Durable VCT Flooring | Pisos VCT for Commercial Spaces

The Strategic Advantage of Pisos VCT: Durability Meets Design

In the dynamic landscape of commercial and industrial flooring, the choice of material significantly impacts operational efficiency, long-term costs, and user well-being. Among the myriad options, pisos vct, or Vinyl Composition Tile, stands out as a highly versatile and cost-effective solution. While traditional VCT has long been a staple, advancements in manufacturing have introduced sophisticated variants, such as heterogeneous flooring with specialized surfaces. Enlio's heterogeneous floor with Nora surface exemplifies this evolution, offering enhanced performance characteristics that transcend conventional expectations. This type of flooring is engineered for environments demanding superior durability, simplified maintenance, and a higher degree of aesthetic flexibility. It represents a significant leap from basic resilient flooring, incorporating multiple layers and advanced surface treatments to deliver specialized benefits tailored to demanding commercial and industrial applications.

The robust construction of modern pisos vct ensures exceptional resistance to heavy foot traffic, impacts, and abrasions, making it an ideal choice for high-traffic areas such as hospitals, educational institutions, retail spaces, and corporate offices. Beyond its inherent toughness, contemporary VCT solutions are increasingly designed with sustainability in mind, often featuring recycled content and low volatile organic compound (VOC) emissions, contributing to healthier indoor air quality. This commitment to environmental responsibility, combined with economic viability, positions pisos vct as a preferred flooring material for architects, facility managers, and B2B decision-makers. The strategic implementation of such advanced flooring systems leads to measurable improvements in operational efficiency, reductions in maintenance expenditure, and an elevated overall environmental quality for building occupants. Furthermore, the aesthetic versatility of VCT allows for intricate design patterns and seamless integration into diverse interior concepts, providing both functional excellence and visual appeal. The integration of cutting-edge technologies and materials ensures that these flooring solutions are not merely functional but also contribute significantly to the overall architectural and ergonomic quality of a space.

Pisos VCT: Navigating Industry Trends and Market Dynamics

The global resilient flooring market, a significant segment of which is dominated by pisos vct, is experiencing steady growth, driven by increasing construction activities in both developed and emerging economies. Industry reports indicate a compound annual growth rate (CAGR) of approximately 4-6% for resilient flooring over the next five years, with VCT maintaining a substantial share due to its proven performance and cost-effectiveness. A key trend shaping the market is the escalating demand for sustainable building materials. Manufacturers are responding by innovating processes to incorporate post-consumer and pre-consumer recycled content, reducing the carbon footprint, and striving for certifications like FloorScore, which ensures low VOC emissions for improved indoor air quality. This focus on environmental stewardship is not merely a regulatory compliance measure but a strategic imperative driven by conscious consumers and corporate sustainability goals. The evolution extends to enhanced surface treatments and wear layers, providing superior resistance to scuffs, stains, and chemicals, thus extending the product's lifespan and reducing the need for intensive maintenance.

