully met the stringent technical requirements. Spills of common laboratory reagents were easily cleaned without staining or damage to the floor, and electrostatic discharge incidents were eliminated, protecting expensive scientific apparatus and ensuring a safe working environment.

Frequently Asked Questions (FAQ)

Lead Time, Fulfillment, and Support

For B2B projects, understanding the logistical and support framework is critical for seamless execution and long-term satisfaction.

Lead Time and Fulfillment:

- Standard Orders: Typically, standard product lines for heterogeneous vinyl sheet can be fulfilled within 2-4 weeks, depending on order volume and current stock levels.

- Customized Orders: For bespoke designs or specialized technical requirements, lead times may extend to 6-10 weeks, allowing for R&D, material sourcing, and dedicated production runs.

- Shipping and Logistics: We partner with global logistics providers to ensure efficient and reliable delivery to project sites worldwide. Detailed shipping schedules and tracking information are provided upon order confirmation. Express shipping options are available for urgent projects.

Warranty Commitments:

Our heterogeneous vinyl sheet products, including the Nebula surface range, are backed by comprehensive commercial warranties, typically ranging from 10 to 15 years. This warranty covers manufacturing defects, ensuring that your investment is protected. Specific terms and conditions, including coverage details and proper maintenance requirements, are provided with each purchase. Our commitment is to deliver quality and peace of mind for your flooring.

Customer Support and After-Sales Service:

- Dedicated Account Management: Each B2B client is assigned a dedicated account manager to streamline communication and ensure all project requirements are met from initial inquiry to post-installation.

- Technical Assistance: Our team of flooring experts provides comprehensive technical support, including installation guidance, product data sheets, and troubleshooting assistance.

- After-Sales Support: We are committed to ensuring long-term satisfaction. Our support team is readily available to address any post-installation queries, maintenance advice, or warranty claims, ensuring a hassle-free experience.

References

- ISO 24346: Resilient floor coverings — Determination of overall thickness, residual thickness of the wear layer and thickness of layers. International Organization for Standardization.

- EN 13501-1: Fire classification of construction products and building elements — Part 1: Classification using data from reaction to fire tests. European Committee for Standardization.

- ASTM F1700: Standard Specification for Solid Vinyl Tile and Solid Vinyl Plank. ASTM International.

- EN 14041: Resilient, textile and laminate floor coverings — Essential characteristics. European Committee for Standardization.

- The Vinyl Institute. "Vinyl's Role in Sustainable Design." Accessed June 2024.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025