- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

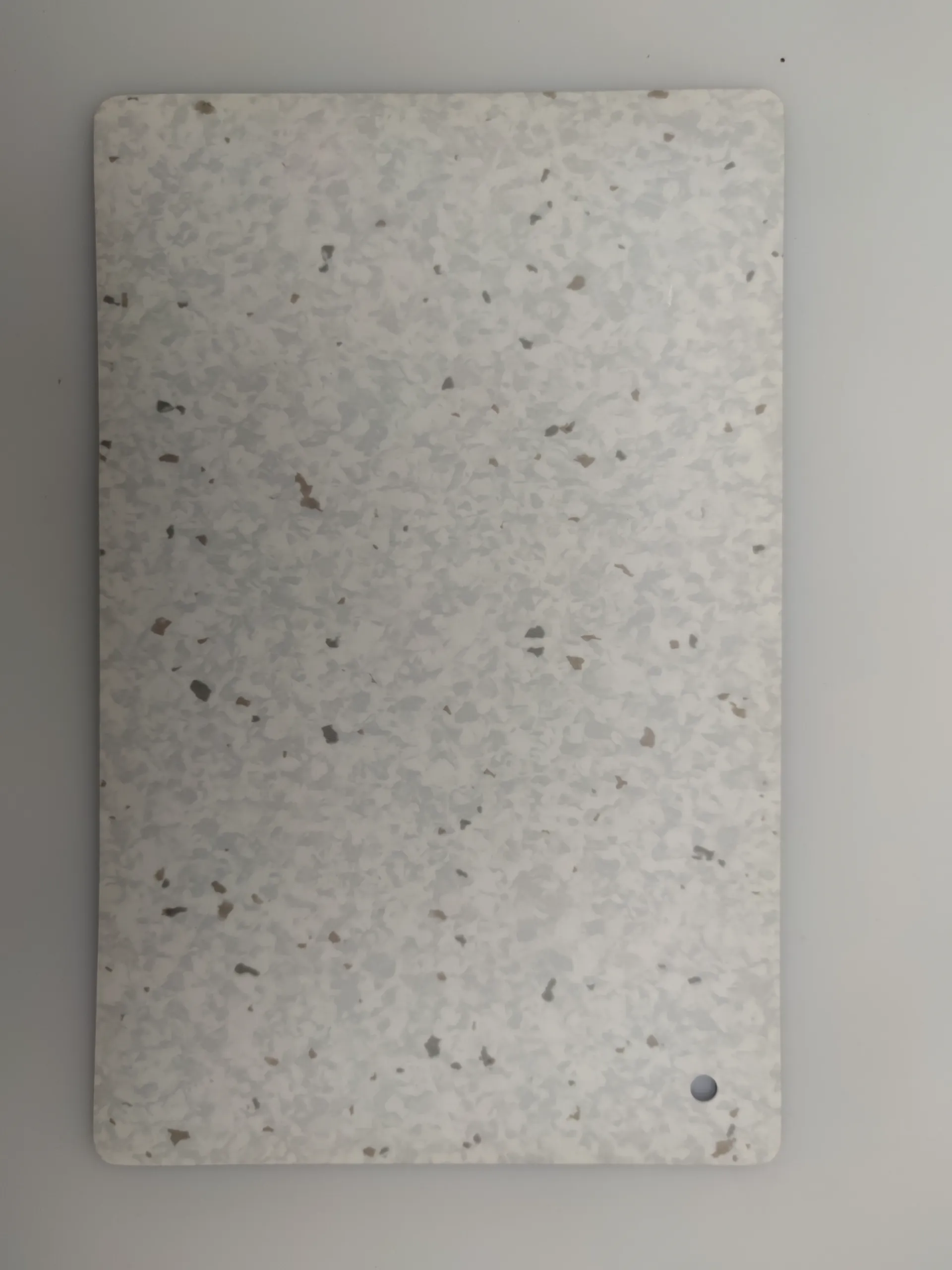

Looking for durable, waterproof heterogeneous viny designs?

Heterogeneous Floors With Stariver Surface: What Pros Are Choosing in 2025

If you’re hunting for a resilient sheet that doesn’t feel clinical, you’ve probably bumped into 이질적인 포도나무 more than once. I’ve been walking job sites and lab halls for years, and to be honest, this category has had a glow-up: smarter wear layers, less noise, cleaner air. Enlio’s Finequin series—specifically the heterogeneous floor with Stariver surface—has become a quiet favorite among facility managers who care about lifecycle cost more than brochure gloss.

What’s New: Trends You’ll Actually Notice

The big pushes this year: quieter floors (ΔLw around 16–19 dB), tougher abrasion classes (T group), and low-VOC chemistries that meet FloorScore/GREENGUARD Gold equivalents. Many customers say maintenance has become almost boring—just occasional damp mopping—thanks to UV-cured PU finishes like Stariver. And yes, 이질적인 포도나무 now routinely hits Bfl-s1 fire ratings in Europe and ASTM F1913 compliance in North America.

