- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

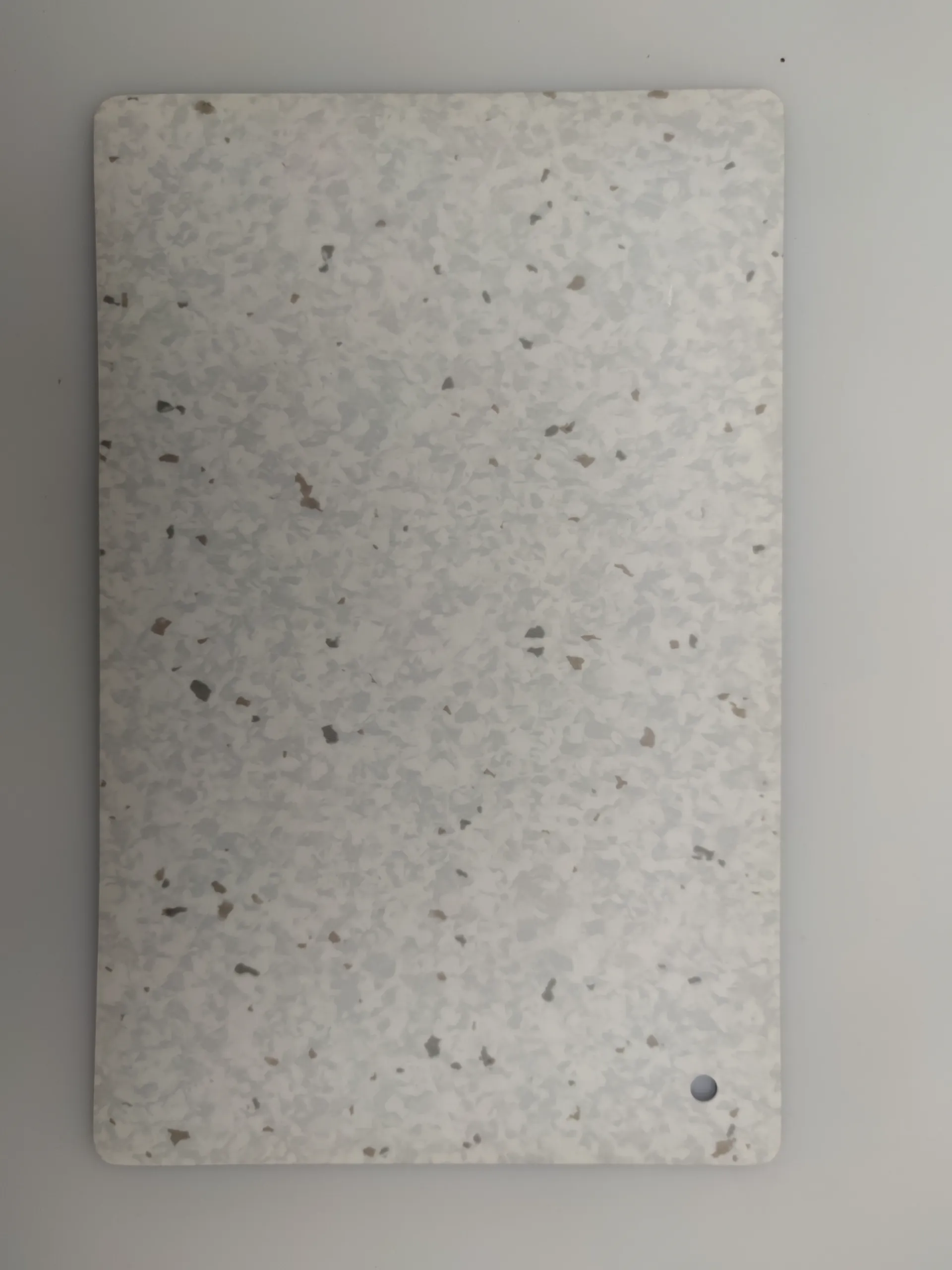

Hawk Flooring: Durable, Stylish Heterogeneous Vinyl Sheets

Industry Trends in Advanced Resilient Flooring

The global market for resilient flooring, particularly in the B2B sector, continues to experience robust growth, driven by increasing demands for durability, aesthetics, and sustainability in commercial and institutional environments. Among the forefront of these innovations is vinícola heteroxéneal, which offers a superior blend of performance characteristics suitable for a multitude of high-traffic applications. Market analysis indicates a steady upward trajectory, with projections highlighting significant expansion in healthcare, education, and retail sectors due to technological advancements and evolving design preferences.

