- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Durable VCT Flooring Near Me | Affordable Commercial Solutions

Understanding Advanced Resilient Flooring: What to Look for When Searching for vct flooring near me

The demand for high-performance, durable, and aesthetically versatile flooring solutions in commercial and institutional settings is continuously growing. While the term "VCT flooring" is widely recognized, modern advancements in resilient flooring, particularly heterogeneous vinyl flooring, offer superior performance characteristics for demanding environments. This comprehensive guide delves into the technical aspects, application scenarios, and advantages of modern resilient flooring, focusing on solutions that meet the rigorous demands of B2B sectors.

For businesses seeking durable and cost-effective flooring, the query for vct flooring near me often leads to a deeper exploration of various vinyl flooring options. Heterogeneous vinyl, such as the Enlio heterogeneous floor with fleme surface, represents a significant leap forward, providing multi-layered construction for enhanced durability, design flexibility, and specialized performance attributes like acoustic dampening or slip resistance.

The Advanced Manufacturing Process of High-Performance Resilient Flooring

The production of modern resilient flooring, specifically heterogeneous vinyl, involves a sophisticated process designed to ensure product integrity, performance, and longevity. Unlike traditional VCT, which is largely homogeneous in composition, heterogeneous flooring is engineered with distinct layers, each contributing to the overall product's superior characteristics.

Key Stages in Manufacturing:

- Raw Material Preparation: High-grade PVC resins, plasticizers for flexibility, limestone fillers for stability and cost-effectiveness, stabilizers to prevent degradation, and color pigments are meticulously measured and mixed. For advanced products like Enlio's heterogeneous flooring, specific additives for anti-microbial properties or enhanced wear resistance are incorporated.

- Layer Formation (Calendering/Extrusion): The mixed compounds are processed through calendering or extrusion. Calendering involves passing the material through heated rollers to form precise, thin sheets. For heterogeneous flooring, individual layers – a backing layer, a fiberglass reinforcement layer (for dimensional stability), a printed design layer, and a clear wear layer – are produced.

- Lamination and Bonding: The distinct layers are then carefully laminated together under heat and pressure. This multi-layer construction is what defines heterogeneous vinyl flooring, allowing for specialized performance characteristics not found in single-layer VCT. The fiberglass layer, for instance, is crucial for preventing expansion and contraction, ensuring excellent dimensional stability.

- Surface Treatment and Embossing: A high-performance wear layer, often enhanced with polyurethane (PU) or ceramic bead coatings, is applied to protect the design layer and provide superior scuff, stain, and scratch resistance. For products like the fleme surface, a specialized embossing process creates a textured finish, enhancing grip and aesthetic appeal.

- Curing and Cooling: The laminated sheets undergo a controlled cooling process to set the materials and ensure optimal adhesion between layers.

- Cutting and Finishing: Large rolls of flooring are precisely cut into specific dimensions, either as planks, tiles, or sheet goods, depending on the product line. Edge finishing ensures clean, uniform pieces ready for installation.

Rigorous Testing Standards:

To guarantee the highest quality, manufacturers adhere to international testing standards. Key certifications and tests include:

- ISO 10582: Specifies requirements for heterogeneous polyvinyl chloride floor coverings in sheet or tile form. It covers dimensions, physical properties (e.g., residual indentation, dimensional stability, wear resistance), and chemical resistance.

- ASTM F1700: Standard Specification for Solid Vinyl Floor Tile, offering guidelines for commercial applications.

- EN 14041: Essential characteristics for resilient, textile, and laminate floor coverings, including slip resistance, fire behavior, and formaldehyde emissions.

- EN 685: Classification of resilient floor coverings based on area of use (e.g., commercial, industrial) and intensity of use.

- Fire Safety (e.g., EN 13501-1): Testing for reaction to fire, crucial for public buildings.

These stringent standards ensure that products like Enlio's heterogeneous flooring not only meet but often exceed the performance expectations associated with traditional vct flooring near me.

