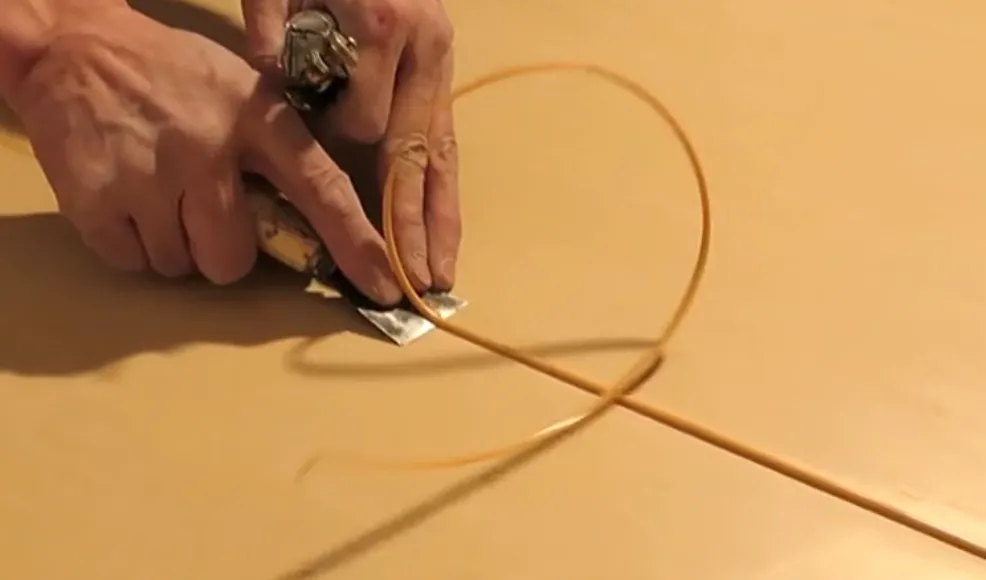

When utilizing PVC for such extensive and demanding applications, a robust installation method is imperative to ensure longevity and resilience. Enter the welding rod. This indispensable tool is instrumental in the seamless installation of PVC sports court surfaces. The welding rod, often made of the same Polyvinyl Chloride (PVC) material, is utilized to fuse the individual pieces of PVC together, creating a uniform and unblemished surface. This process not only augments the aesthetic appeal of the sports court but also enhances its strength, preventing the edges from peeling or lifting – a common issue in high-traffic areas. The welding process typically involves heating the rod and the adjoining PVC surfaces to a specific temperature where they can meld together without compromising the material's intrinsic properties. Professional installers often rely on precision tools, such as welders equipped with temperature controls, to ensure a consistent bond. The result is a seamless and durable surface that can withstand the various pressures and impacts associated with sports activities. Moreover, the use of PVC material along with welding rods is an eco-friendly choice, aligning with contemporary environmental standards, as PVC is recyclable and can be reprocessed into new products at the end of its lifespan. Thus, the integration of welding rods in the installation of PVC sports court surfaces exemplifies a blend of modern engineering and environmental stewardship. From basketball courts to tennis courts, the widespread adoption of PVC and welding rod technology underscores its efficacy in providing safe, durable, and aesthetically pleasing surfaces for athletes of all levels. This comprehensive approach not only ensures that the surface maintains its integrity over years of rigorous use but also contributes significantly to the overall safety and performance of the athletes, fostering an environment where excellence in sports can thrive.