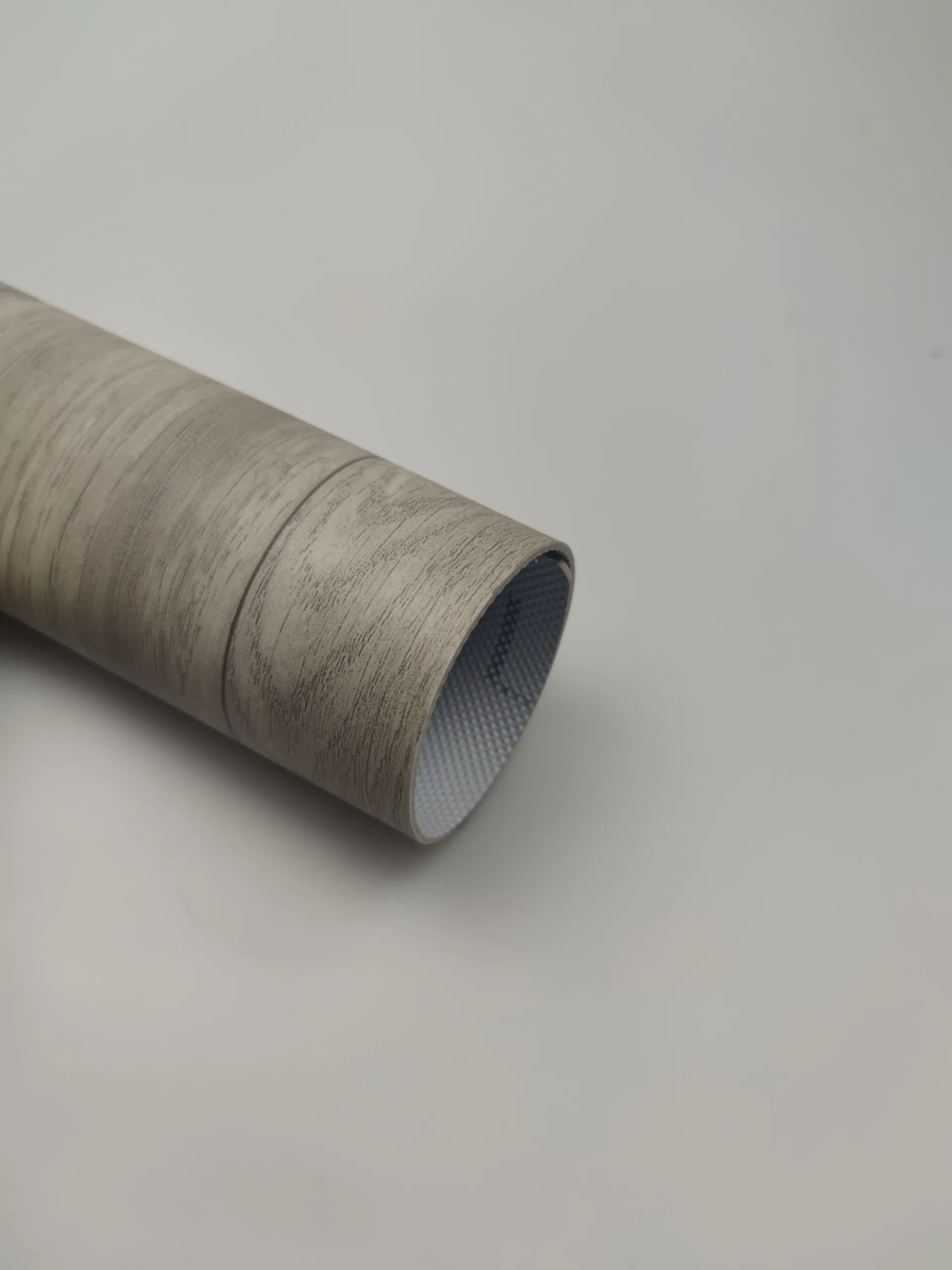

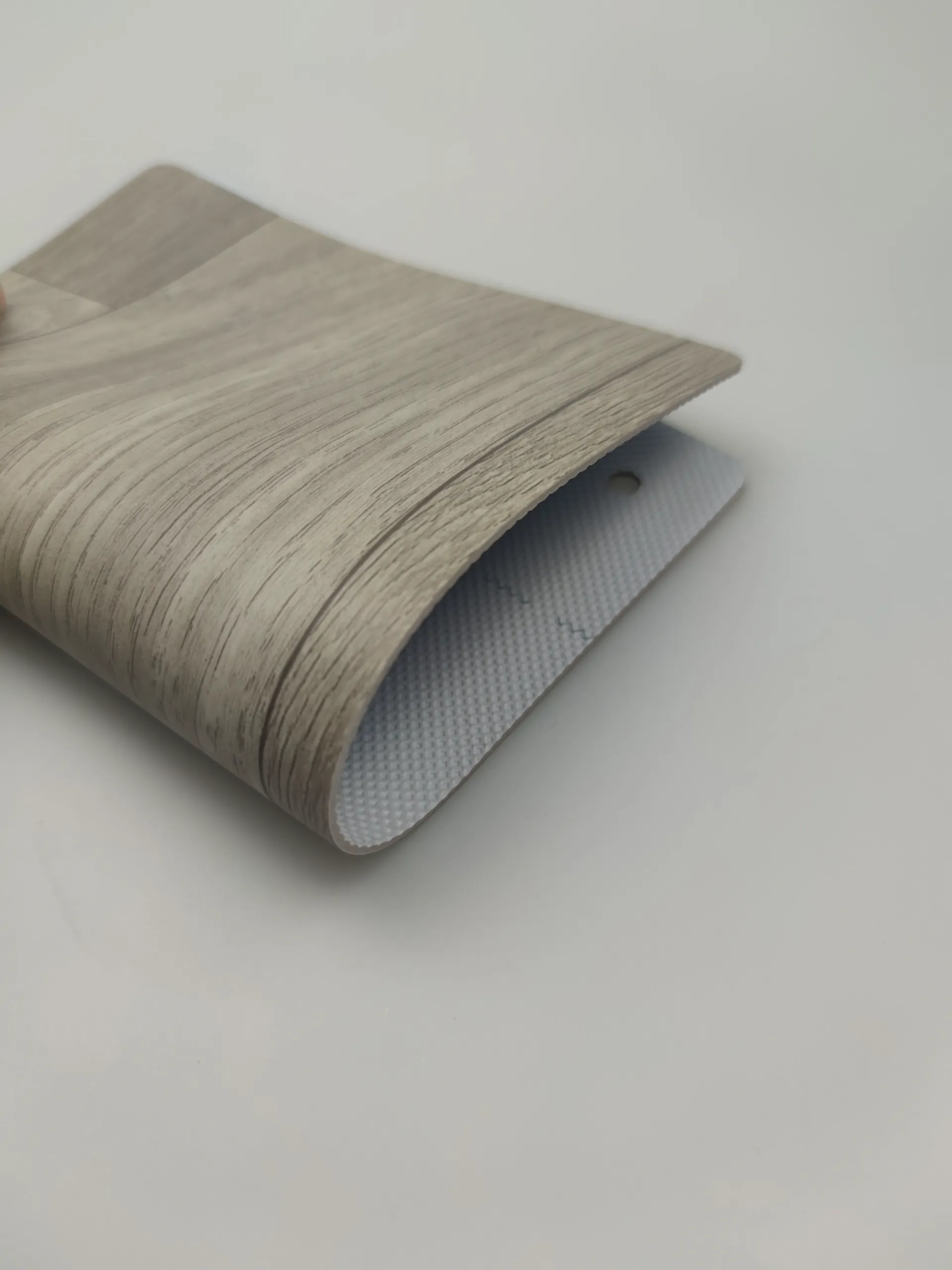

Technological advancements are also transforming the aesthetic capabilities of pisos vct. Digital printing technologies now allow for highly realistic wood, stone, and abstract patterns, offering designers unprecedented flexibility without compromising on durability or cost. This enables the creation of complex and visually engaging floor designs that mimic natural materials with greater precision and consistency. Furthermore, the market is seeing a push towards specialized VCT formulations, such as those with enhanced acoustic properties, anti-static capabilities, or improved slip resistance, catering to niche applications like data centers, laboratories, and specialized healthcare environments. Major players like Tarkett VCT, Mohawk VCT, and Johnsonite VCT continue to innovate within this space, but emerging manufacturers like Enlio are carving out significant market share by offering highly specialized products, such as their heterogeneous floor with Nora surface, which combines the benefits of multi-layer construction with a high-performance top layer for superior resilience and chemical resistance. This competitive landscape fosters continuous innovation, pushing the boundaries of what resilient flooring can achieve in terms of performance, aesthetics, and sustainability.