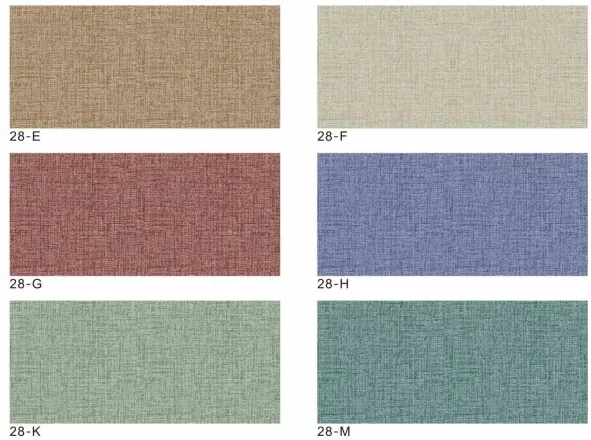

Technical Specifications: Enlio Heterogeneous Floor with Fleme Surface

For B2B buyers evaluating options, understanding the precise technical specifications is paramount. Enlio's heterogeneous floor with fleme surface is designed for demanding environments, offering a unique blend of durability, aesthetics, and performance.

Enlio's advanced heterogeneous flooring solution.

Product Specification Table:

| Parameter | Specification | Standard / Test Method |

|---|---|---|

| Product Name | Heterogeneous Floor with Fleme Surface | Manufacturer's Designation |

| Total Thickness | 2.0mm - 4.0mm (Customizable) | EN 428 |

| Wear Layer Thickness | 0.35mm - 0.70mm | EN 429 |

| Roll Width | 1.8m / 2.0m | EN 426 |

| Abrasion Resistance | Group T (High Traffic) | EN ISO 10582 |

| Dimensional Stability | ≤ 0.1% | EN 434 |

| Residual Indentation | ≤ 0.1mm | EN 433 |

| پرچي مزاحمت | R9 - R10 | EN 13893 / DIN 51130 |

| Fire Classification | Bfl-s1 | EN 13501-1 |

| Anti-Bacterial / Fungal | Yes (Treated Surface) | ISO 22196 |

| Acoustic Impact Sound Reduction | 15dB - 19dB (Depending on thickness) | EN ISO 717-2 |

| VOC Emissions | Very Low (e.g., AgBB, FloorScore compliant) | EN 16516 |

| Service Life (Estimated) | 10-20 Years in Commercial Use | Manufacturer's Warranty & Testing |

These specifications highlight why a specialized heterogeneous floor is often a superior choice when considering options typically covered by the broad term تجارتي وي سي ٽي فرش. The multi-layered construction provides enhanced performance in critical areas such as dimensional stability, wear resistance, and acoustic properties, which are often limited in traditional VCT.

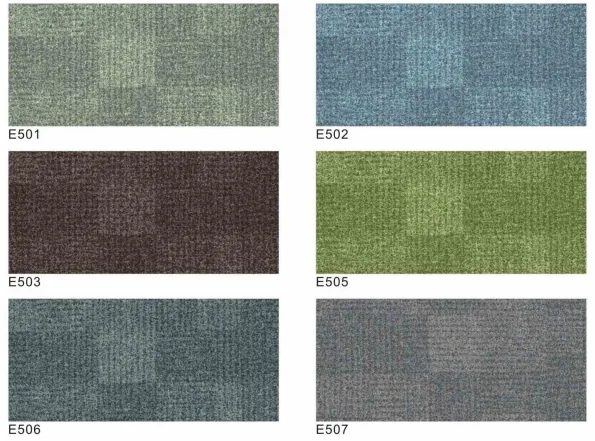

Application Scenarios and Industry Trends

The versatility of heterogeneous vinyl flooring makes it suitable for a wide array of commercial and institutional applications where durability, hygiene, and aesthetics are paramount. While the search for vct flooring near me often originates from a need for resilient and economical solutions, modern heterogeneous floors transcend these basic requirements.

Target Industries:

- صحت جون سهولتون: Hospitals, clinics, nursing homes. Requirements: aseptic surfaces, easy to clean, chemical resistance, acoustic comfort (to reduce noise levels), slip resistance. Heterogeneous flooring excels here with its seamless installation options (for hygiene) and specialized coatings.

- تعليمي ادارا: Schools, universities, daycares. Requirements: high traffic durability, impact resistance, low maintenance, sound absorption, vibrant design options.

- Retail Spaces: Supermarkets, boutiques, department stores. Requirements: heavy foot traffic, aesthetic appeal, brand consistency, easy cleaning, quick installation to minimize downtime.

- Corporate Offices: Open-plan offices, conference rooms, break areas. Requirements: professional appearance, acoustic properties (reducing impact sound), durability for rolling chairs, ease of maintenance.