Innovations in wear layer technology, coupled with advancements in digital printing, allow for an unprecedented range of designs and textures, mimicking natural materials like wood and stone with remarkable realism. Furthermore, the focus on indoor air quality (IAQ) and eco-friendly manufacturing processes has propelled the demand for products that meet stringent environmental certifications. This convergence of aesthetic flexibility, enhanced performance, and ecological responsibility positions heterogeneous sheet vinyl as a leading solution for modern commercial flooring projects, offering long-term value and operational efficiency.

For instance, the global vinyl flooring market was valued at approximately USD 34 billion in 2022 and is projected to reach over USD 60 billion by 2030, demonstrating a compound annual growth rate (CAGR) exceeding 7%. This expansion is largely attributed to the robust performance and versatility of products such as heterogeneous vinyl sheet, which caters to demanding commercial specifications.

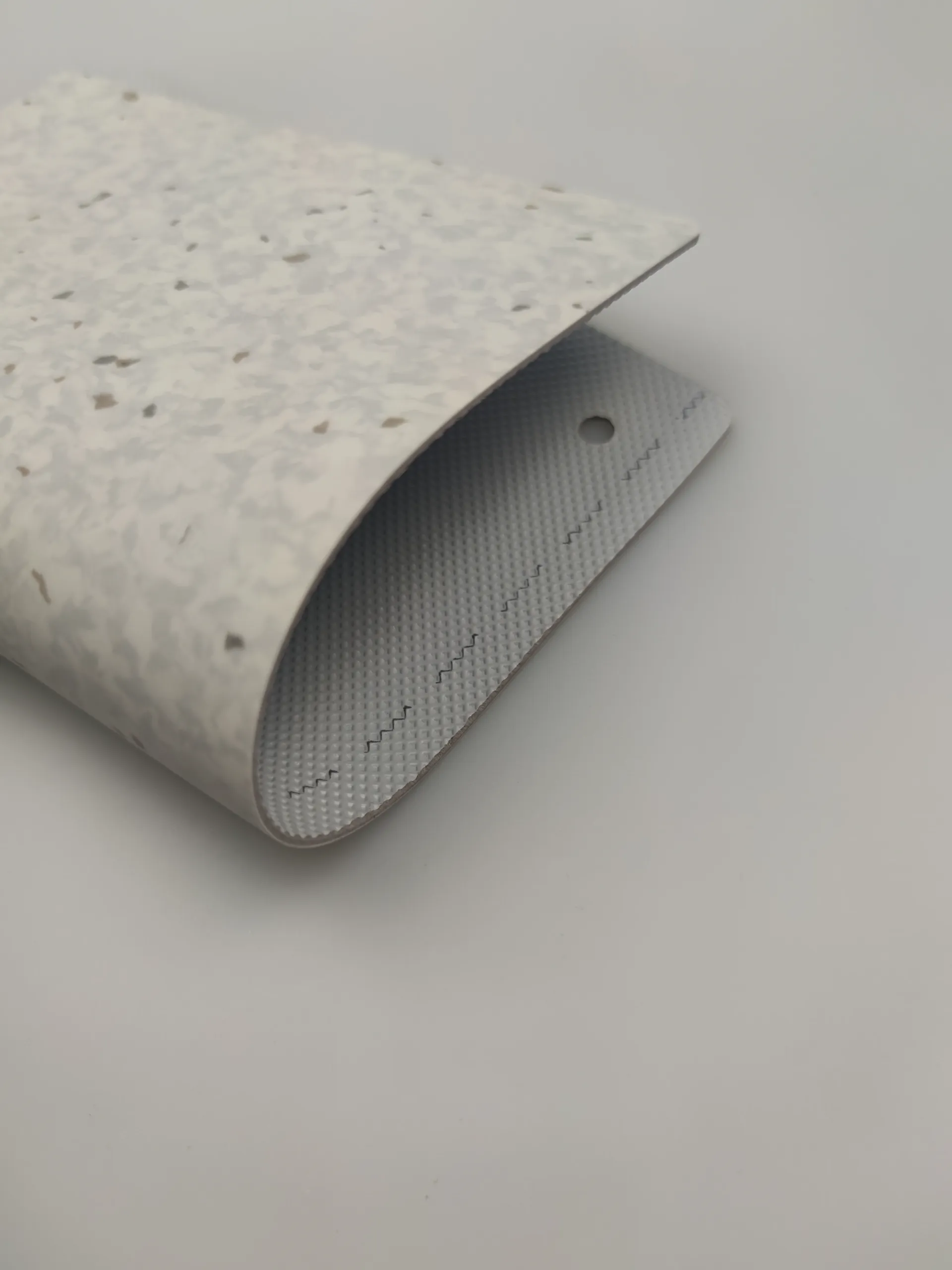

Manufacturing Process Flow of Heterogeneous Vinyl

The production of heterogeneous vinyl flooring is a sophisticated, multi-stage process designed to create a product with superior durability, stability, and aesthetic appeal. Each layer is meticulously engineered to contribute to the overall performance characteristics of the final floor. The process adheres to stringent international quality standards, such as ISO 9001 for quality management and ISO 14001 for environmental management, ensuring consistent product excellence and sustainability.

1. Raw Material Preparation

High-grade PVC resins, plasticizers, stabilizers, pigments, and fillers are precisely measured and mixed to form the base compounds for each layer.

2. Base Layer Extrusion/Calendering