Another significant trend is the increasing adoption of integrated flooring solutions, where VCT is often part of a broader system that includes subfloor preparation, adhesives, and specialized finishing treatments. This holistic approach ensures optimal performance and longevity, addressing common issues such as moisture mitigation and substrate irregularities. The drive for lifecycle cost reduction also plays a pivotal role, with facility managers increasingly prioritizing flooring solutions that offer lower total cost of ownership through reduced maintenance requirements, extended product lifespan, and ease of repair. This translates into a strong demand for products like advanced pisos vct, which combine initial affordability with long-term economic benefits. The emphasis on user experience is also paramount, with flooring choices influencing acoustics, underfoot comfort, and ergonomic support in commercial spaces, contributing to productivity and occupant satisfaction. The ability of VCT to meet stringent health and safety regulations, including slip resistance and fire ratings, further solidifies its position as a go-to material for public and private sector projects requiring robust and reliable flooring infrastructure.

The Advanced Manufacturing Process of High-Performance Pisos VCT

The production of modern pisos vct, particularly advanced heterogeneous vinyl flooring like Enlio's "heterogeneous floor with Nora surface," involves a sophisticated, multi-stage manufacturing process designed to impart specific performance characteristics. Unlike homogeneous VCT, which is a single layer of uniform composition, heterogeneous VCT is constructed from multiple distinct layers fused together, each contributing a unique property. The primary raw materials typically include polyvinyl chloride (PVC) resins, which form the base polymer; plasticizers, to impart flexibility; fillers such as limestone or calcium carbonate, for dimensional stability and cost-effectiveness; pigments, for color and pattern; and stabilizers, to protect against heat and UV degradation. The selection and precise blending of these materials are critical for achieving the desired physical and chemical properties of the final product. The manufacturing journey begins with the meticulous preparation and compounding of these raw materials into a homogeneous mix, ensuring uniform dispersion of all components.

