- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

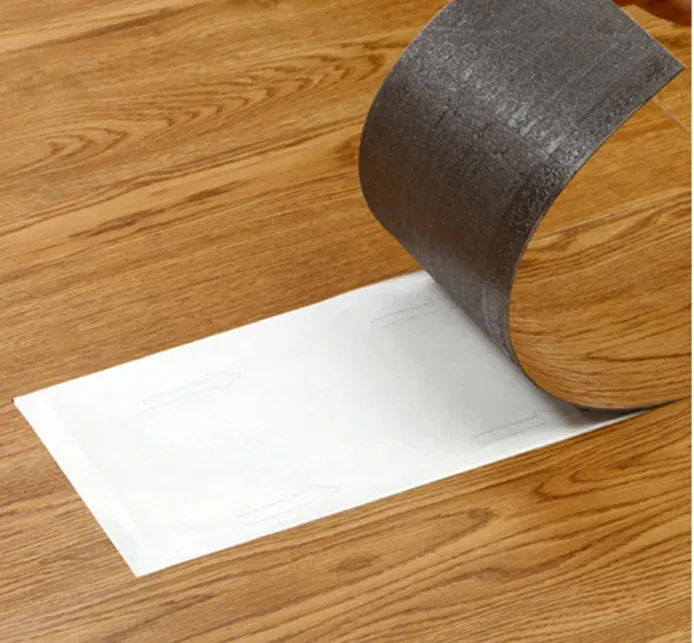

Best Dry Back LVT Flooring | Durable, Stylish & Easy Install

Industry Trends and Market Dynamics

The commercial flooring market is experiencing significant evolution, driven by demand for durable, aesthetically pleasing, and cost-effective solutions. Among the forefront of this innovation is Luxury Vinyl Tile (LVT), which has carved out a substantial niche due to its versatility and performance. Specifically, dry back LVT flooring is gaining considerable traction within the B2B sector. Industry reports indicate a compound annual growth rate (CAGR) for the global LVT market of approximately 6-8% from 2023 to 2030, with dryback LVT contributing significantly to this expansion, particularly in high-traffic commercial environments.

This growth is primarily fueled by its superior wear resistance, ease of maintenance, and ability to mimic natural materials like wood and stone with remarkable realism. Architects, facility managers, and procurement specialists are increasingly specifying dry back LVT flooring for projects ranging from healthcare facilities and educational institutions to corporate offices and retail spaces. The robust construction and adhesive-based installation method of LVT dryback ensure a stable, long-lasting surface that can withstand the rigors of heavy commercial use, making it an economically viable and aesthetically superior alternative to traditional flooring options.

Key trends influencing the adoption of dry back luxury vinyl plank include a heightened focus on indoor air quality, leading to demand for low-VOC products, and a push for sustainable manufacturing practices. Manufacturers are responding by developing LVT dryback solutions that are phthalate-free and incorporate recycled content, aligning with global environmental standards and corporate social responsibility initiatives. Furthermore, advancements in digital printing technology allow for an unprecedented array of designs and textures, offering unparalleled creative freedom for interior design professionals.

Detailed Manufacturing Process of Dry Back LVT Flooring

The production of dry back LVT flooring is a sophisticated, multi-stage process designed to create a highly durable and aesthetically versatile product. Emphasizing precision and quality control, the manufacturing workflow ensures that each plank or tile meets stringent industry standards.

Core Materials and Composition:

- PVC Base Layer: Comprised of virgin or recycled polyvinyl chloride (PVC) resin, plasticizers (increasingly phthalate-free), stabilizers, and fillers (e.g., limestone). This forms the robust and dimensionally stable core.

- Fiberglass Scrim: A reinforcing layer, typically made of fiberglass, is embedded within the core layer to enhance dimensional stability, preventing expansion and contraction due to temperature fluctuations.

- Print Film Layer: A high-definition photographic film, printed with advanced digital or rotogravure techniques, replicates the appearance of natural wood, stone, or abstract patterns.

- 着用層: A transparent, durable layer made of clear PVC, often enhanced with ceramic bead or aluminum oxide particles, providing resistance to scratches, scuffs, and abrasions.

- UV Coating: An outermost layer, cured with ultraviolet light, offering additional protection against fading, staining, and surface wear, while also simplifying cleaning.

Manufacturing Process Flow:

- Raw Material Preparation: PVC resins, plasticizers, stabilizers, and fillers are carefully weighed and mixed to create a homogeneous compound. Quality control checks ensure material purity and consistency.

- Calendering/Extrusion of Base Layers: The PVC compound is fed into calendering machines, which use a series of heated rollers to flatten and compress the material into precise, uniform sheets for the base layer. Alternatively, extrusion processes might be used.

