Hawk Flooring: Durable Heterogeneous Vinyl Sheet Solutions

Introduction to Heterogeneous Vinyl Flooring Solutions

In the demanding landscape of commercial and industrial flooring, the selection of materials is paramount for ensuring durability, safety, and long-term cost-effectiveness. Among the myriad options, heterogeneous viny flooring stands out as a superior choice, particularly for high-traffic environments requiring robust performance and specialized characteristics. This article delves into the intricate details of heterogeneous vinyl, focusing on its technical specifications, manufacturing processes, diverse applications, and inherent advantages that make it an indispensable material in modern infrastructure. We will explore how products like the heterogeneous floor with Stariver surface exemplify innovation in this field, meeting stringent industry requirements.

Heterogeneous vinyl sheet, often synonymous with heterogeneous sheet vinyl, is engineered with multiple distinct layers, each serving a specific function to enhance the overall performance of the flooring system. This multi-layer construction provides exceptional wear resistance, dimensional stability, acoustic comfort, and aesthetic versatility, catering to a broad spectrum of B2B needs. From healthcare facilities to educational institutions and corporate offices, the strategic deployment of such advanced flooring solutions is critical for operational efficiency and user experience.

Manufacturing Process of Heterogeneous Vinyl

The production of heterogeneous viny flooring involves a sophisticated multi-stage process designed to create a product with unparalleled performance attributes. Understanding this process is key to appreciating the material's inherent quality and durability.

Process Flow Overview:

- Raw Material Preparation: High-grade PVC resins, plasticizers, stabilizers, pigments, and fillers are precisely measured and blended. Quality control at this stage ensures consistent material properties.

- Substrate Layer Extrusion: A robust backing layer, typically made from fiberglass-reinforced PVC, is extruded. This layer provides dimensional stability, preventing shrinkage and expansion, crucial for the long service life of heterogeneous viny.

- Print Layer Application: A high-definition decorative film, often produced through rotogravure printing, is applied onto the substrate. This layer dictates the aesthetic appearance, mimicking wood, stone, or abstract designs.

- Wear Layer Lamination: A transparent, highly durable wear layer, composed of pure PVC or polyurethane (PUR) reinforced with ceramic beads or other hard particles, is laminated over the print layer. This critical layer provides resistance against abrasion, scratches, and stains.

- Surface Treatment (Stariver Technology): For advanced products like the heterogeneous floor with Stariver surface, a specialized surface treatment is applied. This often involves a UV-cured coating that enhances scratch resistance, simplifies maintenance, and provides superior chemical resistance. The Stariver technology typically integrates micro-textured finishes for improved slip resistance and a matte appearance, reducing glare.

- Calendaring/Pressing: The multi-layered structure is then passed through heated rollers (calendaring) or presses under specific pressure and temperature to ensure complete fusion and compaction of all layers, achieving uniform thickness and density.

- Curing and Cooling: The consolidated material undergoes a controlled cooling process to set the layers and prevent warping, maintaining dimensional stability.

- Trimming and Finishing: The cooled sheets are trimmed to precise dimensions, inspected for quality, and then rolled or cut into tiles for packaging.

Key Materials and Standards:

Typical materials include virgin PVC, plasticizers (increasingly phthalate-free for environmental and health reasons), and fiberglass. Testing standards adhered to during manufacturing include ISO 24346 for overall thickness, ISO 23999 for dimensional stability, ISO 10582 for wear resistance (Group T for heavy commercial use), and EN 13893 for slip resistance. These rigorous standards ensure that the final product, such as the heterogeneous vinyl sheet, meets international benchmarks for safety, performance, and environmental responsibility.

Figure 1: Cross-section illustrating the multi-layered structure of heterogeneous vinyl.

Industry Trends and Market Dynamics

The flooring industry is witnessing significant shifts driven by sustainability concerns, technological advancements, and evolving aesthetic preferences. Heterogeneous viny flooring is at the forefront of these changes, offering solutions that balance performance with ecological responsibility.

- Sustainability Focus: Increasing demand for phthalate-free, low-VOC (Volatile Organic Compound) vinyl products. Manufacturers are investing in greener formulations and closed-loop recycling programs.

- Enhanced Durability & Performance: Continuous innovation in wear layer technology, such as the Stariver surface, to withstand extreme traffic, reduce maintenance, and extend service life. This includes improved scratch, scuff, and stain resistance.

