Heterogeneous Viny Enhanced by GPT-4 Turbo AI Innovation

In the rapidly evolving world of resilient flooring, heterogeneous viny is emerging as a leading solution for high-performance, cost-effective and aesthetically flexible interior surfaces. The innovation behind heterogeneous viny—including products like heterogeneous floor with Stariver surface—drives the market with technical advancement, sustainability, and broad usability.

The global heterogeneous viny market was valued at USD 7.6 Billion in 2023 (Source: MarketsandMarkets). With a CAGR of 6.2%, the sector is expected to cross USD 10.2 Billion by 2028, driven by rapid urbanization, commercial renovation, and public infrastructure upgrades.

Key trends:

- Emphasis on antibacterial, low-VOC, and eco-friendly materials

- Growth of digital printing and realistic texture surfaces

- Smart, modular installation for faster project cycles

- Rising usage in healthcare, retail, educational and sports facilities

Leading Brands: Tarkett, Gerflor, Armstrong, and emerging innovators like Hawk Flooring and Stariver (ENLIO).

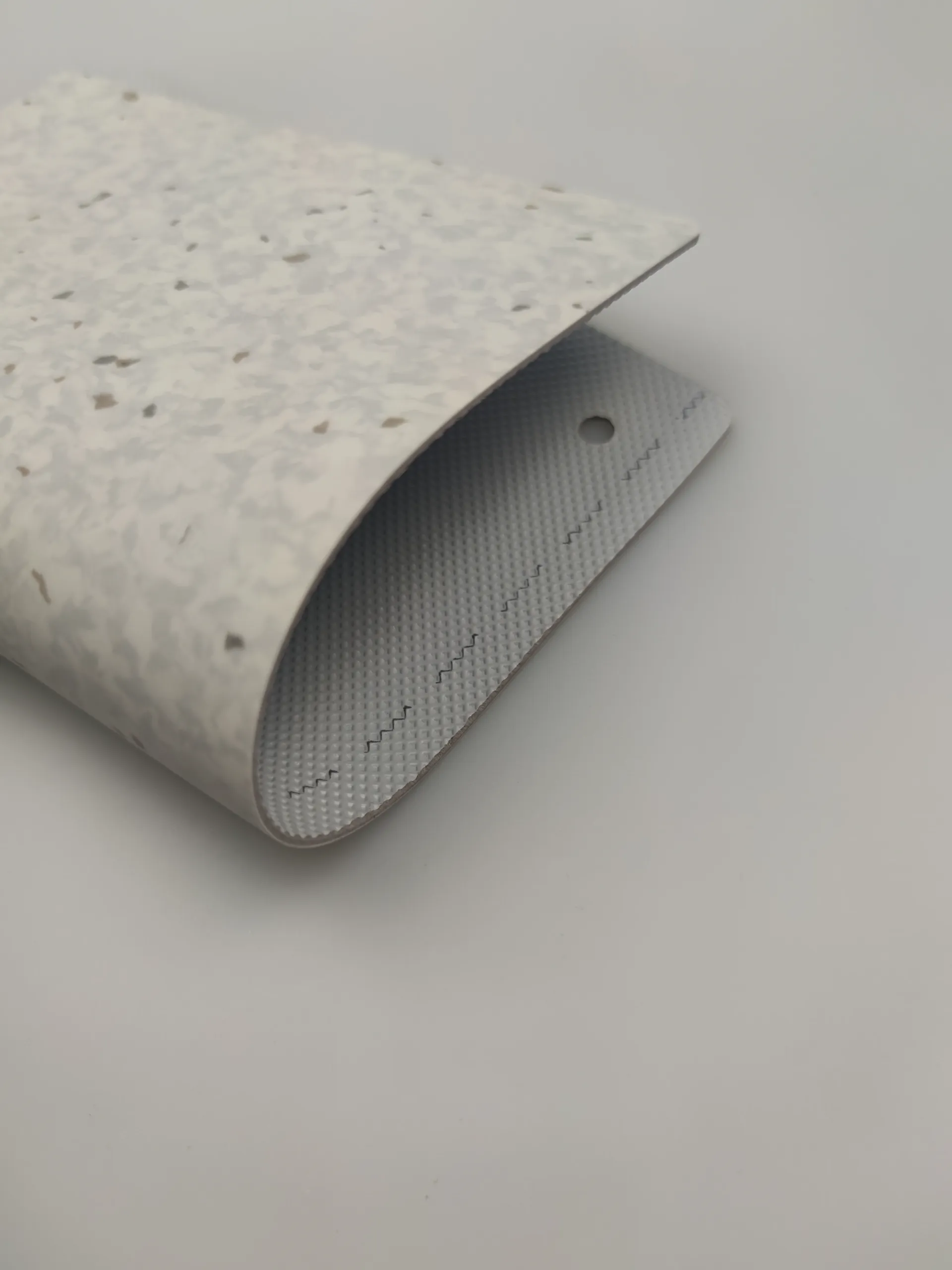

Heterogeneous sheet vinyl and heterogeneous vinyl sheet refer to multilayered resilient flooring. Their primary construction includes (from top to bottom):