Quick Specs (Real-World Ready)

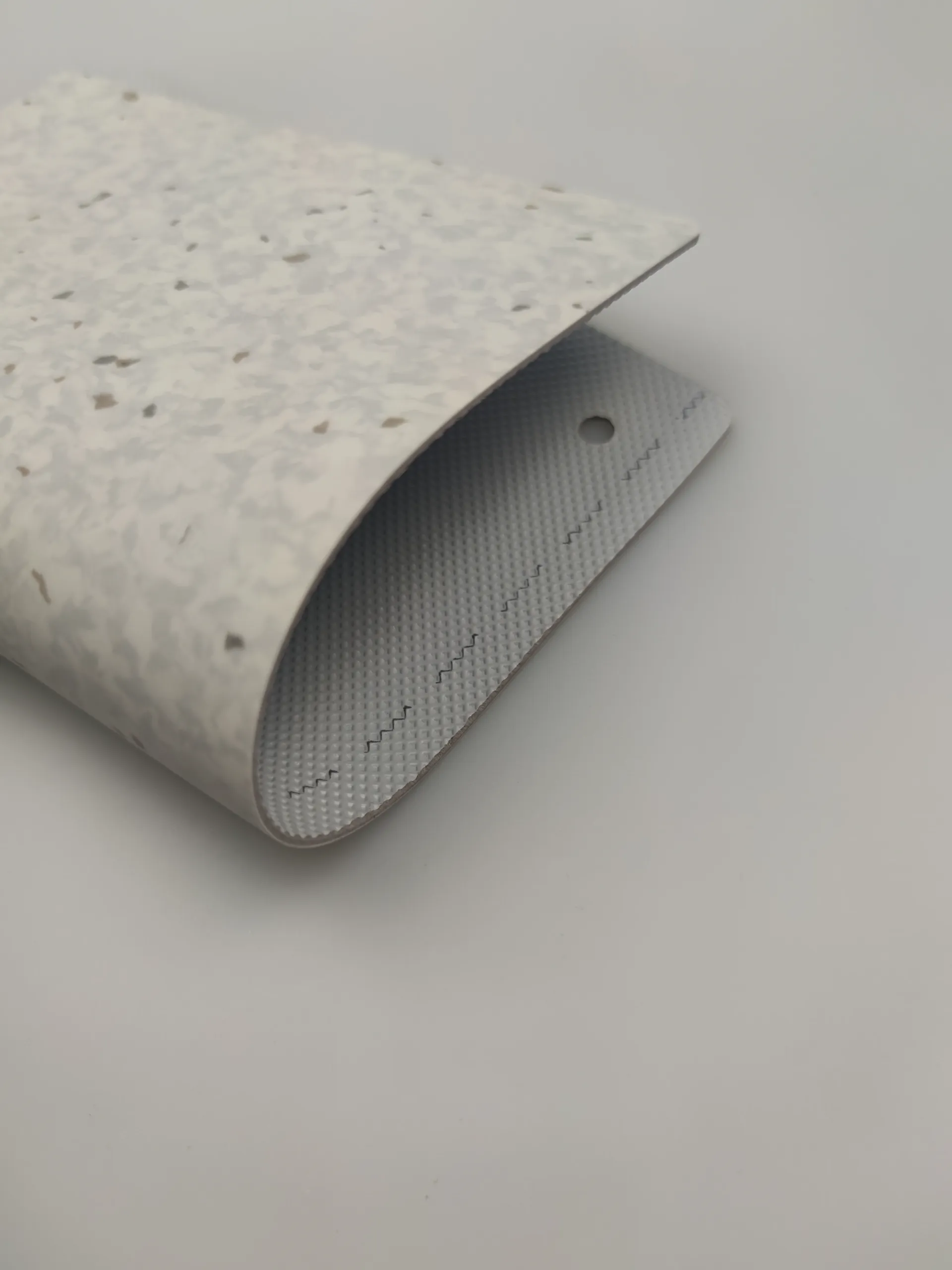

| Construction | Multi-layer PVC with fiberglass reinforcement; UV-cured Stariver PU top |

| Total thickness | ≈ 2.0–2.5 mm (real-world use may vary by SKU) |

| Wear layer | 0.55–0.7 mm, abrasion group T (EN 660-2) |

| Slip resistance | R10 (DIN 51130); EN 13845 compliant options |

| Acoustic | ΔLw ≈ 16–19 dB |

| Fire / VOC | Bfl-s1 (EN 13501-1); low TVOC per ISO 16000; meets common hospital criteria |

| Service life | 10–20 years with preventive care |

Where It Works (And Why)

Healthcare corridors, classrooms, labs, retail aisles, offices—places that punish floors daily. The Stariver surface shrugs off staining agents (EN ISO 26987), resists chair castors (EN 425), and keeps dimensional stability in check (EN ISO 23999). Feedback from a university FM: “We cut buffing cycles by half.” Not bad for 이질적인 포도나무 that still looks sharp after exam week.

