Durable Pisos VCT: Commercial Vinyl Composite Tile Flooring

Navigating Modern Commercial Flooring: The Rise of Advanced Pisos VCT Solutions

In the demanding landscape of commercial and institutional facilities, flooring solutions must deliver an optimal blend of durability, aesthetic appeal, and cost-effectiveness. Vinyl Composition Tile, commonly referred to as pisos vct, has long been a foundational choice for high-traffic environments due to its resilience and economic advantages. However, as industry standards evolve, so too do the expectations for performance and specialized features. This comprehensive guide explores the advanced capabilities of modern VCT, focusing on sophisticated options like Enlio's heterogeneous floor with Nora surface, designed to meet the rigorous demands of today's commercial applications. We will delve into manufacturing intricacies, performance metrics, and strategic comparisons with leading brands such as tarkett vct, mohawk vct, and johnsonite vct, providing insights crucial for B2B decision-makers.

Understanding Pisos VCT: Materials and Manufacturing Excellence

The production of modern pisos vct involves a precise, multi-stage manufacturing process that ensures consistent quality and performance. At its core, VCT is a composite material comprising polyvinyl chloride (PVC) resins, plasticizers for flexibility, finely ground limestone or other mineral fillers for dimensional stability and density, and various color pigments and stabilizers. The process typically begins with the compounding phase, where raw materials are precisely mixed under controlled temperatures to form a homogenous blend. This blend is then subjected to calendering, a process where the material is pressed through a series of heated rollers to form continuous, dense sheets. Subsequently, these sheets undergo annealing to relieve internal stresses, ensuring dimensional stability, before being precisely cut into tiles. Rigorous quality control checks, adhering to international standards such as ISO 10581 and ASTM F1066, are integrated throughout the entire process, from raw material inspection to final product verification. This meticulous approach guarantees that each pisos vct tile meets stringent criteria for durability, colorfastness, and overall integrity, offering an impressive lifespan in demanding commercial settings.

