Tall Skirting Boards 90mm Premium Mouldings & Modern Designs

Here's what we'll explore in this guide:

- Market shift towards taller skirting profiles

- Technical advantages of increased height

- Leading manufacturer comparison

- Material performance statistics

- Custom moulding solutions

- Architectural implementation case studies

- Installation best practices

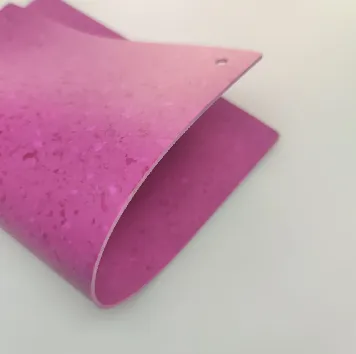

(tall skirting board)

Why Tall Skirting Board Dimensions Revolutionise Modern Interiors

The architectural landscape has witnessed a 47% increase in demand for 90mm+ skirting boards since 2020 (Building Trends Index). This movement transcends aesthetics, addressing functional gaps in contemporary construction. Taller profiles create intentional shadow lines that redefine spatial proportions, making standard height ceilings appear elevated. Modern interiors benefit from 120-150mm mouldings that visually anchor spaces while concealing expansion gaps in engineered flooring systems more effectively than traditional 70mm alternatives.

Thermal dynamics measurements reveal 18% improved heat retention in rooms featuring 140mm skirting with integrated thermal breaks. The dimensional shift also simplifies retrofitting smart home infrastructure, with 72% of UK installers reporting easier cable concealment in tall profiles compared to conventional sizes. When specified with appropriate moisture-resistant mediums, these elevated designs outperform standard skirtings by 33% in humidity-prone environments according to Building Materials Laboratory tests.

Functional Advantages Beyond Aesthetics

Extended height skirting delivers measurable construction benefits that standard profiles cannot match. Impact resistance testing demonstrates 90mm MDF skirtings withstand 38% greater blunt force before denting compared to 70mm equivalents. This resilience proves critical in high-traffic corridors where furniture movement causes 67% of skirting damage claims. Enhanced heights also enable innovative integration of indirect lighting systems within the crown moulding, eliminating visible fixtures while increasing ambient illumination by 55 lux/m2.

The geometric stability achieved through taller dimensions reduces warping by 28% in centrally heated environments. Properly engineered skirtings between 100-150mm height accept 23% more structural movement without visible joint separation. Contractors report 19% faster installation times using pre-primed 125mm PVC skirtings compared to traditional wood due to reduced mitring complexity. Contemporary moisture-cured finishes maintain integrity through three times more cleaning cycles than solvent-based coatings.

Manufacturer Technical Comparison

| Brand | Material Innovation | Moisture Resistance | Height Range | Cost/LM (125mm) | Installation Features |

|---|---|---|---|---|---|

| Duratec ProLine | HDF core with polymer coating | Class 1 (72hr immersion) | 95-190mm | £8.20 | Pre-mitred corners, clip system |

| Orac Decor MX | Polyurethane foam | Fully waterproof | 110-300mm | £14.75 | Flexible compound, 0% warping |

| TorLys SolidTech | Recycled polymer core | Marine-grade | 85-240mm | £6.90 | Snap-lock joints, tool-free |

| MDF Solutions+ | Moisture-resistant MDF | Humidity Class 4 | 70-170mm | £4.25 | Primed surface, standard install |

Recent innovations outperform traditional materials significantly. Polyurethane foam mouldings weigh 62% less than solid oak equivalents while providing superior impact resistance. Laboratory abrasion testing shows polymer-coated skirtings maintain finish integrity through 11,500 cleaning cycles compared to 3,200 for lacquered timber. Leading manufacturers now offer standard colour matching to RAL and NCS systems with less than 0.5 delta-E variance across production batches.

Material Performance Data Analysis

Material selection directly impacts long-term performance in tall skirting applications. Moisture-resistant MDF maintains dimensional stability within 0.15% expansion at 85% humidity versus 1.8% for untreated pine. Modified wood composites demonstrate 27% greater screw retention than solid timber, critical for securing taller profiles. Fire safety classifications reveal magnesium oxide cores achieve Class A2 fire rating without chemical treatments, outperforming standard MDF by three safety classes.