- Hospitality: Hotels, restaurants, convention centers. Requirements: upscale aesthetics, comfort underfoot, sound dampening, robust wear characteristics against spills and heavy use.

- Light Industrial / Laboratories: Areas with specific chemical resistance or static control needs. Requirements: specialized coatings for ESD (Electrostatic Discharge) control, high chemical resistance, heavy load bearing capacity.

Versatile applications for high-performance flooring.

Key Industry Trends:

- Sustainability and Green Building: Growing emphasis on low VOC emissions, recycled content, and cradle-to-cradle principles. Manufacturers like Enlio are investing in sustainable production and product lifecycles.

- Enhanced Hygiene and Anti-Microbial Properties: Post-pandemic, the demand for easily sanitizable and anti-bacterial surfaces in public spaces has surged. Flooring with integrated anti-microbial treatments is becoming standard in healthcare and education.

- Design Flexibility and Customization: Digital printing technologies allow for unlimited design possibilities, mimicking natural materials or creating unique brand-specific aesthetics, far surpassing the design limitations of traditional VCT.

- Improved Acoustics: As open-plan designs become prevalent, flooring solutions that reduce impact sound and improve ambient acoustics are highly sought after.

- Durability and Reduced Maintenance: Businesses prioritize flooring that can withstand heavy traffic with minimal upkeep, translating to lower lifecycle costs. Advanced wear layers and surface treatments are key to achieving this.

Technical Advantages Over Traditional VCT

When businesses search for vct flooring near me, they are typically looking for a resilient, durable, and cost-effective solution. However, heterogeneous vinyl flooring, like Enlio's specialized offerings, presents several distinct technical advantages that make it a superior choice for many modern commercial applications.

Key Advantages:

- Superior Durability and Wear Resistance: Heterogeneous flooring features a distinct, often thicker, wear layer (e.g., 0.35mm to 0.70mm) that is typically pure PVC or enhanced with PU/ceramic beads. This contrasts with VCT, where wear is distributed throughout the tile's homogeneous composition. This top layer provides exceptional resistance to abrasion, scratches, and scuffs, extending the service life significantly.

- Enhanced Dimensional Stability: The inclusion of a fiberglass reinforcement layer in heterogeneous structures dramatically improves dimensional stability, minimizing expansion and contraction due to temperature fluctuations. This reduces the risk of gapping or curling, a common concern with some traditional VCT installations.

- Improved Hygiene and Ease of Maintenance: Many heterogeneous vinyl floors, especially sheet goods, can be installed with heat-welded seams, creating a monolithic, impermeable surface. This prevents dirt, moisture, and pathogens from penetrating, making cleaning and disinfection significantly easier and more effective – a critical advantage in healthcare and food service compared to tiled تجارتي وي سي ٽي فرش.

- Advanced Acoustic Performance: The multi-layered construction can be engineered to include sound-absorbing backing layers, significantly reducing both impact sound (foot traffic) and ambient noise. This is a crucial benefit in educational, healthcare, and office environments where noise reduction contributes to comfort and productivity.

- Design Versatility: With a distinct print layer, heterogeneous flooring offers limitless design possibilities, including realistic wood and stone patterns, abstract designs, and custom branding. This flexibility is far beyond the limited color and chip patterns typically found in VCT.

- Chemical and Stain Resistance: The high-performance wear layer provides superior resistance to chemicals, common stains, and aggressive cleaning agents, which is essential in laboratories, healthcare, and industrial settings.

- Lower Lifecycle Cost: While initial investment might be slightly higher than basic VCT, the enhanced durability, lower maintenance requirements (no waxing/buffing needed for many modern vinyls), and longer service life often result in a significantly lower total cost of ownership over the product's lifespan.

Vendor Comparison and Customized Solutions

Selecting the right flooring vendor is as critical as choosing the right product. While many providers offer vct flooring near me, a comprehensive evaluation involves looking at product quality, customization capabilities, and after-sales support.

