My Floor SPC Hybrid Floors: Durable, Waterproof, Stylish

Understanding the Evolution of Modern Flooring: SPC Technology

The landscape of modern building materials is continually evolving, driven by demands for enhanced durability, sustainability, and aesthetic versatility. Among the innovations, Stone Plastic Composite (SPC) flooring has emerged as a frontrunner, particularly for residential and light commercial applications. This advanced flooring solution, often referred to as my floor spc, leverages a unique composition to deliver superior performance compared to traditional options. Its robust structure, comprising a rigid SPC core, offers exceptional resistance to impacts, temperature fluctuations, and moisture, making it an ideal choice for a wide array of environments. The core trend driving its adoption is the seamless blend of wood and tile aesthetics with the practical benefits of vinyl, providing a cost-effective, long-lasting alternative that requires minimal maintenance.

The market is increasingly demanding flooring solutions that offer both visual appeal and robust functionality. Products like Home SPC Flooring and deco floor spc timber are gaining significant traction because they address these dual requirements. Their realistic wood grain or stone patterns, achieved through advanced printing technology, coupled with their inherent waterproof properties, make them suitable for areas historically challenging for natural materials, such as kitchens, bathrooms, and basements. Furthermore, the rise of spc hybrid floors signifies a broader shift towards multi-layered, engineered flooring that can withstand heavy foot traffic while providing comfort underfoot, often incorporating IXPE or EVA sound-absorbing backings. This holistic approach to flooring design is setting new benchmarks for residential and commercial installations, reflecting a clear industry trend towards integrated performance.

The Advanced Manufacturing Process of SPC Flooring

The superior performance of my floor spc is directly attributable to its sophisticated multi-layered construction and precision manufacturing process. At its core, SPC stands for Stone Plastic Composite, signifying a material blend predominantly made from natural limestone powder, polyvinyl chloride (PVC) resin, and stabilizers. This composition gives the core unparalleled rigidity and dimensional stability. The manufacturing process typically involves several key stages, beginning with the mixing of raw materials, which are then extruded through a specialized calendering machine under high heat and pressure to form the dense SPC core board. This core is then precisely cut to size before moving to the lamination stage.