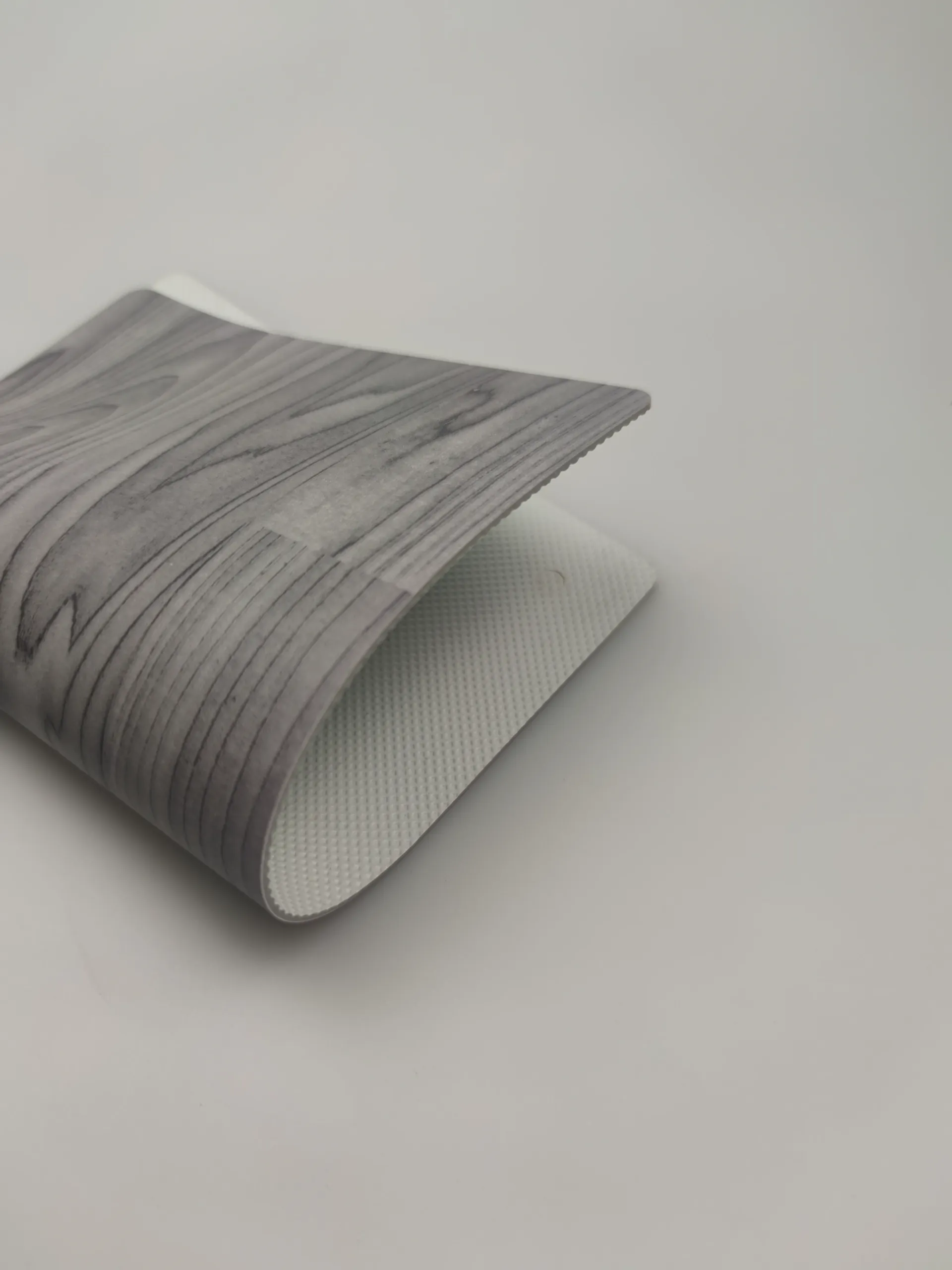

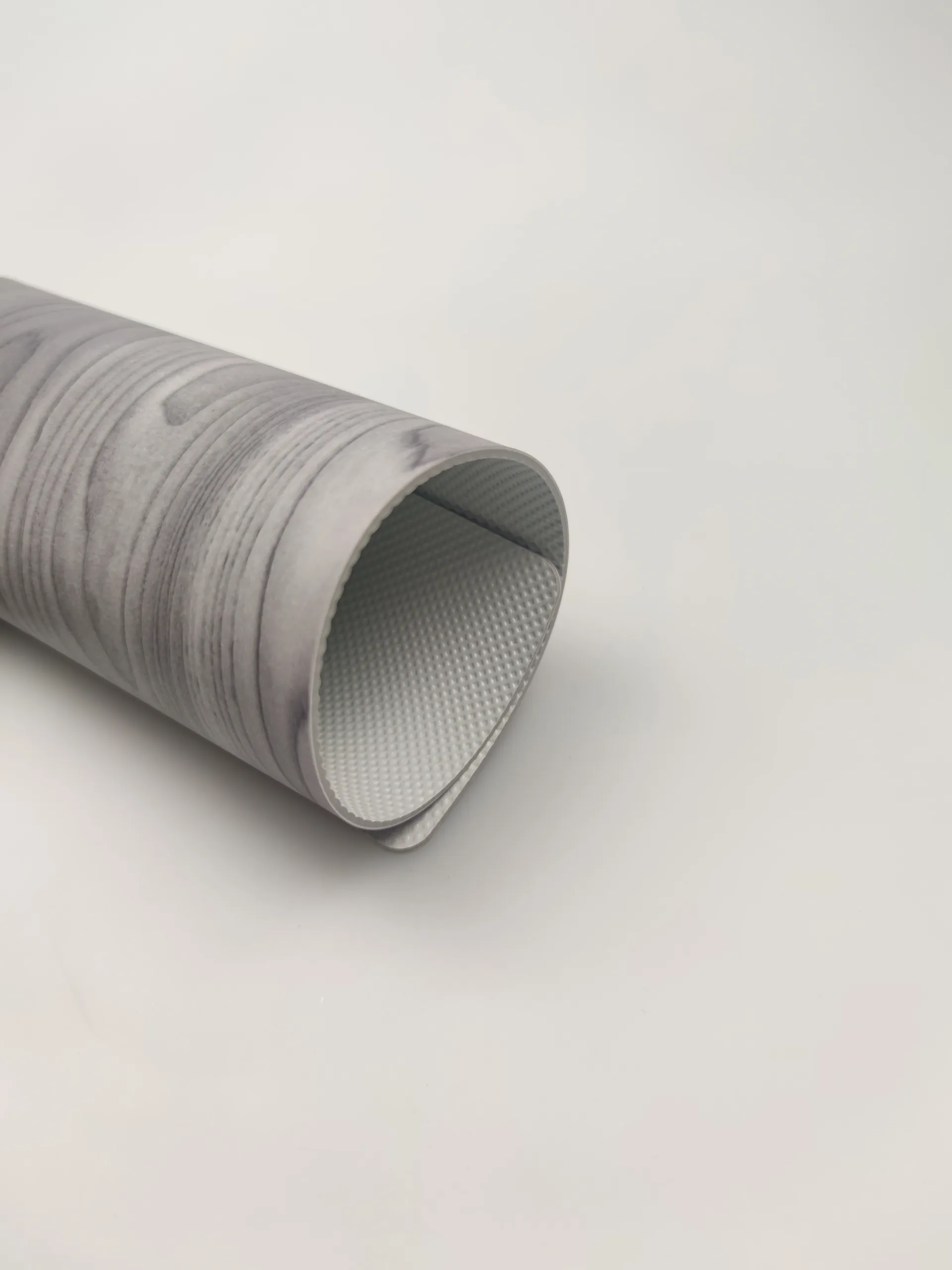

Following compounding, the mixed material undergoes a process known as calendering or extrusion. In calendering, the compound is passed through a series of heated rollers that flatten and compress it into continuous sheets of precise thickness. For heterogeneous flooring, multiple sheets, each representing a different layer (e.g., backing layer, fiberglass reinforcement layer, printed decorative layer, clear wear layer, and finally, the specialized Nora surface layer), are then brought together and fused under high pressure and temperature. This lamination process ensures a strong bond between layers, preventing delamination over the product's lifespan. The top clear wear layer, often made from highly durable transparent PVC, provides resistance to scratches, abrasions, and stains. The unique "Nora surface" application, in Enlio's case, signifies a specialized, high-performance top finish that enhances chemical resistance, cleanability, and overall longevity, often providing rubber-like properties such as superior slip resistance and comfort underfoot, distinguishing it from standard vinyl wear layers.