Vendor Comparison: Enlio vs. Other Leading Brands

The market for resilient flooring includes several well-established players. While brands like Shaw, Armstrong, and Tarkett offer a range of vinyl flooring, including VCT and heterogeneous options, it's crucial to compare specific product lines and vendor strengths.

| Feature/Criterion | Enlio (Heterogeneous Fleme Surface) | Traditional VCT (Typical Brands) | Other Premium Heterogeneous Vinyl (e.g., Shaw, Tarkett) |

|---|---|---|---|

| Construction | Multi-layered (wear, print, fiberglass, backing) | Homogeneous composition (vinyl, filler, pigment) | Multi-layered, varying structures |

| Wear Layer Performance | Dedicated thick wear layer (0.35-0.7mm), often PU/ceramic enhanced; Group T Abrasion | Wear distributed throughout; requires waxing/buffing | Dedicated wear layer, comparable to Enlio (may vary) |

| Dimensional Stability | Excellent (Fiberglass reinforcement ≤ 0.1%) | Good, but prone to gapping if not acclimated/installed well | Excellent (often with fiberglass) |

| Maintenance Regimen | Low (no waxing/polishing typically required) | High (regular stripping, waxing, buffing) | Low (similar to Enlio) |

| Design Versatility | High (photo-realistic prints, custom designs, fleme texture) | Limited (chip/speckled patterns, solid colors) | High (photo-realistic prints, various textures) |

| Acoustic Performance | Good to Excellent (15-19dB reduction) | Limited (low inherent sound absorption) | Good to Excellent (depending on backing) |

| Hygiene (Seams) | Heat-welded seams possible for seamless, impermeable surface | Seams susceptible to dirt/moisture ingress | Heat-welded seams possible |

| Typical Cost (Installed) | Mid-High tier (Higher upfront, lower lifecycle) | Entry-level (Lower upfront, higher lifecycle) | Mid-High tier |

While brands like Enlio and Shaw both offer robust flooring solutions, Enlio specializes in high-performance vinyl products with a strong focus on technical innovation and customization, often providing competitive solutions in the "enlio vct flooring near me" segment.

Customized Solutions:

Modern manufacturing capabilities allow for significant customization to meet specific project requirements:

- Thickness and Wear Layer: Tailored to match anticipated traffic levels and desired service life.

- Color and Pattern: Bespoke designs, corporate branding integration, or specific aesthetic matching.

- Specialized Coatings: Enhanced slip resistance (R11-R12), anti-static (ESD), anti-microbial, or extra chemical resistance.

- Acoustic Backing: Integration of foam or felt backings for superior sound dampening.

Tailored flooring solutions for unique commercial needs.

Application Case Studies and Customer Experience

Real-world application demonstrates the tangible benefits of high-performance heterogeneous flooring solutions over traditional vct flooring near me. Enlio has a proven track record of delivering specialized flooring for diverse commercial environments.

Case Study 1: Major Regional Hospital Renovation

Client: St. Jude's Medical Center, [Fictional City]

Challenge: The hospital required a flooring solution for high-traffic corridors and patient rooms that offered superior hygiene, chemical resistance to disinfectants, acoustic comfort, and ease of maintenance, replacing outdated VCT.

Solution: Enlio's 3.0mm heterogeneous floor with a smooth, anti-microbial surface and heat-welded seams was selected. The flooring provided a Bfl-s1 fire rating and excellent slip resistance (R10), meeting all critical healthcare standards.

Outcome: The installation resulted in significantly improved infection control due to the seamless, non-porous surface. Staff reported easier cleaning protocols and reduced noise levels, contributing to a calmer healing environment. The flooring has maintained its aesthetic and functional integrity after 5 years of intense use.

Case Study 2: University Science Laboratory

Client: Department of Chemistry, Metro University, [Fictional City]

Challenge: The lab needed flooring resistant to a wide range of chemicals, abrasions from equipment, and capable of handling spills without compromising safety or structural integrity. Previous flooring had degraded quickly.

Solution: Enlio provided a specialized 2.5mm heterogeneous vinyl floor with an enhanced chemical-resistant wear layer and superior abrasion resistance (Group T). The fleme surface texture also provided added slip resistance, crucial in a laboratory setting.

Outcome: The flooring successfully withstood accidental chemical spills (acids, bases, solvents) without etching or discoloration. The textured surface reduced slip hazards. Lab personnel praised the easy clean-up and robust feel, noting a significant improvement over the old تجارتي وي سي ٽي فرش.

Customer Feedback:

"We were initially looking for basic VCT, but Enlio's heterogeneous flooring offered a lifecycle cost and performance profile that far exceeded our expectations. The durability and ease of maintenance have been exceptional in our busy retail environment."

— Operations Director, Regional Retail Chain

Trustworthiness and Support: FAQ, Lead Times, Warranty, and After-Sales

Frequently Asked Questions (FAQ):

- Q: How does heterogeneous vinyl flooring compare to traditional VCT in terms of total cost of ownership?