- Fiberglass Reinforcement: A fiberglass scrim is integrated into the PVC core layer during the calendering process. This critical step imbues the flooring with superior dimensional stability, an essential feature for commercial applications where temperature and humidity fluctuations can occur.

- Lamination of Print Film: The high-definition print film, carrying the desired aesthetic pattern, is precisely aligned and laminated onto the core layer using heat and pressure.

- Application of Wear Layer: A clear, robust PVC wear layer is then applied over the print film. This layer is engineered for extreme durability and forms the primary defense against foot traffic, abrasions, and impacts. Modern wear layers often incorporate ceramic bead technology for enhanced resistance.

- UV Coating Application and Curing: The final protective UV coating is applied to the surface. This coating is then cured using ultraviolet light, creating a strong, transparent finish that resists fading, stains, and scuffs, while also making cleaning easier.

- Embossing and Texturing: To enhance realism, an embossing process might be applied, either in-register with the print film (EIR - Embossed In Register) or general texturing. This adds tactile depth that mimics natural material grains.

- Cutting and Shaping: The continuous sheets are then precisely cut into individual planks or tiles using advanced CNC machining, ensuring consistent dimensions and squareness. Edges are often micro-beveled for a realistic appearance and easier installation.

- Quality Control and Testing: Throughout the entire process, rigorous testing is conducted. This includes checks for dimensional stability (ISO 23999), indentation resistance (ASTM F1914), wear resistance (EN 660-2), colorfastness, fire performance (EN 13501-1), and slip resistance (EN 13893). These standards ensure product reliability and compliance with international regulations.

- パッケージ: Finished and inspected planks/tiles are then packaged for shipment, ensuring protection during transit.

The service life of a well-manufactured LVT dryback product, installed correctly in its target environment, can exceed 15-20 years. Target industries benefiting from these advantages include healthcare (hygiene, durability), education (high traffic, ease of cleaning), retail (aesthetics, wear resistance), and corporate environments (noise reduction, modern appeal). The inherent properties of the material, such as water resistance and chemical resistance, make it ideal for areas prone to spills or requiring frequent cleaning, like laboratories or food service areas.

Technical Specifications and Performance Parameters

Understanding the technical specifications of dry back LVT flooring is crucial for B2B decision-makers to ensure optimal performance and longevity in demanding commercial environments. These parameters directly correlate with the product's suitability for various application scenarios and its compliance with industry standards.

Typical Dry Back LVT Flooring Specifications:

| Parameter | Typical Range/Value | Relevant Standard |

|---|---|---|

| Total Thickness | 2.0mm - 3.0mm (Commercial: 2.5mm - 5.0mm) | EN 428 |

| Wear Layer Thickness | 0.3mm - 0.7mm (Commercial: 0.5mm - 0.7mm) | EN 429 |

| Panel Size (Plank/Tile) | 180x1220mm, 305x610mm, 457x914mm (variable) | Manufacturer Specific |

| Weight per m² | 3.5 - 6.0 kg/m² (depending on thickness) | EN 430 |

| Dimensional Stability | ≤ 0.1% - 0.05% | ISO 23999 / EN 434 |

| Residual Indentation | ≤ 0.10 mm | EN 433 / ASTM F1914 |

| Fire Performance | Bfl-s1 (Europe), Class A/B (US) | EN 13501-1 / ASTM E648 |

| Slip Resistance (Dry) | R9 - R10 | DIN 51130 |

| Chemical Resistance | Excellent resistance to common household chemicals | EN 423 |

| Sound Absorption | 3-5 dB (without additional underlayment) | ISO 717-2 |

| Lightfastness | ≥ 6 (Blue Wool Scale) | EN ISO 105-B02 |

| Underfloor Heating Suitability | Suitable (max. surface temp 27°C) | Manufacturer Specific |

These specifications highlight the engineering behind LVT dryback. For instance, a wear layer of 0.5mm or higher is typically recommended for heavy commercial applications, providing the necessary resilience against high foot traffic and heavy rolling loads. The low residual indentation ensures that furniture and equipment do not leave permanent marks, preserving the floor's appearance over time. High dimensional stability, often achieved through fiberglass reinforcement, is critical in preventing gapping or buckling, especially in large commercial installations subject to environmental variations. Compliance with fire performance standards (e.g., Bfl-s1) is mandatory for public buildings, ensuring safety.

Application Scenarios and Technical Advantages

The robust nature and adaptable aesthetic of LVT dryback flooring make it an ideal choice for a diverse range of commercial and institutional application scenarios. Its technical characteristics provide distinct advantages over many conventional flooring materials, making it a preferred solution for B2B stakeholders.