The backing layer, often incorporating recycled PVC and fiberglass for dimensional stability, is extruded or calendared into a sheet. This process ensures the product meets EN 685 classification standards for heavy commercial use.

3. Printing Layer Application

A high-resolution print film, featuring desired patterns and colors, is applied. This digital printing process allows for intricate designs replicating natural materials or custom branding.

4. Wear Layer & Surface Treatment

A transparent, highly durable PVC wear layer is applied over the print. For products like the heterogeneous floor with Stariver surface, specialized surface treatments are integrated at this stage to enhance scratch, stain, and scuff resistance.

5. Curing & Embossing

The multi-layered structure is subjected to heat and pressure to ensure optimal adhesion and material integrity. Embossing may be applied to create textured surfaces, enhancing realism and slip resistance (e.g., R9-R10 as per DIN 51130).

6. Quality Control & Finishing

Each roll undergoes rigorous testing for dimensions, color consistency, indentation resistance (EN ISO 24343-1), and delamination. Finally, the material is cut into specified widths and lengths, then rolled for packaging.

This meticulous process ensures a service life often exceeding 15 years in typical commercial environments, making it ideal for target industries such as healthcare, education, retail, and light industrial settings. In scenarios demanding energy saving, the thermal insulation properties of heterogeneous vinyl sheet can contribute to reduced HVAC loads, while its exceptional corrosion resistance makes it a prime choice for chemical laboratories and pharmaceutical facilities where spills are a concern. The controlled manufacturing environment guarantees a consistent, high-performance product.