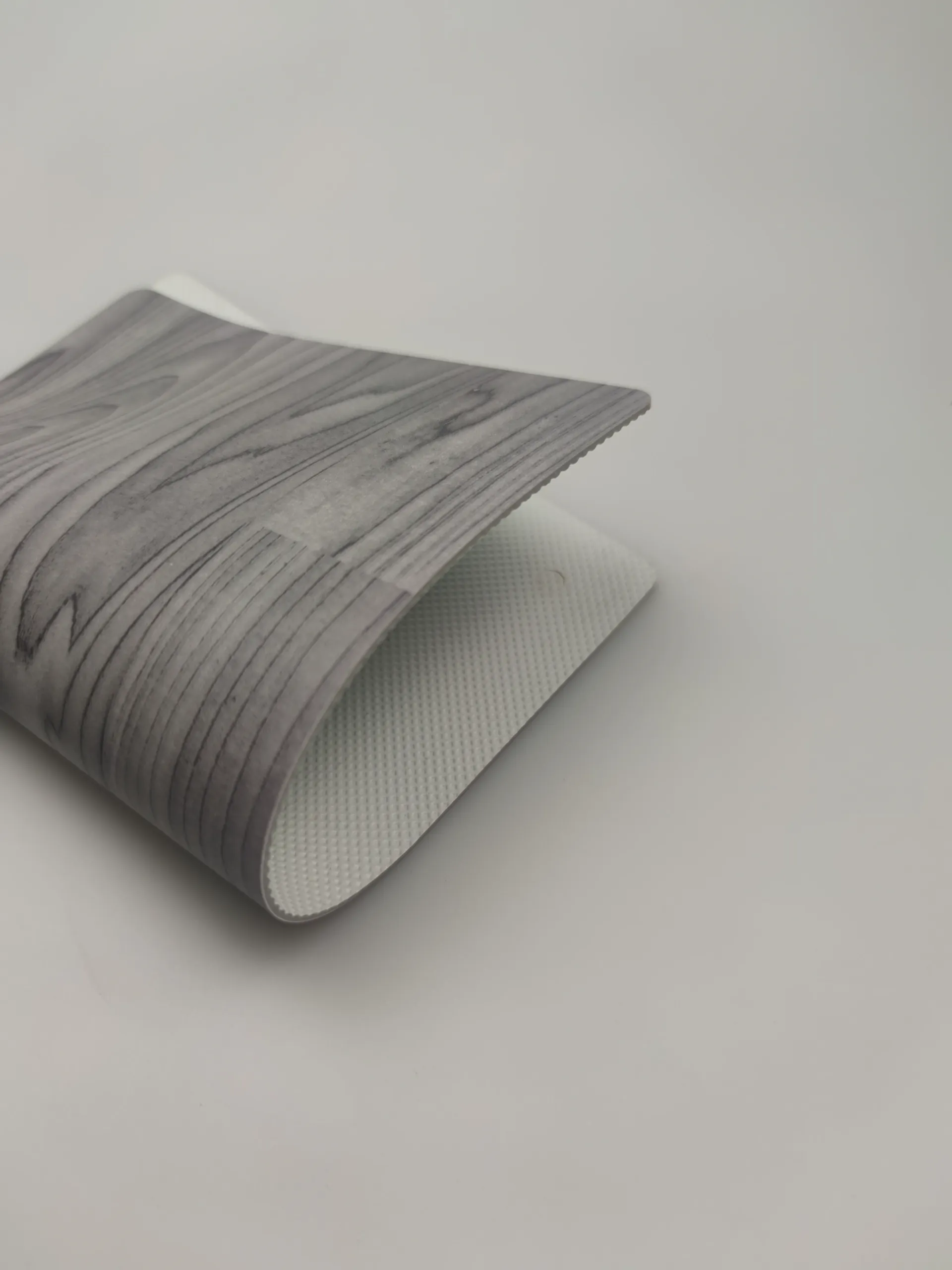

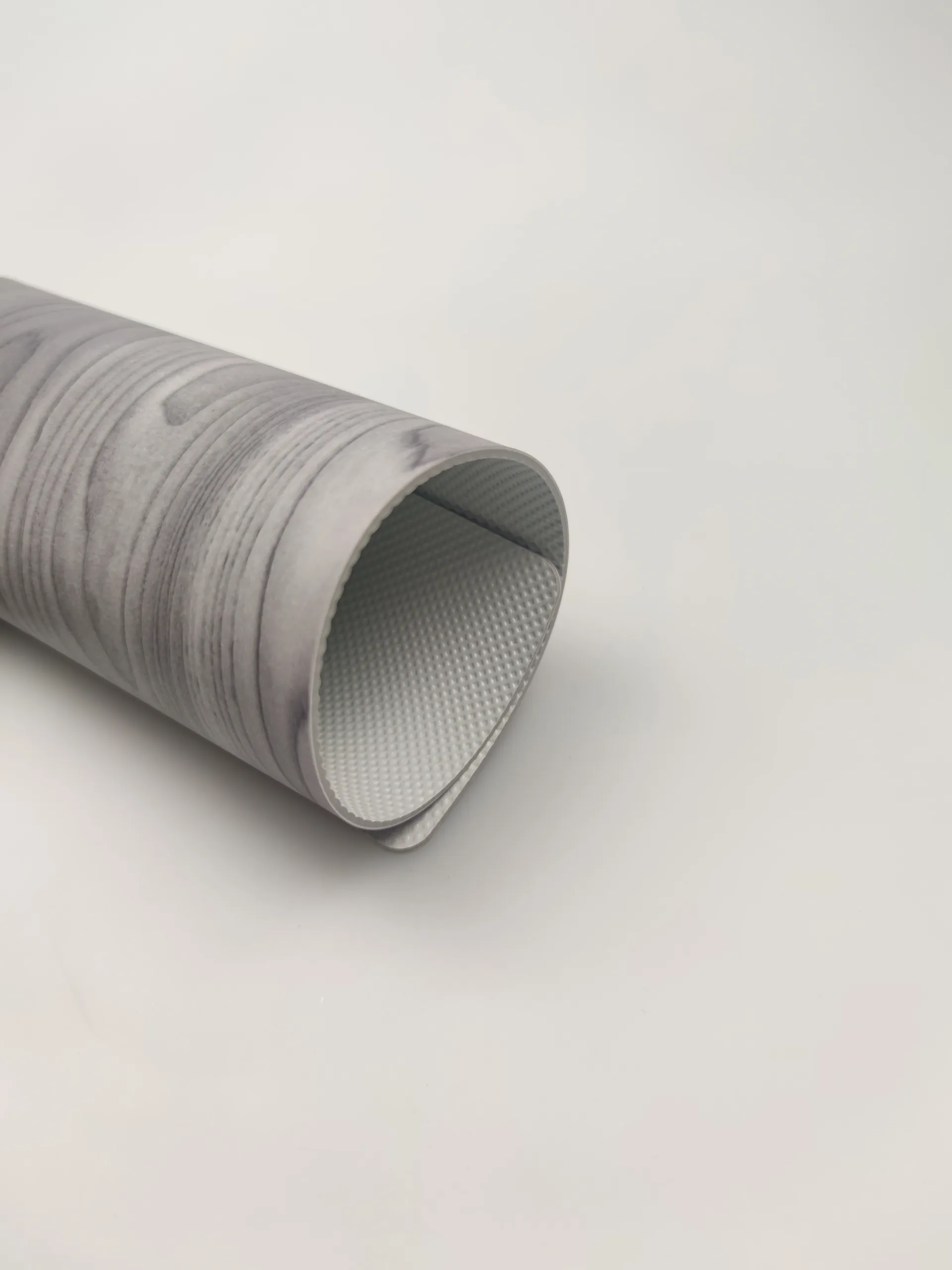

Figure 1: Depiction of the multi-layered manufacturing process for advanced VCT.

Technical Parameters and Performance Insights

Understanding the technical specifications of pisos vct is paramount for selecting the optimal flooring solution for any given application. Modern VCT offers a range of critical parameters that directly influence its suitability for high-traffic areas, specific chemical exposures, and aesthetic requirements. Key metrics include overall thickness, typically ranging from 2.0 mm to 3.2 mm, which contributes to wear resistance and comfort underfoot. The wear layer thickness, though less prominent in homogeneous VCT, becomes a defining feature in heterogeneous structures, offering enhanced protection against abrasions and scuffs. Indentation resistance, chemical resistance, and slip resistance are also vital, particularly in environments like healthcare facilities or educational institutions where safety and hygiene are critical. Furthermore, fire ratings (e.g., ASTM E648 Critical Radiant Flux) and light fastness ensure compliance with safety regulations and long-term aesthetic stability.

| Parameter | Unit | Typical Range / Value | Test Standard |

|---|---|---|---|

| Overall Thickness | mm | 2.0 - 3.2 | ASTM F1066 |

| Wear Layer Thickness (Heterogeneous) | mm | 0.3 - 0.7 | ISO 24346 |

| Residual Indentation | mm | ≤ 0.10 | ISO 24343-1 |