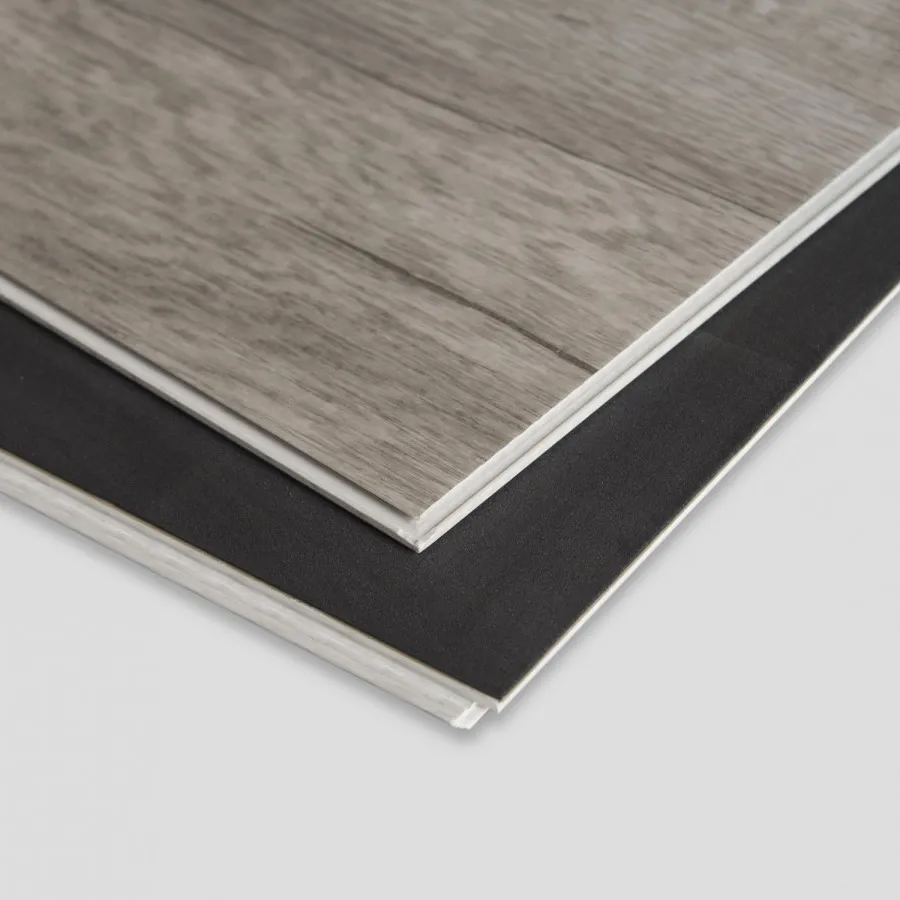

Following the core production, a decorative film, replicating the appearance of wood or stone, is heat-laminated onto the SPC core. This is then covered by a transparent wear layer, typically made of PVC, which provides the primary resistance against scratches, stains, and dents. Finally, a UV coating is applied to enhance durability, color retention, and ease of cleaning. Many modern SPC products also integrate an attached underlayment, such as IXPE or EVA foam, during this process to improve sound insulation and provide a softer feel underfoot. Throughout these stages, stringent quality control measures are implemented, adhering to international standards such as ISO 9001 for quality management and ISO 14001 for environmental management. These checks ensure uniform thickness, dimensional stability, wear resistance, and adherence to volatile organic compound (VOC) limits, guaranteeing a product with an impressive service life, often exceeding 20-25 years in residential settings. While traditional processes like casting and forging are not applicable, the hot-pressing and calendering techniques employed for SPC are highly specialized, ensuring a consistently high-quality final product.

Figure 1: Cross-sectional view illustrating the multi-layered composition of SPC flooring, from the UV layer to the integrated underlayment.

Technical Parameters and Performance Benchmarks

When evaluating my floor spc for your project, understanding its key technical parameters is crucial. These specifications dictate the flooring's suitability for various applications and its long-term performance. The total thickness of SPC planks typically ranges from 3.5mm to 8.0mm, with the wear layer thickness being a critical factor, often between 0.3mm (12 mil) and 0.7mm (28 mil). A thicker wear layer correlates directly with higher durability and extended lifespan, making it ideal for high-traffic commercial environments. Dimensional stability, measured as the change in length and width under varying temperature and humidity, is exceptionally high for SPC, usually less than 0.06% according to ISO 23999, far surpassing traditional LVT.

Other vital parameters include indentation resistance, which ensures the flooring withstands heavy furniture and impacts without permanent marks, and slip resistance, rated according to standards like R9 or R10, essential for safety in both residential and commercial settings. SPC meaning floor specifically refers to its Stone Plastic Composite core, which inherently grants it superior rigidity and water resistance, making it entirely waterproof. This characteristic eliminates concerns about spills, moisture, or humidity, a common challenge for wood or laminate flooring. The integrated click-lock system, a key feature of spc hybrid floors, also facilitates rapid and glue-free installation, significantly reducing labor costs and project timelines. Below is a detailed table outlining typical parameters for high-quality my floor spc products.

| Parameter | Specification Range | Relevant Standard / Benefit |

|---|---|---|

| Total Thickness | 4.0mm - 6.0mm (typical for Home SPC Flooring) | Enhanced stability and durability |

| Wear Layer Thickness | 0.3mm - 0.5mm | AC3-AC5 equivalent wear rating; scratch & abrasion resistance |

| Plank Dimensions | 1220mm x 180mm / 1524mm x 228mm (Common) | Versatile sizing for various room layouts |

| Dimensional Stability | ≤ 0.06% (ISO 23999) | Prevents expansion/contraction, gaps, and warping |

| Indentation Resistance | ≤ 0.1mm residual indentation (EN 433) | Resists dents from heavy objects or impacts |

| Fire Resistance | Bfl-s1 (EN 13501-1) | Low flammability and smoke emission |

| Formaldehyde Emission | E0/E1 Compliant, CARB P2 compliant | Ensures healthy indoor air quality (low VOCs) |

| Waterproof Rating | 100% Waterproof | Suitable for bathrooms, kitchens, basements; no swelling |

| Lifespan (Residential) | 20-25 Years | Long-term value and durability |

Figure 2: An example of Home SPC Flooring installed, showcasing its aesthetic versatility and ease of integration into modern interiors.

Versatile Application Scenarios and Advantages

The inherent properties of my floor spc, particularly its exceptional waterproof nature and dimensional stability, make it suitable for a diverse range of application scenarios that demand both resilience and aesthetic appeal. In residential settings, from moisture-prone areas like kitchens, bathrooms, and basements to high-traffic living rooms and hallways, SPC flooring offers a durable and hygienic solution that withstands daily wear and tear. Its ability to be installed over existing hard surfaces, often without extensive subfloor preparation, significantly reduces renovation time and costs for homeowners. This makes Home SPC Flooring an attractive option for quick upgrades and new constructions alike.