Technical Specifications: Heterogeneous Floor with Stariver Surface

The Enlio heterogeneous floor with Stariver surface is engineered for superior performance in demanding commercial environments. Its multi-layered construction, combined with the innovative Stariver surface treatment, provides exceptional durability, ease of maintenance, and enhanced safety features. These specifications are meticulously tested to comply with leading international standards, including ISO and EN norms, ensuring reliability and long-term value.

| Parameter | Specification (Stariver Surface) | Testing Standard |

|---|---|---|

| Total Thickness | 2.0mm - 3.0mm (Customizable) | EN ISO 24346 |

| Wear Layer Thickness | 0.5mm - 0.7mm | EN ISO 24340 |

| Weight | ~2.8 kg/m² - 4.2 kg/m² | EN ISO 23997 |

| Residual Indentation | EN ISO 24343-1 | |

| Resistencia ao deslizamento | R9 (Standard) - R10 (Optional) | DIN 51130 |

| Fire Classification | Bfl-s1 | EN 13501-1 |

| Sound Absorption | ~4-6 dB (Impact Sound Reduction) | EN ISO 717-2 |

| Chemical Resistance | Excellent (Resistant to common chemicals) | EN ISO 26987 |

| Dimensional Stability | EN ISO 23999 | |

| VOC Emissions | Very Low (A+ classified) | AgBB/DIBt/EN 16000 |

These specifications highlight the premium construction of the heterogeneous floor with Stariver surface, ensuring it meets the rigorous demands of various commercial applications, from high-traffic corridors to specialized healthcare zones. The Stariver surface itself contributes to unparalleled resistance against scuffs, stains, and daily wear, significantly extending the flooring's aesthetic and functional lifespan.

Versatile Application Scenarios

The inherent adaptability and robust performance characteristics of heterogeneous vinyl make it an ideal choice for a diverse range of commercial and industrial applications. Its multi-layered structure is specifically designed to meet the unique challenges of various environments, ensuring long-term durability, hygiene, and aesthetic appeal. Enlio's heterogeneous floor with Stariver surface excels in environments where performance cannot be compromised.

- ✓ Instalacións sanitarias: Hospitals, clinics, laboratories, and elderly care homes benefit from the hygienic, easy-to-clean surface, superior chemical resistance, and seamless installation options that reduce pathogen harborage. Acoustic properties contribute to a quieter healing environment.

- ✓ Institucións educativas: Schools, universities, and daycare centers require flooring that withstands heavy foot traffic, resists scuffs and stains, and offers sound absorption for improved learning environments. The aesthetic versatility also allows for vibrant, engaging spaces.

- ✓ Retail & Hospitality: High-traffic retail spaces, hotels, and restaurants demand flooring that combines visual appeal with extreme durability. The design flexibility of heterogeneous sheet vinyl supports brand aesthetics while resisting wear from constant footfall and spills.

- ✓ Offices & Corporate Environments: Modern workspaces require flooring that enhances aesthetics, reduces noise, and offers easy maintenance. Heterogeneous vinyl sheet provides comfort underfoot and resistance to castor chair traffic, supporting productive work environments.

- ✓ Light Industrial & Technical Areas: While not for heavy machinery, it is suitable for clean rooms, laboratories, and light manufacturing facilities where chemical resistance, easy cleaning, and antistatic properties are crucial.

These diverse applications underscore the versatility and robust engineering of Enlio's heterogeneous flooring solutions, designed to meet the exacting standards of professional clients worldwide.

Technical Advantages of Enlio Heterogeneous Vinyl

Enlio's heterogeneous vinyl, particularly with its Stariver surface, offers a compelling suite of technical advantages that set it apart in the B2B flooring market. These benefits are derived from advanced material science and precision manufacturing, ensuring superior long-term performance and cost efficiency for commercial installations.

- ● Exceptional Durability and Wear Resistance: The thick wear layer, often enhanced by the Stariver surface treatment, provides superior resistance to abrasion, scratches, and indentations. This multi-layered construction, reinforced with fiberglass, maintains structural integrity and appearance even under constant heavy traffic and static loads, significantly extending product lifespan.

- ● Enhanced Hygiene and Ease of Maintenance: The non-porous surface, especially with advanced treatments like Stariver, repels dirt, stains, and microbes, making cleaning simple and effective. This reduces maintenance costs and is critical in environments requiring stringent hygiene protocols, such as healthcare and food service.