| Dimensional Stability | % | ≤ 0.40 | ISO 23999 |

| Slip Resistance (Dry) | Coefficient | > 0.50 | ASTM D2047 |

| Fire Performance | CRF (kW/m²) | ≥ 4.5 | ASTM E648 |

Figure 2: Illustrative technical data and performance metrics for VCT.

Beyond Basic VCT: Enlio's Heterogeneous Flooring with Nora Surface

While traditional pisos vct offers a cost-effective solution, Enlio's heterogeneous floor with Nora surface represents a significant leap forward in performance and specialized features. Unlike homogeneous VCT, which has a uniform composition throughout its thickness, heterogeneous flooring consists of multiple distinct layers. This includes a robust backing, a high-density core, a printed design layer for aesthetic versatility, and critically, a transparent wear layer engineered for superior protection. The integration of a "Nora surface" elevates this product, signifying a high-performance top finish that often implies enhanced properties akin to high-grade rubber flooring, such as superior slip resistance, advanced chemical and stain resistance, and excellent acoustic properties. This engineered multi-layer construction provides unparalleled durability against heavy foot traffic, extends the product's lifespan, and significantly reduces maintenance requirements and associated long-term costs. For demanding environments, this specialized flooring translates into improved operational efficiency and a healthier, safer environment.