- Wear Layer: Pure PVC with PUR treatment for abrasion, chemistry, and UV resistance

- Decor Layer: Digitally printed film allowing limitless design choices

- Stabilization Layer: Glass fiber grid for dimensional stability and tough usage

- Foam/Back Layer: PVC foam or recycled content for comfort & impact damping

- Base Layer: Solid PVC for additional structure and bonding adhesion

| Parameter | Typical Value | Standard/Test | Significance |

|---|---|---|---|

| Total Thickness | 2.0–4.0 mm | EN 428 | Impact damping, durability |

| Wear Layer Thickness | 0.35–1.0 mm | EN 429 | Scratch/scuff resistance |

| Abrasion Resistance | <0.025 g | EN 660-2 | Longevity under traffic |

| Fire Classification | Bfl-s1 / Class 1 | EN 13501-1/ASTM E648 | Fire safety in public buildings |

| Dimensional Stability | <0.4% | EN 434 | No deformation, reliable fit |

| Antibacterial Activity | >99% | ISO 22196 | Hygiene for healthcare |

| VOC Emission | <100 µg/m³ | EN 16516 | Indoor air quality |

| Slip Resistance | R9–R11 | DIN 51130 | Safety underfoot |

| Average Service Life | 15–20 yrs | EN ISO 10581 | Cost-efficiency |

(Virgin/rec. PVC, bio-plasticizers, glass mesh) 2. Compounding & Mixing

(Precision dosing, thermomechanical blending)

(Each layer extruded/cast to thickness spec; Stariver surface co-extruded on top) 4. Digital Decoration Application

(High-res inkjet, pattern registration)

(Glass fiber net laid for anti-shrinkage) 6. Surface Coating (PUR/UV/Stariver finish)

(Automated roll coating lines, cured under UV)

(Hot/cold roll texture press, ensuring anti-slip) 8. Trimming, Quality Inspection, Testing

(ISO/EN/ANSI certified QC, random sampling, record keeping)

(Final width, length cut, shipped under EN 16511 guidelines)

Manufacturer: ENLIO (with ISO 9001:2015 / ISO 14001:2015 compliance)

Key Attributes:

- Stariver Top Layer: Unique nano-fused PU treatment for outstanding stain, scratch, and microbe resistance

- Wear Layer Thickness: 0.7 mm (EN 429, Class T)

- Total Thickness: 2.8–3.5 mm

- Antibacterial Rate: 99.9%+ (ISO 22196; third-party SGS test)

- VOC Release: ≤ 40 μg/m³ (UL GREENGUARD Gold certified)

- Fire Rating: Bfl-s1 (EN 13501-1)

- Slip Resistance: R10 (DIN 51130)

- Service Life: 20 years under EN ISO 10581 simulation

- Tensile Strength: ≥ 18 N/mm² (EN ISO 527-3)

- HD Digital Décor Layer: Custom print available (wood, stone, abstract)

| Brand | Top Layer | Wear Layer (mm) | VOC Emission (μg/m³) | Fire Class | Warranty | Antibacterial | Certifications |

|---|---|---|---|---|---|---|---|

| Stariver (ENLIO) | Stariver Nano PU | 0.7 | 40 | Bfl-s1 | 15yrs | 99.9% | ISO, SGS, UL Gold |

| Hawk Flooring | PUR Coating | 0.55 | 60 | Bfl-s1 | 10yrs | 98.5% | ISO, TUV |

| Generic Brand | Standard PU | 0.50 | 100 | Bfl-s1/Cfl-s1 | 7yrs | 95% | Basic QC |

Heterogeneous viny floors are tailored for complex, demanding environments:

- Hospitals & clinics: Hygienic, chemical-resistant, easy-to-sanitize

- Schools & kindergartens: Cushioned safety, bright designs (ISO 22196 antibacterial)