From Granule to Roll: The Process Flow

- Materials: PVC resins, bio-lean plasticizers, mineral fillers, stabilizers, printed film, fiberglass grid.

- Methods: Multilayer calendaring → hot-lamination → in-register embossing → UV-cured Stariver topcoat.

- Testing: EN 660-2 abrasion, EN 13845 slip, EN 13501-1 fire, ASTM F1913 composition, ISO 16000 VOC.

- QA: ISO 9001 and ISO 14001 systems; batch tracking from Origin: #C3, No. 36 Xiangyuan Rd., Baiyun Dist., Guangzhou, China.

Vendor Snapshot (What You’ll Compare Anyway)

| Vendor / Line | Wear Layer | Surface | Acoustic (ΔLw) | Certs | Notes |

| Enlio Finequin (Stariver) | 0.55–0.7 mm | UV-cured PU | ≈16–19 dB | ISO 9001/14001, EN, ASTM | Strong stain resistance; easy upkeep |

| Gerflor Taralay Impression | 0.7 mm | Protecsol | ≈19 dB | CE, ISO | Broad décor library |

| Tarkett Acczent Excellence 80 | 0.8 mm | TopClean XP | ≈15–17 dB | CE, ISO | Heavy-traffic staple |

| Armstrong Rejuvenations Sheet | 0.5–0.7 mm | Urethane | ≈13–16 dB | ASTM, FloorScore | Healthcare-friendly |

Customization & Options

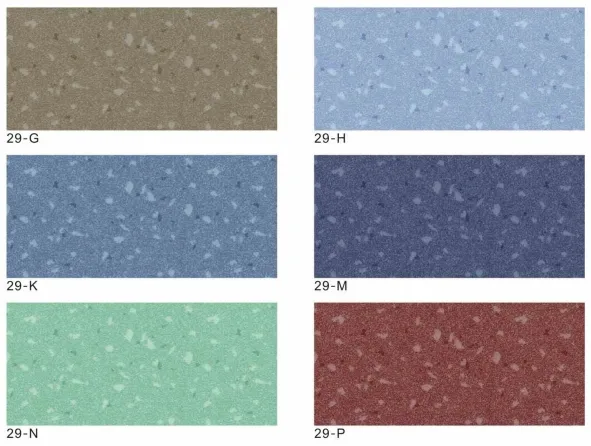

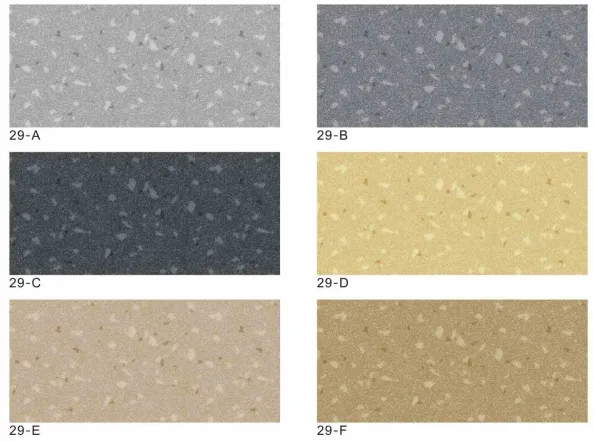

Print layers (wood, terrazzo, linen), emboss depths, anti-static options, cove-formable backing, welded seams, and color-matched accessories. For 이질적인 포도나무 in labs, consider chemical-resistant grades; in classrooms, go acoustic.

Mini Case Files

- Provincial Hospital, OR corridors: 3,800 m² installed. Reported 28% cleaning time reduction and zero seam failures at 18 months.

- K–12 Campus: 6,200 m². Measured noise drop ≈ 3–4 dB(A) during peak transitions; teachers noticed fewer squeaks (anecdotally, but consistent).

- Retail chain: 2,400 m². Abrasion index held within T group after 1200 cycles (EN 660-2 lab test), gloss retention “stable.”

Certifications and test data available on request; third-party reports are commonly shared under NDA. Installation tip: acclimate rolls 24–48h, use approved adhesives, and heat-weld seams for hygiene-critical zones.

References

- EN 13845: Resilient floor coverings—Safety flooring with particle enhanced slip resistance. https://standards.cen.eu

- ASTM F1913: Standard Specification for Vinyl Sheet Floor Covering With Backing. https://www.astm.org/f1913

- EN 13501-1: Fire classification of construction products and building elements. https://standards.cen.eu

- ISO 16000 series: Indoor air—VOC testing. https://www.iso.org

- EN 660-2: Abrasion resistance for resilient floor coverings. https://standards.cen.eu

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025