Post-lamination, the continuous sheet is cooled, cut into specific tile dimensions, and then subjected to rigorous quality control protocols. These protocols adhere to international standards such as ASTM F1700 (Standard Specification for Solid Vinyl Tile), EN 649 (Resilient floor coverings – Homogeneous and heterogeneous polyvinyl chloride floor coverings – Specification), and ISO 9001 for quality management systems. Key performance metrics tested include dimensional stability, indentation resistance, static load limits, slip resistance (e.g., coefficient of friction), residual indentation, color fastness, and chemical resistance. Specialized tests are also conducted for flame spread ratings (e.g., ASTM E648), smoke density, and acoustic properties. This meticulous process ensures that each batch of pisos vct meets stringent performance criteria, providing an exceptional service life of 15-25 years or more under typical commercial conditions, contingent on proper installation and maintenance. The applicable industries for these advanced VCT products are diverse, including healthcare facilities (where hygiene and chemical resistance are paramount), educational institutions (demanding high durability and low maintenance), retail environments (requiring aesthetic versatility and wear resistance), and light industrial settings. These flooring solutions significantly contribute to reduced operational costs, enhanced safety, and improved environmental quality due to their low VOC emissions and often recyclable nature.

Unpacking the Technical Specifications of Pisos VCT

Understanding the technical specifications of pisos vct is crucial for B2B professionals to select the optimal flooring solution for their specific project requirements. These specifications define the performance characteristics, durability, and suitability of the material for various applications. For heterogeneous flooring with a specialized surface like Enlio's Nora finish, these parameters are often elevated compared to standard VCT. Key technical parameters include overall thickness, typically ranging from 2.0mm to 3.0mm, with the wear layer thickness being a critical determinant of longevity, often ranging from 0.3mm to 0.7mm or even thicker for extreme durability. The composition of the wear layer, especially with a Nora surface, dictates its resistance to abrasions, scratches, and stains, significantly extending the floor's aesthetic and functional life.

Other vital parameters include dimensional stability, which is the material's resistance to expansion or contraction due to temperature and humidity fluctuations, typically measured as a percentage change (e.g.,

Below is a comparative table detailing typical technical specifications for standard pisos vct versus advanced heterogeneous flooring like Enlio's product:

| Parameter | Standard VCT (Homogeneous) | Enlio Heterogeneous Floor with Nora Surface | Test Standard (Examples) |

|---|---|---|---|

| Total Thickness | 2.0mm - 3.2mm | 2.0mm - 4.0mm (multi-layer) | EN 428, ASTM F387 |

| Wear Layer Thickness | Full thickness (homogeneous) | 0.5mm - 0.8mm (clear PVC/PUR + Nora surface) | EN 429 |

| Abrasion Resistance | T group (EN 660-2) | Group T / P (Superior, EN 660-2) | EN 660-2 |

| Residual Indentation | ≤ 0.15mm (after 24h) | ≤ 0.10mm (Superior, after 24h) | EN 433, ASTM F970 |

| Slip Resistance | R9 | R9 / R10 (Enhanced due to Nora surface) | DIN 51130 |

| Dimensional Stability | ≤ 0.4% | ≤ 0.1% (Excellent) | EN 434 |

| Fire Resistance | Class Bfl-s1 or Cfl-s1 | Class Bfl-s1 (Superior) | EN 13501-1, ASTM E648 |

| Sound Reduction | 3-6 dB (Impact Sound) | 6-10 dB (Enhanced, due to layers) | EN ISO 717-2 |

| VOC Emissions | Low VOC (often FloorScore) | Very Low VOC (FloorScore Certified) | CDPH 01350, FloorScore |

The distinction between standard VCT and advanced heterogeneous vinyl flooring like Enlio's product is evident in these technical specifications. The multi-layer construction, coupled with specialized surface treatments like the Nora surface, provides superior performance in critical areas such as abrasion resistance, residual indentation, and chemical resistance. This makes products like Enlio Johnsonite VCT or Enlio Tarkett VCT II (as references to high-performance, specialized vinyl flooring) more suitable for demanding commercial environments where longevity and minimal maintenance are paramount. The meticulous engineering behind these enhanced versions of pisos vct ensures that they not only meet but often exceed industry standards, providing a robust and reliable flooring solution that stands the test of time and intensive use.

Strategic Application Scenarios for Pisos VCT

The versatility and robust performance of pisos vct, especially advanced heterogeneous options, make it an ideal choice for a diverse range of commercial and institutional applications. Its ability to combine durability, ease of maintenance, and aesthetic appeal positions it as a preferred material for decision-makers across various sectors. In healthcare facilities, such as hospitals, clinics, and long-term care homes, VCT is invaluable due to its non-porous surface, which inhibits bacterial growth and facilitates stringent cleaning protocols. The chemical resistance of surfaces like Enlio's Nora finish ensures that aggressive disinfectants can be used without damaging the floor, maintaining aseptic environments critical for patient safety. Furthermore, the acoustic properties of heterogeneous VCT contribute to noise reduction, creating a calmer and more conducive healing environment, while its ergonomic properties provide comfort for staff who spend long hours on their feet.

Educational institutions, from K-12 schools to universities, present environments with high foot traffic, frequent spills, and the need for durable, easy-to-clean surfaces. Pisos vct excels here by offering exceptional wear resistance against heavy student traffic, rolling carts, and furniture movement. Its low maintenance requirements, which often involve simple dry sweeping and occasional damp mopping, translate into significant operational savings for school districts. The wide array of colors and patterns available also allows for creative and engaging learning environments, supporting school branding and wayfinding. In retail and commercial spaces, aesthetic appeal is as important as durability. VCT offers unparalleled design flexibility, allowing for custom patterns, intricate logos, and seamless transitions between different zones. Its resistance to scuffs and stains ensures that the flooring maintains its pristine appearance even under constant customer footfall, contributing to a positive brand image and customer experience. The ease of repair and replacement of individual tiles minimizes disruption during renovation or repair, a crucial advantage in active commercial settings.