- Aesthetic Versatility: Advancements in digital printing allow for highly realistic and diverse designs, catering to bespoke interior design requirements across various sectors.

- Health & Wellness: Anti-bacterial and anti-fungal treatments integrated into the flooring surface, particularly relevant for healthcare and education sectors. Improved indoor air quality is a key driver.

- Acoustic Comfort: Integrated acoustic backing layers are becoming standard, reducing impact sound transmission, a crucial factor in multi-story commercial buildings.

The market for heterogeneous sheet vinyl is projected for steady growth, with a CAGR often cited around 5-7% in various reports, driven by increasing construction activities in the commercial and industrial sectors globally, particularly in emerging economies. This growth is underpinned by the superior performance-to-cost ratio offered by these advanced flooring solutions.

Technical Specifications and Parameters

The precise technical specifications of heterogeneous viny are critical for engineers and procurement specialists. These parameters define the performance capabilities and suitability for specific applications. Below are typical specifications for a high-performance heterogeneous floor with Stariver surface.

Product Specification Table: Heterogeneous Floor with Stariver Surface

| Parameter | Specification | Testing Standard |

|---|---|---|

| Total Thickness | 2.0 mm - 4.0 mm (e.g., 2.5 mm typical) | EN ISO 24346 |

| Wear Layer Thickness | 0.5 mm - 1.0 mm (e.g., 0.7 mm for heavy duty) | EN ISO 24340 |

| Wear Group | T (Very Heavy Commercial) | EN ISO 10582 |

| Dimensional Stability | ≤ 0.1% | EN ISO 23999 |

| Residual Indentation | ≤ 0.05 mm | EN ISO 24343-1 |

| Slip Resistance (Ramp Test) | R9 - R10 (depending on surface finish) | DIN 51130 |

| Fire Resistance | Bfl-s1 (low flammability, limited smoke) | EN 13501-1 |

| Sound Absorption (Impact Sound) | 8 dB - 19 dB (with acoustic backing) | EN ISO 717-2 |

| Chemical Resistance | Excellent against common diluted acids, alkalis, oils | EN ISO 26987 |