Key Application Scenarios:

- 医療施設: Hospitals, clinics, and assisted living centers benefit from its hygienic, easy-to-clean surface, resistance to common disinfectants, and excellent indentation resistance from medical equipment. Its sound-dampening properties also contribute to a quieter healing environment.

- 教育機関: Schools, universities, and daycare centers require flooring that can withstand heavy foot traffic, spills, and impact. Dryback LVT offers durability, slip resistance, and a comfortable underfoot feel, alongside diverse design options to create engaging learning spaces.

- Retail & Hospitality: High-traffic retail stores, boutiques, hotels, and restaurants demand flooring that combines aesthetic appeal with exceptional wear resistance. LVT dryback can replicate upscale finishes like marble or exotic hardwoods, enhancing brand image while enduring constant use and spillages.

- Corporate Offices: Modern office environments prioritize comfort, acoustics, and sophisticated design. LVT dryback flooring contributes to improved indoor air quality, reduces impact sound, and provides versatile design options for open-plan areas, conference rooms, and private offices.

- Light Industrial & Laboratories: In areas with specific technical requirements, such as light manufacturing zones or laboratories, the chemical resistance and easy maintenance of dryback LVT are critical. Its seamless installation method, when properly executed, helps prevent contaminant ingress.

- Multi-Family Housing & Public Spaces: From apartment common areas to libraries and community centers, the durability, low maintenance, and design flexibility of LVT dryback make it a practical and attractive choice.

Technical Advantages:

- Exceptional Durability: Engineered with a robust wear layer and reinforced core, LVT dryback excels in resisting abrasions, scratches, and scuffs, ensuring a longer service life in high-traffic commercial settings compared to many traditional flooring types.

- Superior Dimensional Stability: The fiberglass-reinforced core minimizes expansion and contraction, crucial for maintaining a seamless appearance across large floor areas and preventing issues like gapping or curling, even with fluctuating temperatures and humidity.

- Water and Moisture Resistance: Its non-porous surface and composition make it highly resistant to water and moisture, preventing mold and mildew growth and making it suitable for wet areas like restrooms, kitchens, and entryways.

- メンテナンスの手間がかからない: The sealed, smooth surface of dryback LVT is easy to clean with standard commercial cleaning agents, reducing operational costs and maintaining hygienic conditions. No special waxing or polishing is typically required.

- Acoustic Performance: While not a primary sound insulator, its density and installation method can contribute to reducing impact sound transmission within a building, enhancing comfort in multi-story commercial environments.

- Design Versatility: Advanced printing and embossing technologies allow for an extensive range of realistic wood, stone, and abstract designs, offering unparalleled aesthetic flexibility to match any interior design concept.

- コスト効率: When considering the total cost of ownership, including purchase, installation, and long-term maintenance, LVT dryback often presents a more economical solution over its lifespan compared to natural materials or less durable alternatives.

- Energy Saving Potential: As a thin, dense material, LVT dryback has a low thermal resistance, making it highly efficient when installed over underfloor heating systems, contributing to energy savings.

Vendor Comparison and Customized Solutions

Selecting the right supplier for lvt ドライバックフローリング is a critical decision for B2B buyers. Beyond base product specifications, factors such as manufacturing capabilities, certification, customization options, and after-sales support differentiate leading vendors.

Vendor Comparison Factors for Dry Back LVT:

| Feature/Service | Leading Vendor (Example) | Standard Vendor (Example) |

|---|---|---|

| Wear Layer Options | 0.3mm to 1.0mm (incl. ceramic bead/UV reinforced) | 0.3mm to 0.5mm (standard PVC) |

| Dimensional Stability | ≤ 0.05% (ISO 23999 compliant) | ≤ 0.1% (Basic compliance) |

| Certifications | ISO 9001, ISO 14001, CE, FloorScore/Greenguard, Phthalate-Free | Basic CE/Fire Rating |

| Design & Customization | Extensive pattern library, custom printing, size/shape customization, EIR embossing | Limited standard patterns, fixed sizes |

| Project Support | Technical consultations, CAD details, installation guides, site visits | Basic product data sheets |

| Warranty (Commercial) | 15-25 Years | 5-10 Years |

| Lead Time (Standard) | 2-4 weeks | 4-8 weeks |

Customized Solutions:

For large-scale commercial projects, off-the-shelf solutions may not always meet specific aesthetic or functional requirements. Leading manufacturers of LVT dryback flooring offer comprehensive customization capabilities to address unique project demands:

- Bespoke Design & Patterns: Clients can work with design teams to develop exclusive patterns, colors, or incorporate corporate branding into the flooring. High-resolution digital printing enables endless possibilities, from intricate mosaics to photographic reproductions.