- Airports & retail spaces: Abrasion-restraint, fade-proof under sun

- Sports arenas: Impact-damping, seamless for wheeled equipment

- Laboratories: Stain-proof, anti-static options

- Factories (petrochemical, metallurgy): Chemical/abrasion resistance, anti-slip, fire-rated

- Aquatic centers: Water-resistant, high slip resistance

- Need: Seamless antimicrobial flooring to reduce nosocomial infection risk

- Solution: Heterogeneous floor with Stariver surface – 3500 sqm installed, PUR Stariver+UV finish

- Results: 42% fewer surface microbe incidents (3-year follow-up), reduced patient cleaning downtime by 19%

- Need: Durable, slip-resistant floor for multipurpose sports with minimal ongoing maintenance

- Solution: Hawk Flooring (heterogeneous viny), R10 slip resistance, cushioned foam back

- Results: Zero major surface failures in 5 years, 88% positive feedback on joint seamlessness & comfort

- Need: Quiet, low-VOC flooring for air quality-sensitive installations

- Solution: Stariver Surface, GREENGUARD Gold certified; 97% reduction in formaldehyde detected (EPA test)

- Results: Staff absenteeism due to allergy reduced by 15%; improved foot comfort scores

“The antimicrobial performance and cleanability of heterogeneous viny in our pediatric facility exceed not just regulatory requirements but also real-world expectations.” — Facility Manager, Singapore General Hospital

Leading factories like ENLIO offer full project consultation:

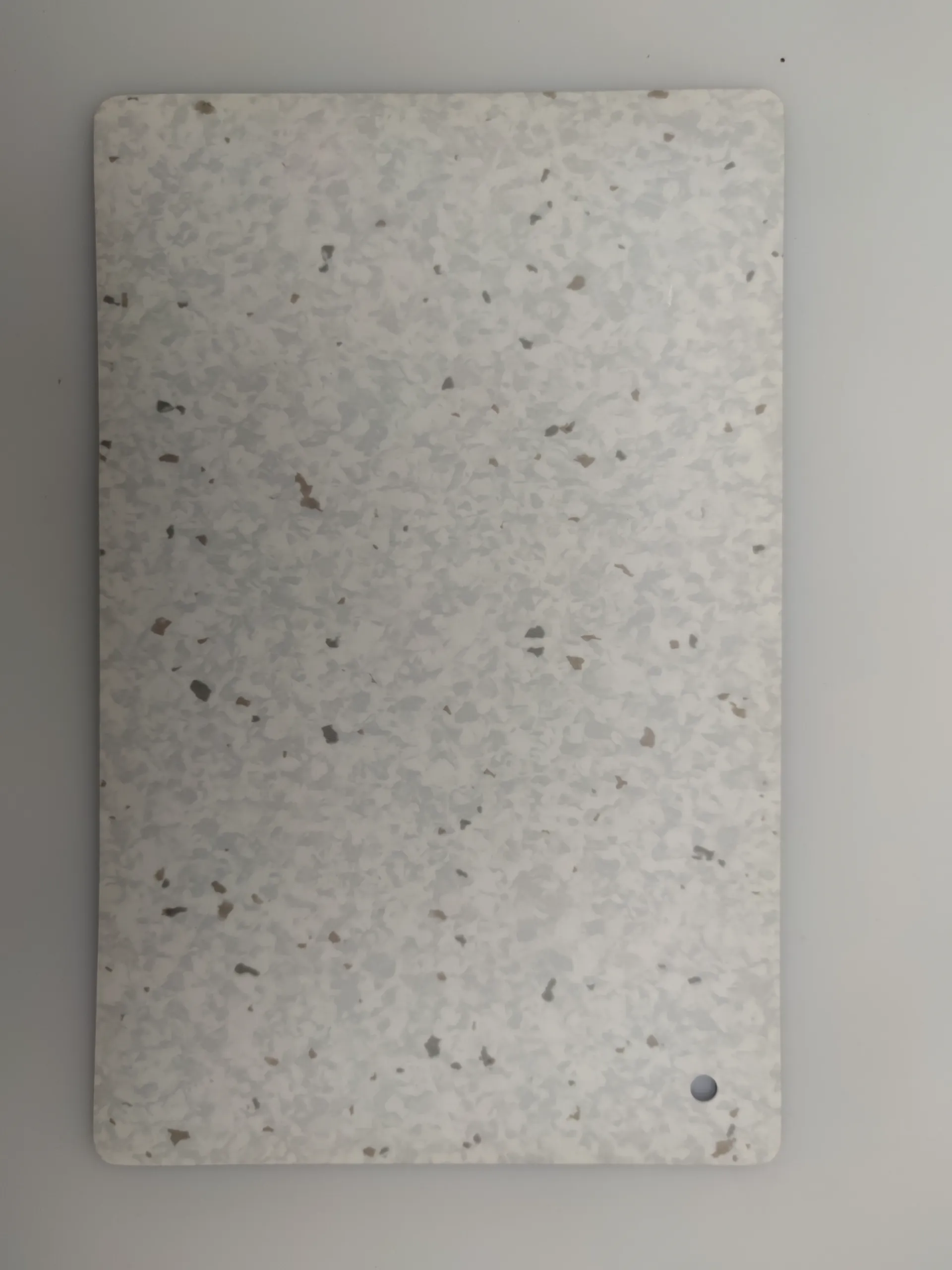

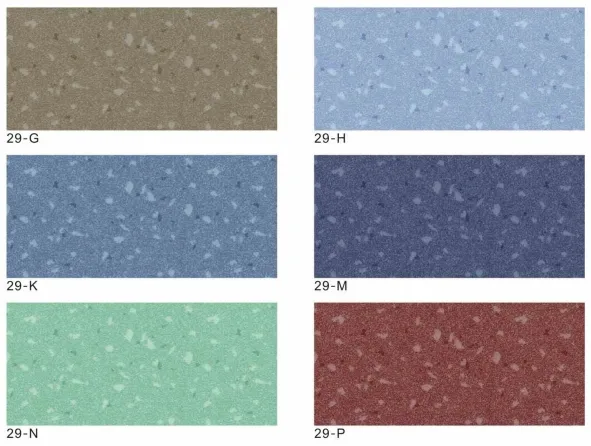

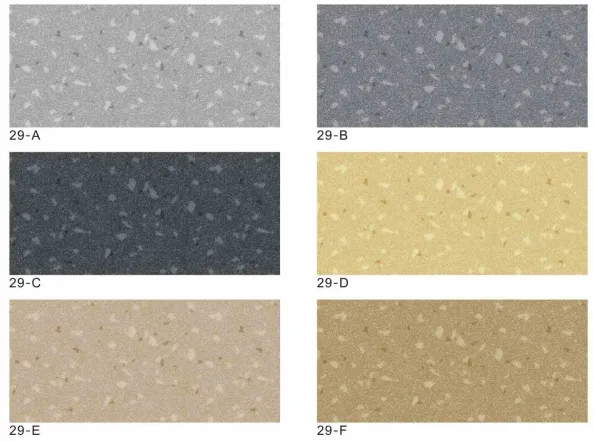

- Custom Print & Color: Match any RAL/Pantone shade, wood, stone, or abstract pattern

- Dimensional Adjustments: Thickness, width, underlayment per user needs

- OEM/ODM: Branding, market localization, regional fire/safety compliance

- Support: Subfloor survey, sample panels, maintenance training, documentation (EN, ISO/ANSI certified)

- Bespoke chemical/antistatic package for industry: For petrochemical, pharma labs

- Standard: 7–15 days for regular models

- Custom Spec: 18–28 days typical

- QC: 100% sample records archived; full third-party test reports (SGS, ISA)

Customer Service: 24/7 tech hotline, on-site guidance and technical datasheet download

- ENLIO & Hawk Flooring: ISO 9001, ISO 14001, SGS, UL, TUV, FloorScore, and VOC Gold certifications

- Major hospital, retail chain, educational, and sports architecture projects over 12+ years

- Official partner to international sports federations and healthcare construction consortia

- Products tested per ISO 22196, ASTM E648, EN 13501-1

- Cited in industry whitepapers: "Next-Gen Vinyl Surface Engineering", Resilient Flooring Forum 2023

- Global Industry Report: Vinyl Flooring Market by Type (2024)

- International Resilient Flooring Association (RFCI): What are Heterogeneous Vinyl Sheet Floors?

- Resilient Flooring Forum: Latest Heterogeneous Viny Trends

- "Performance Evaluation of Hospital Vinyl Floors" – Journal of Facility Engineering, 2023. Read PDF

-

SPC Vinyl FlooringJul.18,2025

-

Home SPC FlooringJul.18,2025

-

Heterogeneous Sheet Vinyl: The Ultimate Commercial Flooring SolutionJul.15,2025

-

Dry Back LVT Flooring: A Durable and Stylish Flooring SolutionJul.15,2025

-

Click LVT Flooring: A Stylish and Convenient Flooring SolutionJul.15,2025

-

SPC FlooringJun.24,2025