| VOC Emissions | Very Low, compliant with AgBB, FloorScore | ISO 16000-9 |

| Service Life | 15-20+ years under proper maintenance | Manufacturer's Data |

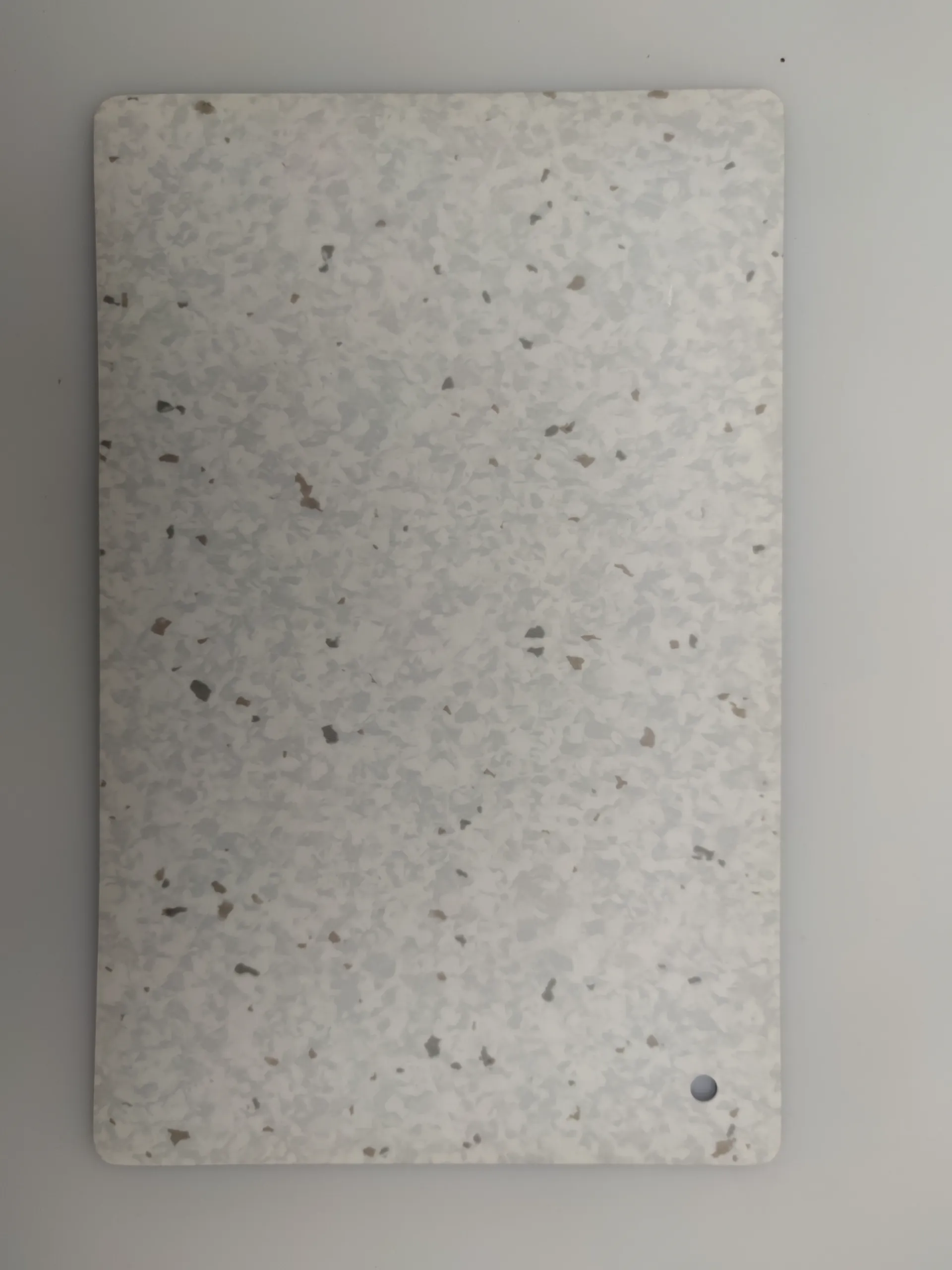

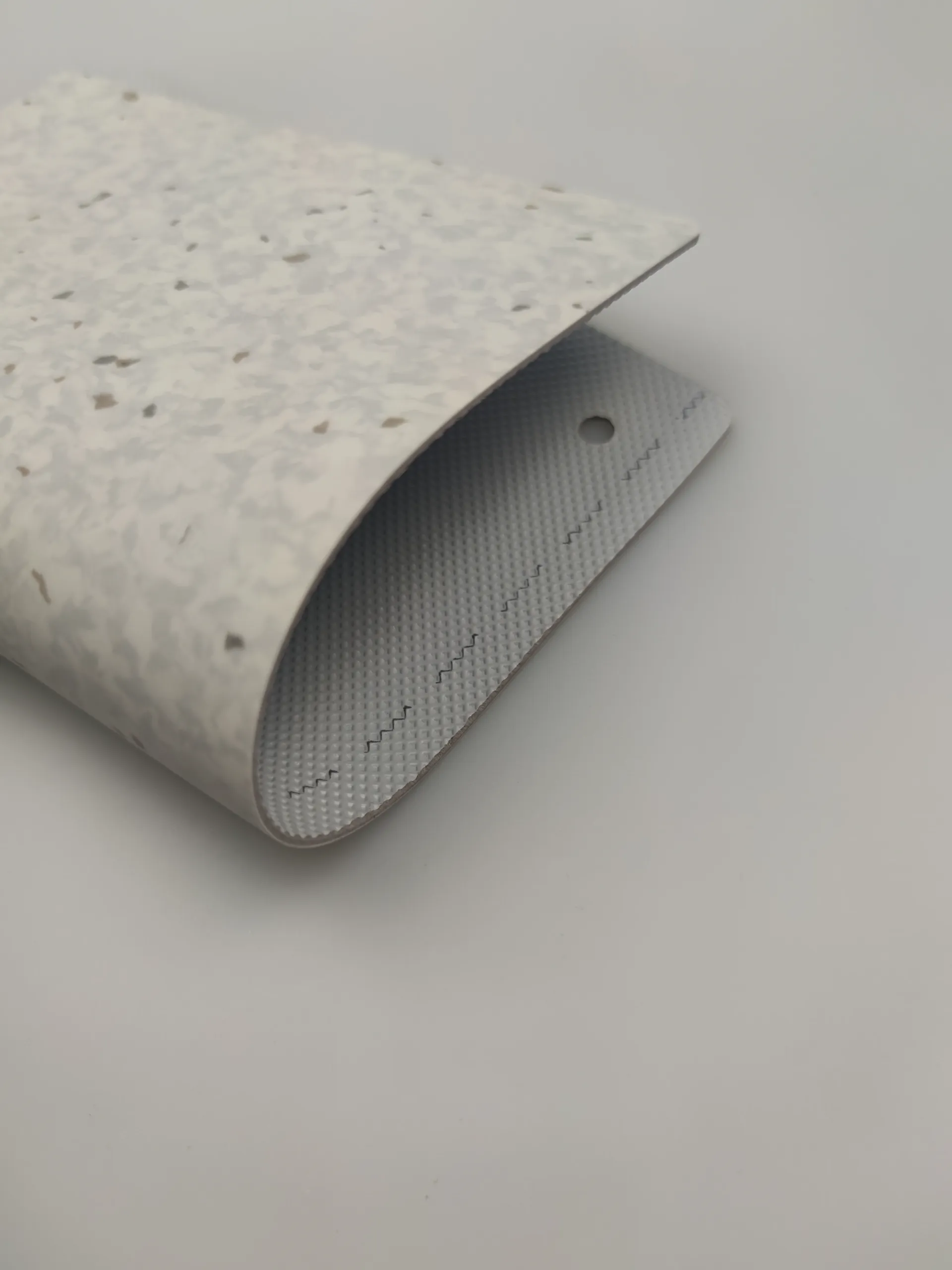

Figure 2: Illustrative pattern and texture of heterogeneous vinyl sheet.

Application Scenarios and Technical Advantages

The versatility and robust performance of heterogeneous viny make it suitable for a wide array of demanding B2B environments. Its engineered layers provide specific advantages tailored to various industries.

Target Industries:

- Healthcare: Hospitals, clinics, laboratories. Requires anti-bacterial properties, ease of cleaning, chemical resistance, and high foot traffic durability. Heterogeneous vinyl sheet with PUR surface treatments excels here.

- Education: Schools, universities, dormitories. Demands extreme wear resistance, acoustic comfort, and low maintenance.

- Retail & Hospitality: Shops, hotels, restaurants. Focus on aesthetics, slip resistance, and ability to withstand heavy daily traffic.

- Corporate Offices: Enhances acoustics, provides aesthetic flexibility, and ensures underfoot comfort for employees.

- Industrial (Light to Medium Duty): Control rooms, assembly areas. Benefits from chemical resistance, ease of repair, and resilience to wheeled traffic.

Key Technical Advantages:

- Superior Wear Resistance: The thick wear layer, often reinforced with ceramic or PUR, offers exceptional protection against abrasion, ensuring a longer service life even in intense footfall areas.