Diverse Application Scenarios of Pisos VCT

The versatility and robust nature of pisos vct make it an ideal flooring solution across a broad spectrum of commercial and public sectors. In healthcare facilities, VCT is valued for its ease of maintenance, resistance to common hospital chemicals, and hygienic properties, crucial for patient safety and infection control. Educational institutions benefit from its extreme durability, capable of withstanding constant foot traffic, spills, and heavy loads from equipment, while its acoustic properties can contribute to a quieter learning environment. Retail spaces and corporate offices leverage VCT for its aesthetic flexibility, allowing for creative designs and brand integration, coupled with its ability to handle high-volume pedestrian traffic without showing premature wear. From high-traffic corridors to administrative offices and waiting areas, advanced pisos vct provides a resilient, visually appealing, and cost-effective foundation, demonstrating its adaptability to specific functional and environmental requirements.

Figure 3: Illustrating the widespread application of VCT in various commercial settings.

Comparative Analysis: Tarkett, Mohawk, Johnsonite, and Enlio

The market for pisos vct features several prominent manufacturers, each offering distinct product lines. Brands like tarkett vct, mohawk vct, and johnsonite vct (a brand often associated with Tarkett) are recognized for their extensive color palettes, standard performance, and broad availability. While these brands provide reliable VCT solutions for various commercial projects, Enlio distinguishes itself, particularly with its specialized offerings like the `heterogeneous floor with Nora surface`. This product innovation positions Enlio as a leader in delivering enhanced performance attributes, often surpassing standard VCT in areas like wear resistance, slip resistance, and sound absorption. For instance, `enlio johnsonite vct` or `enlio tarkett vct ii` variants would imply a fusion of established quality with Enlio's specialized surface technologies, offering clients a superior value proposition through extended lifespan and reduced lifecycle costs. The choice often depends on specific project demands, including budget, performance requirements, and desired aesthetic, but Enlio consistently pushes the boundaries of VCT capabilities.

| Feature/Brand | Tarkett VCT | Mohawk VCT | Johnsonite VCT (Tarkett) | Enlio (Heterogeneous w/ Nora Surface) |

|---|---|---|---|---|

| Primary Composition | Homogeneous PVC/filler | Homogeneous PVC/filler | Homogeneous PVC/filler | Multi-layered PVC/filler |

| Wear Layer | Integral | Integral | Integral | Dedicated, High-Performance (Nora surface) |

| Slip Resistance | Standard | Standard | Standard/Enhanced | Superior |

| Maintenance | Moderate (requires waxing) | Moderate (requires waxing) | Moderate (requires waxing) | Low (no/minimal waxing) |