- Custom Sizes & Shapes: While standard plank and tile sizes are common, projects requiring unique dimensions (e.g., extra-long planks, specific geometric shapes) can be accommodated through advanced CNC cutting.

- Specialized Wear Layers: For environments with extreme wear or specific chemical exposure, custom wear layer formulations can be developed to enhance resistance to particular agents, heavy loads, or abrasive conditions. This includes options for anti-microbial treatments or enhanced slip resistance.

- Acoustic Backing Integration: Although LVT dryback is glue-down, some manufacturers can integrate thin, high-density acoustic underlayments directly into the product layers or recommend specific compatible underlayment systems to achieve desired sound reduction ratings (e.g., IIC, STC).

- Phthalate-Free & Low VOC Formulations: For projects with stringent environmental or health specifications, manufacturers can guarantee phthalate-free compositions and provide certifications for ultra-low VOC emissions (e.g., FloorScore, Greenguard Gold), contributing to LEED or WELL Building standards.

- Matching Accessories: Custom solutions often extend to providing matching accessories such as stair nosings, transitions, and wall base, ensuring a cohesive and professional finish throughout the installation.

Application Case Studies: Dry Back LVT in Action

The proven performance of lvt dryback in real-world commercial environments underscores its value proposition for B2B applications. These case studies highlight the successful deployment and benefits observed by clients.

Case Study 1: High-Traffic Retail Chain Renovation

- Client: A leading national department store chain with 50+ locations.

- Challenge: Their existing ceramic tile flooring was prone to cracking, difficult to clean, and offered poor acoustic properties in a high-traffic retail environment. They needed a durable, aesthetically flexible, and quick-to-install solution for a phased renovation across multiple stores.

- Solution: The client opted for a 3.0mm dryback LVT flooring with a 0.55mm wear layer, featuring a sophisticated wood-look design. Over 500,000 sq ft was installed across various store departments.

- Results: The LVT dryback provided superior durability against heavy foot traffic and shopping cart abuse. Its water and stain resistance significantly reduced cleaning time and costs. The adhesive-based installation allowed for minimal disruption during store operating hours, and the enhanced underfoot comfort was noted positively by both staff and customers. The new aesthetic dramatically improved the store's modern appeal.

Case Study 2: University Science Laboratory Upgrade

- Client: Department of Chemistry, large public university.

- Challenge: The existing sheet vinyl in their research labs was showing signs of wear, chemical staining, and required frequent replacement. They needed a flooring solution that could withstand various chemical spills, heavy lab equipment, and frequent cleaning, while also meeting stringent safety standards.

- Solution: A specialized 2.5mm dryback LVT with a 0.7mm enhanced wear layer, featuring superior chemical resistance properties, was selected. A custom dark grey tile pattern was chosen to mask minor scuffs. The supplier provided comprehensive chemical resistance data (EN 423) before specification.

- Results: The installed LVT dryback has demonstrated exceptional resistance to acids, bases, and common solvents used in the lab, minimizing staining and surface degradation. Its seamless installation (when combined with appropriate welding techniques for LVT sheet if applicable for this scenario or precise tile fitting) reduced points of vulnerability for spills. The robust construction easily supported heavy lab benches and equipment, significantly extending the flooring's lifespan compared to previous installations.

Case Study 3: Corporate Headquarters Remodel

- Client: A growing tech company establishing new headquarters.

- Challenge: The company sought a modern, high-performance flooring solution that aligned with their brand image – innovative, sleek, and sustainable. They required excellent acoustics, ergonomic benefits, and a sophisticated aesthetic for open-plan offices, executive suites, and collaboration zones.

- Solution: A premium dryback LVT flooring product (3.0mm thickness, 0.55mm wear layer) with an embossed-in-register (EIR) finish mimicking reclaimed wood was chosen for general office areas. Custom-designed geometric LVT tiles were used in collaboration spaces. The selected product was FloorScore certified for low VOC emissions.

- Results: The LVT flooring delivered a high-end aesthetic that perfectly matched the company's brand. Its inherent acoustic properties contributed to a quieter office environment, crucial for productivity in open-plan layouts. The low-VOC certification supported the company's commitment to employee well-being and environmental stewardship. The durability of the LVT ensured the floor maintained its pristine appearance despite constant movement of office chairs and foot traffic, offering a significant improvement over previous carpet tiles.