Beyond these common applications, pisos vct also finds niche uses in specialized industrial and technical environments. In light industrial facilities and warehouses, its robust construction withstands heavy static and dynamic loads, while specific formulations can offer enhanced chemical resistance to industrial spills. In data centers and control rooms, certain VCT products are engineered with anti-static (ESD) properties, crucial for protecting sensitive electronic equipment from electrostatic discharge. The inherent resistance to moisture, combined with proper subfloor preparation, makes VCT suitable for areas prone to humidity. Furthermore, its ability to be installed quickly and efficiently minimizes downtime, a critical factor for businesses needing rapid facility turnarounds. The proven longevity and low lifecycle cost of modern VCT, especially those with advanced wear layers, cement its status as a highly strategic investment for any commercial or institutional project aiming for long-term value and sustained performance. The breadth of its application underscores its engineering adaptability and its capacity to meet diverse functional and aesthetic demands across the B2B spectrum.

Comparative Analysis: Leading Pisos VCT Manufacturers

The market for pisos vct is characterized by a mix of long-established global leaders and innovative emerging players, each bringing unique strengths to the table. Understanding the distinct offerings and philosophies of these manufacturers is crucial for B2B procurement and specification. Companies like Tarkett VCT, Mohawk VCT, and Johnsonite VCT (a brand historically associated with Tarkett and now part of the Tarkett family) have built formidable reputations on decades of experience, extensive product portfolios, and strong distribution networks. Tarkett, for instance, is renowned for its comprehensive range of resilient flooring solutions, including traditional VCT, homogeneous, and heterogeneous vinyls, with a strong emphasis on sustainability initiatives like circular economy principles and recycled content. Their products are widely specified in healthcare and education, known for consistent quality and broad availability.

Mohawk Group, a division of Mohawk Industries, offers a diverse portfolio of commercial flooring, including high-performance VCT solutions that prioritize design flexibility and durability for corporate, retail, and hospitality sectors. Their strength lies in combining aesthetic innovation with robust performance, often incorporating advanced wear layers and proprietary surface treatments for enhanced scratch and stain resistance. Johnsonite, particularly recognized for its specialized rubber and vinyl flooring accessories, also provides high-quality VCT lines that are often integrated into complete flooring systems, focusing on performance in demanding environments and offering specialized features like static dissipative properties and enhanced chemical resistance. Their extensive range of transition strips, wall base, and other accessories ensures a fully integrated flooring solution, often specified in healthcare and laboratory settings where seamless transitions and hygienic perimeters are paramount.

Enlio, while a relatively newer entrant to the global stage compared to these giants, has rapidly distinguished itself by specializing in high-performance sports flooring and advanced commercial resilient flooring, exemplified by their "heterogeneous floor with Nora surface." Enlio's strategic focus on innovation and specific niche applications allows them to engineer products with highly specialized features that cater to precise performance demands. The integration of a "Nora surface" implies a commitment to superior surface properties, potentially leveraging the renowned durability, elasticity, and comfort of rubber-based surfaces, combined with the hygienic and robust characteristics of multi-layer vinyl. This specialized approach often results in products that offer superior chemical resistance, enhanced slip resistance, better acoustic properties, and extended lifespan, making them particularly attractive for facilities where these attributes are non-negotiable, such as high-traffic public areas, specialized medical facilities, or laboratories. The ability of manufacturers like Enlio to offer tailored, high-tech solutions provides a strong alternative to the broader, more generalized offerings of larger corporations. This specialization is why products like Enlio Johnsonite VCT or Enlio Tarkett VCT II, even if hypothetical product names, imply a convergence of specialized technology with established market needs for high-performance vinyl flooring.

| Manufacturer | Key Strengths | Product Focus (Pisos VCT) | Typical Applications |

|---|---|---|---|

| Tarkett | Global presence, extensive portfolio, strong sustainability focus (e.g., Cradle to Cradle), broad distribution. | Standard & premium VCT, homogeneous & heterogeneous vinyl, integrated systems. | Healthcare, Education, Retail, Corporate. |

| Mohawk Group | Design innovation, robust performance, commercial market focus, extensive warranty programs. | High-performance VCT, LVT, modular designs, often with enhanced wear layers. | Corporate, Retail, Hospitality, Education. |

| Johnsonite (Tarkett) | Specialization in accessories, integrated solutions, performance in demanding environments, ESD options. | High-performance VCT, rubber flooring, specialized vinyls (e.g., static control). | Healthcare, Laboratories, Data Centers, Education. |

| Enlio | Niche specialization, innovation in surface technology (e.g., Nora surface), competitive pricing, performance-driven. | Heterogeneous vinyl flooring with specialized high-performance surfaces, sports flooring expertise. | Healthcare, Education, Sports Facilities, Specialized Commercial Spaces. |

The choice among these manufacturers ultimately depends on the specific project parameters, including budget, performance requirements, aesthetic preferences, and sustainability goals. For projects demanding a robust, multi-layered flooring solution with enhanced surface properties like those provided by a Nora finish, Enlio presents a compelling option that combines advanced engineering with a focused product offering, ensuring that critical performance needs are not just met but exceeded. This competitive landscape ensures that B2B buyers have access to a wide array of high-quality pisos vct solutions tailored to almost any commercial or industrial application.