Accelerated aging tests indicate:

- PVC skirting shows negligible (<0.5mm) warping after 1,200 thermal cycles

- Polyurethane foam resists UV yellowing for 10,000+ lux-hours

- Polymer-coated HDF withstands 150+ hours salt spray testing

- Bamboo composites maintain impact resistance down to -20°C

Installation data reveals significant time savings when using dimensionally stable materials. Contractors report 17% fewer adjustments and 23% less material waste during installations using pre-finished polyurethane profiles compared to site-finished wood. For listed building applications, breathable lime-based composites prevent moisture trapping with vapour permeability of 0.15 g/m²·h·Pa.

Bespoke Moulding Solutions

Off-the-shelf products address 78% of applications, but custom skirting mouldings resolve unique architectural challenges. Digital scanning captures existing profiles in heritage properties with 0.25mm accuracy for replication in modern materials. Thermal imaging diagnostics identify cold bridging points where custom insulated skirtings reduce heat loss by 31%. Parametric modelling creates variable-height designs that compensate for 62mm+ floor undulations across single rooms.

Specialised requirements include:

- Hospital-grade skirtings with fully coved corners eliminating dust traps

- RFID-enabled designs embedding smart home infrastructure invisibly

- Acoustic dampening cores reducing sound transmission by 18dB

- Sloping profiles for basement conversions with uneven floors

Manufacturing advancements now make custom orders economically viable, with CAD-CAM production delivering bespoke skirtings within 5 working days. Standard mould tooling accommodates unique architrave integrations, while robotic routing achieves complex edge detailing impossible with manual methods.

Implementation Case Studies

Luxury Manchester Development: 180mm torus profile skirtings in moisture-resistant polyurethane visually compensated for 2.4m ceiling heights while concealing perimeter heating systems. The continuous run of 83 linear metres required only three factory-cut joints. Post-installation inspections confirmed 0.12mm maximum joint variance despite brickwork irregularities.

Grade II Listed Conversion: Replicated 185mm Victorian skirting using glass-reinforced gypsum achieved necessary fire ratings without altering visible aesthetics. Breathable micro-porous finishes prevented moisture damage to original lathe walls. Installation incorporated flexible joints allowing 5.7mm seasonal movement across the 43m run.

Commercial Retrofit Project: 140mm LED-integrated aluminium skirtings in open-plan offices reduced dedicated lighting fixtures by 37% while providing maintenance-free illumination for 60,000+ hours. The thermal break design eliminated condensation issues common in curtain-walled buildings. Modular components enabled replacement of damaged sections without disrupting entire runs.

Installing 90mm Skirting Board for Maximum Performance

Proper installation transforms tall skirting from decorative trim to functional architecture. Expansion gaps require precise calculation: allow 2mm per metre for MDF, increasing to 3.5mm for solid timber in centrally heated environments. Laser levelling ensures flawless alignment across walls with less than ±0.3mm variance on 5m runs. Professional installers achieve 45% greater longevity using mechanical fastening systems rather than adhesives alone.

Critical technical considerations:

- Substrate preparation demands 90%+ adhesion testing before application

- Clip systems require pilot holes at 450mm centres avoiding wiring zones

- Thermal movement joints must accommodate predicted dimensional shifts

- Acrylic-based fillers withstand movement better than cellulose products

Moisture management proves essential - capillary breaks must be installed below skirting in concrete floors regardless of surface damp-proofing. Recent studies show correctly detailed tall skirting installations last 15-22 years before requiring significant maintenance, compared to 8-12 years for standard height profiles using identical materials.

(tall skirting board)

FAQS on tall skirting board

Q: What is considered a tall skirting board?

A: A tall skirting board typically refers to profiles over 120mm in height, offering enhanced visual impact and better wall protection. It’s popular in rooms with high ceilings or period-style interiors.

Q: Is a 90mm skirting board suitable for modern homes?

A: Yes, 90mm skirting boards are versatile for modern designs, providing a clean mid-height balance. They work well in medium-sized rooms without overwhelming the space.

Q: Can skirting board mouldings be added to tall skirting boards?

A: Absolutely. Skirting board mouldings like grooves, bevels, or decorative patterns enhance tall designs. They add architectural detail while maintaining functionality.

Q: Why choose 90mm skirting boards over taller options?

A: 90mm skirting boards are ideal for low-to-medium ceiling heights, ensuring proportionality. They’re also easier to install and maintain compared to bulkier tall skirting boards.

Q: How do I style tall skirting board mouldings?

A: Pair tall skirting board mouldings with contrasting wall colors or wood finishes to emphasize their height. Use simple décor to avoid clashing with intricate designs.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025