| Acoustic Performance | Basic | Basic | Basic | Enhanced |

Customized Solutions and Project Implementation

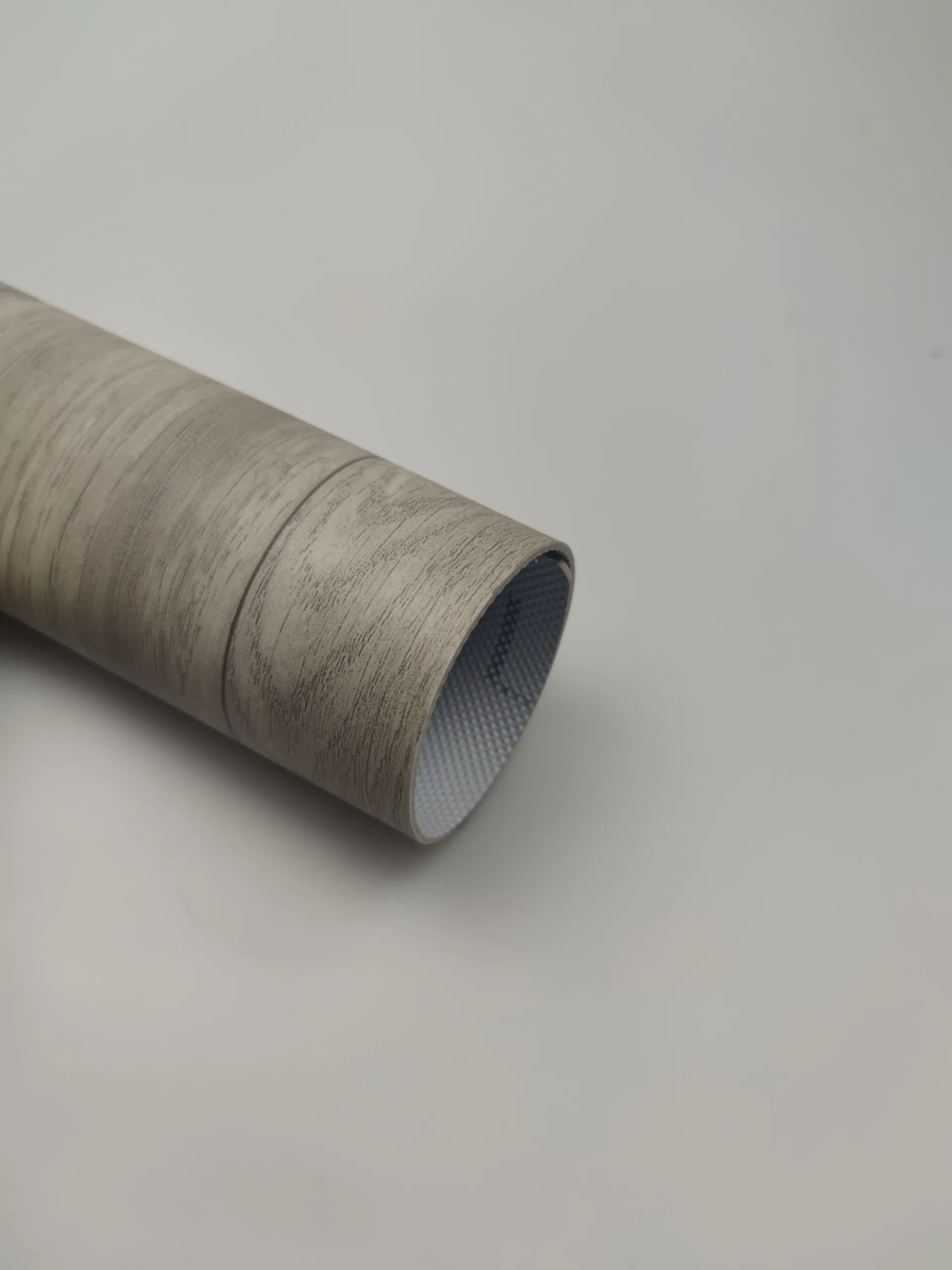

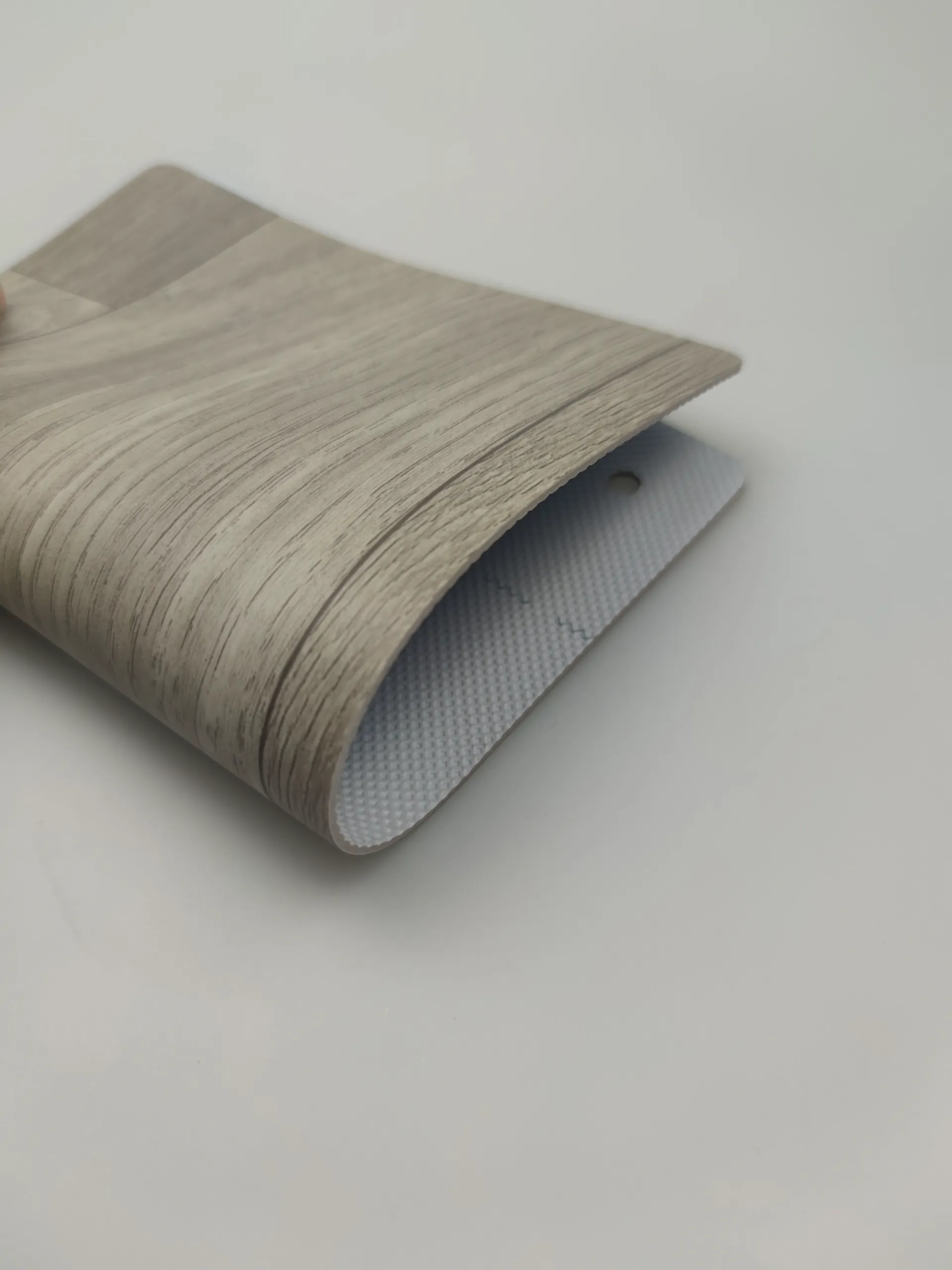

Beyond standard offerings, modern pisos vct manufacturers like Enlio provide extensive customization options to precisely match project specifications and brand aesthetics. This includes a wide array of colors, patterns, and even custom cutting to create intricate designs or incorporate corporate logos directly into the flooring. Effective project implementation requires meticulous planning, starting with precise measurements and subfloor preparation to ensure a smooth, durable installation. Enlio's technical team collaborates closely with clients from initial concept to final installation, offering expert guidance on material selection, design integration, and installation best practices. Post-installation, comprehensive maintenance protocols are provided to maximize the lifespan and aesthetic appeal of the flooring. For our heterogeneous floor with Nora surface, the enhanced wear layer and surface treatment significantly simplify cleaning routines, reducing the need for costly and time-consuming stripping and waxing, a common requirement for traditional pisos vct.

Figure 4: Examples of customized VCT designs and colors for unique project needs.

Real-World Impact: Pisos VCT Application Case Studies

The tangible benefits of advanced pisos vct are best illustrated through real-world applications. In a recent project involving a large university campus, the selection of Enlio's heterogeneous floor with Nora surface for high-traffic corridors and common areas resulted in a remarkable reduction in maintenance costs by approximately 30% annually, primarily due to the floor's superior stain resistance and no-wax requirement. Furthermore, post-installation surveys indicated a significant improvement in perceived indoor air quality and reduced noise levels, contributing to a more conducive learning environment. Another notable case involved a busy retail chain that switched from traditional pisos vct to Enlio's advanced solution. The chain reported a 25% increase in the average lifespan of their flooring, reducing the frequency and disruption of replacements. These results underscore the long-term value and operational efficiencies achieved when investing in high-performance VCT solutions that go beyond basic functionality.