Tailored Solutions and Customization in Pisos VCT Flooring

One of the significant advantages of modern pisos vct, particularly heterogeneous vinyl flooring, is its remarkable potential for customization and tailored solutions. In B2B environments, where branding, specific functional requirements, and unique architectural visions often dictate material choices, the ability to adapt a flooring product to precise needs is invaluable. Customization extends far beyond merely selecting from a standard catalog of colors and patterns; it encompasses bespoke designs, specialized performance attributes, and even custom dimensions for specific project layouts. For instance, in educational settings, VCT can be custom-cut to incorporate school mascots, directional arrows, or vibrant learning zones, enhancing both aesthetics and functionality. Retail spaces can leverage custom VCT to feature intricate brand logos or create distinct pathways that guide customer flow, thereby contributing to an immersive brand experience.

Beyond aesthetics, customization in pisos vct can involve modifying technical specifications to meet unique performance demands. For example, a healthcare facility might require a specific level of slip resistance beyond standard offerings, or a laboratory might need enhanced chemical resistance to a particular reagent. Manufacturers like Enlio, with their advanced heterogeneous flooring and specialized Nora surface, are well-positioned to offer such tailored solutions. This could involve adjusting the wear layer composition for increased abrasion resistance in extremely high-traffic areas, or incorporating anti-static properties for sensitive electronic environments like server rooms or manufacturing cleanrooms. The multi-layered structure of heterogeneous VCT inherently provides a platform for such specialized engineering, allowing different layers to be optimized for specific functions, whether it's acoustic dampening, static control, or superior dimensional stability under fluctuating environmental conditions.

The process of developing customized pisos vct solutions typically involves close collaboration between the client, architects, designers, and the manufacturer's technical team. This ensures that the proposed solution not only meets aesthetic preferences but also adheres to all functional and regulatory requirements. Digital visualization tools and sample prototyping are often employed to allow clients to preview and refine their selections before full-scale production. This collaborative approach minimizes risks and ensures that the final product perfectly aligns with project goals. Furthermore, the modular nature of VCT tiles simplifies installation and allows for easier repair or replacement of individual sections, reducing long-term maintenance costs and extending the overall lifespan of the flooring system. This inherent adaptability, combined with the growing capabilities of manufacturers to offer specialized formulations and unique aesthetic options, solidifies pisos vct's position as a highly flexible and cost-effective material for achieving highly specific and demanding flooring outcomes in diverse commercial and industrial settings.

Real-World Impact: Case Studies and Pisos VCT Application Success

The true testament to the value of pisos vct lies in its successful application across numerous demanding real-world scenarios. These case studies highlight not only the product's inherent durability and aesthetic versatility but also its tangible benefits in terms of operational efficiency, safety, and long-term cost savings. Consider a large public university that recently undertook a renovation of its main student union building. Faced with high foot traffic, frequent spills from food service areas, and the need for a durable yet appealing floor, they opted for a heterogeneous pisos vct solution with enhanced wear resistance. The outcome was a vibrant, easy-to-clean floor that significantly reduced maintenance hours by 30% compared to their previous flooring, while maintaining its aesthetic integrity despite thousands of students traversing it daily. The low VOC emissions also contributed to improved indoor air quality, a key metric for student well-being.

Another compelling case involved a multi-specialty hospital looking to upgrade its patient corridors and common areas. Hygiene, chemical resistance to disinfectants, and acoustic properties were paramount. By specifying a high-performance heterogeneous vinyl floor, similar to Enlio's "heterogeneous floor with Nora surface," the hospital achieved a flooring system that could withstand daily rigorous cleaning protocols without degradation, ensuring an aseptic environment. The enhanced sound absorption significantly reduced noise levels from foot traffic and rolling equipment, contributing to a quieter, more therapeutic atmosphere for patients and reducing staff fatigue. Furthermore, the superior slip resistance provided an added layer of safety, minimizing the risk of falls in an environment where patient and staff safety is critical. The long lifecycle of the flooring meant fewer disruptions for replacement and renovation, minimizing impact on hospital operations.

In the retail sector, a major grocery chain sought a flooring solution for its new store concept that would offer both aesthetic appeal and exceptional durability against heavy cart traffic and potential spills. They chose a customized pisos vct with a distinctive pattern and a high-performance wear layer. The outcome was a visually appealing floor that enhanced the store's modern design, while simultaneously delivering superior resistance to scuffs, stains, and impacts. The ease of maintenance allowed store staff to quickly clean up spills, minimizing safety hazards and maintaining a pristine shopping environment. The modular nature of the VCT tiles also meant that in the event of severe damage to a single tile, it could be replaced quickly and efficiently without disrupting a large section of the store. These examples underscore how tailored pisos vct solutions deliver measurable benefits, translating into improved operational efficiency, enhanced safety, and substantial long-term savings for B2B clients across various industries. The ability to integrate advanced surface technologies, such as the Nora finish, further amplifies these benefits, providing a robust and sustainable flooring investment.

Ensuring Confidence: FAQs, Delivery, and Support for Your Pisos VCT Investment

Investing in a high-quality flooring solution like pisos vct, particularly advanced heterogeneous types, requires comprehensive understanding beyond mere product specifications. For B2B decision-makers, assurance regarding product longevity, ease of maintenance, and reliable manufacturer support is paramount. This section addresses common queries and outlines the commitment to trustworthiness provided by leading manufacturers like Enlio.

Frequently Asked Questions (FAQs)

- What is the typical lifespan of advanced heterogeneous pisos vct?

High-quality heterogeneous VCT, especially with enhanced wear layers and specialized surfaces like Nora, can have a service life of 15-25 years or even longer in commercial environments with proper installation and maintenance. Factors like traffic intensity and specific application (e.g., healthcare vs. office) can influence this. - How does the Nora surface enhance performance?