- Miljeufreonlike grûnstoffen, duorsum

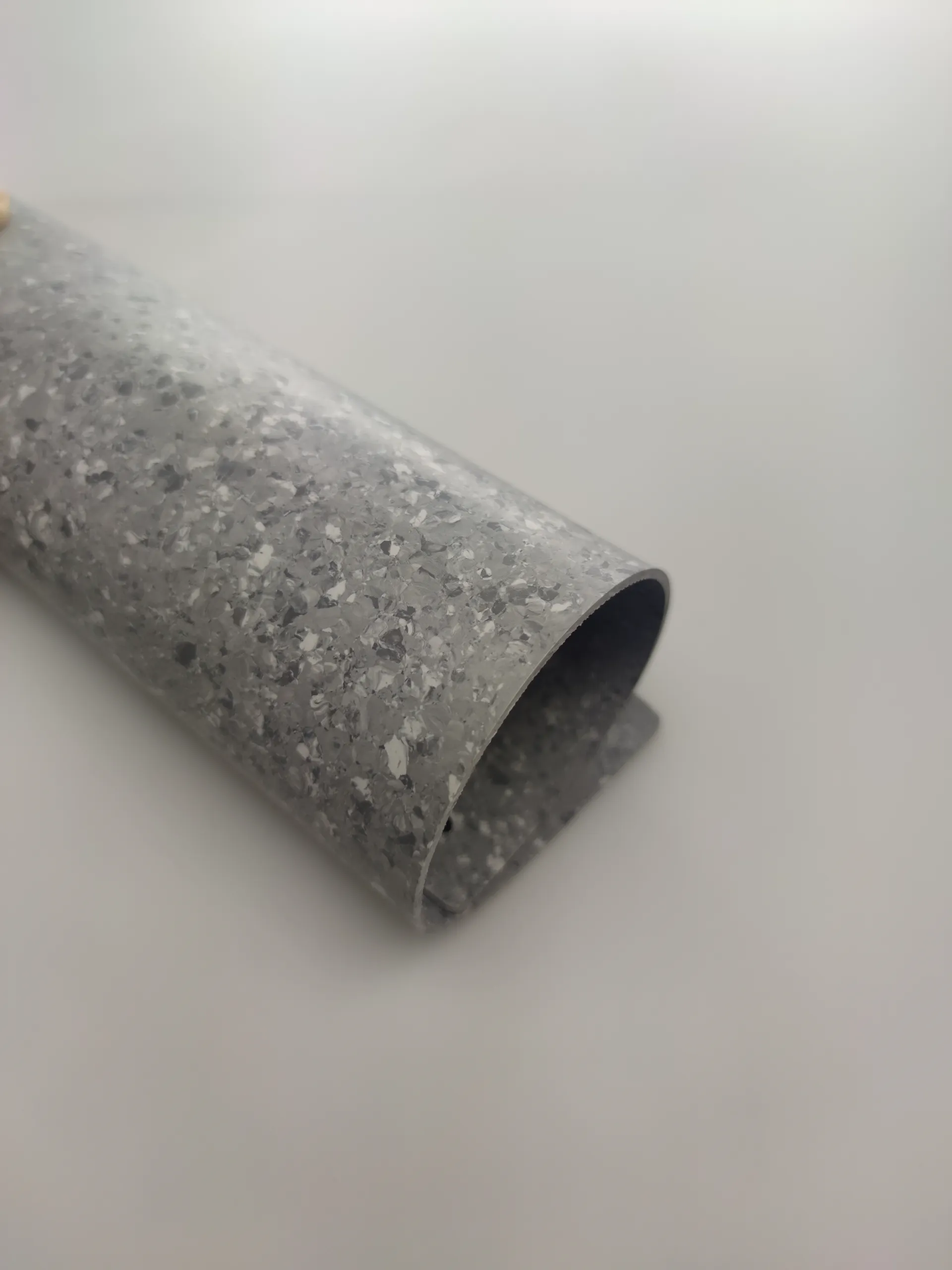

Gebrûk fan miljeufreonlik PVC wear-resistant materiaal, net tafoegje recycled ôffal kin feilich brûkt wurde

- Sterke taaiens, net maklik te brekken

Fêst materiaal Standert diameter 4mm Standert diameter wurdt net beheind troch de side

- Tapassing fan in breed oanbod fan elastyske flier welding wire

Maklik te ferfoarmjen sterke fleksibiliteit maklik te ynstallearjen

- Moisture-proof en mildew bewiis