- Hygienic and Easy Maintenance: Non-porous surface, especially with Stariver treatments, prevents bacterial growth and makes cleaning effortless, reducing maintenance costs and promoting a healthier environment. This contributes to energy saving by reducing cleaning effort and chemical usage.

- Dimensional Stability: Fiberglass reinforcement in the backing layer minimizes expansion and contraction, preventing gaps and warping over time.

- Sound Absorption: Often features an integrated foam or fiber backing that significantly reduces impact sound, crucial for multi-level buildings and quiet environments.

- Chemical and Stain Resistance: The dense wear layer provides excellent resistance to a wide range of chemicals, disinfectants, and common stains, making it ideal for healthcare and laboratory settings (corrosion resistance in this context means resistance to chemical degradation, not metal corrosion).

- Design Versatility: The print layer allows for an extensive range of realistic wood, stone, and abstract designs, offering aesthetic flexibility without compromising performance.

- Safety: Excellent slip resistance (R9-R10) reduces the risk of falls, a critical factor in public and commercial spaces.

Figure 3: Heterogeneous vinyl installed in a commercial setting, showcasing durability and aesthetic appeal.

Vendor Comparison and Customized Solutions

Choosing the right supplier for heterogeneous viny requires a thorough evaluation of product quality, service, and customization capabilities. While many manufacturers offer competitive products, key differentiators lie in material sourcing, advanced surface treatments, and adherence to international standards.