- A: While the initial purchase price of heterogeneous vinyl might be slightly higher than traditional VCT, its superior durability, lower maintenance requirements (often eliminating the need for waxing and stripping), and longer service life typically result in a significantly lower total cost of ownership over its lifespan. VCT often requires more intensive maintenance, adding to long-term operational expenses.

- Q: Is Enlio's heterogeneous flooring suitable for high-moisture areas?

- A: Yes, with proper installation and heat-welded seams, heterogeneous sheet vinyl creates an impermeable barrier against moisture, making it ideal for wet areas like bathrooms, kitchens, and laboratories. Its dimensional stability also minimizes the risk of water penetration at the seams.

- Q: What are the environmental certifications for Enlio products?

- A: Enlio products adhere to stringent environmental standards, including low VOC emissions compliant with FloorScore and AgBB. We are committed to sustainable manufacturing practices and regularly seek relevant green building certifications to ensure our products contribute positively to indoor air quality and environmental stewardship.

- Q: Can I get customized designs or specific colors for my project?

- A: Absolutely. Enlio offers extensive customization options for heterogeneous flooring, including bespoke colors, patterns, and even integrating corporate logos. Our digital printing capabilities allow for high-fidelity design reproduction, providing unparalleled design flexibility to match your brand or aesthetic vision.

Lead Time and Fulfillment:

Enlio maintains a robust supply chain to ensure timely delivery for commercial projects, whether you're searching for enlio vct flooring near me or our specialized heterogeneous products.

- Standard Products: Typically 2-4 weeks from order confirmation to shipment, depending on quantity and destination.

- Customized Orders: May require 4-8 weeks, allowing for design approval, production, and quality control.

- Logistics: We partner with global freight forwarders to ensure efficient and secure delivery to your project site. Expedited shipping options are available upon request.

Warranty Commitments:

Enlio stands behind the quality and performance of its flooring products with comprehensive warranty programs. Our heterogeneous flooring typically comes with a commercial warranty of 10-15 years, covering manufacturing defects and wear layer performance under normal commercial use. Specific warranty terms vary by product and application; full details are provided upon quotation.

Customer Support and After-Sales Service:

Our commitment to customer satisfaction extends beyond the sale. Enlio provides extensive after-sales support:

- Technical Assistance: Our team of flooring experts is available to assist with installation guidance, maintenance best practices, and troubleshooting.

- Maintenance Guides: Detailed product-specific cleaning and maintenance protocols are provided to ensure the longevity and appearance of your flooring.

- Replacement Parts/Rolls: We maintain inventory for quick replacement of damaged sections or for future expansion needs.

- Global Network: With a network of distributors and partners, support is accessible to clients worldwide.

Conclusion

The journey from searching for "vct flooring near me" to specifying a high-performance heterogeneous vinyl solution like Enlio's fleme surface is a testament to the evolution of commercial flooring. Modern advancements offer businesses not just a floor, but a critical component of their operational environment, delivering unparalleled durability, hygiene, aesthetic flexibility, and a superior total cost of ownership. By understanding the technical advantages, engaging with reputable vendors, and considering tailored solutions, businesses can invest in flooring that truly supports their long-term objectives and elevates their commercial spaces.

References

- ISO 10582: Resilient floor coverings — Heterogeneous polyvinyl chloride floor coverings — Specification. International Organization for Standardization.

- ASTM F1700 / F1700M – 21: Standard Specification for Solid Vinyl Floor Tile. ASTM International.

- EN 14041: Resilient, textile and laminate floor coverings — Essential characteristics. European Committee for Standardization.

- FloorScore® Certification Program: SCS Global Services.

- The Vinyl Institute: Benefits of Vinyl Flooring.

-

Masking Tape: Clean Removal, Precision Lines, Pro-GradeNov.10,2025

-

Skirting: MDF, Oak & SPC | Durable, Easy-FitNov.10,2025

-

Commercial VCT Tile Flooring – Durable, Low-MaintenanceNov.10,2025

-

LVT Vinyl Floors – Waterproof, Scratch‑Resistant, Easy ClickNov.10,2025

-

Masking Tape - Pro-Grade, Clean Removal, Crisp LinesNov.10,2025

-

Premium Masking Tape - Sharp Lines, Clean RemovalNov.10,2025