- ● Superior Dimensional Stability: Integrated fiberglass reinforcement within the core layers minimizes expansion and contraction, preventing common issues like gapping or curling. This stability is crucial for large-scale installations and contributes to a long-lasting, flat floor surface.

- ● Excellent Acoustic Performance: The material composition provides significant impact sound reduction (typically 4-6 dB), contributing to quieter indoor environments, a key factor in educational, healthcare, and office settings.

- ● Safety Features (Slip and Fire Resistance): Engineered with controlled surface textures, our heterogeneous sheet vinyl offers reliable slip resistance (R9-R10). Furthermore, it achieves critical fire classification (Bfl-s1), ensuring minimal flame spread and smoke production, enhancing occupant safety.

- ● Environmental Responsibility: Manufactured with low VOC emissions (A+ certified) and often incorporating recycled content, these products contribute to healthier indoor air quality and sustainable building practices. They meet stringent environmental standards such as AgBB and DIBt.

These advantages underscore Enlio's commitment to delivering high-performance, long-lasting, and environmentally responsible flooring solutions tailored for the demanding B2B sector.

Vendor Comparison: Enlio vs. Competitors (e.g., Hawk Flooring)

Selecting the right flooring vendor is a critical decision for B2B clients, impacting project costs, long-term performance, and operational efficiency. While many suppliers offer heterogeneous vinyl sheet, differentiators in technical specifications, material quality, and after-sales support are paramount. Here, we present a comparison between Enlio's heterogeneous floor with Stariver surface and a hypothetical competitor, Hawk Flooring, to highlight key considerations.

| Feature/Metric | Enlio (Stariver Surface) | Hawk Flooring (Example Competitor) |

|---|---|---|

| Wear Layer Thickness | 0.5mm - 0.7mm (High Grade) | 0.3mm - 0.6mm (Variable) |

| Surface Treatment | Stariver (Enhanced scratch & stain resistance) | Standard PU (Polyurethane) coating |

| Dimensional Stability | < 0.1% (Fiberglass reinforced) | < 0.25% (Standard PVC backer) |

| Certifications | ISO 9001, ISO 14001, CE, FloorScore, AgBB A+ | CE, ISO 9001 |

| Warranty (Commercial) | 10-15 Years (Comprehensive) | 5-10 Years (Standard) |

| Customization Options | Extensive (Design, thickness, specific properties) | Limited (Standard color/pattern range) |

| Lead Time & Fulfillment | Optimized supply chain, global distribution | Regional distribution |

This comparison illustrates that while multiple vendors operate in the heterogeneous vinyl market, Enlio differentiates itself through superior technical specifications, advanced surface treatments like Stariver, and a strong commitment to industry certifications and extended warranties. These factors directly translate into lower total cost of ownership, enhanced project reliability, and superior long-term performance for our clients.