Figure 5: A successful installation of advanced VCT in a high-traffic commercial environment.

Frequently Asked Questions (FAQ) about Pisos VCT

-

Q: What makes heterogeneous VCT different from homogeneous VCT?

A: Homogeneous VCT has a uniform composition throughout its thickness, meaning the color and pattern extend through the entire tile. Heterogeneous VCT, like Enlio's `heterogeneous floor with Nora surface`, consists of multiple distinct layers, including a specialized wear layer, a printed design layer, and a backing. This layered construction allows for superior performance characteristics such as enhanced durability, better dimensional stability, and often, improved maintenance profiles. It also allows for more intricate designs and realistic patterns.

-

Q: Is Pisos VCT suitable for areas with heavy rolling loads?

A: Yes, high-quality pisos vct is engineered to withstand heavy rolling loads, making it ideal for healthcare environments with medical equipment, retail spaces with carts, and educational facilities. Its high filler content provides excellent indentation resistance. For critical applications, ensure the product's static and dynamic load ratings meet your specific requirements, and use proper installation techniques including a flat, smooth subfloor.

-

Q: How long does Pisos VCT typically last?

A: The lifespan of pisos vct can vary depending on traffic levels, maintenance, and the specific product quality. Standard VCT can last 15-20 years with proper care. Advanced heterogeneous options, especially those with high-performance wear layers like the Nora surface, can significantly extend this lifespan, often exceeding 25 years, while requiring less intensive maintenance, thus offering a lower total cost of ownership over its lifecycle.

Ensuring Trust: Warranty, Support, and Delivery

At Enlio, our commitment to client satisfaction extends beyond product innovation to comprehensive support and reliable service. We understand that timely delivery and robust after-sales support are critical for commercial projects. Our standard delivery lead times for pisos vct typically range from 2 to 4 weeks, depending on order volume and customization requirements, with expedited options available for urgent projects. Every Enlio `heterogeneous floor with Nora surface` comes with an extensive limited commercial warranty, covering manufacturing defects and wear-through under normal conditions for up to 15 years, reflecting our confidence in the product's enduring quality. Our dedicated customer support team provides expert technical assistance, from pre-sale consultations to post-installation troubleshooting, ensuring a seamless experience. This unwavering commitment to quality and service builds long-term partnerships and reinforces trust in Enlio as a leading supplier of advanced flooring solutions.

Conclusion

The evolution of pisos vct, particularly advanced heterogeneous formulations like Enlio's `heterogeneous floor with Nora surface`, offers compelling advantages for modern commercial environments. These innovations address critical needs for enhanced durability, simplified maintenance, superior aesthetic versatility, and improved long-term cost-effectiveness. By understanding the intricate manufacturing processes, key technical parameters, and comparing options from leading manufacturers, B2B decision-makers can make informed choices that contribute significantly to the safety, efficiency, and visual appeal of their facilities. Embracing these advanced VCT solutions ensures a robust and sustainable foundation for diverse commercial applications.

References

- ASTM F1066 - 21. Standard Specification for Vinyl Composition Tile. ASTM International, 2021.

- ISO 10581:2011. Resilient floor coverings -- Homogeneous and heterogeneous polyvinyl chloride floor coverings -- Specification. International Organization for Standardization, 2011.

- National Institute of Building Sciences (NIBS). Whole Building Design Guide (WBDG): Vinyl Composition Tile (VCT). Accessed 2023.

- Building Owners and Managers Association (BOMA) International. Commercial Floor Maintenance Best Practices. Accessed 2023.

-

Waterproof Advantages of SPC Flooring Vinyl in KitchensAug.06,2025

-

SPC Hybrid Waterproof Flooring Thickness GuideAug.06,2025

-

Leveling Subfloor Before My Floor SPC InstallAug.06,2025

-

How Mesh Deck Skirting Improves Outdoor Pest ControlAug.06,2025

-

Choosing the Right Commercial Flooring for Your Business NeedsAug.06,2025

-

Choosing the Best Residential Flooring: A Comprehensive Guide to Style, Durability, and ComfortAug.06,2025