Beyond residential use, SPC flooring excels in light commercial environments. Retail stores, offices, hotels, educational institutions, and healthcare facilities benefit from its high-traffic resistance, ease of cleaning, and low maintenance requirements. Unlike traditional flooring materials that might degrade rapidly under constant foot traffic or require specialized cleaning agents, deco floor spc timber and similar products maintain their appearance with simple routine cleaning. The superior acoustic properties provided by integrated underlayments in spc hybrid floors also contribute to quieter environments, a critical factor in offices and multi-unit dwellings. The non-porous surface of SPC flooring prevents the growth of mold and mildew, making it a healthy choice for indoor environments, aligning with modern building standards focused on indoor air quality and occupant well-being.

Figure 3: SPC flooring installed in a commercial space, demonstrating its durability and aesthetic integration under typical usage conditions.

Customization and Client Support Excellence

As a leading provider of my floor spc solutions, we understand that every project has unique requirements. Our extensive customization capabilities allow clients to specify various aspects of their flooring, including plank dimensions, wear layer thickness, decorative film patterns (ranging from classic wood grains to contemporary stone textures), and integrated underlayment options (IXPE/EVA). This flexibility ensures that the final product, whether it's Home SPC Flooring or a specialized solution for high-traffic commercial areas, perfectly aligns with aesthetic vision, performance demands, and budget constraints. Our technical team works closely with B2B partners, architects, and interior designers to provide tailored solutions and expert guidance from concept to completion.

Our commitment to client success extends beyond product customization. We maintain rigorous quality assurance protocols, ensuring every batch of my floor spc meets or exceeds international standards, including ISO 9001, CE, and FloorScore certifications for indoor air quality. Delivery cycles are streamlined through efficient logistics, with typical lead times clearly communicated and adhered to. We offer comprehensive warranty programs that underscore our confidence in product longevity and performance, providing peace of mind to our clients. Our dedicated customer support team is available to address any inquiries, provide technical assistance, and resolve issues promptly, ensuring a seamless experience from order placement to post-installation support. This holistic approach to client service is paramount to building lasting partnerships and ensuring the complete satisfaction of our B2B clientele.

Frequently Asked Questions (FAQ)

- Q: What does "SPC meaning floor" signify for durability?

- A: SPC stands for Stone Plastic Composite. This core makes the flooring extremely dense, rigid, and resistant to impacts, scratches, and indentation, far exceeding traditional vinyl or laminate in durability. It's also 100% waterproof, making it ideal for moisture-prone areas.

- Q: Is my floor spc suitable for underfloor heating systems?

- A: Yes, SPC flooring is generally compatible with most types of underfloor heating systems, provided the surface temperature does not exceed 28°C (82°F). Its high dimensional stability ensures it won't warp or buckle due to temperature fluctuations, unlike some other flooring types. It is recommended to follow specific manufacturer guidelines for installation over radiant heat.

- Q: How does the wear layer thickness affect the lifespan of Home SPC Flooring?

- A: The wear layer is the transparent top coating that protects the design layer from abrasion, scratches, and stains. A thicker wear layer (e.g., 0.5mm) provides superior protection and is recommended for high-traffic residential or light commercial applications, significantly extending the flooring's lifespan compared to a thinner layer (e.g., 0.3mm).

- Q: What maintenance is required for deco floor spc timber products?

- A: SPC flooring is remarkably low maintenance. Regular sweeping or vacuuming is sufficient to remove dirt and dust. For deeper cleaning, a damp mop with a pH-neutral cleaner is recommended. Avoid abrasive cleaners or excessive water. No waxing or polishing is required.

References

- American National Standards Institute (ANSI) - Relevant standards for flooring product testing and performance.

- International Organization for Standardization (ISO) - Standards for quality management (ISO 9001) and environmental management (ISO 14001) in manufacturing.

- European Standard (EN) - Building material and flooring specific standards, e.g., EN 13501-1 for fire classification and EN 433 for indentation resistance.

- Resilient Floor Covering Institute (RFCI) - Technical bulletins and guidelines for resilient flooring installation and maintenance.

-

Waterproof Advantages of SPC Flooring Vinyl in KitchensAug.06,2025

-

SPC Hybrid Waterproof Flooring Thickness GuideAug.06,2025

-

Leveling Subfloor Before My Floor SPC InstallAug.06,2025

-

How Mesh Deck Skirting Improves Outdoor Pest ControlAug.06,2025

-

Choosing the Right Commercial Flooring for Your Business NeedsAug.06,2025

-

Choosing the Best Residential Flooring: A Comprehensive Guide to Style, Durability, and ComfortAug.06,2025