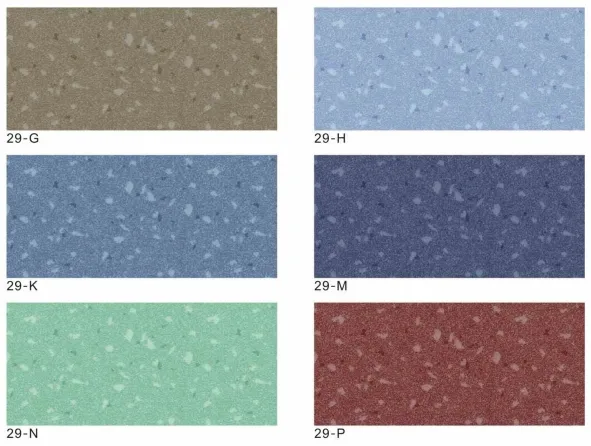

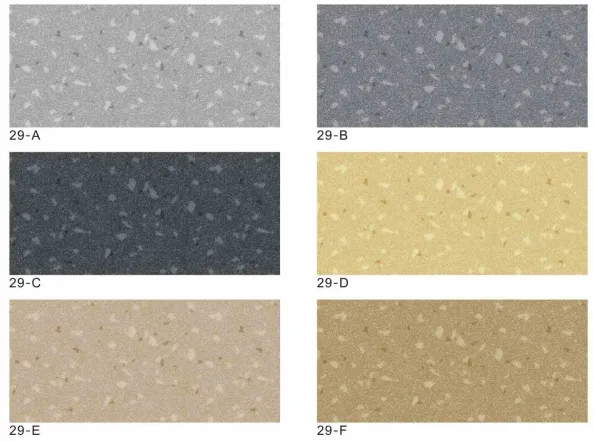

Customized Solutions for Unique Requirements

Recognizing that every B2B project has unique demands, Enlio excels in providing customized heterogeneous vinyl sheet solutions. Our engineering team collaborates closely with clients to develop flooring that precisely matches specific aesthetic visions and performance criteria, going beyond standard offerings.

- ● Bespoke Designs & Color Matching: Leverage our advanced digital printing capabilities to create unique patterns, corporate logos, or precise color matches to architectural specifications, ensuring brand consistency and design integrity.

- ● Enhanced Performance Properties: Customization extends to functional attributes, such as increased wear layer thickness for ultra-heavy traffic, specialized anti-static or conductive properties for server rooms and laboratories, or enhanced slip resistance for wet environments.

- ● Specific Thickness & Roll Dimensions: Tailoring total thickness to meet unique acoustic or comfort requirements, and adjusting roll dimensions for optimized installation efficiency in large-scale projects.

- ● Sustainability Customization: Development of products with higher recycled content or specific bio-based plasticizers to align with stringent green building certifications and corporate sustainability goals.

Our flexibility in manufacturing ensures that even the most complex flooring requirements can be met with precision and quality, offering truly tailored heterogeneous vinyl solutions.

Real-World Application Case Studies

Enlio's heterogeneous floor with Stariver surface has been successfully implemented in numerous prestigious projects globally, demonstrating its robust performance and suitability for diverse B2B applications. These case studies highlight our commitment to client satisfaction and long-term product reliability.

Case Study 1: Major University Hospital Wing

Challenge: A newly constructed wing for a prominent university hospital required a flooring solution that met stringent hygiene standards, offered superior chemical resistance against medical spills, and provided excellent underfoot comfort for staff on long shifts, all while maintaining a contemporary aesthetic.

Solution: Enlio supplied over 15,000 square meters of heterogeneous floor with Stariver surface (2.5mm total thickness, 0.7mm wear layer). The Stariver treatment provided an impermeable barrier against disinfectants and stains, while its R9 slip resistance enhanced safety in corridors and patient rooms. The material's inherent sound absorption contributed to a quieter, more conducive healing environment. Our flooring was chosen over traditional options due to its comprehensive certification portfolio, including ISO 26987 for chemical resistance and EN 13501-1 for fire safety.

Outcome: The flooring exceeded the client's expectations for durability and ease of maintenance. Hospital management praised the enhanced hygienic properties and the significant reduction in ambient noise, contributing to improved patient and staff satisfaction. The project was completed on schedule, aligning with the critical operational timeline of the facility.

Case Study 2: National Retail Chain Flagship Store

Challenge: A leading national retail chain sought a high-performance flooring for its new flagship store. Key requirements included extreme wear resistance to handle daily heavy foot traffic (estimated 10,000+ visitors per day), visual consistency across multiple store sections, and quick, efficient installation to minimize downtime during opening preparations.

Solution: Enlio provided 8,000 square meters of customized heterogeneous sheet vinyl with a wood-look design. The product's 0.7mm wear layer and Stariver surface proved highly effective against scuffs and stains, maintaining its pristine appearance despite intense use. Our ability to supply large rolls with consistent patterns ensured seamless installation and reduced waste, meeting the client's tight project schedule. The client specifically noted the ease of cleaning and minimal maintenance required compared to previous flooring solutions.