Frequently Asked Questions (FAQ)

Q1: What is the primary difference between dry back LVT and click LVT?

A1: Dry back LVT requires a full spread adhesive for installation, providing maximum stability and permanence, especially in large commercial areas with heavy traffic or rolling loads. Click LVT, conversely, features an interlocking edge system for a floating installation, which can be quicker but may offer less subfloor preparation tolerance and potentially less long-term stability in extreme commercial conditions compared to a fully adhered dry back system.

Q2: Is dry back LVT suitable for areas prone to moisture, such as restrooms or commercial kitchens?

A2: Yes, dry back LVT is highly water-resistant due to its PVC composition and adhesive installation, which creates a strong bond to the subfloor. When installed correctly with appropriate subfloor preparation and perimeter sealants, it performs exceptionally well in moisture-prone environments, resisting mold and mildew growth.

Q3: What level of subfloor preparation is required for dry back LVT?

A3: As a fully adhered product, lvt dryback requires a clean, dry, smooth, and level subfloor. Any imperfections in the subfloor will telegraph through the LVT over time. This often necessitates patching, leveling compounds, or priming to achieve the required flatness (typically 1/8 inch in 10 feet or better). This meticulous preparation ensures optimal adhesion and a flawless finish.

Q4: How does dry back LVT contribute to indoor air quality?

A4: Many manufacturers offer dry back LVT that is phthalate-free and certified for low VOC (Volatile Organic Compound) emissions, such as FloorScore or Greenguard Gold. These certifications indicate that the product meets stringent standards for indoor air quality, making it a healthier choice for occupants in commercial buildings.

Q5: Can dry back LVT be installed over existing flooring?

A5: It depends on the existing flooring. While possible in some cases (e.g., well-bonded, smooth, non-cushioned vinyl or ceramic tile with extensive preparation), it is generally recommended to remove old flooring to ensure the best possible adhesion and subfloor integrity. The subfloor must be structurally sound, dry, clean, and perfectly smooth for optimal dry back LVT flooring performance.

Lead Time, Warranty, and Customer Support

Lead Time & Fulfillment:

Our standard lead time for in-stock dryback LVT products is typically 2-4 weeks from order confirmation to shipment for most commercial volumes. For custom orders or very large-scale projects, lead times may extend to 6-10 weeks, depending on the complexity of customization and raw material availability. We operate with a robust supply chain and optimized logistics to ensure timely delivery. Urgent project requirements can often be accommodated through expedited manufacturing and shipping options, subject to project specifics and additional charges. Our fulfillment process includes rigorous quality checks at every stage, from production to packaging, ensuring products arrive in perfect condition.

Warranty Commitments:

We stand behind the quality and durability of our lvt ドライバックフローリング with comprehensive commercial warranties. Our standard commercial warranty ranges from 15 to 25 years, covering manufacturing defects, wear-through of the wear layer, staining, and dimensional stability, provided the product is installed and maintained according to our published guidelines. Specific warranty terms vary by product line and wear layer thickness; detailed warranty documentation is available upon request. This robust warranty reflects our confidence in the long-term performance and reliability of our flooring solutions for demanding B2B environments.

Customer Support & After-Sales Service:

Our commitment to our B2B clients extends far beyond the point of sale. We provide dedicated customer support through a team of experienced technical specialists and sales professionals. Services include:

- Technical Assistance: Expert guidance on product selection, subfloor preparation, installation best practices, and maintenance protocols.

- Project Management Support: Assistance with specification, quantity estimation, and coordination for large-scale commercial installations.

- Training Resources: Access to comprehensive installation guides, video tutorials, and technical data sheets.

- Claim Resolution: A streamlined process for addressing any warranty claims or product-related issues promptly and efficiently.

- Post-Installation Advice: Ongoing support for cleaning, maintenance, and long-term care to maximize the lifespan of your flooring investment.

We aim to be a trusted partner, ensuring that your investment in dryback LVT flooring delivers lasting performance and value.

References

- European Committee for Standardization. EN 660-2: Resilient floor coverings - Determination of wear resistance - Part 2: Frick-Taber method. 2000.

- International Organization for Standardization. ISO 23999: Resilient floor coverings - Determination of dimensional stability and curling after exposure to heat. 2018.

- ASTM International. ASTM F1914: Standard Test Method for Short-Term Indentation and Residual Indentation of Resilient Floor Coverings. 2017.

- Market Research Report: Global Luxury Vinyl Tile (LVT) Flooring Market Report. Grand View Research, Inc. 2023.

- The Resilient Floor Covering Institute (RFCI). Recommended Practice for the Installation and Maintenance of Resilient Flooring. Current Edition.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025