The Nora surface is a specialized top layer application that significantly improves characteristics such as chemical resistance (against common disinfectants and spills), abrasion resistance, slip resistance, and ease of cleaning. It often provides a more durable and resilient surface than standard PU or acrylic wear layers, offering superior long-term performance and reduced maintenance effort. - Is advanced VCT suitable for heavy rolling loads (e.g., hospital beds, forklifts)?

Yes, high-performance heterogeneous pisos vct is designed to withstand heavy static and dynamic loads. Its multi-layer construction and superior indentation resistance (as per EN 433) ensure it performs exceptionally well under constant movement of heavy equipment, making it ideal for healthcare, industrial, and retail environments. - What are the environmental benefits of modern VCT?

Many modern VCT products feature low VOC emissions, contributing to better indoor air quality (often certified by FloorScore or similar). Manufacturers increasingly use recycled content in their products and have programs for recycling post-consumer VCT, aligning with sustainable building practices and LEED certification requirements. - What are the recommended cleaning and maintenance procedures?

Maintenance for advanced VCT is typically low-cost and straightforward. It generally involves daily dry sweeping or dust mopping, routine damp mopping with neutral cleaners, and periodic machine scrubbing with appropriate floor care solutions. The specialized surface finish, like the Nora surface, often reduces the need for frequent waxing or intensive stripping, saving significant labor and material costs over the product's lifespan.

Delivery and Logistics

Efficient delivery and reliable logistics are critical for B2B projects to stay on schedule and within budget. Leading manufacturers of pisos vct offer streamlined global supply chain management to ensure timely delivery regardless of project scale or location. Typical lead times vary based on product customization and order volume, but standard products can often be dispatched within 2-4 weeks. For large-scale or highly customized orders, comprehensive project planning and communication between the manufacturer, distributors, and contractors ensure coordinated delivery schedules that minimize delays and optimize installation timelines. Manufacturers leverage established freight networks and secure warehousing to protect products during transit, providing full transparency and tracking capabilities for clients.

Quality Assurance and Warranty Commitments

Trustworthiness in the B2B sector is built on robust quality assurance and clear warranty commitments. Reputable pisos vct manufacturers adhere to stringent international quality standards, including ISO 9001 for quality management systems and ISO 14001 for environmental management. Products are regularly tested to meet or exceed industry performance standards such as ASTM F1700, EN 649, and CE certifications, validating their durability, safety, and environmental compliance. Furthermore, certifications like FloorScore affirm low VOC emissions, promoting healthier indoor environments.

Enlio, for its "heterogeneous floor with Nora surface," typically provides comprehensive commercial warranties that cover manufacturing defects, wear, and structural integrity for periods ranging from 10 to 15 years or more, depending on the specific product line and application. These warranties provide peace of mind, ensuring that your investment is protected and that the product will perform as expected under specified conditions. Full details of warranty terms, including coverage specifics and claim procedures, are always provided transparently to clients.

Dedicated Customer Support and After-Sales Service

Beyond product delivery, accessible and knowledgeable customer support is essential for ongoing project success. Leading pisos vct manufacturers offer dedicated technical support teams that can assist with product selection, installation guidance, maintenance best practices, and troubleshooting. This includes providing detailed technical data sheets, installation manuals, and cleaning guidelines. Post-sales support often extends to on-site consultations for complex projects, training for maintenance staff, and rapid response to any performance inquiries. This commitment to comprehensive support throughout the product lifecycle underscores a manufacturer's dedication to client satisfaction and fosters long-term partnerships, ensuring that every pisos vct installation achieves its maximum potential for performance and longevity.

Further Insights and Industry References

For B2B professionals seeking to deepen their understanding of pisos vct and the broader resilient flooring industry, a wealth of authoritative information is available from industry associations, academic research, and standards organizations. These resources provide data-driven insights into market trends, technical advancements, sustainability practices, and regulatory landscapes.

- Resilient Floor Covering Institute (RFCI): A leading North American trade association representing manufacturers of resilient flooring products. Their website offers comprehensive information on product types, technical data, and installation guidelines for various resilient flooring materials, including VCT.

https://rfci.com/ - ASTM International: A global organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services. Relevant standards for VCT include ASTM F1700 (Standard Specification for Solid Vinyl Tile) and ASTM E648 (Standard Test Method for Critical Radiant Flux of Floor-Covering Systems).

https://www.astm.org/ - European Standards (CEN/EN): For European markets, the European Committee for Standardization (CEN) publishes EN standards relevant to resilient flooring, such as EN 649 (Resilient floor coverings – Homogeneous and heterogeneous polyvinyl chloride floor coverings – Specification) and EN 13501-1 (Fire classification of construction products and building elements).

https://www.en-standard.eu/ - FloorScore Certification: A certification program for resilient flooring and flooring adhesives that tests and certifies hard surface flooring products for compliance with strict indoor air quality requirements. It's a critical standard for low VOC emissions.

https://www.scscertified.com/products/certs/floorscore

These authoritative sources provide a strong foundation for informed decision-making regarding pisos vct and ensuring compliance with industry best practices and regulatory requirements.

-

Waterproof Advantages of SPC Flooring Vinyl in KitchensAug.06,2025

-

SPC Hybrid Waterproof Flooring Thickness GuideAug.06,2025

-

Leveling Subfloor Before My Floor SPC InstallAug.06,2025

-

How Mesh Deck Skirting Improves Outdoor Pest ControlAug.06,2025

-

Choosing the Right Commercial Flooring for Your Business NeedsAug.06,2025

-

Choosing the Best Residential Flooring: A Comprehensive Guide to Style, Durability, and ComfortAug.06,2025