Comparison Factors for Heterogeneous Vinyl Providers:

| Feature/Service | Standard Offering | Premium Offering (e.g., Enlio) | Value-Add/Differentiation |

|---|---|---|---|

| Wear Layer Composition | Standard PVC/PU | Reinforced PUR with ceramic beads | Enhanced scratch & abrasion resistance, extended lifespan. |

| Surface Treatment | Basic PU coating | Stariver UV-cured finish | Superior stain/chemical resistance, reduced maintenance (no waxing), improved slip. |

| Environmental Certifications | ISO 14001 | FloorScore, CE, AgBB, Phthalate-Free | Compliance with stringent indoor air quality standards, healthier spaces. |

| Acoustic Performance | Minimal (5-8 dB) | Integrated acoustic backing (15-19 dB) | Significant noise reduction, enhanced user comfort in offices/healthcare. |

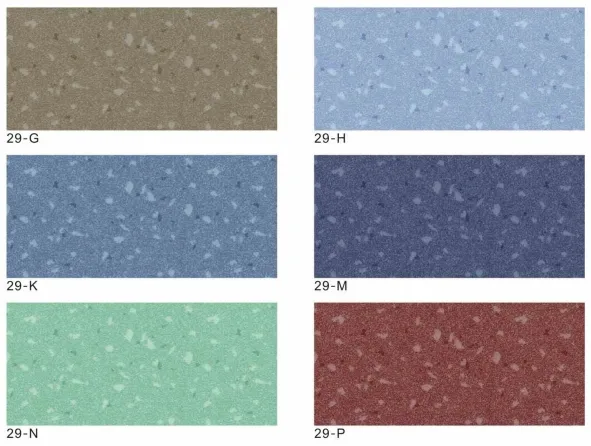

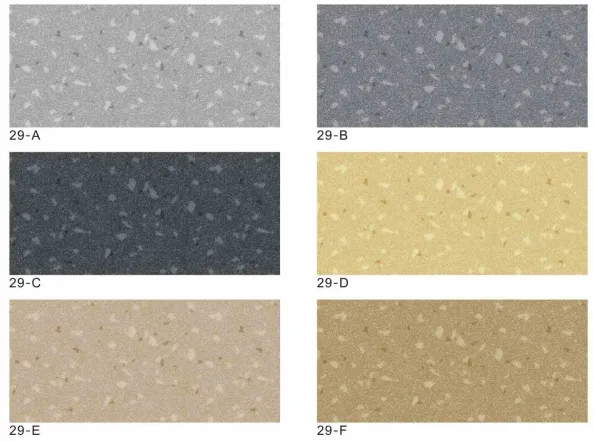

| Customization Options | Limited stock designs | Bespoke print designs, custom colors, size tailoring | Ability to match corporate branding, unique aesthetic requirements for projects. |

| Technical Support | Basic online resources | Dedicated project managers, on-site consultation | Comprehensive project lifecycle support from specification to installation. |

Customized Solutions:

For specialized projects, vendors often provide bespoke solutions. This can include:

- Specific Thicknesses: Tailoring total thickness or wear layer thickness for unique load-bearing or impact resistance needs.

- Custom Designs and Branding: Incorporating corporate logos, specific color palettes, or unique patterns into the print layer, crucial for brand identity in retail or corporate settings.

- Enhanced Performance Attributes: Adding anti-static properties for IT server rooms, heightened slip resistance for wet areas, or extra acoustic dampening for recording studios. A prominent example like Hawk Flooring often provides high-performance custom solutions for demanding sports or industrial applications.

- Specialized Formulations: Developing vinyl formulations that are highly resistant to specific chemicals found in industrial plants or research facilities.

Figure 4: Detailed view of the Stariver surface treatment, showing its fine texture and durability.

Application Case Studies

Real-world applications demonstrate the tangible benefits of installing high-quality heterogeneous viny.

Case Study 1: Major Regional Hospital Renovation

Client: "VitalCare Medical Center", a 500-bed regional hospital.

Challenge: Existing flooring in patient rooms, corridors, and operating theaters was prone to staining, difficult to sanitize, and offered poor acoustic performance, leading to patient and staff discomfort. The hospital required a solution that met stringent hygiene standards, offered superior durability, and contributed to a healing environment.

Solution: Installation of 15,000 sq meters of heterogeneous floor with Stariver surface, specifically designed for healthcare. Its seamless installation minimized bacterial harborage, while the Stariver surface provided enhanced resistance to iodine, blood, and common disinfectants. The integrated acoustic backing reduced noise levels by 18 dB, significantly improving the patient experience.

