- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Why choose my floor spc—waterproof, durable, quiet?

I first heard about my floor spc while touring a factory cluster in Guangzhou—Origin: #C3, No. 36 Xiangyuan Rd., Baiyun Dist., Guangzhou, China. Busy forklifts, PVC mixers humming, and—oddly enough—silence on the finished line; that’s the acoustic core doing its job. Rigid core vinyl has been on a tear for years, and this series is very much the poster child for why.

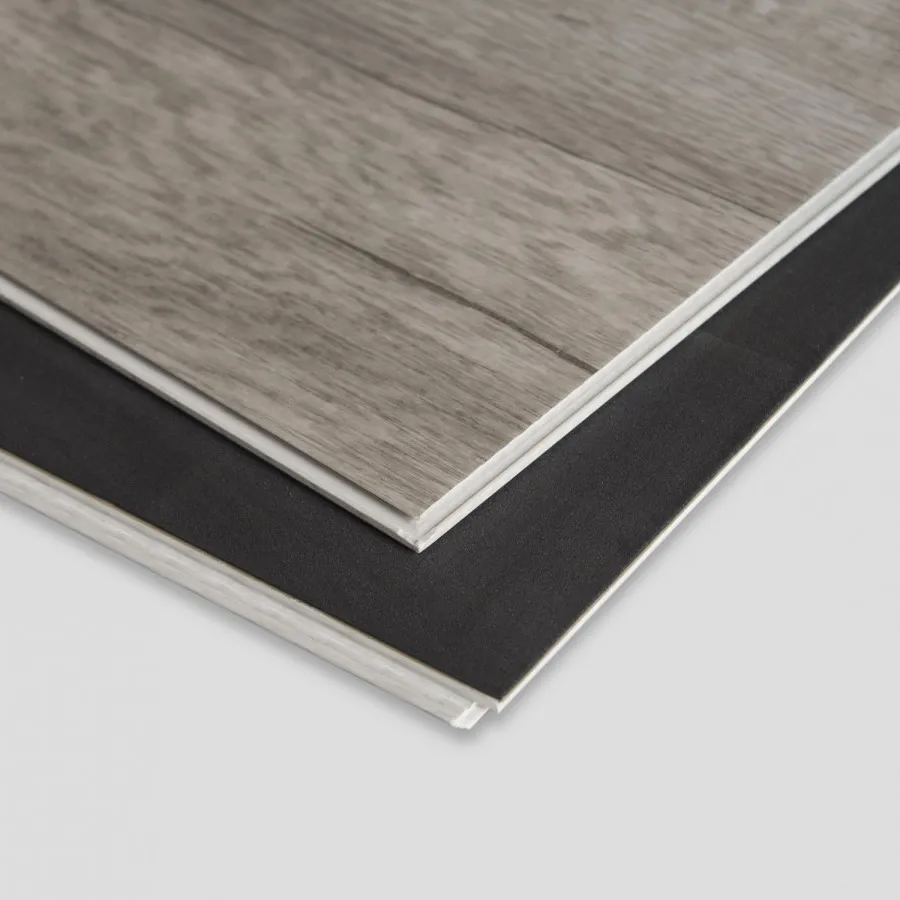

In plain terms, this is SPC: a stone-polymer composite core pressed at high temperature, then dressed with a decorative film and a UV-cured wear layer. It’s waterproof, dent-resistant, easy to click together, and—surprisingly—warmer underfoot than you’d expect. Many customers say installation feels “no-drama,” which, to be honest, is half the battle in renovations.

Industry snapshot

Rigid core is displacing traditional LVT in wet areas and mid-market remodels. Why? Faster installs, fewer callbacks, and strong dimensional stability. Specifiers tell me click-lock systems are winning in multifamily turnarounds because there’s less subfloor drama and fewer odors than glue-down.

Product specifications (Home SPC Flooring)

| Core | SPC (CaCO3 + PVC + stabilizers), high-density ≈ 2000 kg/m³ |

| Total thickness | 4.0–6.5 mm (typical); wear layer 0.3–0.5 mm |

| Plank size | ≈ 1220×180 mm (custom sizes available) |

| Click system | Unilin/Valinge-type interlock, micro-bevel |

| अंडरलेमेंट | Optional IXPE/EVA 1–2 mm pre-attached |

| Fire | EN 13501-1 Bfl-s1 (typical; verify batch test) |

| Slip | DIN 51130 R9–R10 (real-world use may vary) |

| VOC | FloorScore / low-VOC options |

| Warranty | Residential up to 20–25 yrs; light commercial 10–15 yrs |

How it’s made (and tested)

- Materials: refined limestone powder, PVC resin, heat stabilizers, decorative film, UV wear coat.

- Method: high-temperature extrusion of SPC core → lamination of decor + wear layer → UV curing → profiling (click) → inspection.

- Standards: ASTM F3261 for SPC classification; dimensional stability per ISO 23999; stain/color resistance ASTM F1514/F1515; abrasion ASTM D4060 (Taber).

- Service life: around 15–25 years with normal residential maintenance; heavy traffic shortens that, of course.

- Typical test data: dimensional change ≤ 0.15%; curling ≤ 2.0 mm; smoke development within Bfl-s1 envelope (lot-dependent).

Vendor comparison (quick take)

| Vendor | Wear layer | Certifications | Lead time | सानुकूलन |

|---|---|---|---|---|

| Home SPC Flooring (Enlio) | 0.3–0.5 mm | FloorScore, EN/ASTM tested | ≈ 3–5 weeks | Color, EIR, bevel, IXPE |

| Generic Import A | 0.2–0.3 mm | Basic RoHS/VOC | ≈ 6–8 weeks | Limited decors |

| Big-Box Brand B | 0.3–0.5 mm | GREENGUARD/FloorScore | Stock-dependent | Fixed SKUs |

Where it fits

Kitchens, bathrooms, condos with strict HOA rules, retail fronts that mop nightly, pet-friendly rentals—those are the sweet spots. For hydronic radiant systems, check max surface temps (usually ≤ 27°C) and acclimate. Honestly, subfloor flatness is still king.

Customization and real-world feedback

Design teams often request embossed-in-register textures, wider planks, and matte sheens to dodge glare. With my floor spc, IXPE underlayment boosts IIC/STC in multifamily installs; one property manager told me hallway noise “dropped a notch.” Another homeowner liked the scratch resistance but, fair point, said rubber feet can leave marks—use felt pads.

Case notes

- Café retrofit (68 m²): installed over old ceramic with a skim coat; downtime: 1 day; moisture no issue after 3 months of nightly mopping.

- Rental flip: 5 rooms in 7 hours with two installers; 0 callbacks after 6 months—click tolerances help a lot.

If you want one takeaway: my floor spc pairs commercial-grade stability with homeowner-friendly installation. Not perfect—no floor is—but it’s a smart default when water, time, and budget are tight.

Authoritative citations

- ASTM F3261 – Standard Specification for Resilient Flooring in Modular Format with Rigid Polymeric Core (SPC).

- EN 13501-1 – Fire classification of construction products and building elements.

- ISO 23999 – Resilient floor coverings—Determination of dimensional stability and curling after exposure to heat.

- SCS Global Services – FloorScore Indoor Air Quality Certification Program.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025