Outcome: The flagship store opened successfully, with the flooring performing exceptionally well. The management team reported significant savings in maintenance costs and positively remarked on the flooring's ability to retain its aesthetic appeal, enhancing the overall customer experience and brand image. This project led to subsequent orders for other store locations.

Frequently Asked Questions (FAQ)

Q1: What exactly is heterogeneous vinyl flooring?

A1: Heterogeneous vinyl is a multi-layered vinyl flooring product, distinct from homogeneous vinyl which is a single layer. It typically consists of a compacted backing layer, a fiberglass reinforcement layer for stability, a printed design layer, and a transparent wear layer, often treated with special coatings like Enlio's Stariver surface for enhanced performance. This construction allows for greater design flexibility and specialized performance characteristics.

Q2: What is the expected service life of Enlio's heterogeneous floor with Stariver surface?

A2: With proper installation and maintenance, our heterogeneous floor with Stariver surface is designed for a commercial service life of 10-15 years, often extending beyond in less demanding environments. The advanced Stariver surface significantly contributes to its longevity by resisting wear, scratches, and stains.

Q3: Is this flooring suitable for high-traffic areas?

A3: Absolutely. Enlio's heterogeneous vinyl sheet is specifically engineered for high-traffic commercial and industrial environments. Its robust multi-layer construction, coupled with a durable wear layer and the Stariver surface treatment, ensures excellent resistance to abrasion and indentation from heavy footfall and rolling loads, meeting classifications for very heavy commercial use (e.g., Class 33-34 under EN 685).

Q4: How does the Stariver surface enhance performance?

A4: The Stariver surface is a proprietary treatment applied to the wear layer, providing superior resistance to scratches, scuffs, and stains compared to standard PU coatings. It also enhances the ease of cleaning, reducing the need for harsh chemicals and prolonged maintenance efforts, thus lowering operational costs.

Q5: What are the environmental certifications for Enlio's heterogeneous sheet vinyl?

A5: Our products typically meet stringent environmental standards such as ISO 14001 for manufacturing processes, FloorScore, and AgBB A+ for very low VOC emissions, contributing to healthier indoor air quality. We are committed to sustainable practices and transparent product declarations.

Lead Time, Warranty, and Customer Support

Enlio is committed to delivering not just high-quality products but also exceptional service throughout the entire project lifecycle, ensuring trustworthiness and client satisfaction.

Lead Time and Fulfillment

Our efficient manufacturing processes and robust global supply chain enable competitive lead times. For standard orders of heterogeneous floor with Stariver surface, typical production lead times range from 3 to 4 weeks, with an additional 1-2 weeks for international shipping, depending on destination. For customized solutions, lead times will be confirmed upon final specification approval. We maintain strategic inventory levels for popular designs to facilitate urgent requirements and are proficient in managing large-volume project logistics.

Warranty Commitments

Enlio provides a comprehensive commercial warranty of 10 to 15 years for our heterogeneous vinyl products, including the heterogeneous floor with Stariver surface. This warranty covers manufacturing defects, excessive wear, and dimensional stability when installed and maintained according to our guidelines. Our warranty reflects our confidence in the superior quality and longevity of our flooring solutions, providing peace of mind to our B2B clients.

Customer Support and After-Sales Service

Our dedicated customer support team is available to assist with technical queries, product selection, installation guidance, and any post-purchase concerns. We offer multilingual support and are committed to prompt responses to ensure seamless project execution and long-term client satisfaction. From initial consultation to after-sales support, Enlio partners with clients to ensure optimal flooring performance and value.

References

- Grand View Research. (2023). Vinyl Flooring Market Size, Share & Trends Analysis Report By Product (LVT, VCT, Vinyl Sheet), By Application (Residential, Commercial, Industrial), By Region, And Segment Forecasts, 2023 - 2030.

- European Standards Organization (CEN). (Various). EN ISO 24346, EN ISO 24343-1, EN 13501-1, DIN 51130.

- International Organization for Standardization (ISO). (Various). ISO 9001, ISO 14001.

- Resilient Floor Covering Institute (RFCI). (Various). FloorScore Certification.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025