Outcome: Post-installation, the hospital reported a 30% reduction in daily cleaning time and a marked improvement in patient satisfaction scores due to a quieter and cleaner environment. The flooring's robust wear layer has shown no visible signs of degradation after 5 years of intense use.

Case Study 2: International Airport Terminal

Client: "GlobalHub Airport", a major international travel hub.

Challenge: The departure lounge and retail areas experienced extreme foot traffic, wheeled luggage, and spillages. The previous flooring required frequent replacement and intensive maintenance. Key requirements included extreme durability, ease of maintenance, high slip resistance, and a sophisticated aesthetic.

Solution: A custom design of heterogeneous sheet vinyl was developed, featuring a 1.0 mm wear layer and a unique, high-resolution graphic mimicking polished concrete, integrated with an R10 slip-resistant Stariver finish. Over 25,000 sq meters were installed across multiple concourses.

Outcome: The flooring has consistently performed under continuous heavy traffic, demonstrating exceptional resistance to scuffing and impact. Maintenance crews reported a 40% reduction in cleaning chemical consumption due to the advanced surface treatment. The bespoke aesthetic also contributed positively to the airport's modern branding.

Ensuring Trustworthiness: FAQ, Lead Times, Warranty, and Support

Frequently Asked Questions (FAQ):

A: Yes, with proper installation and seam welding, it forms a monolithic, watertight surface, making it ideal for bathrooms, kitchens, and laboratories. The Stariver surface further enhances slip resistance in these conditions.

A: The Stariver surface is a high-performance, UV-cured treatment that provides superior scratch, scuff, and chemical resistance compared to conventional PU coatings. It also eliminates the need for waxing and significantly reduces cleaning intensity over the lifespan of the flooring.

A: Our products are typically phthalate-free, feature very low VOC emissions, and comply with standards such as FloorScore and AgBB. We adhere to ISO 14001 certified manufacturing processes for environmental management.

Lead Time and Fulfillment:

Standard stock items of heterogeneous viny typically have a lead time of 2-4 weeks from order confirmation to shipment, depending on volume and destination. For customized solutions or large-scale projects, lead times may extend to 6-8 weeks, reflecting the production complexity. We maintain strategic warehousing to facilitate efficient global distribution. Detailed project schedules are provided upon quote finalization.

Warranty Commitments:

Our heterogeneous vinyl sheet products, including the heterogeneous floor with Stariver surface, are backed by a comprehensive commercial warranty ranging from 10 to 15 years, depending on the specific product and application. This warranty covers manufacturing defects and excessive wear under normal commercial use, provided installation and maintenance guidelines are strictly followed. Full warranty terms and conditions are available upon request.

Customer Support and After-Sales Service:

We offer dedicated technical support from project inception through post-installation. Our team of flooring specialists provides guidance on product selection, subfloor preparation, installation best practices, and ongoing maintenance. After-sales support includes problem resolution, spare part availability (if applicable), and advice on extending the product's lifespan. Our commitment is to ensure client satisfaction and the sustained performance of our heterogeneous vinyl sheet solutions.

Conclusion

In summary, heterogeneous viny flooring represents a sophisticated, high-performance solution for a vast array of commercial and industrial applications. Its multi-layered construction, combined with advanced surface treatments like the Stariver technology, delivers unparalleled durability, hygiene, aesthetic flexibility, and long-term cost efficiency. For B2B decision-makers and engineers, understanding the technical depth and comprehensive benefits of products like the heterogeneous floor with Stariver surface is crucial for making informed choices that significantly impact operational success and user well-being. By prioritizing materials that adhere to stringent quality and environmental standards, businesses can invest in flooring infrastructure that offers both immediate benefits and lasting value.

References

- International Organization for Standardization (ISO) official website.

(ISO standards for flooring, e.g., ISO 10582, ISO 23999, ISO 24346, ISO 24343-1, ISO 26987) - European Committee for Standardization (CEN) official website.

(EN standards for flooring, e.g., EN 13501-1, EN 13893, EN ISO 717-2) - Resilient Floor Covering Institute (RFCI) - FloorScore Certification.

(Information on VOC emissions and indoor air quality standards for resilient flooring) - German Committee for Health-related Evaluation of Building Products (AgBB) official website.

(Criteria for VOC emissions from building products) - DIN Deutsches Institut für Normung e. V.

(DIN standards for slip resistance, e.g., DIN 51130)

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025